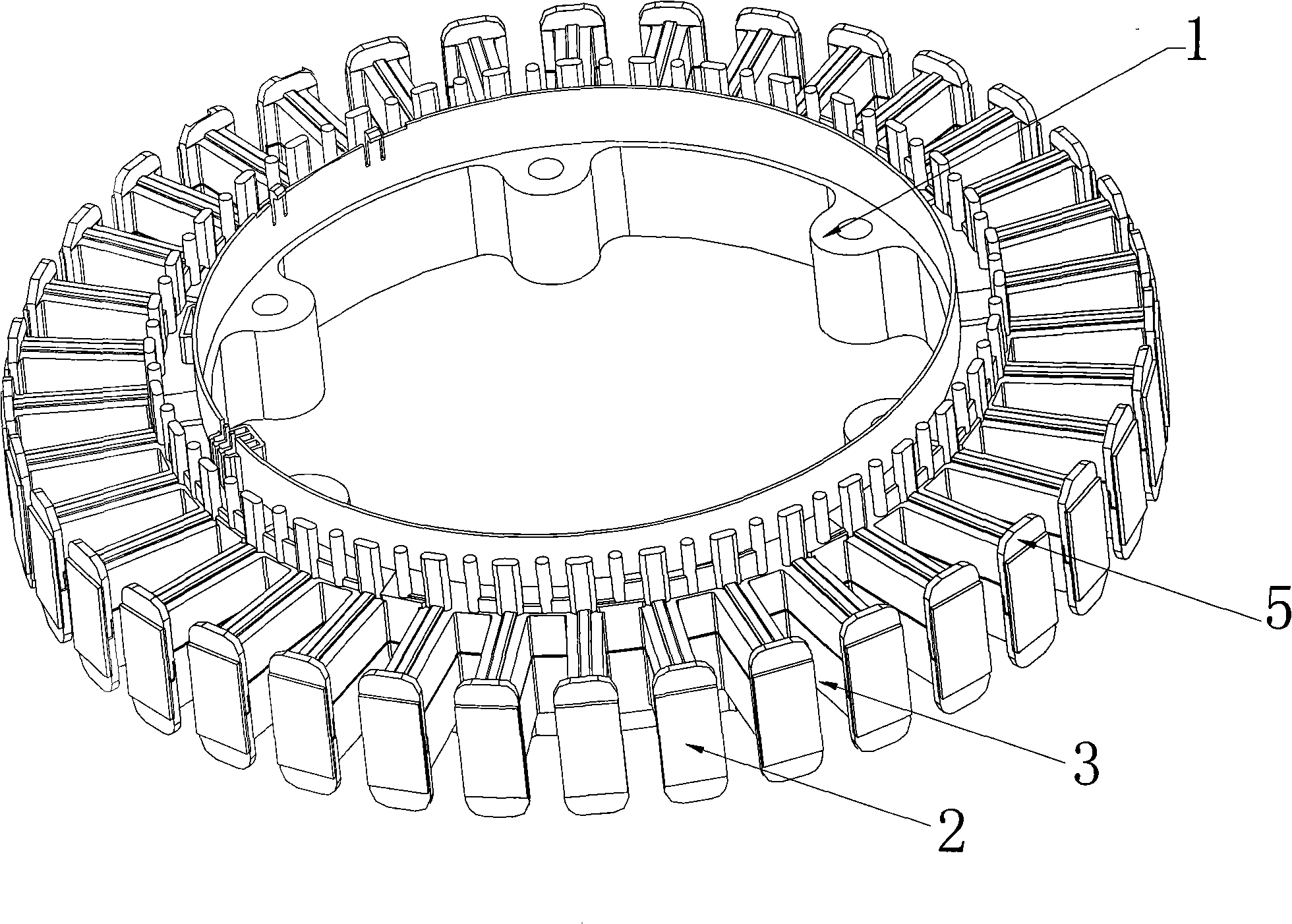

Stator

一种定子、相定子的技术,应用在电气元件、机电装置、绕组等方向,能够解决降低电机使用寿命、电机振动剧烈、齿槽力矩大等问题,达到减少噪音、运行平稳、提高使用寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

