Electro-hydraulic compound control underground decoding device and decoding method thereof

An electro-hydraulic composite and decoding device technology, which is applied to valve devices of wellbore/well, earthwork drilling, wellbore/well components, etc. The existence of small motors and electronic components, the effect of improving the efficiency of layer recognition and improving process reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

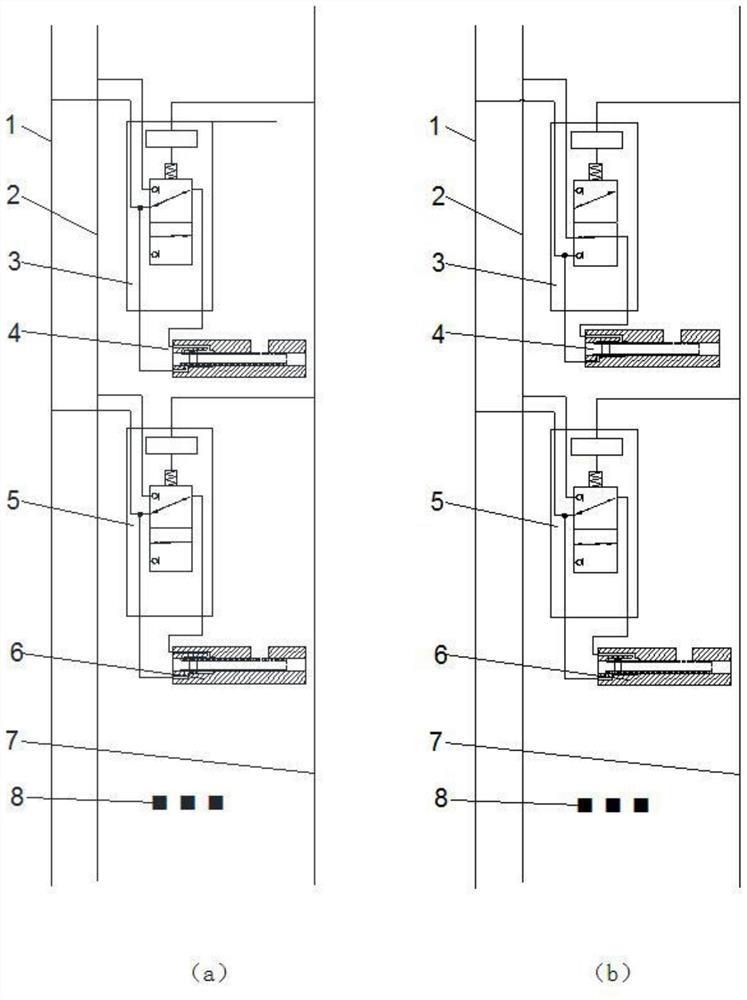

[0032] An electro-hydraulic composite control downhole decoding device, comprising a first hydraulic control pipeline 1, a second hydraulic control pipeline 2, an electro-hydraulic composite control device, a signal control cable 7 and a lower electro-hydraulic composite control system 8,

