Oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and manufacture method

A permanent magnet motor and concentrated winding technology, which is applied in the fields of submersible pump direct drive super slender concentrated winding permanent magnet motor, oilfield oil production machinery and equipment, and permanent magnet synchronous motor, can solve problems such as difficulty and low efficiency, and improve efficiency , The effect of reducing manufacturing costs and improving the winding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

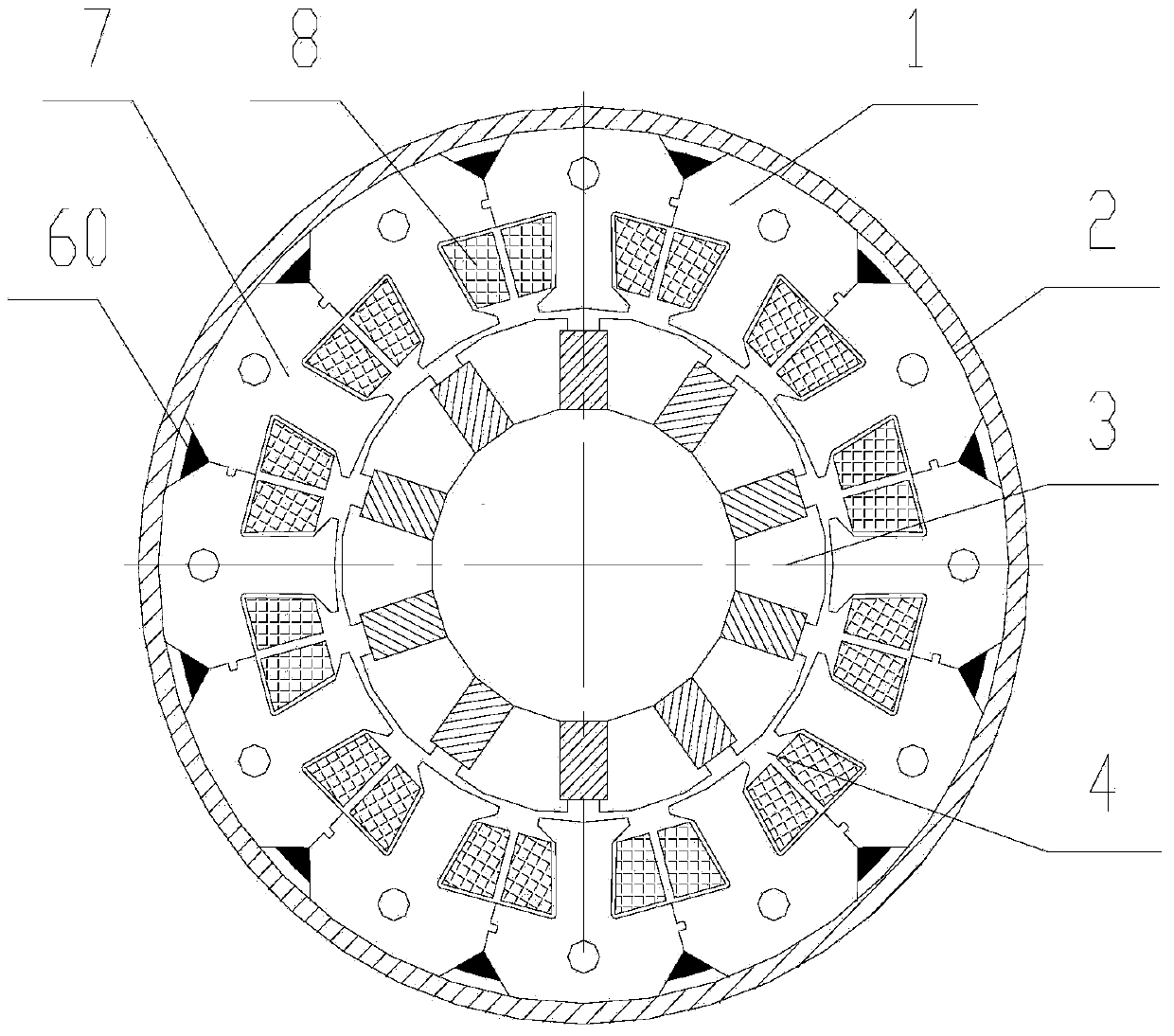

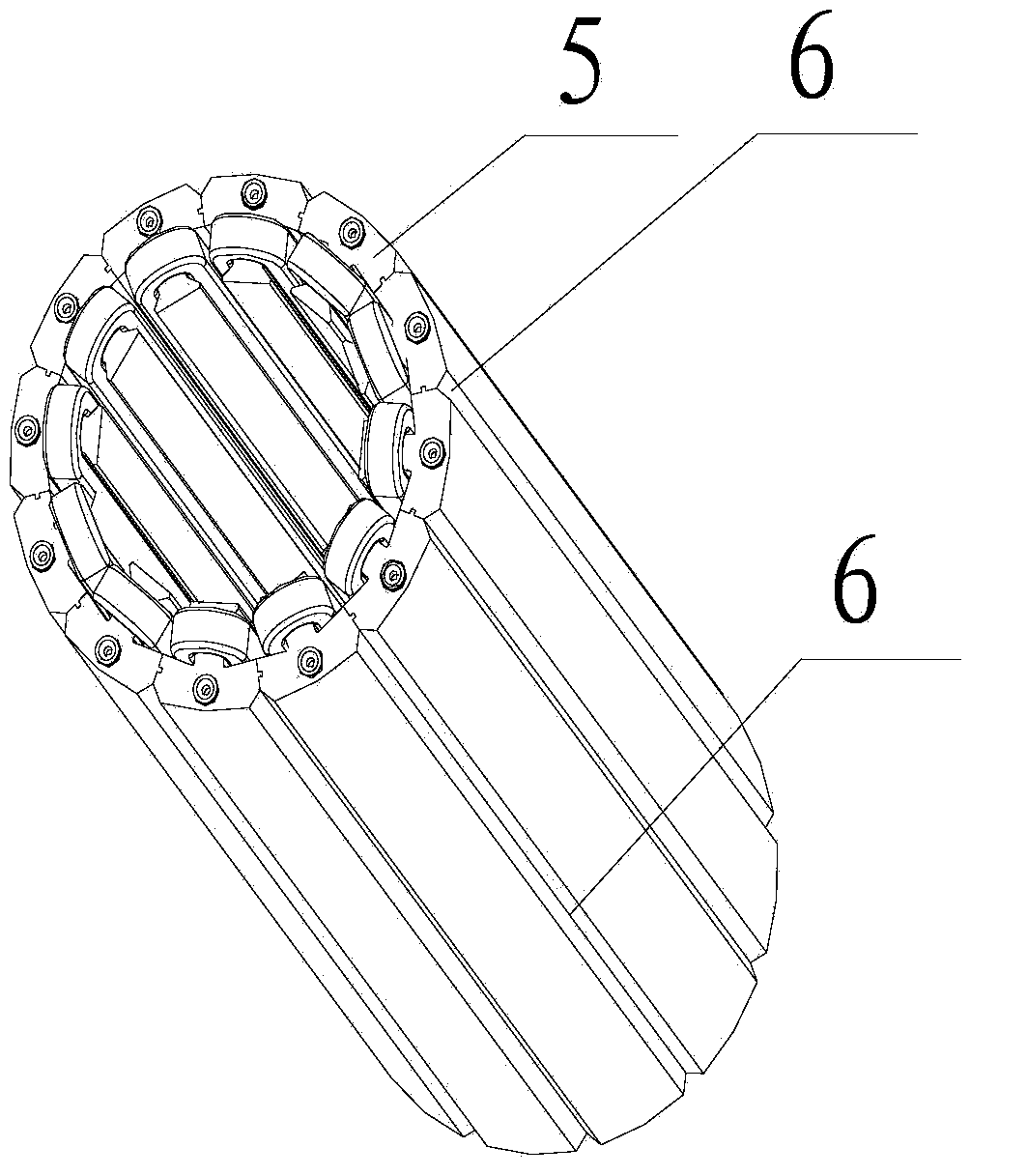

[0034] The submersible pump direct-drive ultra-slender concentrated winding permanent magnet motor according to an embodiment of the present invention includes: at least one motor unit, such as figure 1 and figure 2 As shown, the motor unit includes:

[0035] Stator core 1, the stator core is a split structure, the stator core 1 is assembled into a circular ring by a plurality of winding core blocks 5;

