Novel anti-shake pan-tilt for camera and anti-shake method

A camera, anti-shake technology, applied in image communication, machine/stand, TV and other directions, can solve problems such as image blur, achieve fast response speed, large anti-shake angle, and overcome the effect of magnet interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

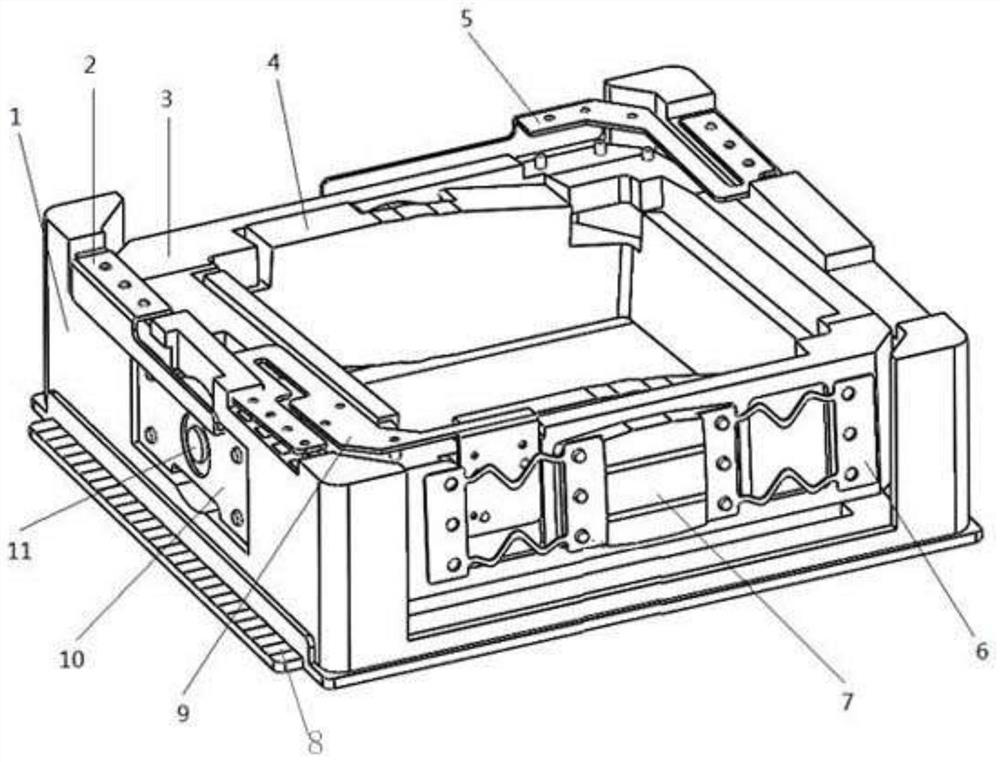

[0047] Such as Figure 1-Figure 16 As shown, a new camera anti-shake pan head includes a base 1, a protective case 12, a frame unit, a vibrator unit, a preload unit and a signal position sensing unit.

