Electric motor

A technology of electric motors and rotating components, which is applied in the direction of electric components, manufacturing motor generators, electromechanical devices, etc., can solve the problems of damaged motor acoustic performance, permanent magnet consumption, high total tolerance, etc., to improve operating characteristics and improve motor efficiency , the effect of small iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

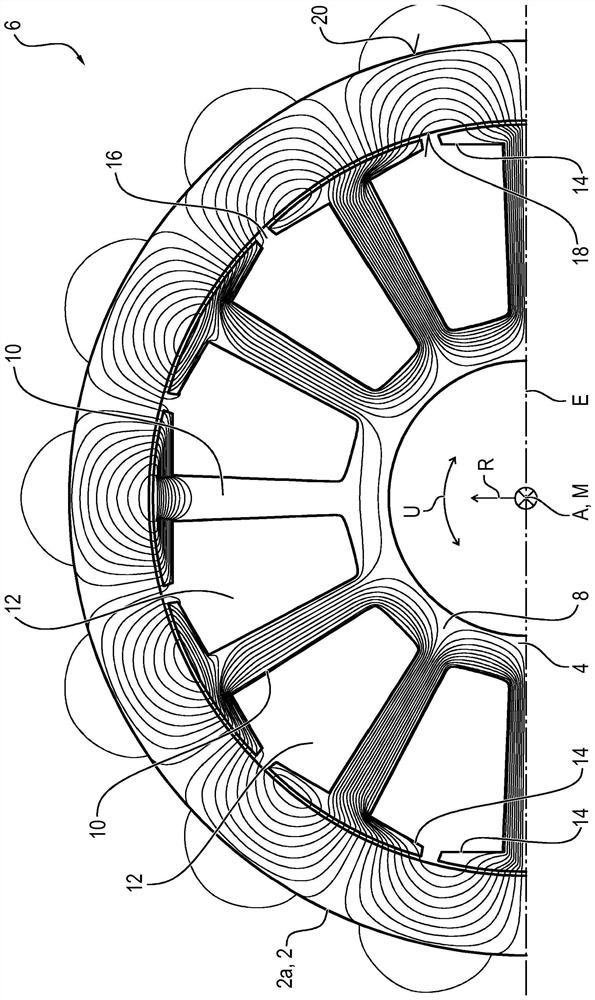

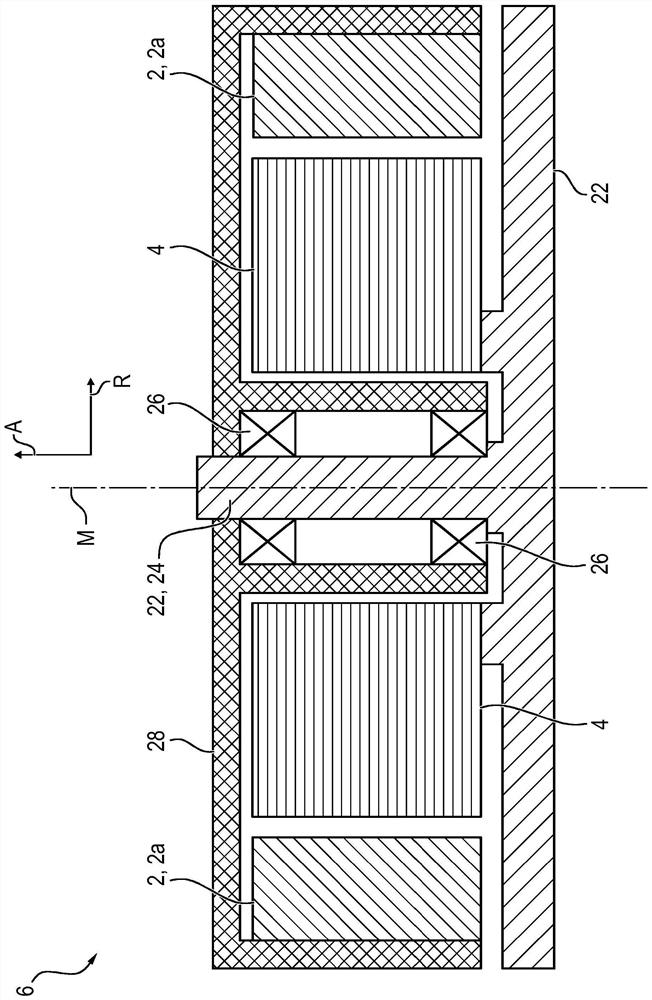

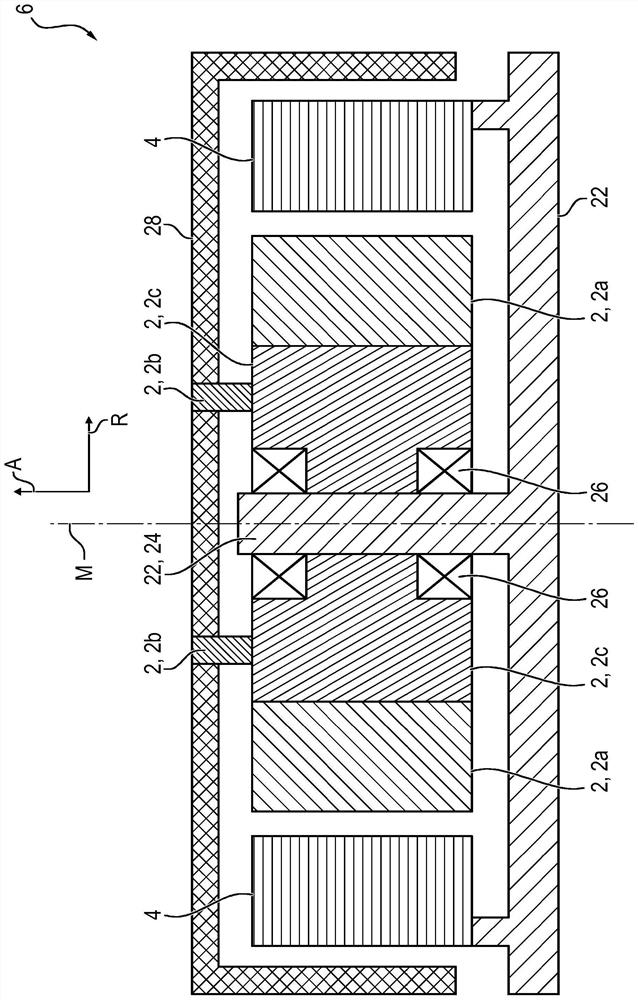

[0034] figure 1 The magnetic field line direction of the magnetic field between the rotor magnet 2a of the rotor 2 and the stator 4 of the brushless electric motor 6 is schematically shown. The rotor is supported in a manner capable of rotating around the motor axis M extending in the axial direction A. Here, for the purpose of better visibility of the magnetic field line direction, it is only partially shown. therefore, figure 1 Only half of the rotor 2 and the stator 4 are shown, wherein the unshown half of the rotor 2 and the stator 4 are mirror-symmetrical with respect to the plane E, the motor axis M extends through the plane, and the plane is perpendicular to the drawing Oriented flat.

[0035] The stator 4 has an annular stator yoke 8 from which stator teeth 10 extend away from the motor axis M toward the rotor 2 in a star-shaped manner, that is, in a radial direction R oriented perpendicular to the axial direction A. Therefore, the rotor 2 is arranged outside the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com