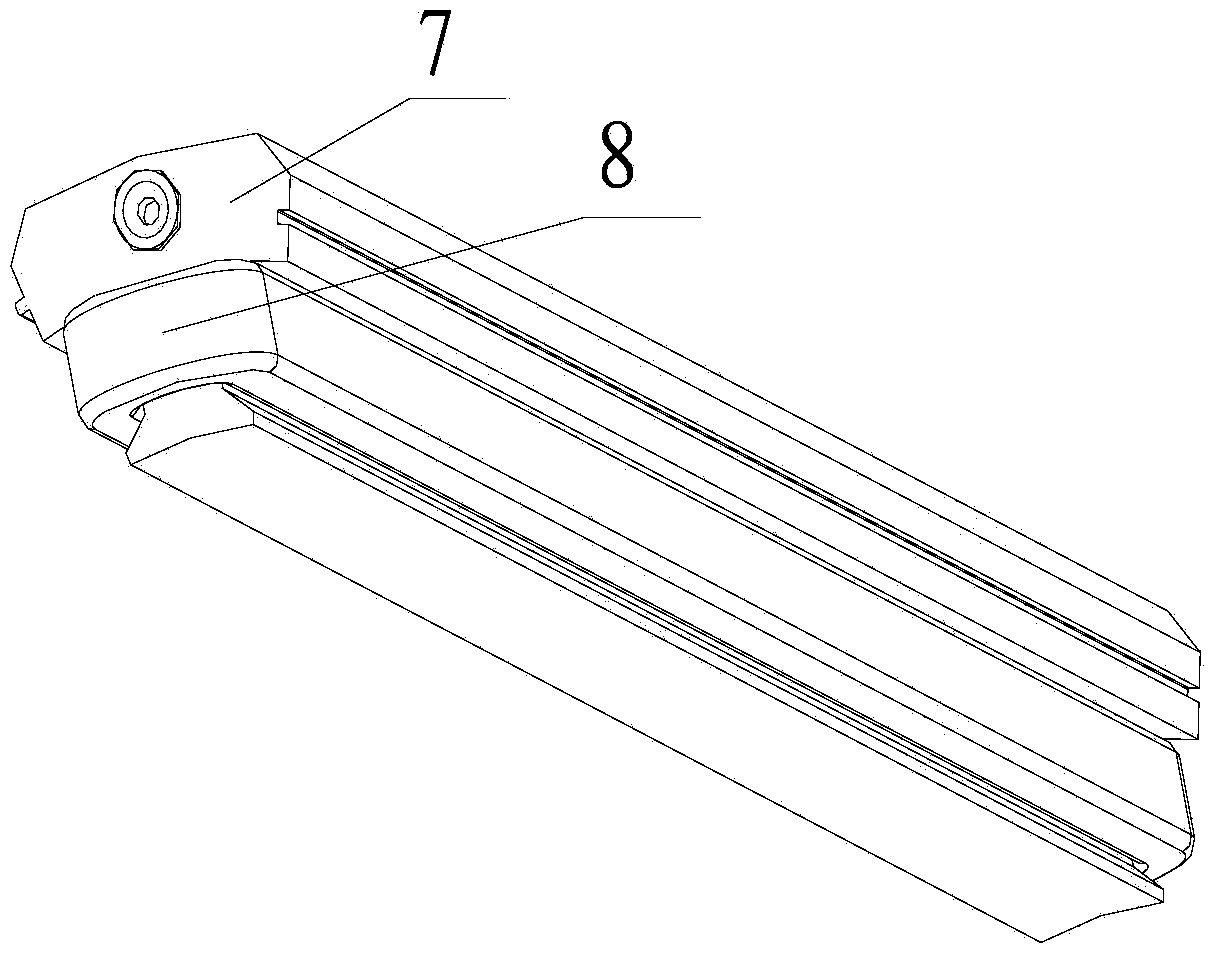

[0036] Such as figure 2 and image 3 , each of the winding core blocks 5 includes: an elongated iron core block 7 and a winding copper wire 8 wound on the elongated iron core block 7;

[0037] Such as image 3 and Figure 4 , the elongated iron core block 7 is formed by stacking a plurality of T-shaped punches, each of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com