Patents

Literature

76 results about "Motor carrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

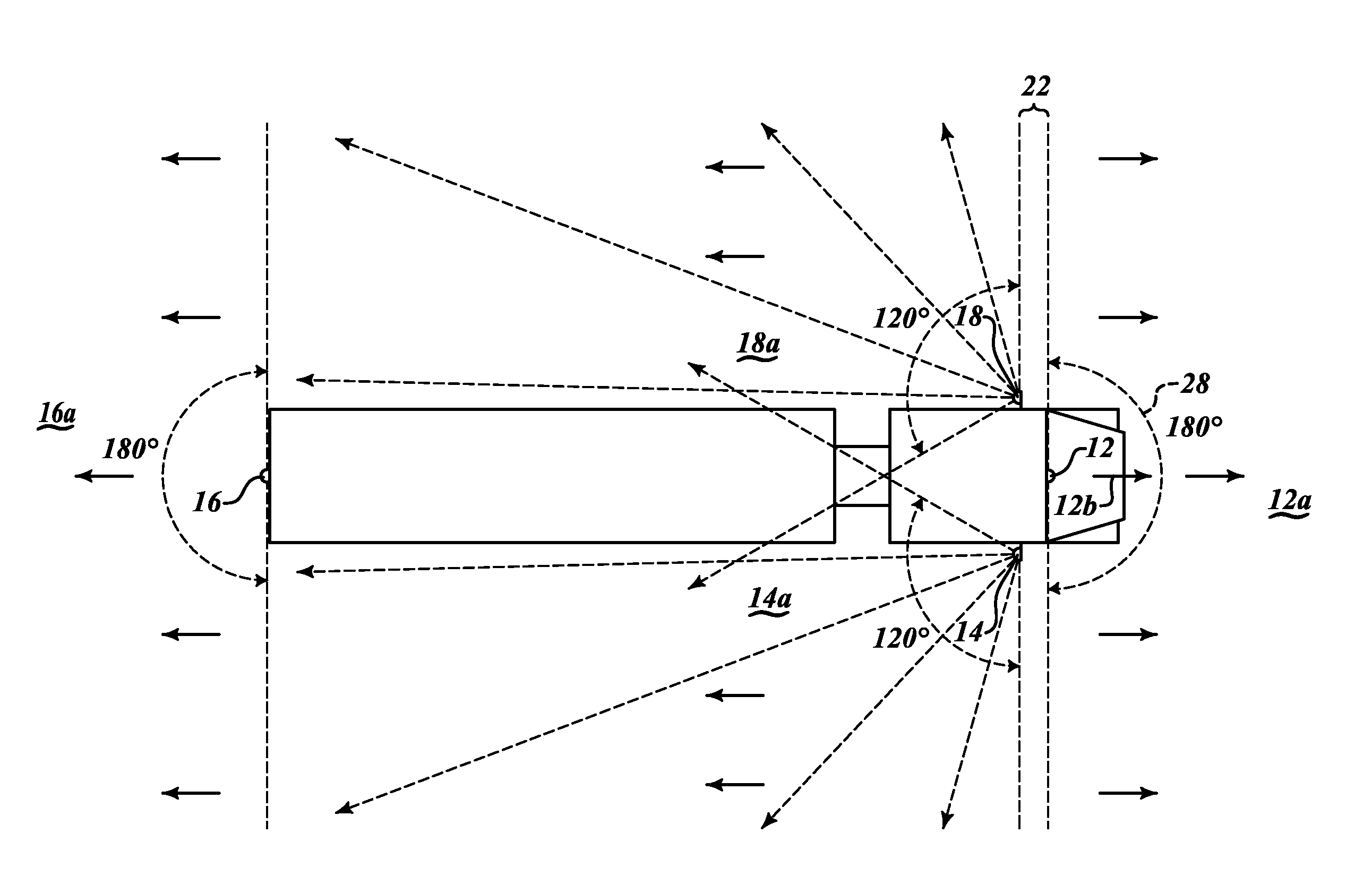

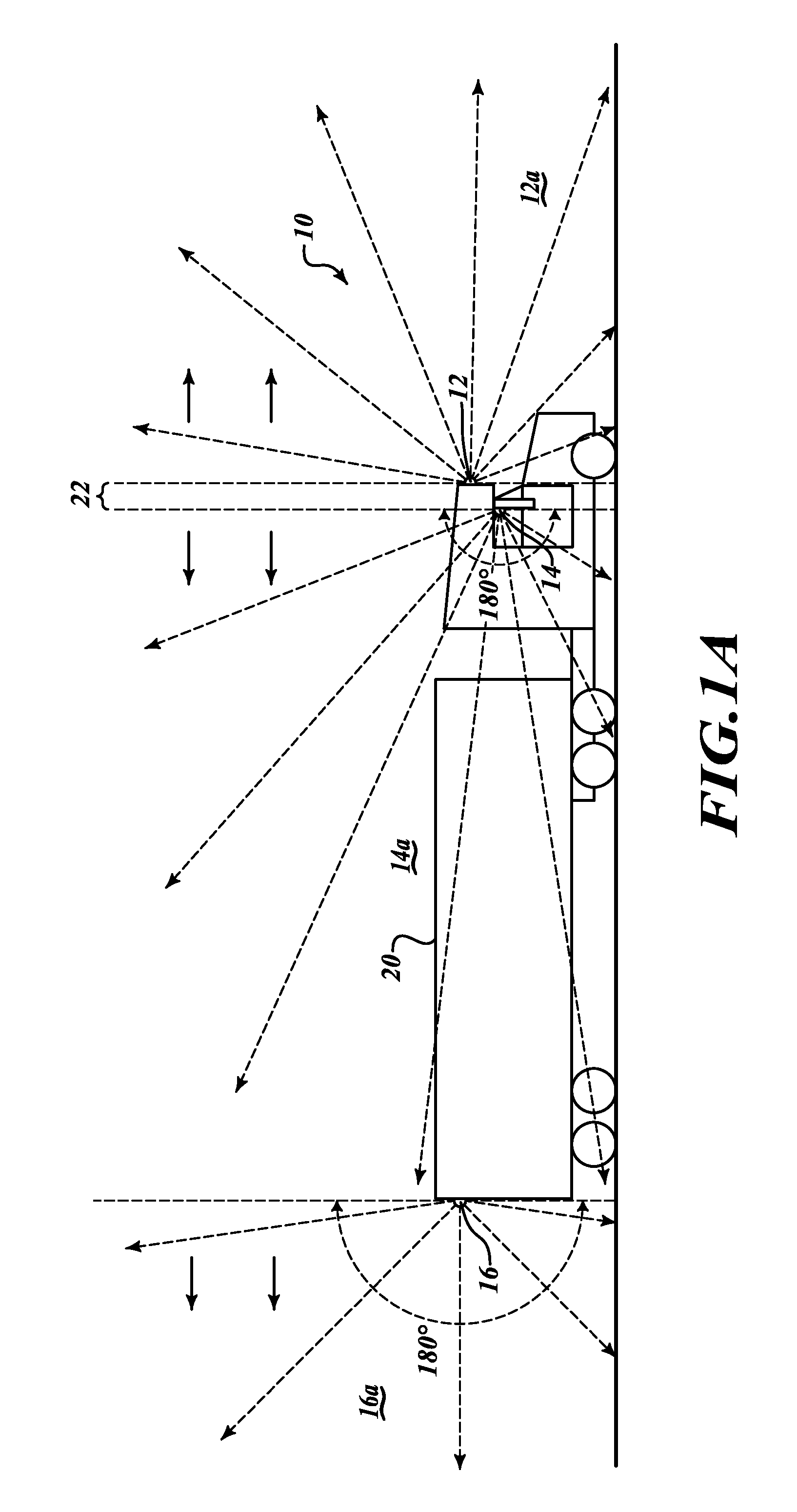

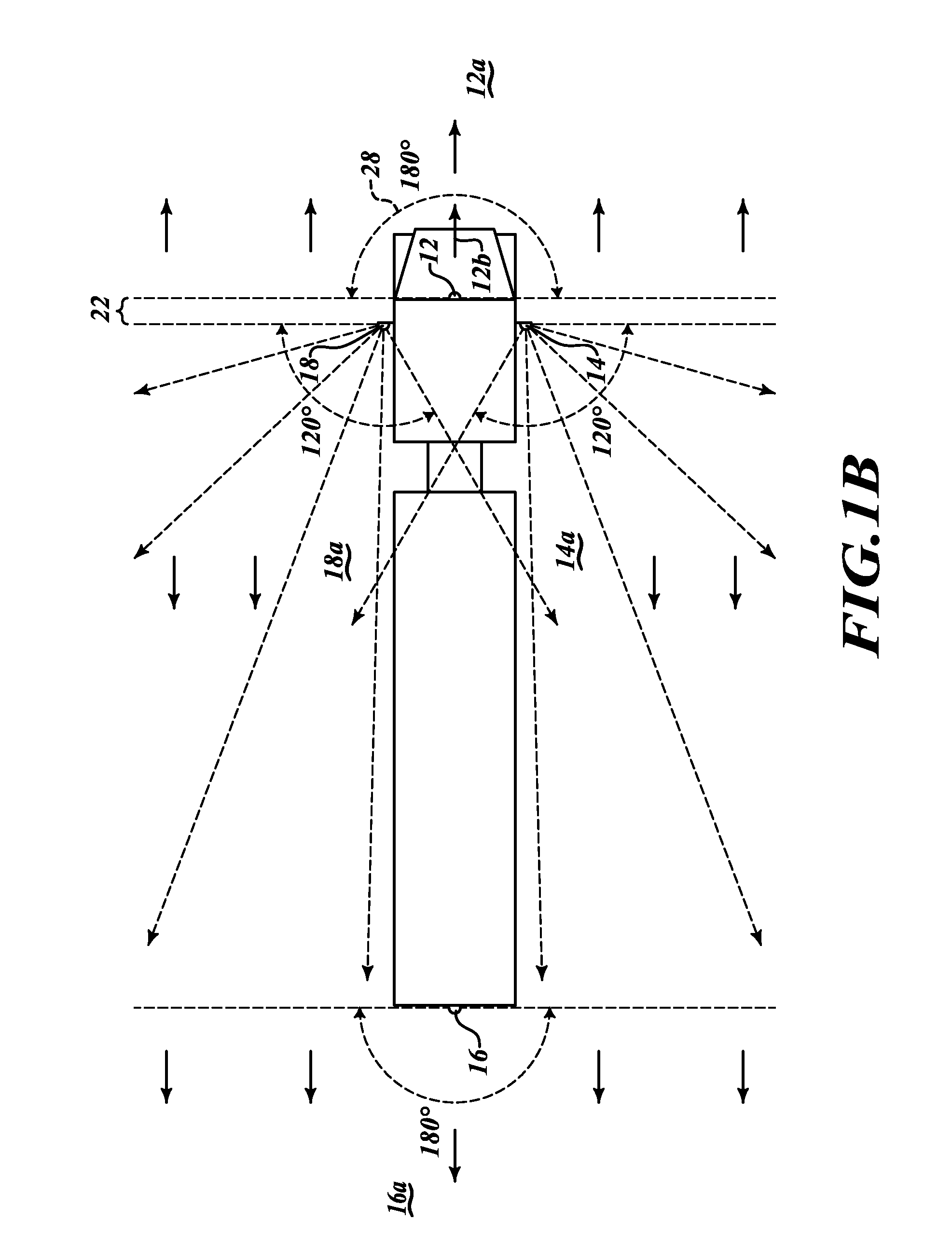

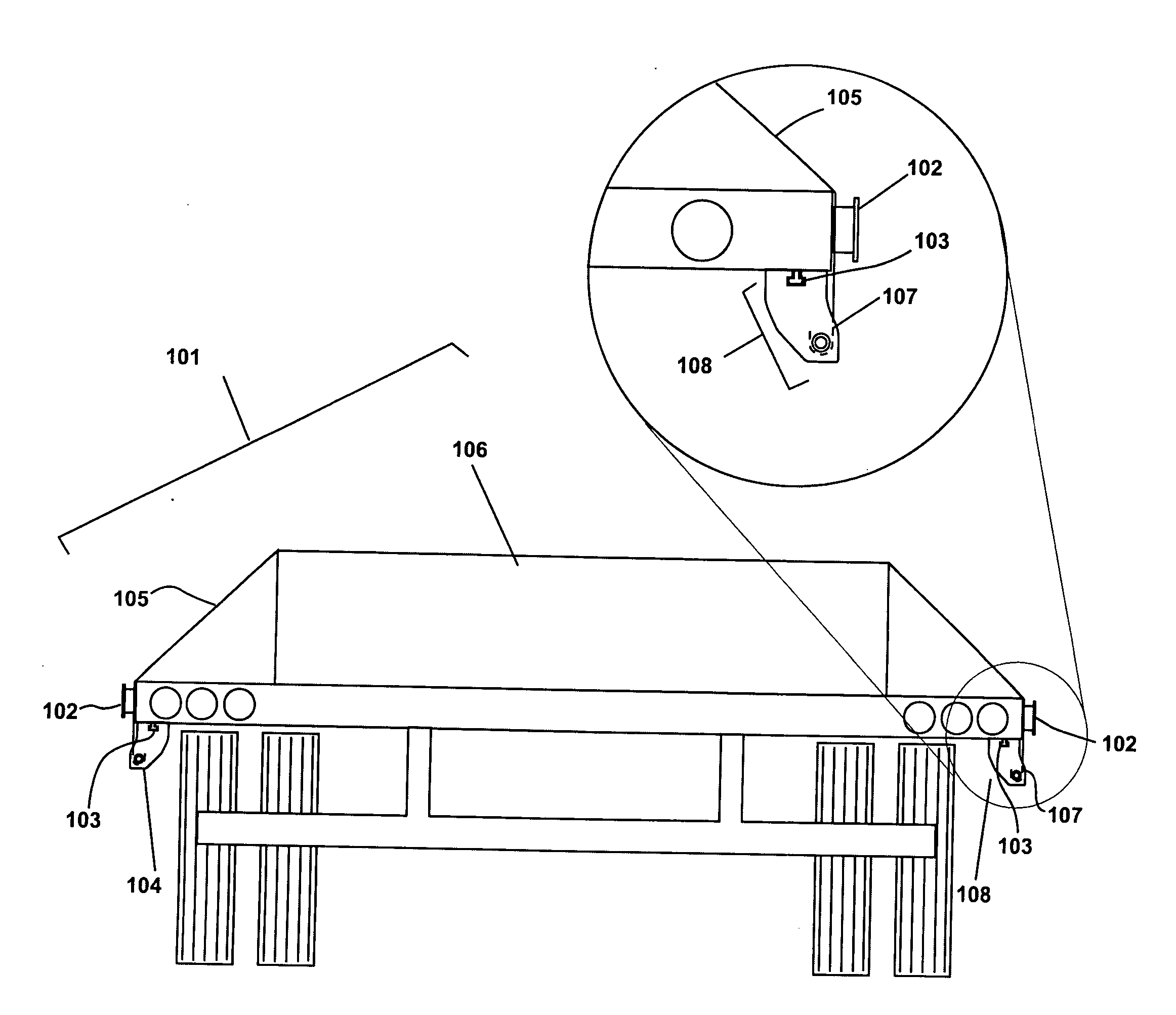

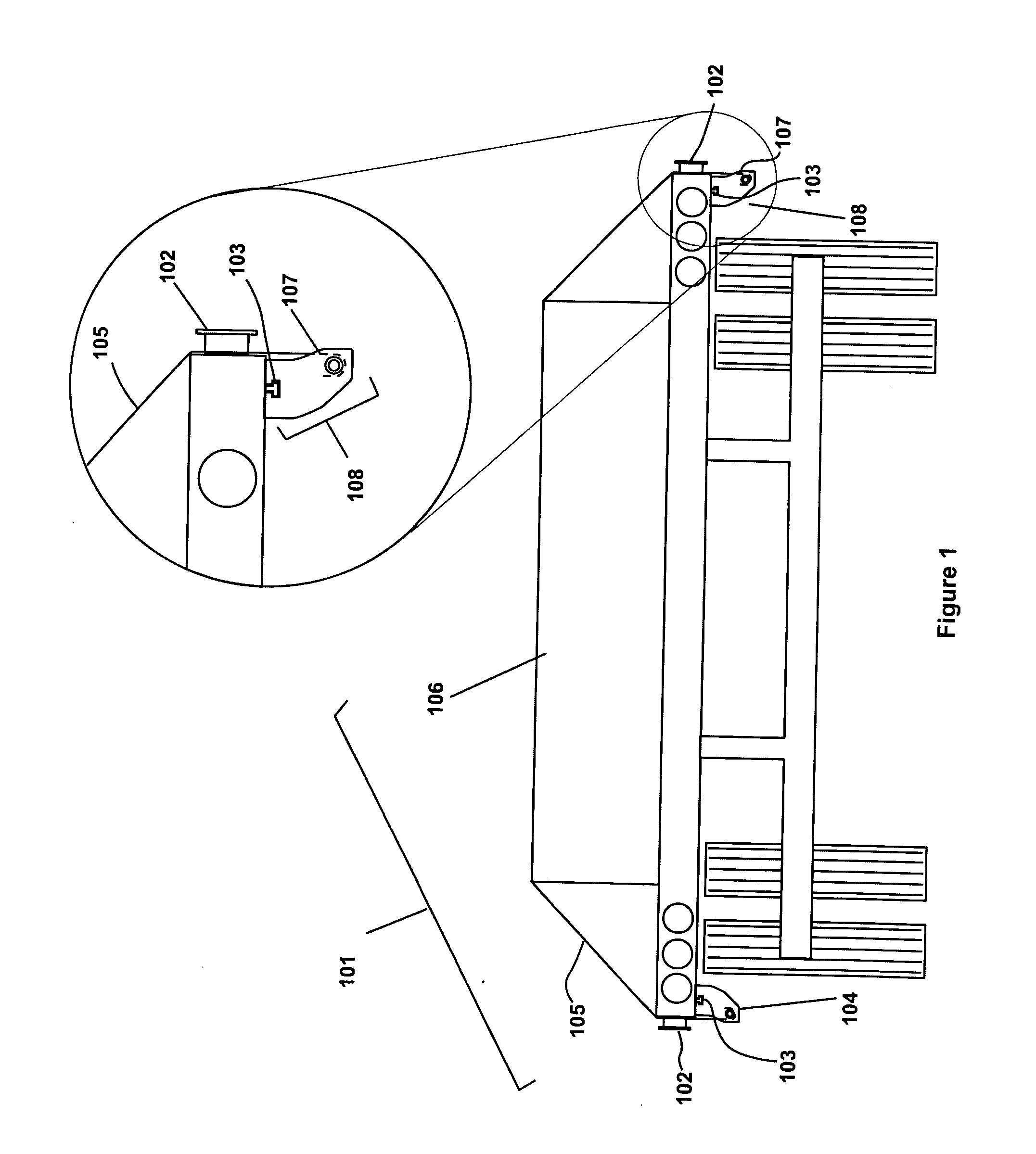

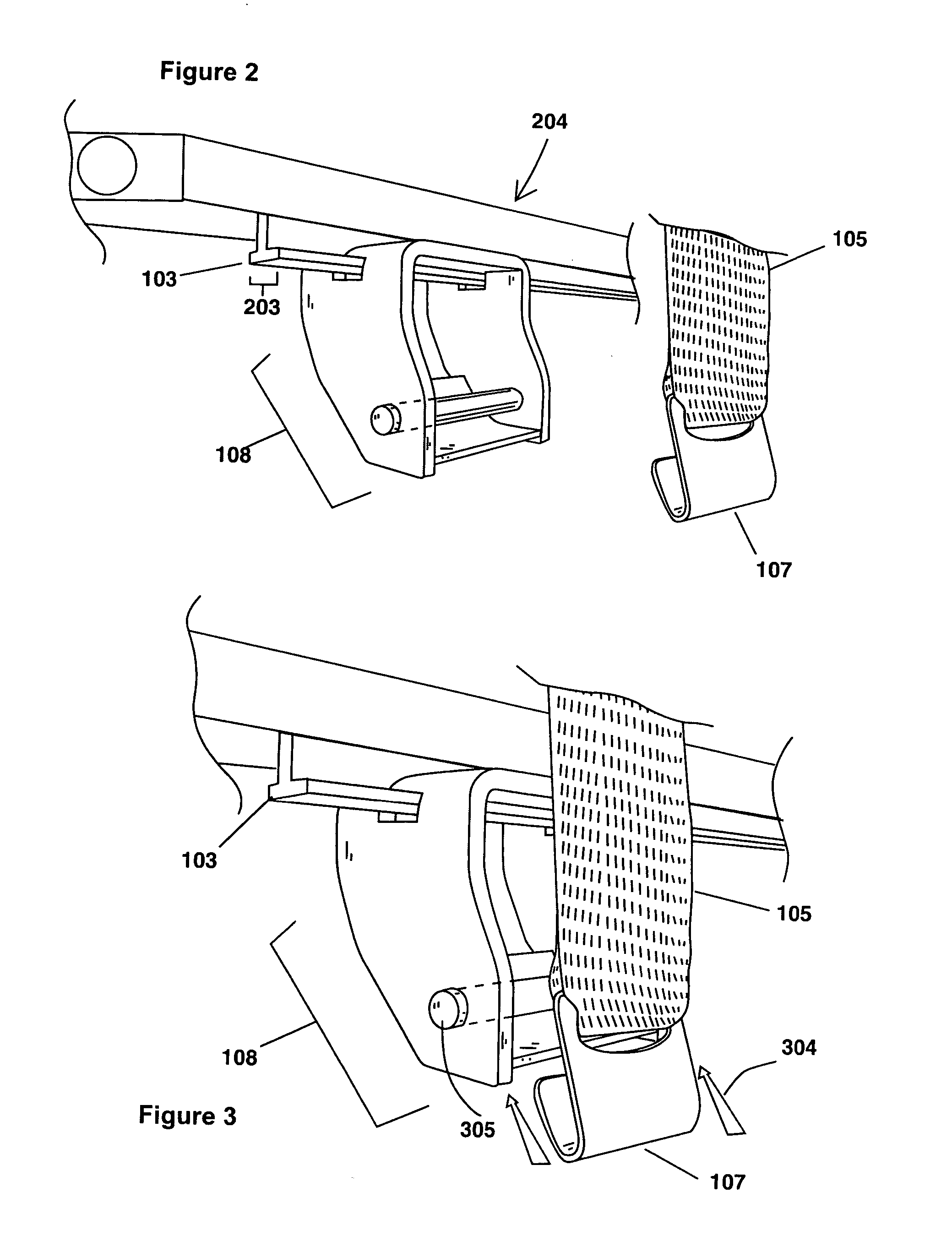

Vehicle Safety Camera System

InactiveUS20100225738A1Save livesMinimization of property damageTelevision system detailsRegistering/indicating working of vehiclesTamper resistanceMotor carrier

An externally-mounted camera system for large commercial trucks. The video cameras are positioned around the outside of the vehicle and feed their video images to a control unit within a tamper-proof black box typically located within the truck's cab. The cameras are wide-angle 360 degree type cameras and only four cameras completely surrounding the truck. This system is designed to work with the Federal Motor Carrier Safety Administration and Accident Reporting regulations, standards, and protocols. The video feeds will be attached to accident reports and reviewed by the federal authorities who provide feedback in compiled statistics and enhanced safety regulations.

