Drive axle double-speed reducer with planetary structure

A technology of planetary structure and drive axle, which is applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems of low driving speed, insufficient driving torque, low efficiency, etc., and achieve the effect of improving efficiency and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

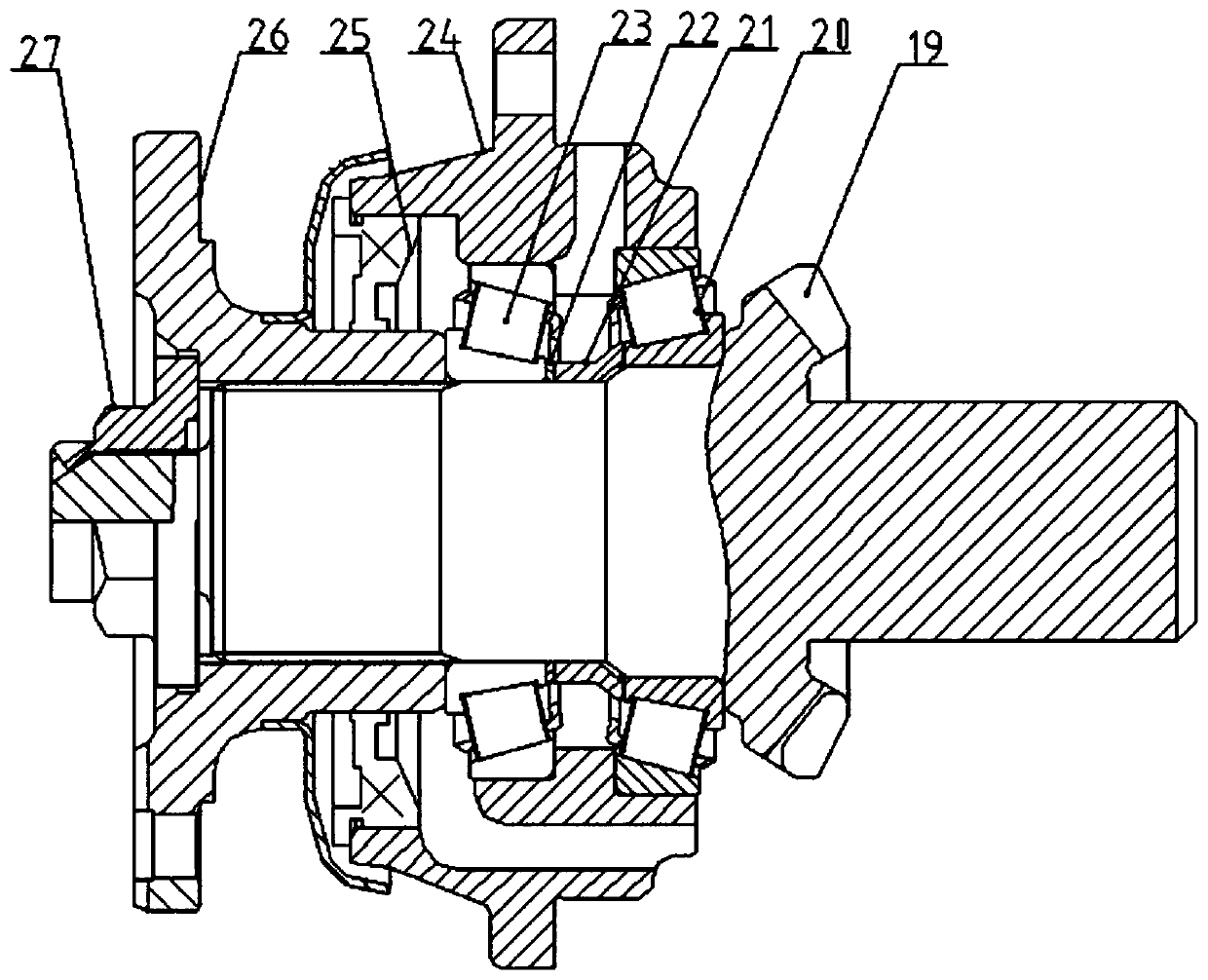

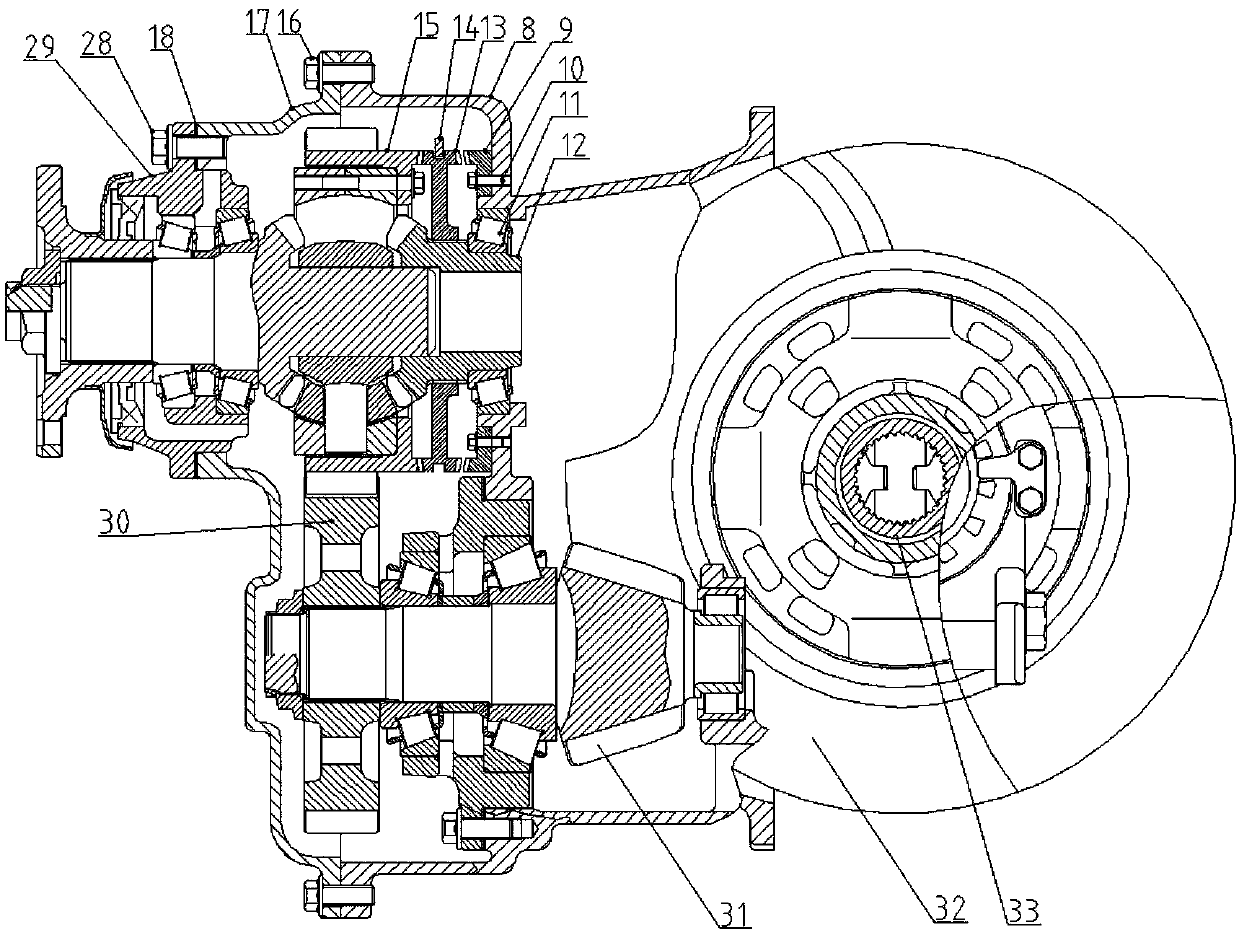

[0031] A drive axle two-speed reducer with a planetary structure, including a reducer housing 8, a fixed meshing sleeve 9, a driven bevel gear 12, a sliding meshing sleeve 13, a planetary gear assembly 15, a bevel gear housing 17 and a driving bevel gear assembly 29;

