Motor fan cover, motor

A wind cover and air inlet technology, applied in the direction of the casing/cover/support, electromechanical devices, electrical components, etc., can solve the problems of reducing the flow rate of the air outlet, reducing the pressure of the fan blade, and unreasonable problems, so as to reduce the flow The effect of reducing resistance, reducing motor temperature rise, and reducing no-load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

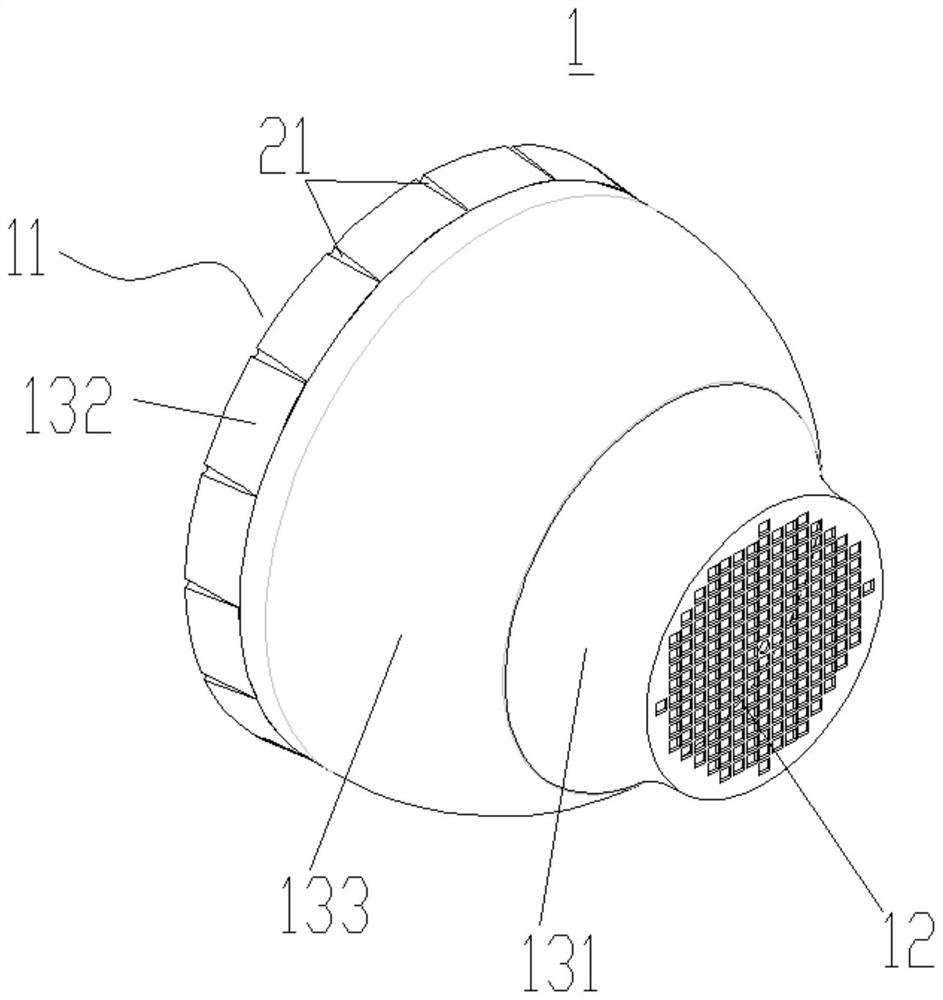

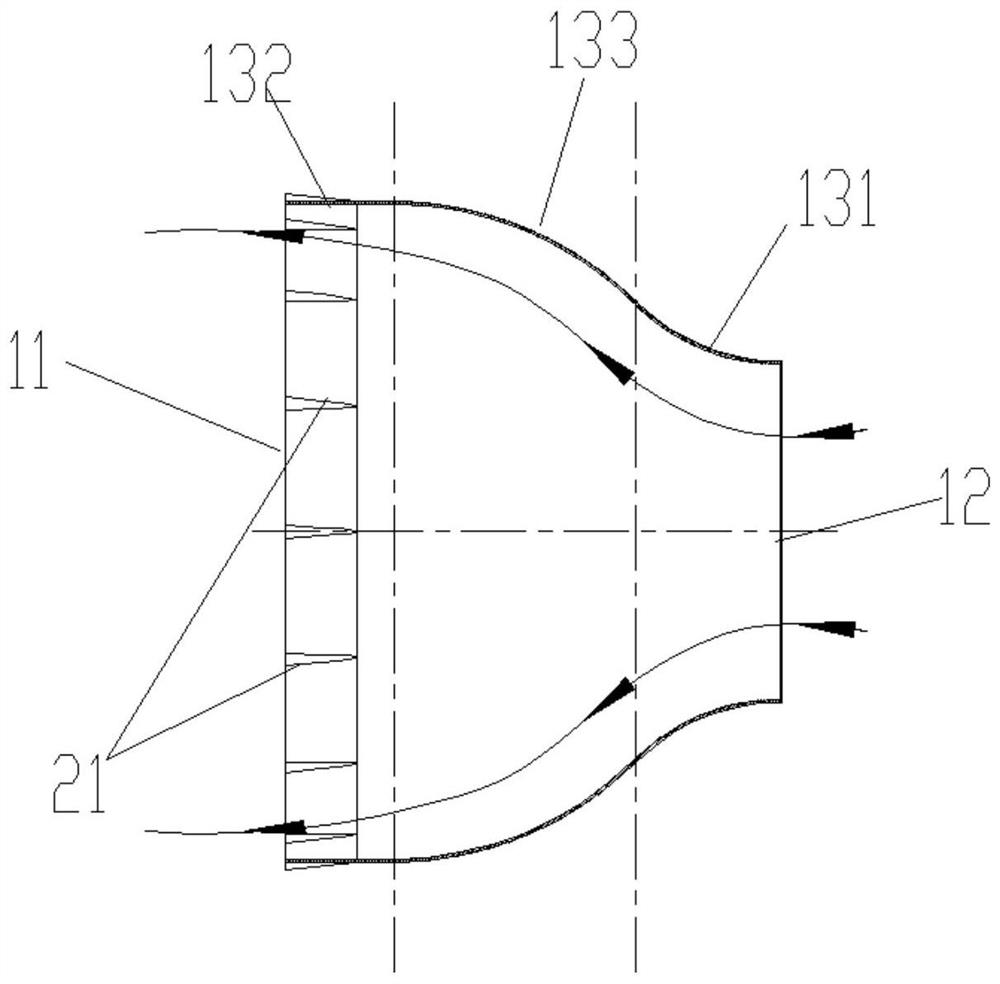

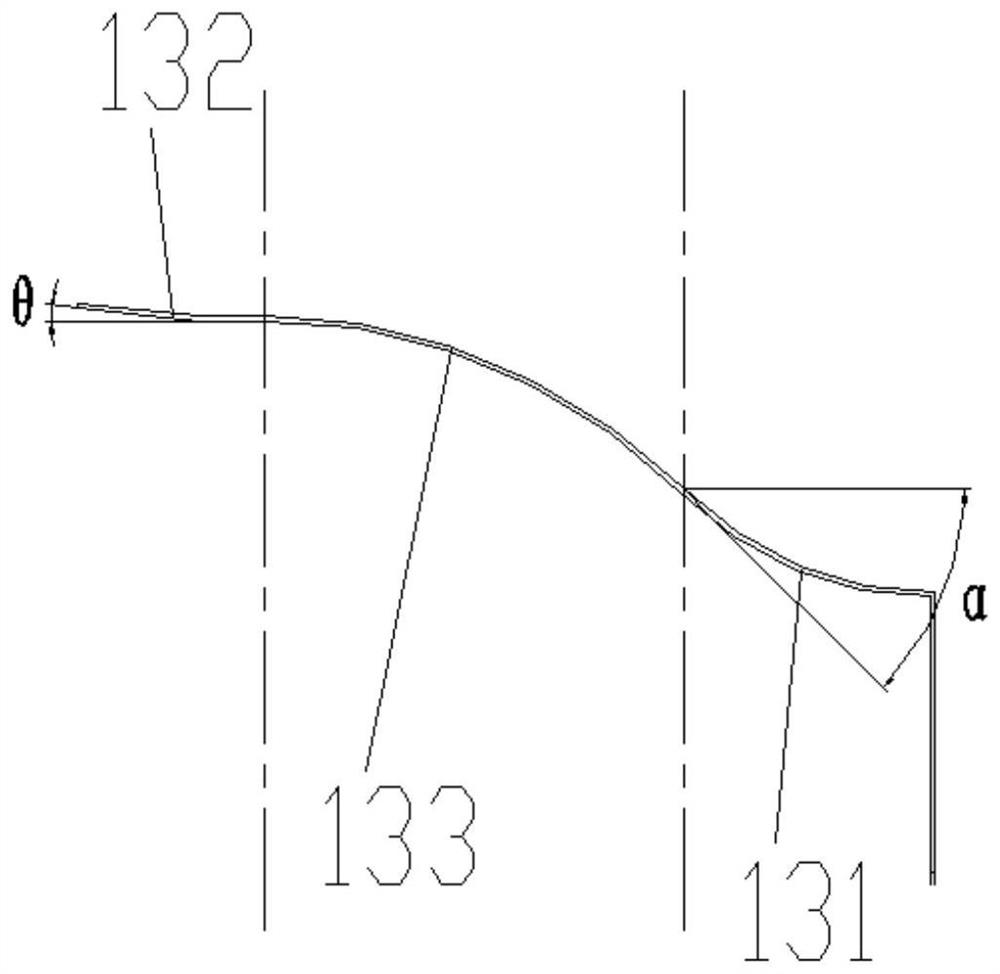

[0032] see in conjunction Figure 1 to Figure 8 As shown, according to an embodiment of the present invention, a motor wind cover is provided, including a wind cover shell 1, the wind cover shell 1 has an air outlet 11 facing to the side of the motor body 100 and is connected with the air outlet 11 The air inlet 12 oppositely arranged, on the axial section of the windshield shell 1, the windshield shell 1 has an air inlet guide curve section 131 inside the air inlet 12, and a curved section 131 at the air outlet. The air outlet curve section 132 on the inner side of 11 and the inner cavity flaring curve section 133 between the air inlet guide curve section 131 and the outlet wind curve section 132, the inlet air guide curve section 131 and the inner cavity The flaring curved section 133 and the smooth transition connection between the inner cavity flaring curved section 133 and the air outlet curved section 132 . In this technical solution, the windshield shell has a smooth t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com