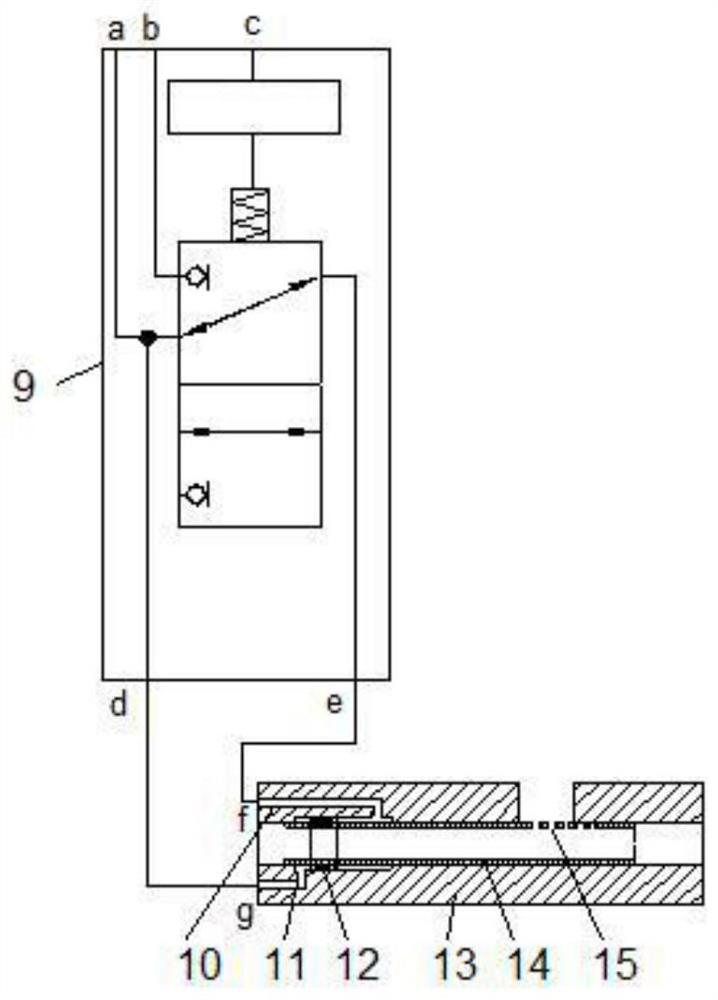

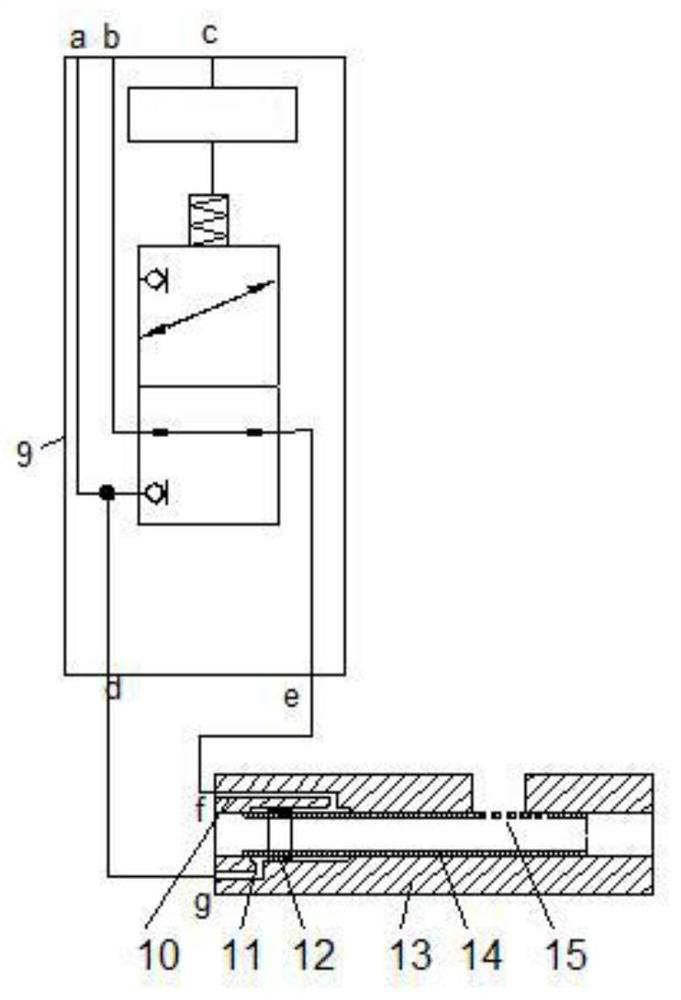

[0033]The electro-hydraulic compound control device includes an electro-hydraulic compound control decoder and a hydraulic control sliding sleeve, and the electro-hydraulic compound control decoder includes a decoder shell 9, a first electro-hydraulic compound control pipeline 16, an electro-hydraulic compound control circuit system 17, a second electric Liquid compound control pipeline 18, two-position three-way solenoid valve 19 and internal signal control cable 20,

[0034] When the electro-hydraulic composite control decoder is in the closed state, the first hydraulic control pipeline 1 is connected to the hole a on the decoder casing 9, and the a hole on the decoder casing 9 is respecti...

Embodiment 2

[0039] On the basis of Embodiment 1, the hydraulic control sliding sleeve includes an upper liquid inlet hole 10, a lower liquid inlet hole 11, a piston 12, a casing 13, a central tube 14, and a liquid outlet hole 15. On the side wall of the casing 13, there are The liquid guide hole that runs through the side wall of the shell 13, the central tube 14 is sleeved in the shell 13, and the liquid outlet hole 15 that runs through the side wall of the central tube 14 is uniformly opened on the lower side wall of the central tube 14 opposite the liquid guide hole , at the head end of the casing 13, there are respectively an upper lifting liquid inlet 10 and a lower lowering liquid inlet 11 through the side wall of the outer casing 13, and the upper lifting liquid inlet 10 and the lower lowering liquid inlet 11 are controlled by the hydraulic pressure and the piston 12. Lifting and lowering of the pipe 14 to realize the adjustment of the horizon.

Embodiment 3

[0041] On the basis of the second embodiment, adjacent electro-hydraulic control devices are separated and hermetically sealed by packers.

[0042] The number of electro-hydraulic composite control devices is 2-12.

[0043] In the initial state, the electro-hydraulic compound control decoder is closed.

[0044] The signal control cable 7 is connected with the ground control equipment, so as to realize the purpose of controlling the downhole electro-hydraulic composite decoder by using the ground control equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com