A Different Pole Inductor Motor with Implied Salient Pole

A technology of opposite poles and inductors, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve problems such as large cogging torque, increased wind friction loss, torque ripple, etc., and achieve cogging The effect of small torque, low wind friction loss and low torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

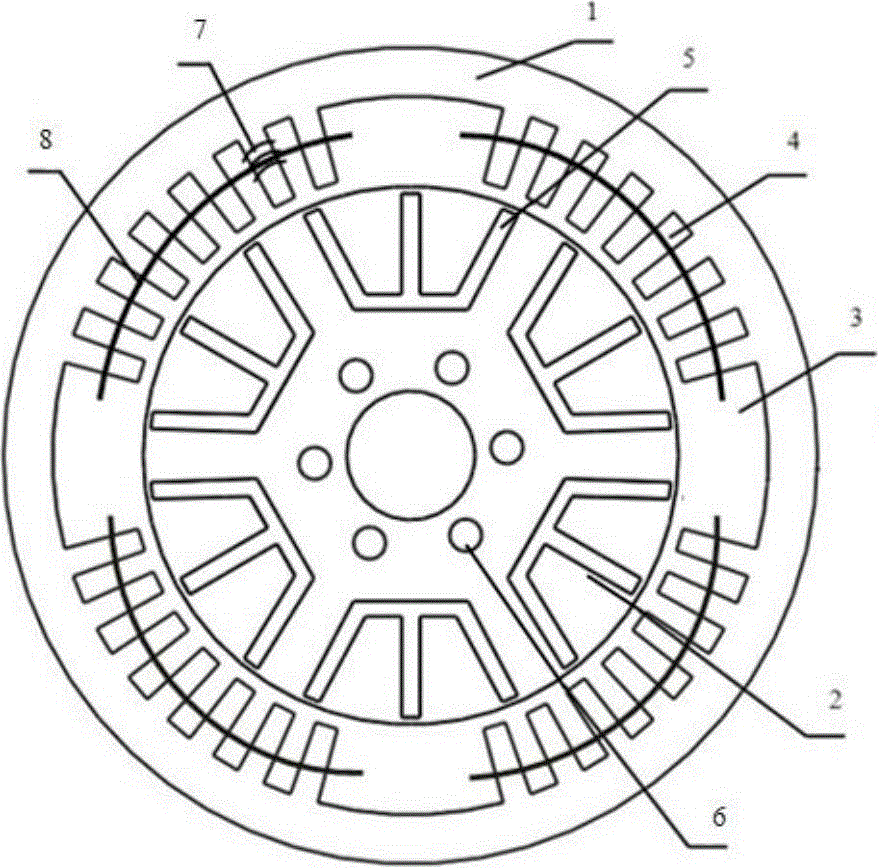

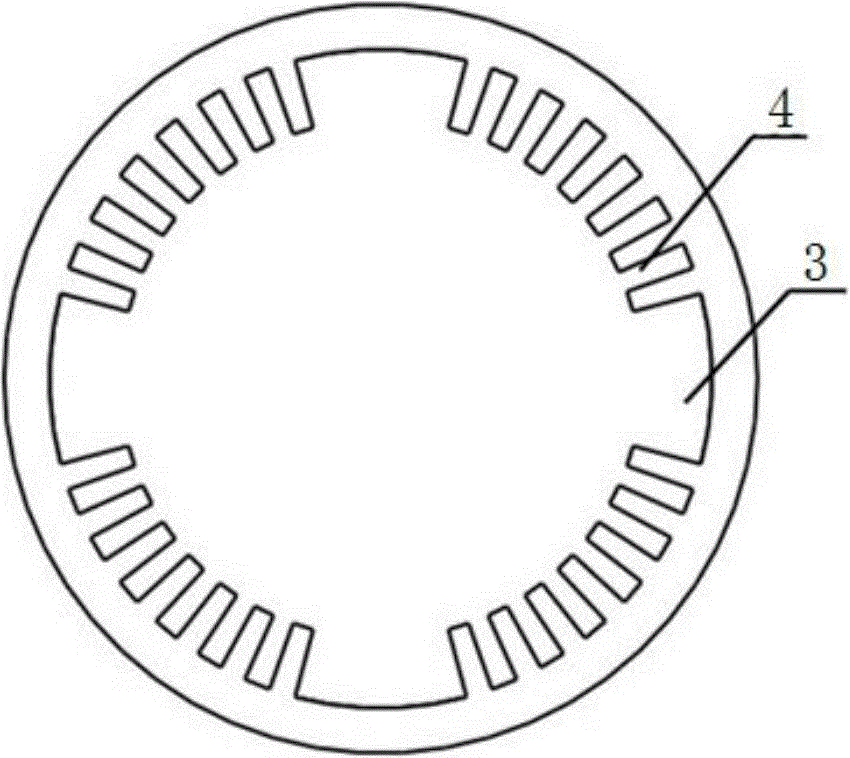

[0019] like figure 1 As shown in the figure, a heteropolar induction motor with implicit salient poles includes a stator and a rotor arranged inside the stator. The stator and rotor are coaxially installed, and the surface of the rotor is smooth and the interior has an implicit salient pole structure.

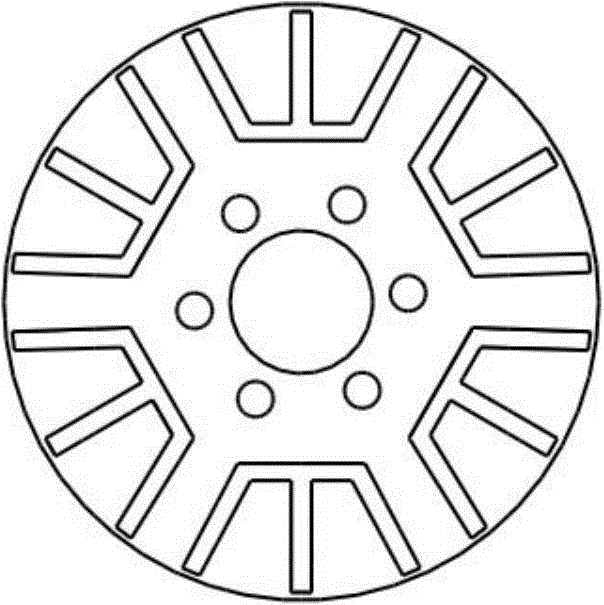

[0020] like figure 2 As shown, the motor rotor 3 is cylindrical, including the rotor core 2 and the rotating shaft, and there is neither permanent magnet nor excitation winding on the rotor. The rotor core 2 is made of laminated silicon steel sheets, and each silicon steel sheet is provided with several "mountain"-shaped magnetic isolation grooves 5 that are symmetrical to the axis of the rotating shaft. In this embodiment, the "mountain"-shaped magnetic isolation grooves 5 is 6, so each "mountain"-shaped magnetic isolation slot occupies a mechanical angle of 60°. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com