Owner:WEBSTER ALLEN E

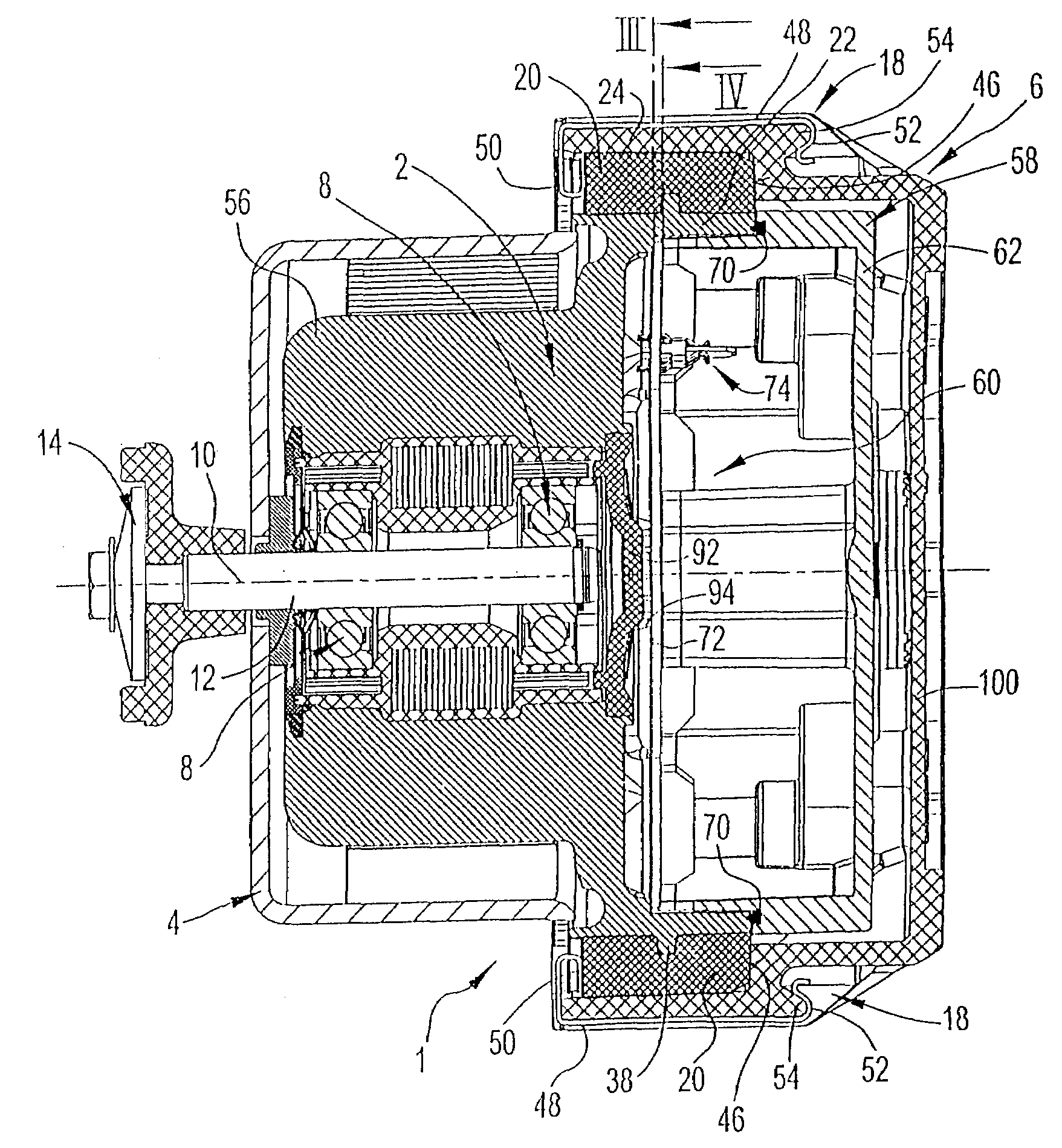

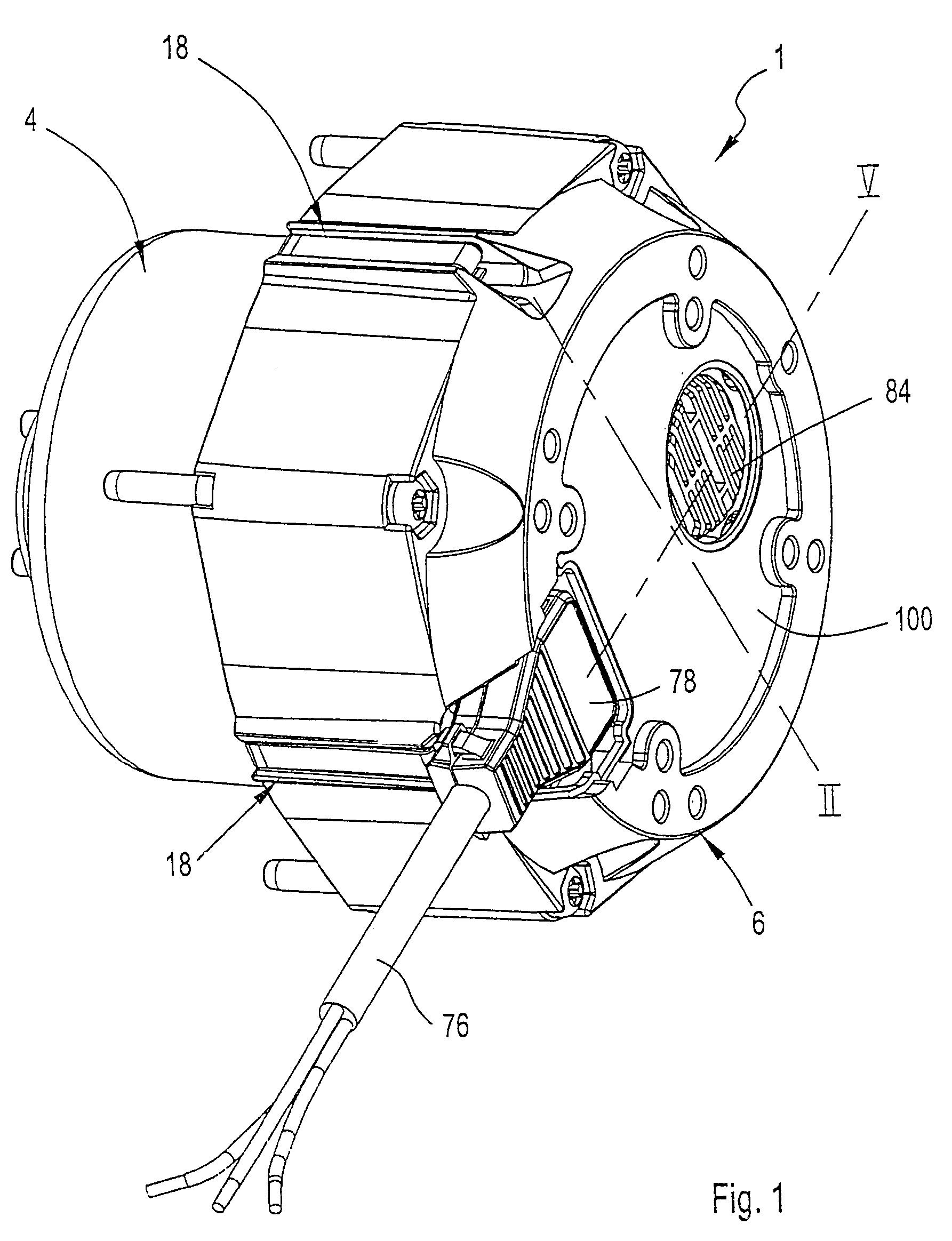

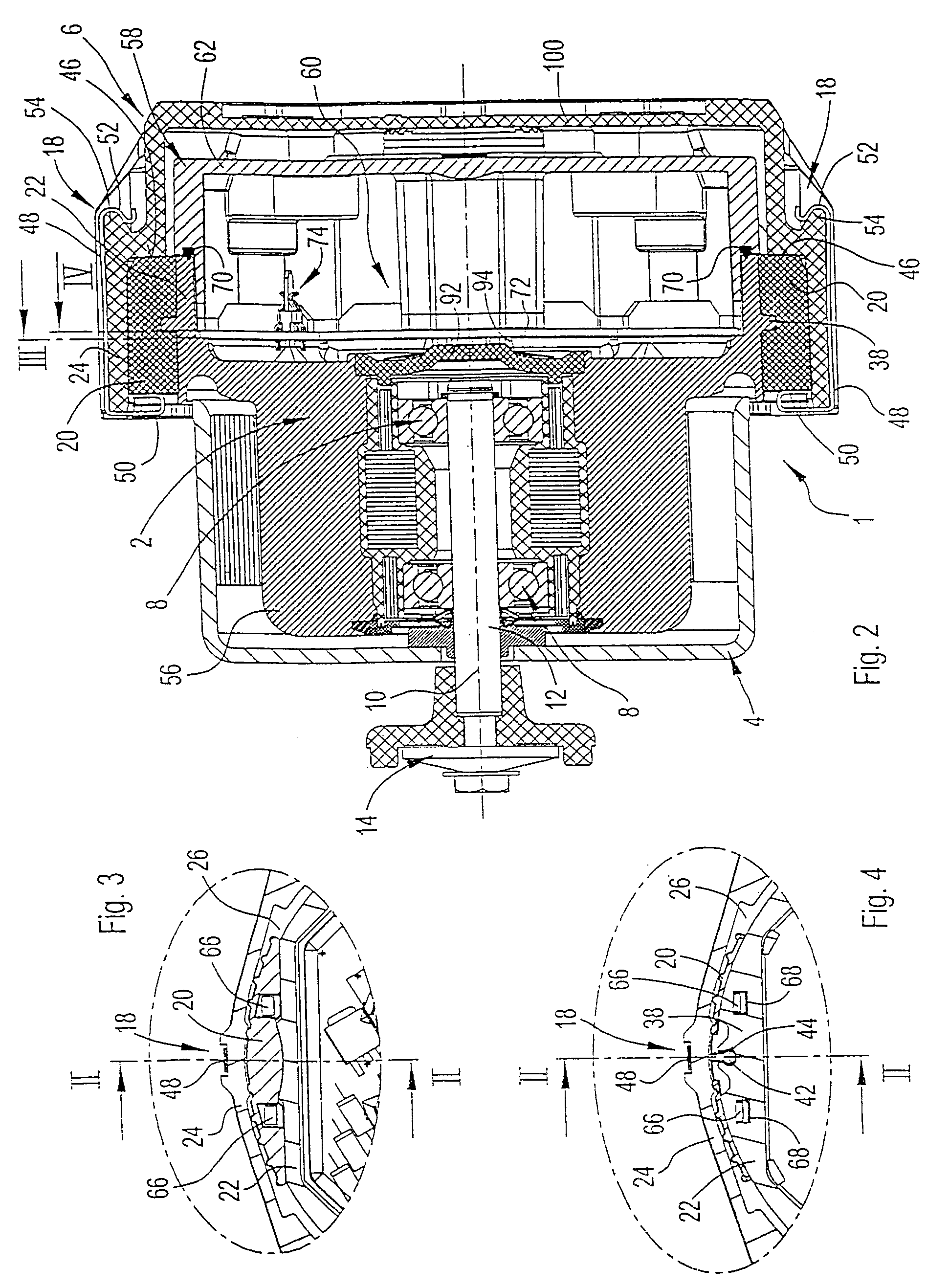

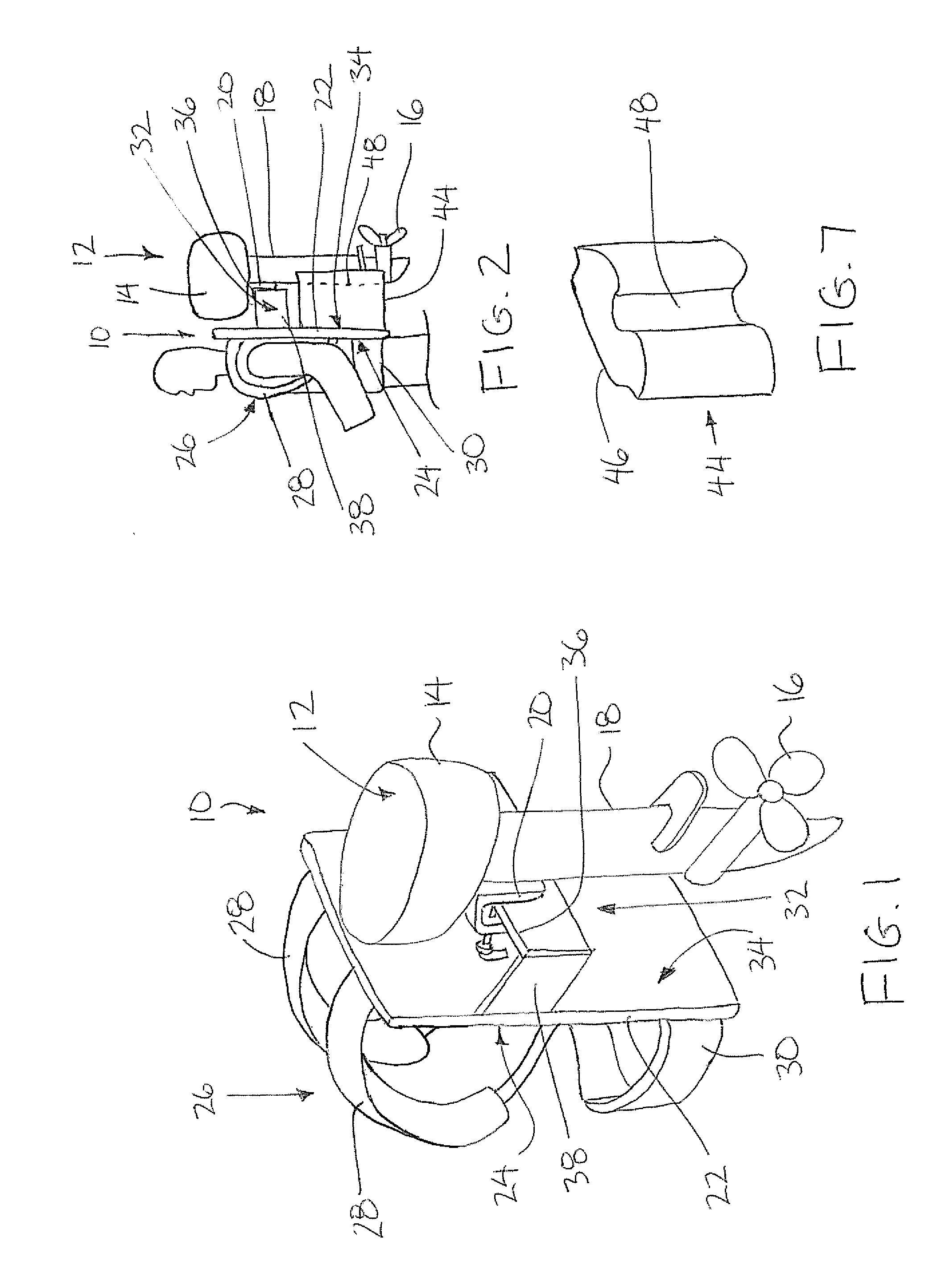

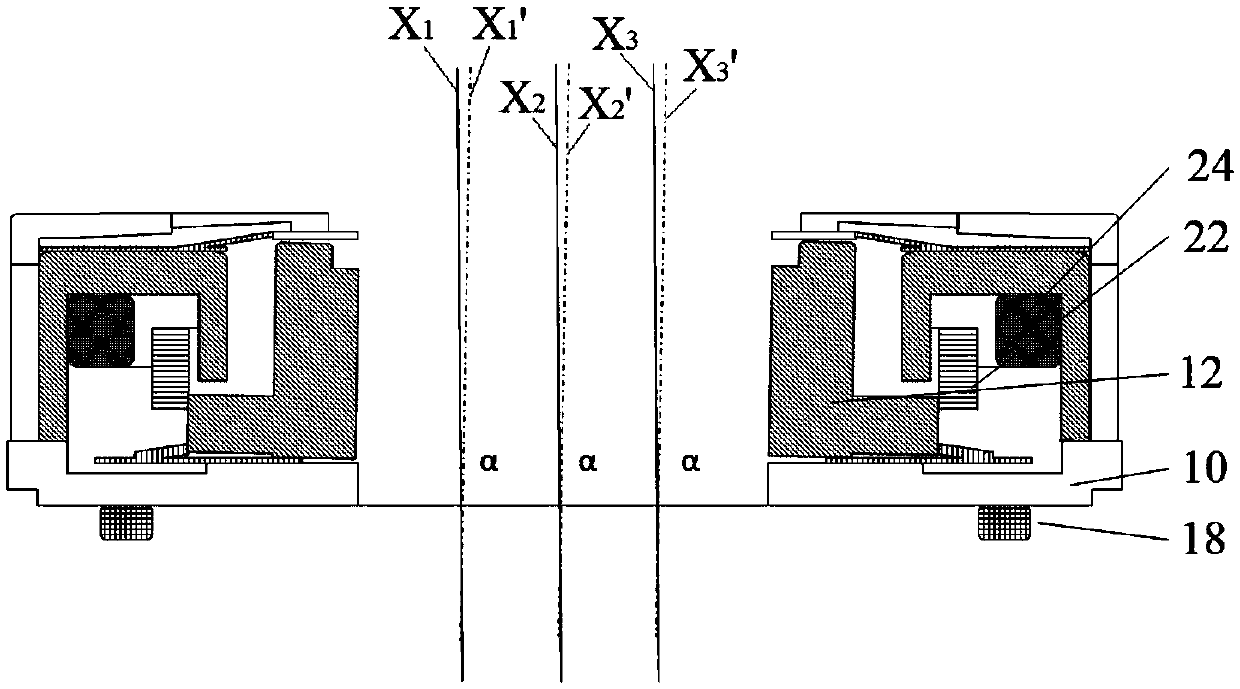