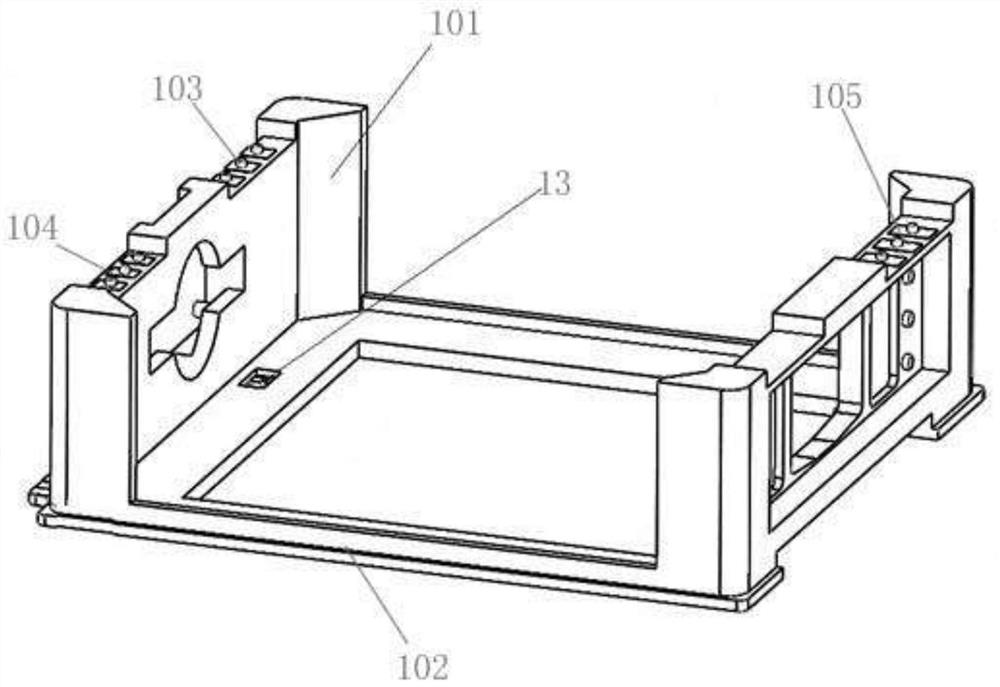

[0048] Wherein, the base 1 includes a base plate 102 and a retaining wall 101 arranged on the base plate 102. In this embodiment, the base plate 102 is a rectangular frame structure, the middle part is empty, and the number of retaining walls 101 is two. 102 is relatively arranged, the bottom plate 102 and the retaining wall 101 are built with metal strips for increasing strength, power taking and signal transmission, and the edge of the bottom plate 102 is provided with a conductive terminal lead-out area 8 connected to the metal strip, and the retaining wall 101 is provided with three conductive connection parts 103, 104, 105 of the metal strip.

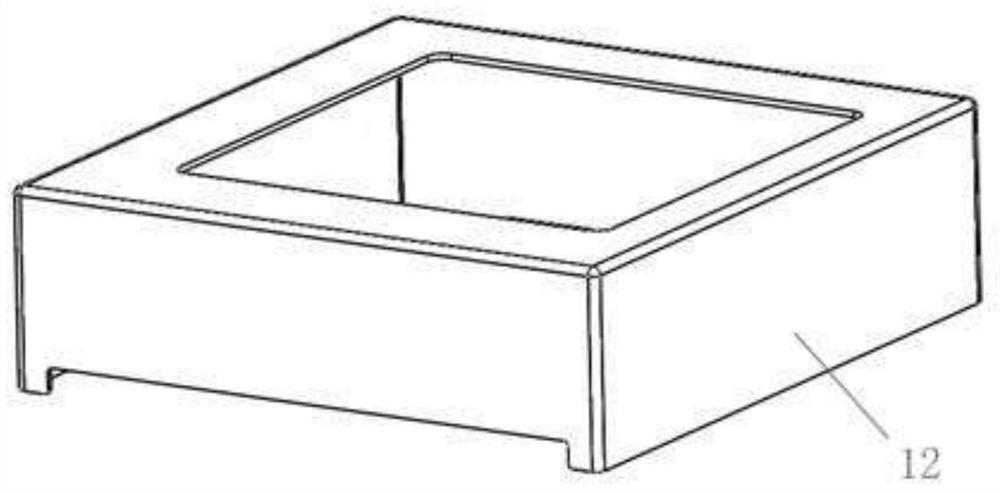

[0049] The protective shell 12 is buckled together with the base 1 to form a cavity that defines and protects.

[0050] The fram...

Embodiment 2

[0062] In this embodiment, the fixing method of the first ring piezoelectric ceramic vibrator assembly and the second ring piezoelectric ceramic vibrator assembly in the vibrator unit is the same as that of the first preload assembly and the second preload assembly in the preload unit. The fixed method is interchanged.

[0063] Take the interchangeable fixing method of the first ring piezoelectric ceramic vibrator assembly and the first preload assembly as an example:

[0064] The two sides of the fixed plate I are respectively connected and fixed with the retaining wall 101 by means of the leaf spring I, and the stepped shaft I11 is not provided in the first ring piezoelectric ceramic vibrator assembly, and the rotary support structure I in the embodiment is arranged on the fixed plate I Between the outer frame 3; the pre-pressing plate I in the first pre-pressing assembly is fixedly connected to the retaining wall 101, and the center is provided with a stepped shaft I11, and...

Embodiment 3

[0068] In this embodiment, the rotary support structure I between the inner side of the pre-pressing plate I and the side wall of the outer frame 3 is different from that in Embodiment 1. The slewing support structure Ⅰ abandons the matching structure of the arc groove and the ball, and adopts a number of elastic metal bending parts to realize the pre-compression function. At the same time, the elastic metal bending parts have the function of elastic deformation and do not affect the outer frame 3 There is a relative displacement with the retaining wall 101.

[0069] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com