10kV high-efficiency three-phase asynchronous motor

A three-phase asynchronous motor technology, applied in the field of electric motors, can solve the problems that users cannot accept price increases, increase the cost of motor materials, and limit the improvement of efficiency, etc., and achieve the goal of reducing stator resistance, saving the amount of insulating materials, and increasing slot utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

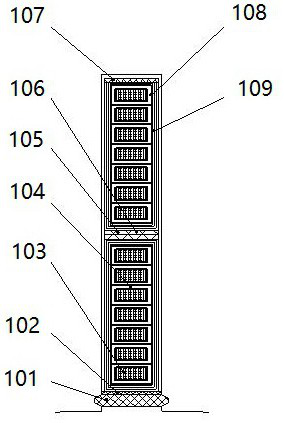

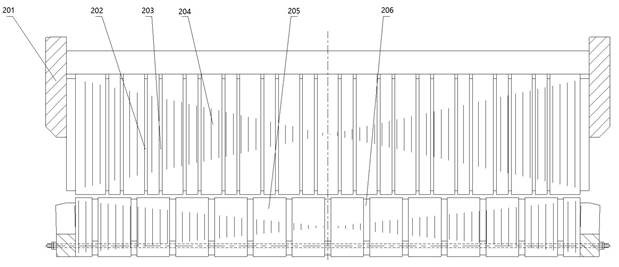

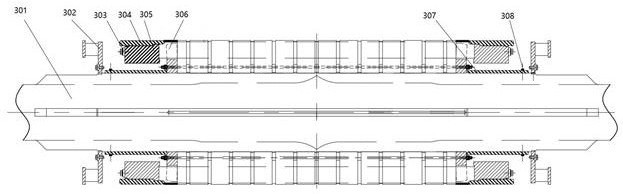

[0030] For ease of understanding, the 10kV high-efficiency three-phase asynchronous motor provided by the embodiment of the present invention is described in detail below with reference to the accompanying drawings.

[0031] The embodiment of the present invention provides a 10kV high-efficiency three-phase asynchronous motor, such as Figure 1-Figure 3 As shown in the figure, the center height of the motor is compressed to achieve high power output with a small frame size; for example, the outer diameter of the H710 motor stator is 1180mm, the embodiment of the present invention adopts 1080mm, and the adaptation is reduced to the center height of the H630, reducing one frame size. , so that under the condition of constant output power, constant voltage and constant cooling method, the efficiency meets the limit value of GB 30254-2013 "Energy Efficiency Limit Value and Energy Efficiency Grade of High Voltage Three-Phase Scratch-Cage Asynchronous Motor";

[0032] The 10kV volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com