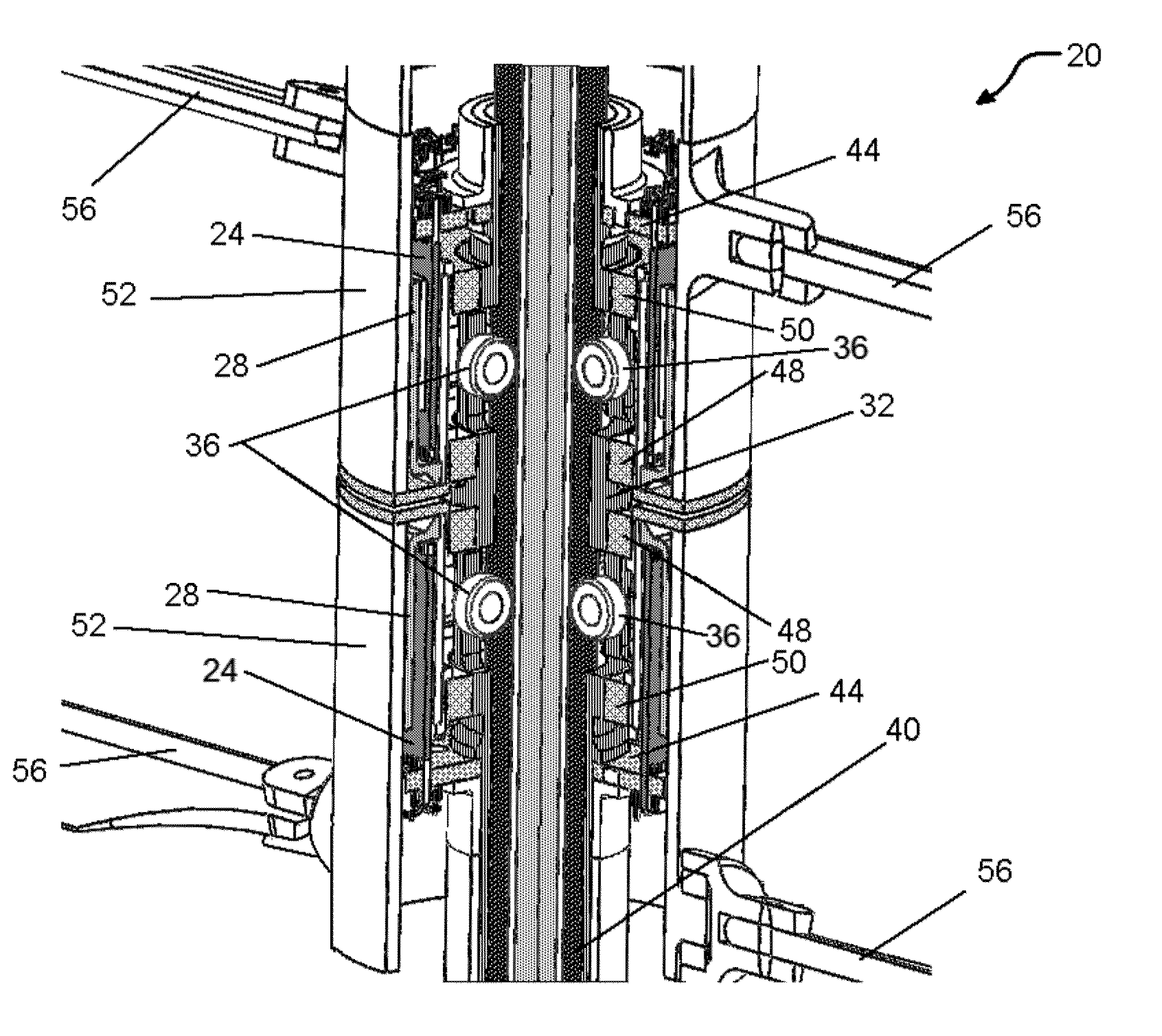

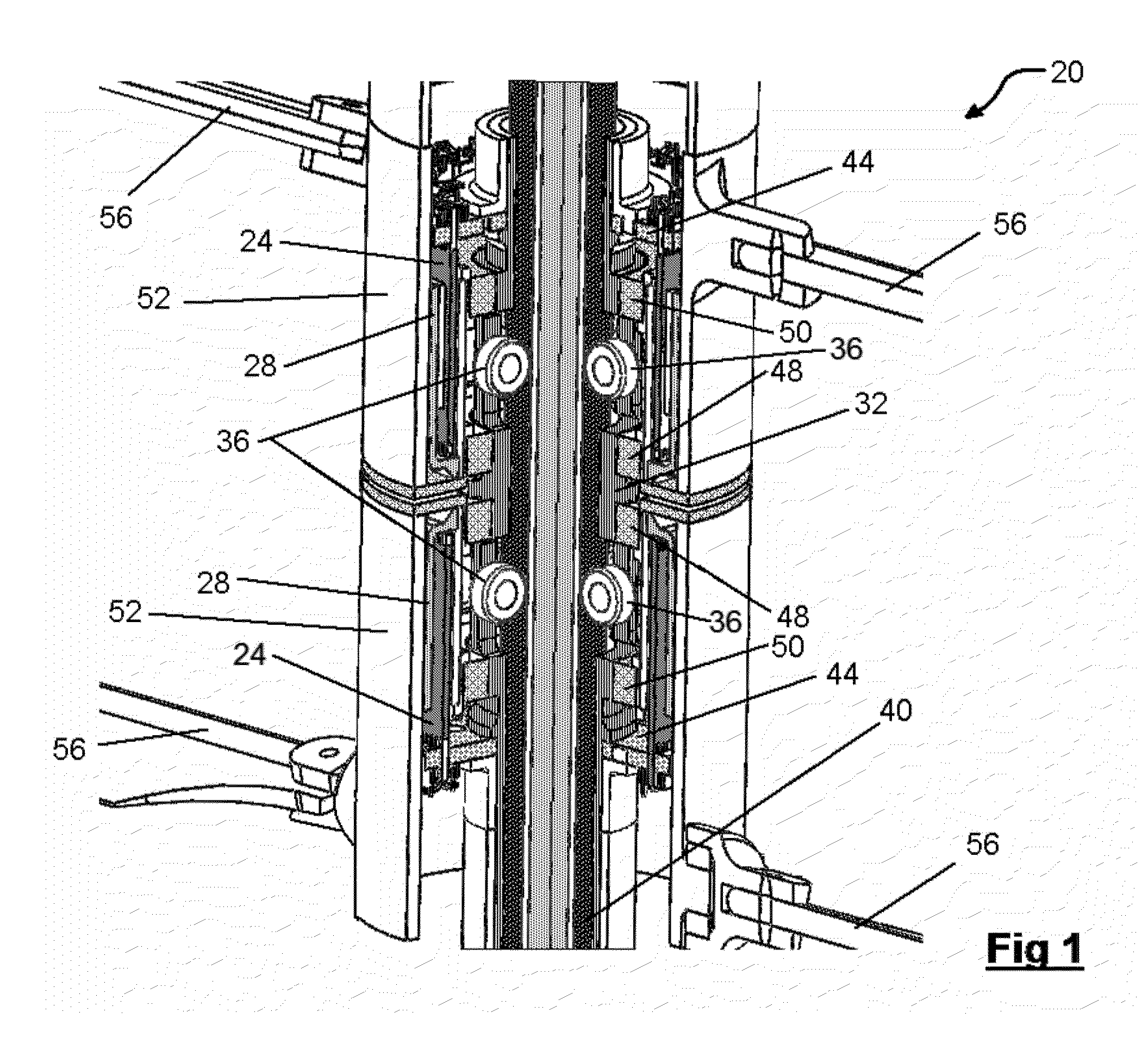

Electric motor with screwless plug-type mounting

ActiveUS6987336B2Emission reductionThe process is simple and fastPump componentsPumpsMotor carrierElectric motor

