Motor rotor winding method

A technology of motor rotor and winding method, which is applied in the direction of manufacturing motor generators, electromechanical devices, electrical components, etc., can solve the problems of consumption of winding quantity, increase of winding time, high cost, etc., and achieve reduction of winding number , reduce process cost, and optimize the effect of winding mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

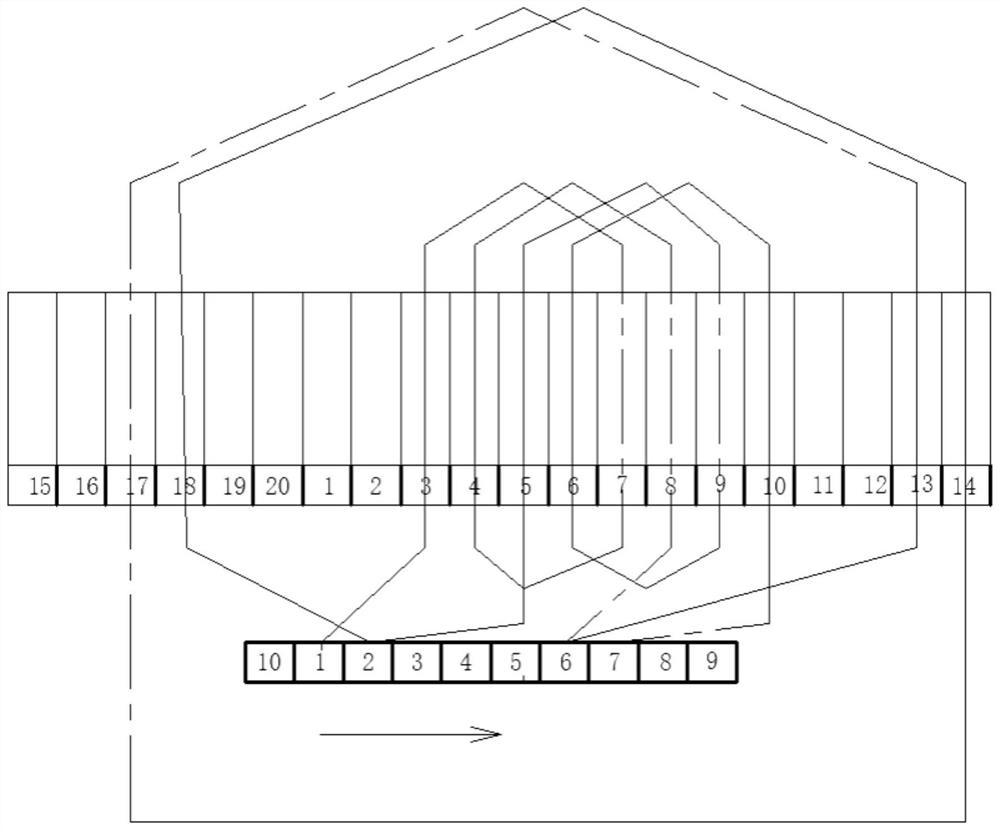

[0027] The present invention will be further described below with reference to the accompanying drawings.

[0028] like Figure 1 to Figure 2 shown,

[0029] A method for winding a motor rotor, the method comprising the following steps:

[0030] Step 1: Set up the motor rotor winding machine, the slot commutator, the motor rotor and the winding material, in which 20 slots are arranged on the motor rotor and 10 slots are arranged on the slot commutator. By making the slot commutation The number of slots of the motor is smaller than the number of slots of the motor rotor. Using a new winding method to reduce the number of windings can reduce the process cost.

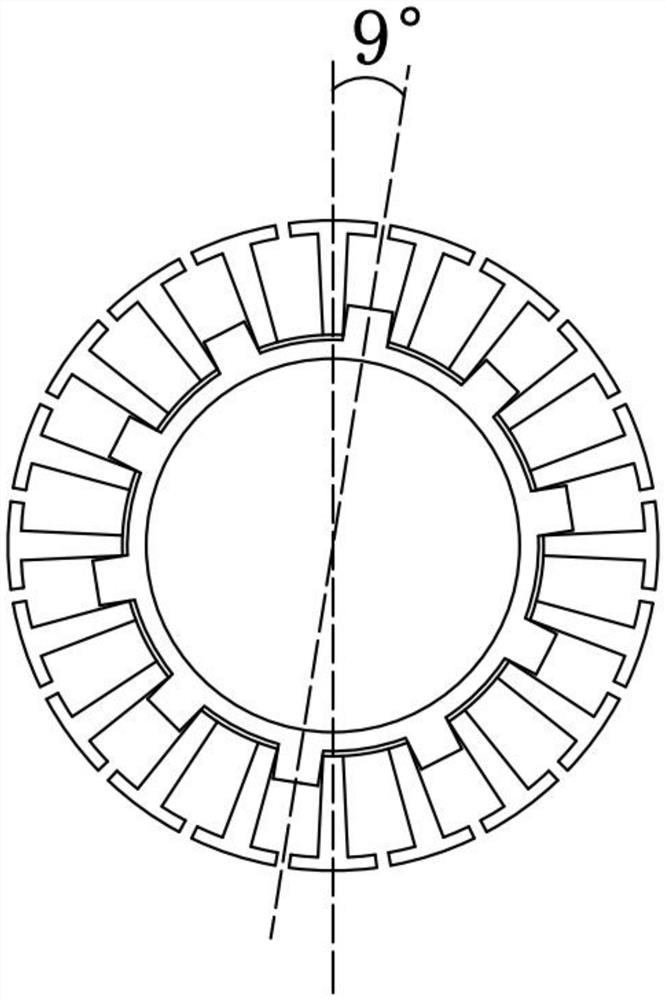

[0031] Step 2: Install the winding material, the motor rotor and the slot commutator on the motor rotor winding machine. In the second step, the slot commutator is detachably connected to the motor rotor. When set on the motor rotor, keep the included angle between the center line of the motor rotor and the center line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com