Three-phase synchronous motor DC converter

A DC converter, three-phase synchronization technology, applied in motors, excitation or armature current control, electric vehicles, etc., can solve the problems of difficult to achieve closed-loop, low speed accuracy requirements, difficult instantaneous control and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

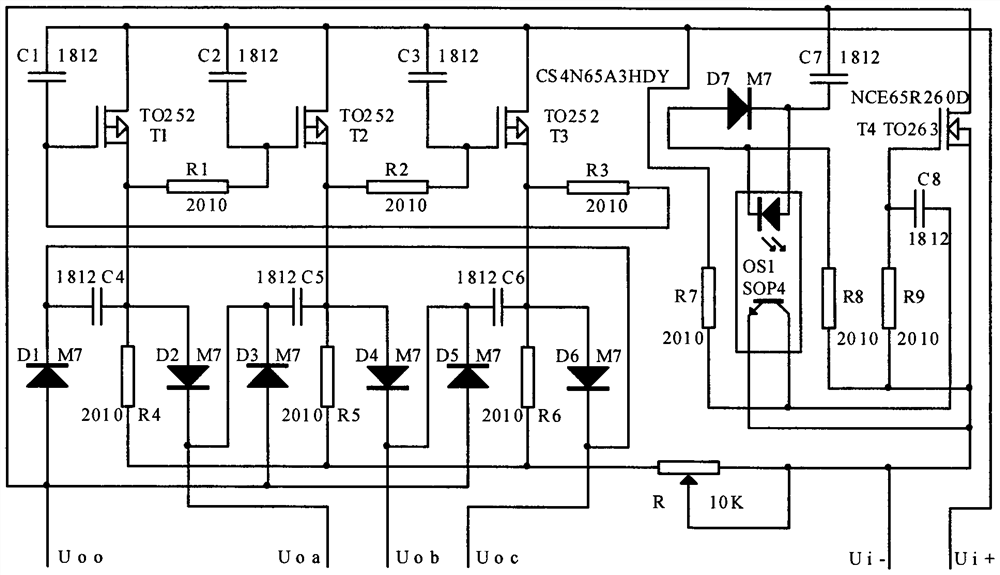

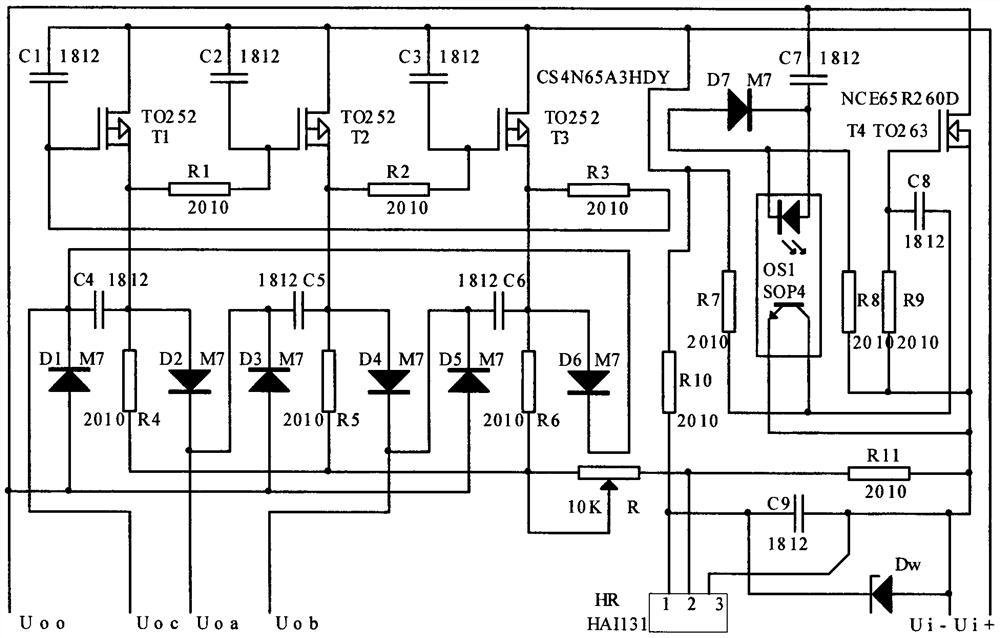

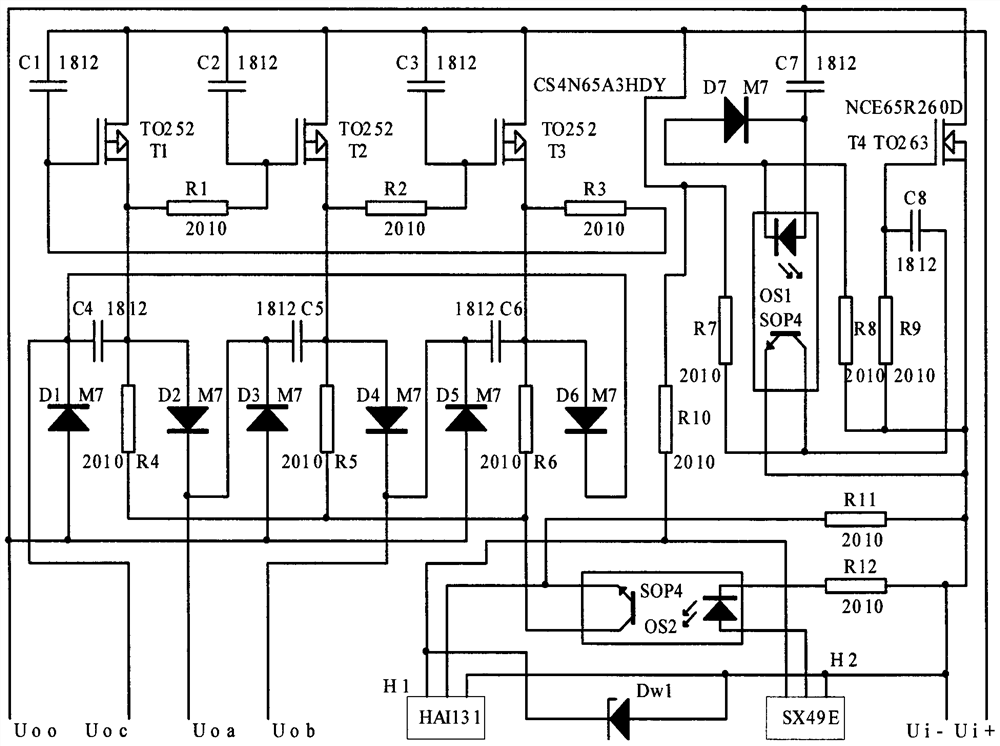

[0008] like figure 1 Shown is the circuit diagram of the open-loop DC converter applying the synchronous motor of the present invention. In the figure, T1, T2, T3 are three P-channel field effect transistors, TO252 is a chip package model, capacitors C1, C2, C3 and resistors R4, R5, R6 is a three-phase oscillating RC, capacitor 1812 and resistor 2010 are SMD package models, R1, R2, R3 are discharge current limiting resistors, C4, C5, C6 are auxiliary output capacitors, and diodes D1--D6 are the main and auxiliary output current directions Control, M7 is a diode chip package model, output three-phase from low to high double-cross unidirectional wave, R is a speed trimmer potentiometer, T4 is a high-frequency oscillation loading wave N-channel field effect transistor, R7, R8 and C7, C8 It is high frequency oscillation RC, R9 is T4 gate resistor, optocoupler OS1 is SOP4 chip package, output Uoa, Uob, Uoc three-phase, and Uoo is 0-wire open-loop three-phase four-wire star connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com