Single Phase Brushless DC Motor

A brushed DC motor, single-phase technology, used in single-phase motor control, single motor speed/torque control, electrical components and other directions, can solve the problems of large motor cogging torque, long service life, poor motor stability, etc. Achieve the effect of large peak torque, easy processing and manufacturing, and small torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

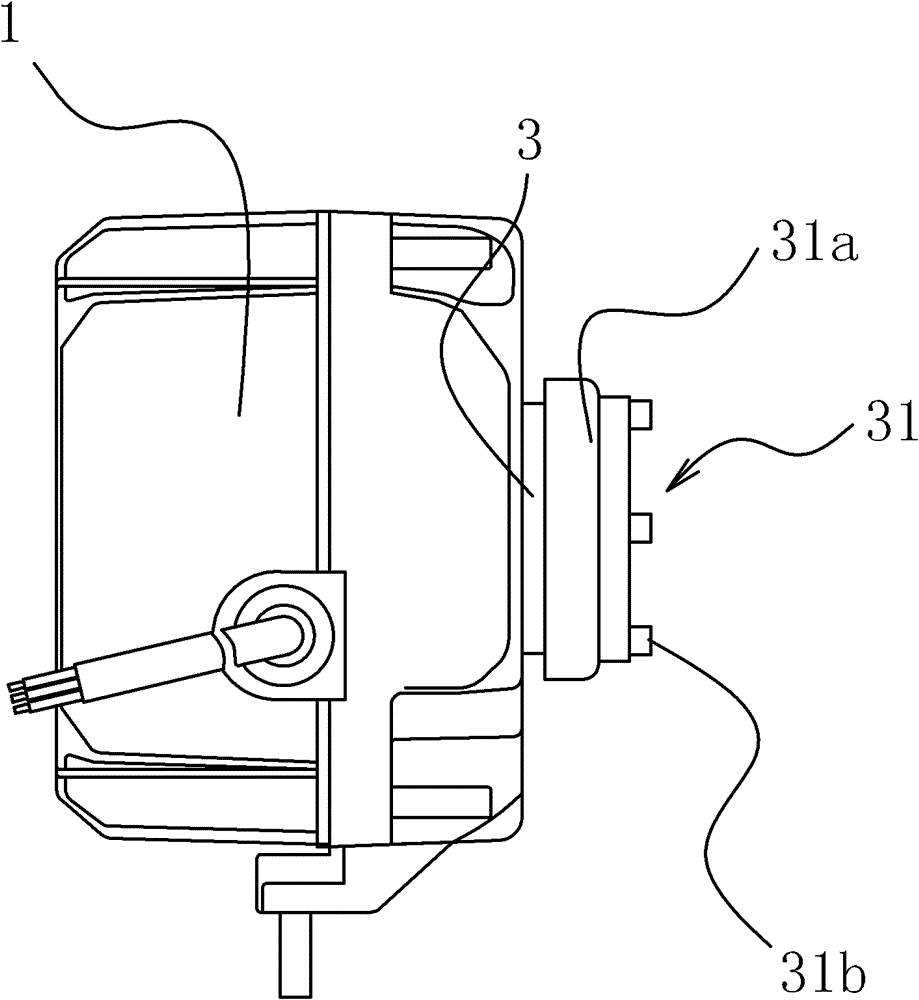

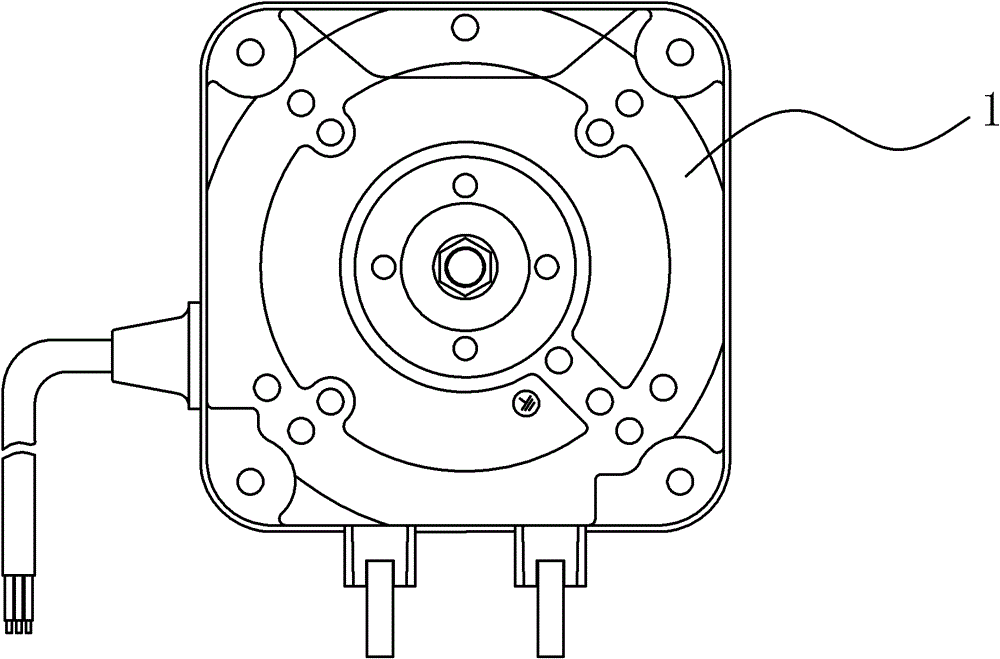

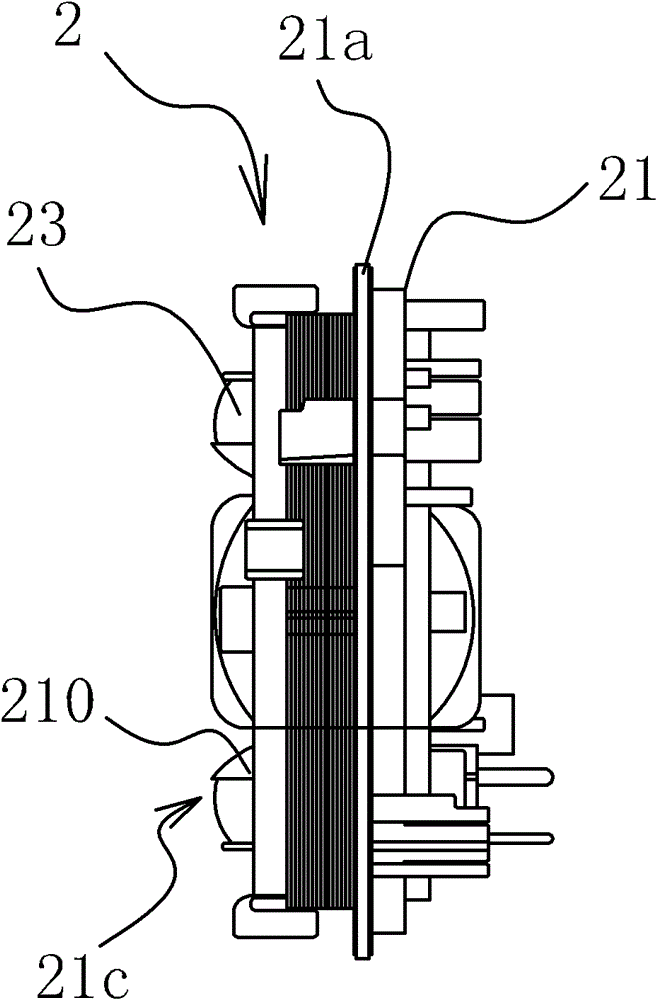

[0021] like figure 1 and 2 As shown, the single-phase brushless DC motor includes a casing 1, a stator assembly 2 is arranged inside the casing 1, and a rotor 3 made of permanent magnet material is pierced in the stator assembly 2. like image 3 and 4 As shown, the stator assembly 2 includes a rear frame 21 on which a stator body 22 is arranged. like Figure 5 As shown, the stator body 22 includes a ring body 221, and a number of winding bodies 222 are arranged inside the ring body 221. The winding body 222 includes a connecting body 22a connected to the inside of the ring body 221 and is arranged on the connection The arc body 22b on the body 22a, the middle part of the arc body 22b is connected with the connecting body 22a, and each arc body 22b has a different arc radius. The number of winding bodies 222 is four, and the centers of the four arc bodies 22 b are distributed around the center of the circle body 221 . like image 3 and 4 As shown, windings 23 are wound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com