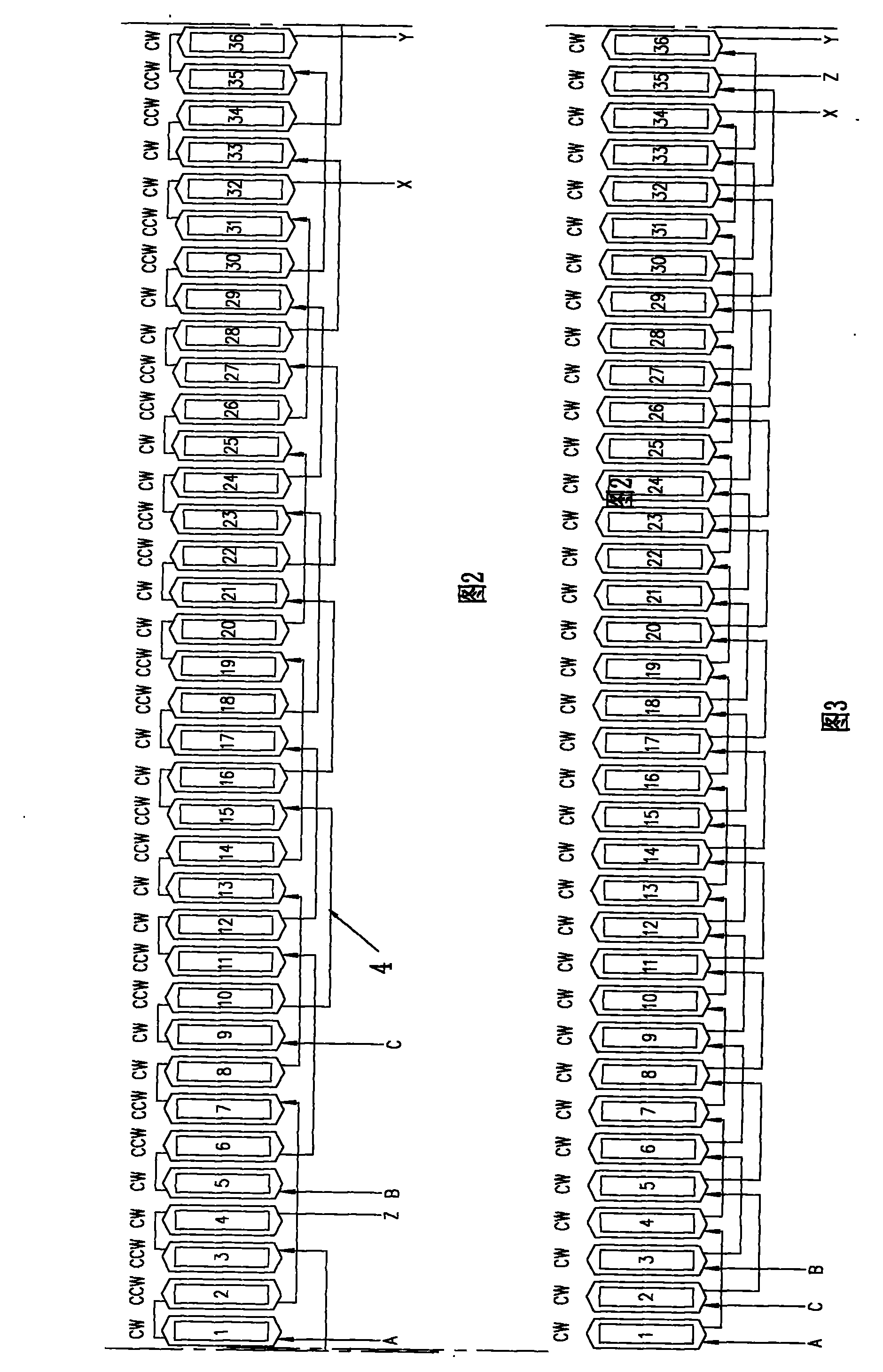

[0019] For a three-phase stator winding of a motor, the order of the teeth wound by the winding method of the present invention is respectively:

