Bicycle pedal device

A bicycle and pedal technology, applied in vehicle parts, transportation and packaging, crank structure and other directions, can solve the problems of small torque, limited torque, low driving efficiency, etc., and achieve the improvement of driving efficiency, driving torque and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

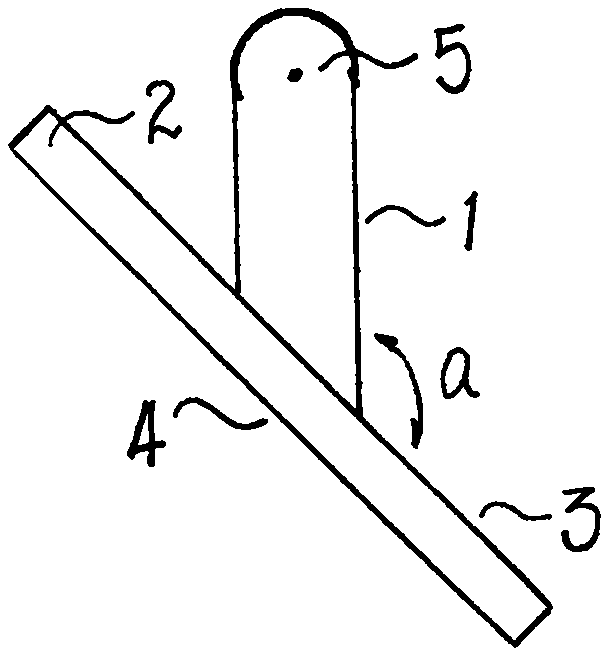

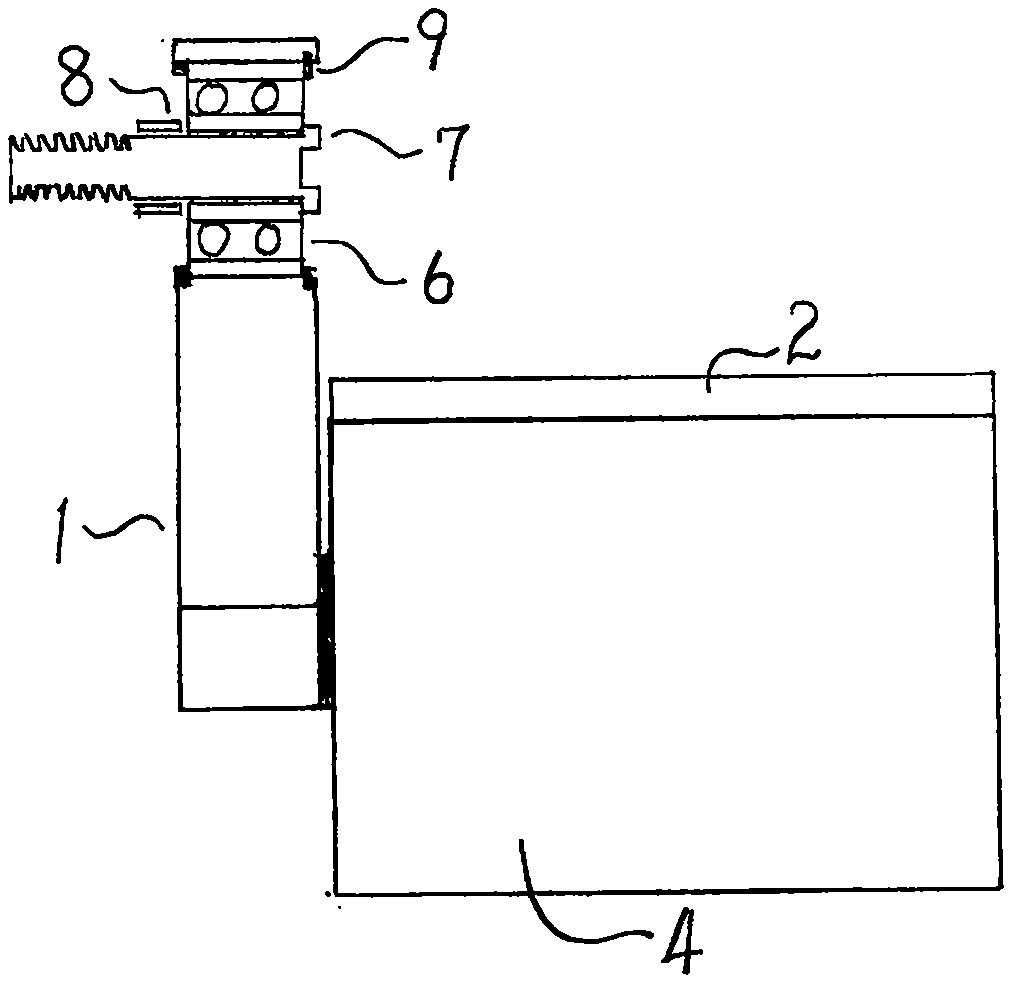

[0013] Such as figure 1 , 2 As shown, one end of the right connecting rod 1 is provided with a bearing 6, and the inner ring of the bearing 6 is covered with a bolt 7, and the bolt 7 is screwed into the screw hole of the right crank (not shown), and the other end of the right connecting rod 1 and the right foot The pedal 2 is fixedly connected or has an integrated structure, and the angle formed by the upper plane 3 of the right pedal and the right connecting rod 1 is 135 degrees.

[0014] Due to self-weight, when the pin is not placed on the right pedal 2, the right pedal device naturally droops, and the upper plane 3 of the pedal is at an angle of 45 degrees with the ground. When the foot is placed on the right pedal 2 , the upper plane 3 of the pedal rotates counterclockwise to a horizontal state, and now the front swing angle of the right connecting rod 1 is about 45 degrees. When riding, if the right pedal 2 is near the highest position, the soles of the feet should be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com