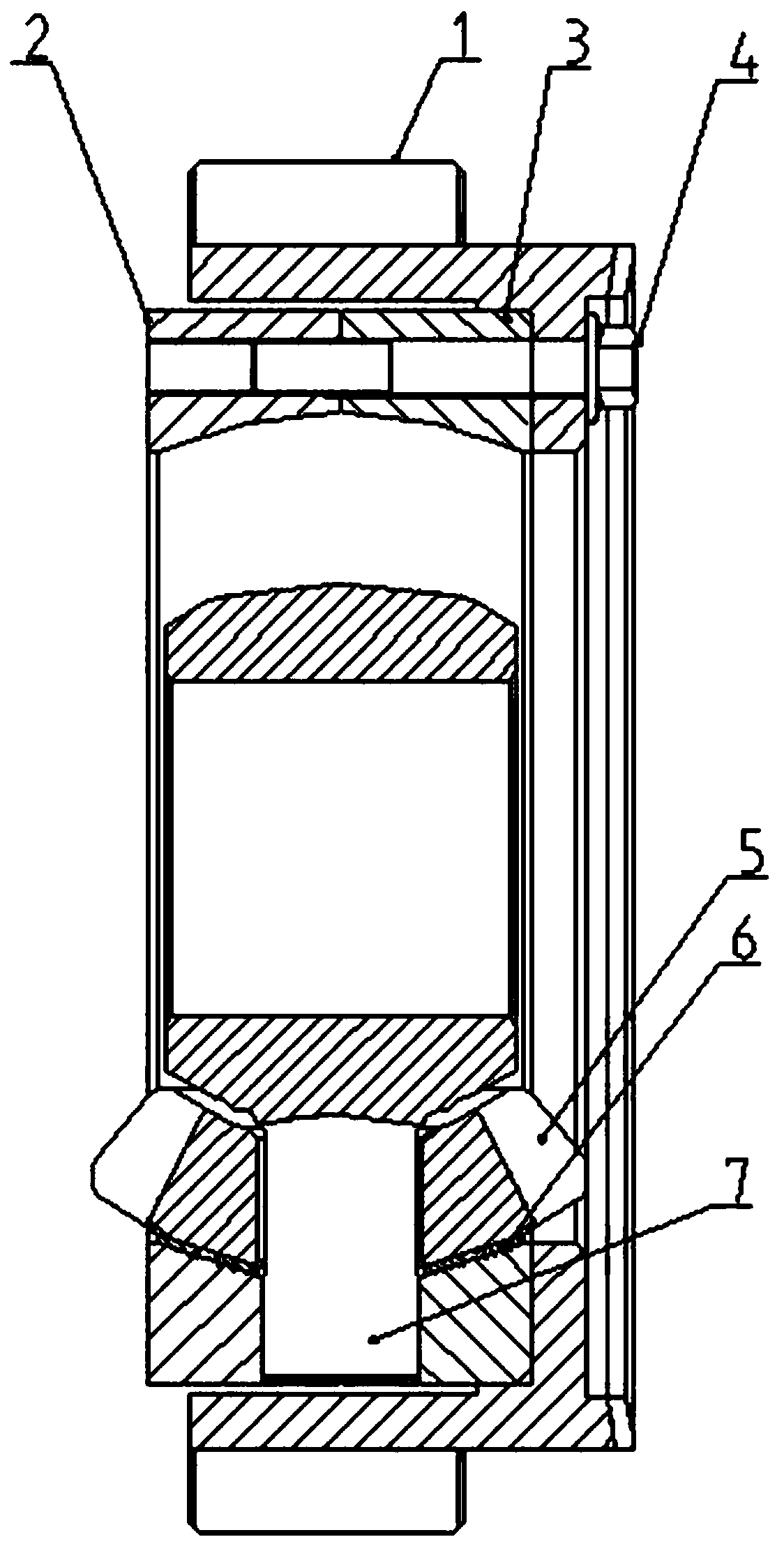

[0032] Wherein, the planetary gear assembly 15 includes the driving cylindrical gear 1, the planetary gear front case 2, the planetary gear rear case 3, the bolt 4, the planetary gear 5, the planetary gear gasket 6 and the cross shaft 7; the planetary gear gasket Plate 6 is put into the shaft diameter of planetary gear 5, and the hole of planetary gear 5 is assembled into the shaft diameter of cross shaft 7. Four semicircular holes are respectively arranged on the planetary gear front case 2 and the planetary gear rear case 3, forming four circles. The hole is used to load the cross shaft 7; the inner stop of the driving cylindrical gear 1 is installed on the outer stop of the planetary gear rear case 3;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com