[0020] For the U-phase winding, there are two ends of A and X: first wind the first tooth in a clockwise CW direction, then wind the second tooth in a counterclockwise CCW direction, and then cross the 4 teeth arranged in sequence and keep CCW in a counterclockwise direction around the 7th tooth Then wind the 8th tooth in a clockwise CW direction, similarly, wind around the 13th and 14th teeth, cross 4 teeth, then wind the 19th and 20th teeth, wind around the 25th and 26th teeth, cross 4 teeth, and then wind the 31st and 26th teeth 32 teeth;

[0021] V-phase winding, with two ends of B and Y: first wind CW around the 3rd tooth in a clockwise direction, then wind around the 4th tooth in a counterclockwise direction CCW, then cross the 4 teeth arranged in sequence and keep CCW around the 9th tooth in a counterclockwise direction Then...

Embodiment 2

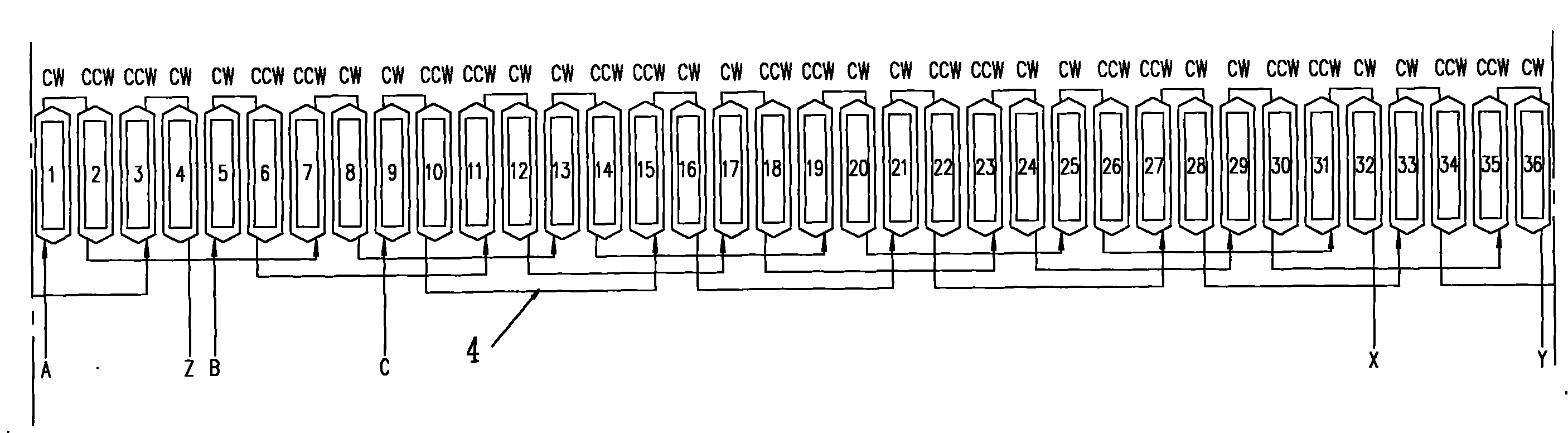

[0024] For a three-phase stator winding of a motor, the order of the teeth wound by the winding method of the present invention is respectively:

[0025] U-phase winding: firstly wind CCW around the first tooth, then wind CW clockwise around the second tooth, then straddle the 4 teeth arranged in sequence, keep clockwise CW around the seventh tooth, and then wind CCW counterclockwise The 8th tooth, in the same way, go around the 13th and 14th teeth, cross 4 teeth, then go around the 19th and 20th teeth, go around the 25th and 26th teeth, cross 4 teeth and then go around the 31st and 32nd teeth;

[0026] V-phase winding: first wind around the 3rd tooth counterclockwise CCW, then wind the 4th tooth clockwise CW, then cross the 4 teeth arranged in a clockwise direction and keep clockwise CW around the 9th tooth, then wind CCW counterclockwise The 10th tooth, in the same way, go around the 15th and 16th teeth, cross 4 teeth, then go around the 21st and 22nd teeth, go around the 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com