Double-bevel gear drive axle double-speed reducer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further elaborated in conjunction with the accompanying drawings.

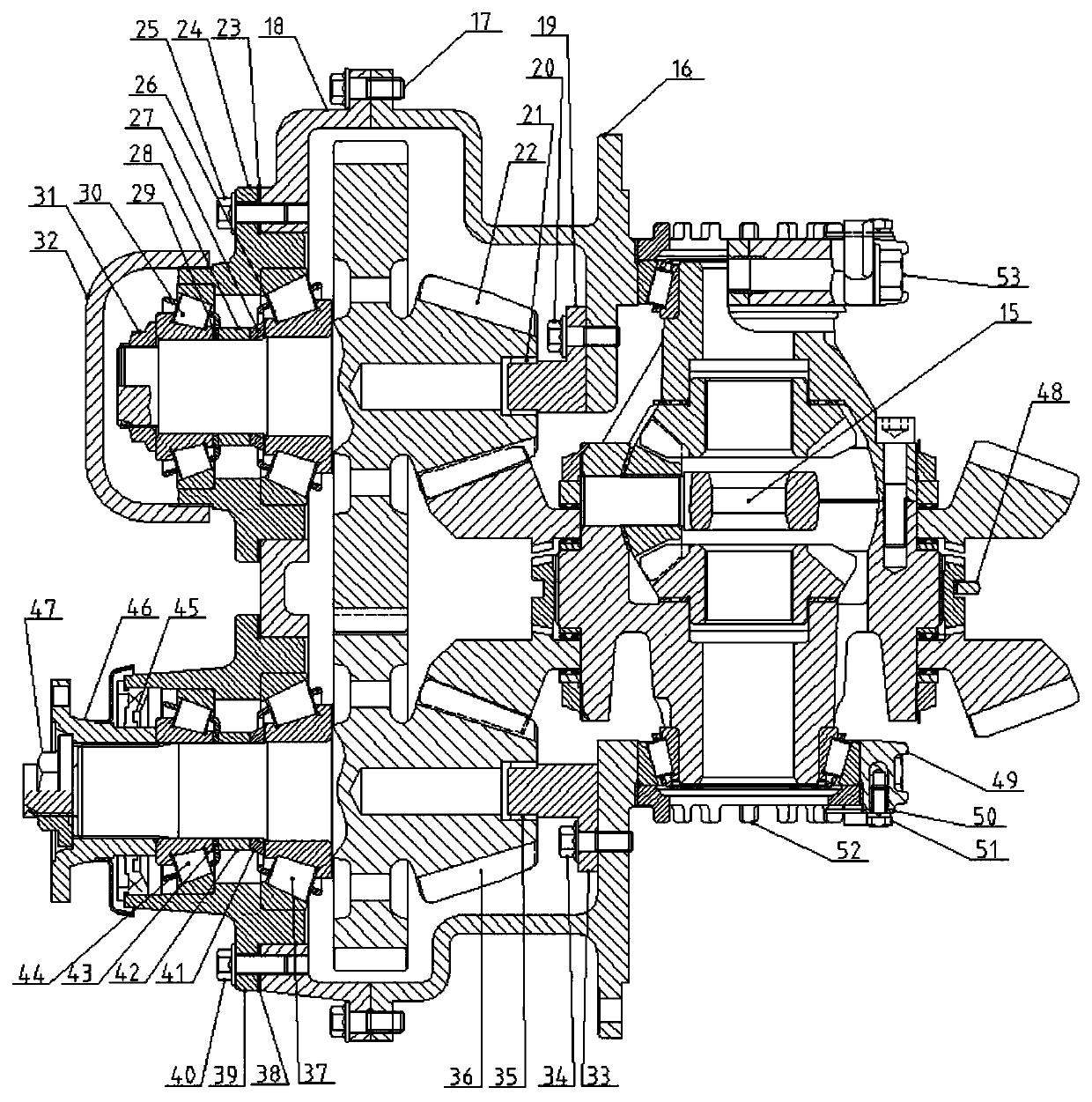

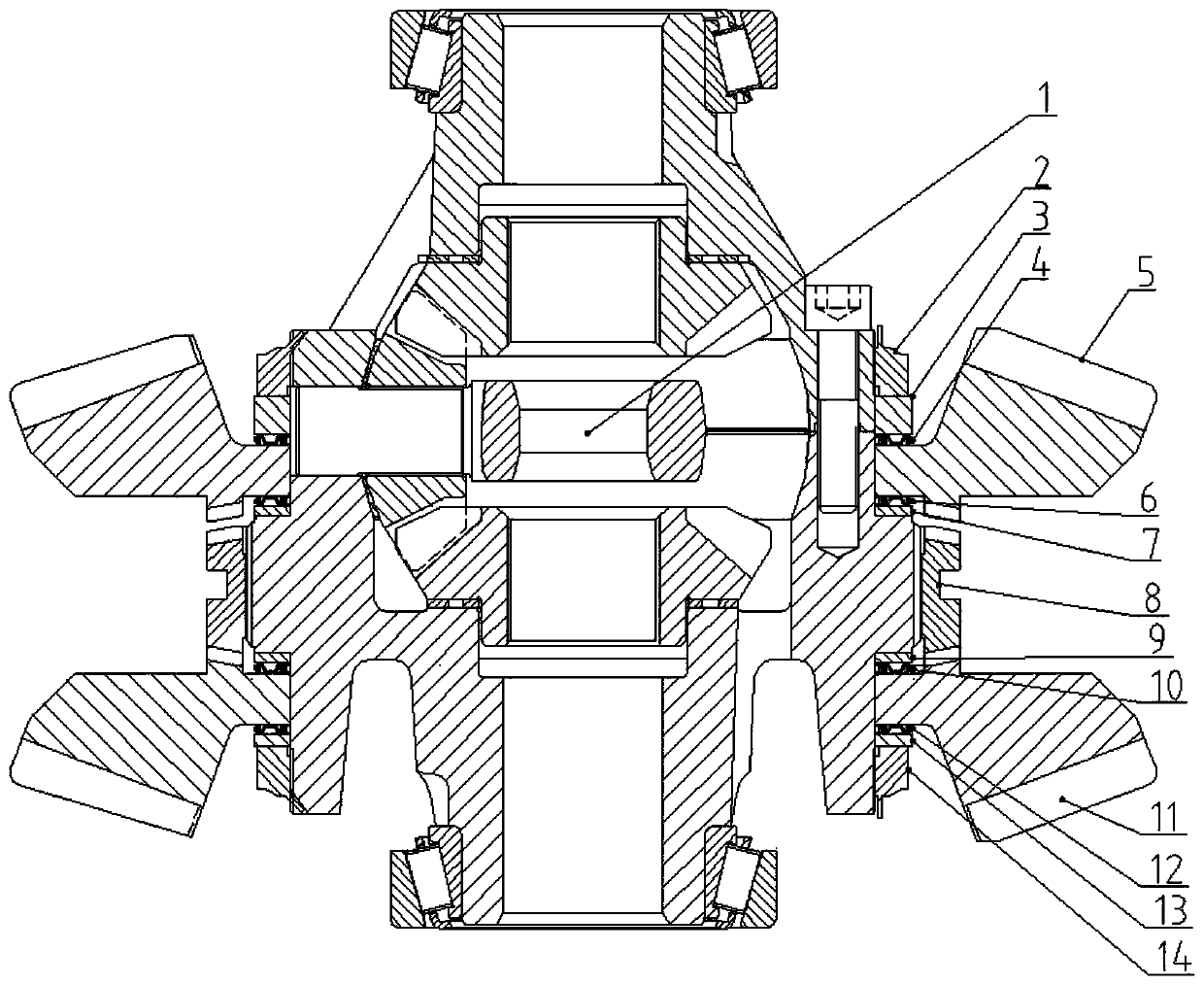

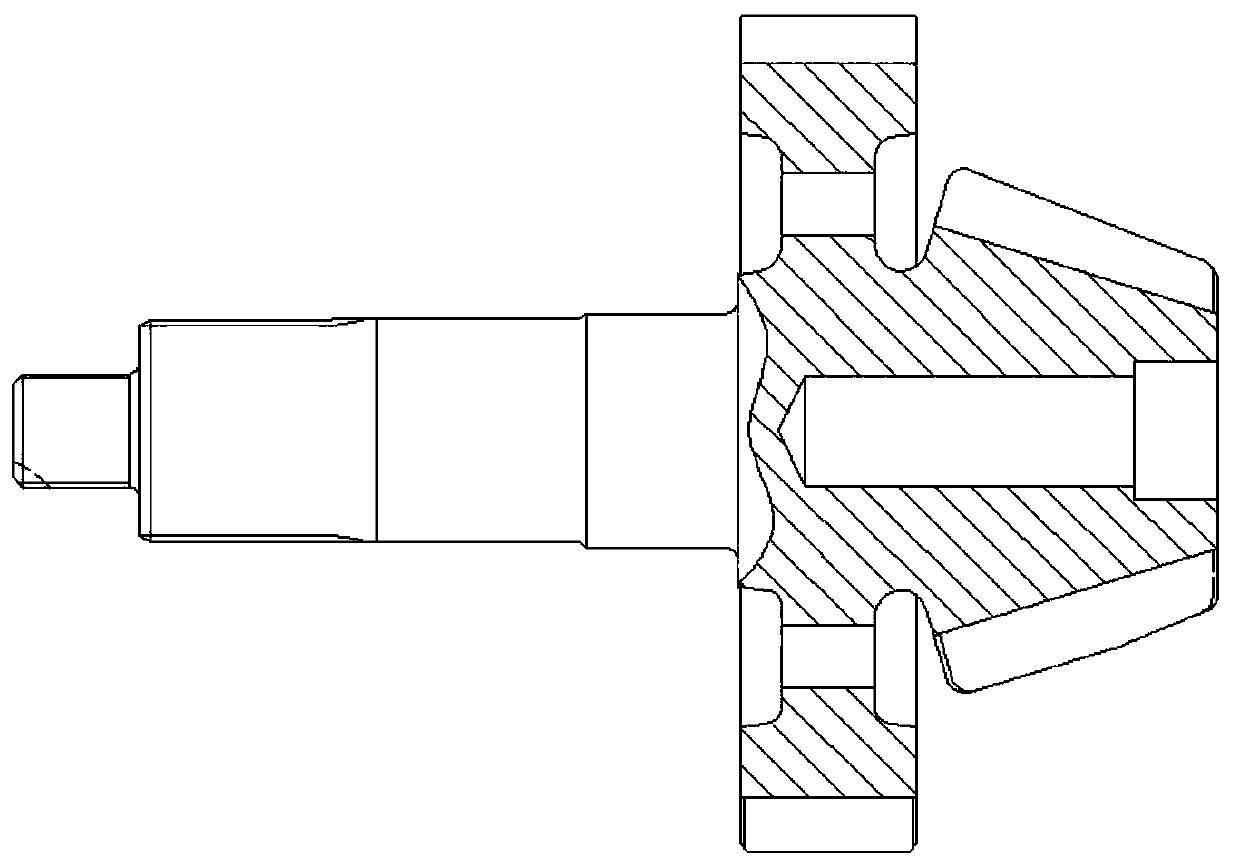

[0062] Double-bevel gear drive axle two-speed reducer structure, mainly composed of differential and driven bevel gear assembly, first shaft driving bevel gear and second shaft driving bevel gear;

[0063] The differential and driven bevel gear assembly includes the differential gear assembly, the first shaft driven bevel gear and the second shaft driven bevel gear;

[0064] Double-bevel gear drive axle two-speed reducer structure, also includes bearing support B33, reducer housing 16, needle bearing and cage assembly F35, tapered roller bearing C37, first shaft driving bevel gear 36, bearing support Seat A19, needle roller bearing and cage assembly E21, tapered roller bearing A26, second shaft driving bevel gear 22, cylindrical gear housing 18, tapered roller bearing D44, first shaft bearing housing 39, second shaft bearing housing 24. Spacer sleeve B28, tapered roller be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com