An electric motor, in particular an external rotor motor, comprising a stator which is attached by means of latching elements to a motor carrier using a plug-in joining operation. The elastic elements for isolating vibration are arranged in the connecting region between the stator and the motor carrier in a way that the stator is indirectly connected to the motor carrier by means of the elastic elements.

Owner:EBM PAPST MULFINGEN GMBH & CO KG

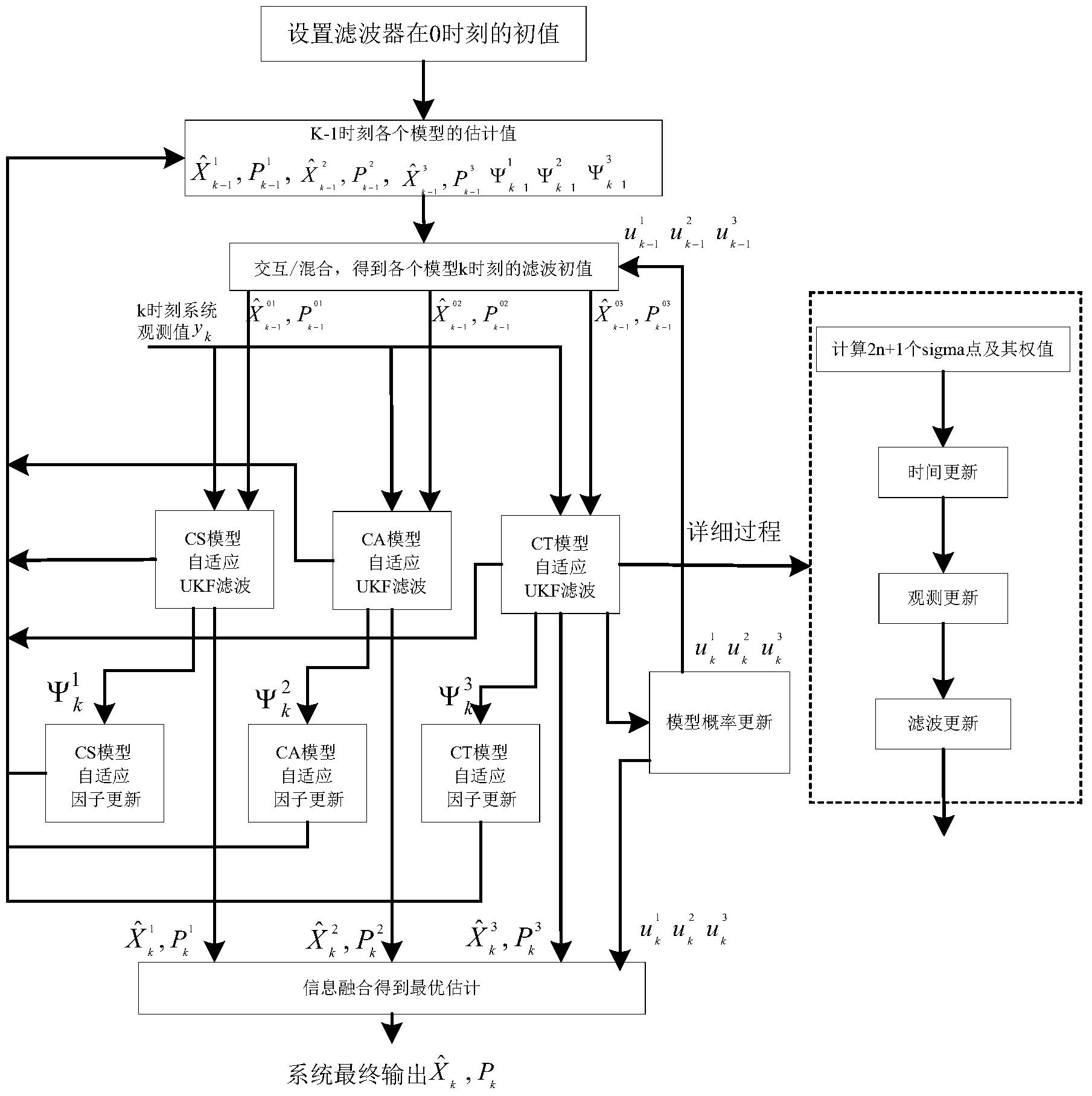

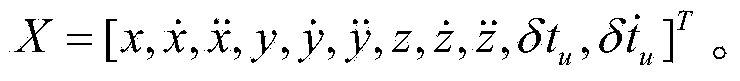

Satellite navigation method for interactive multi-model UKF with self-adapting factors

ActiveCN104020480AHigh positioning accuracyHigh precisionSatellite radio beaconingSpecial data processing applicationsAlgorithmMotor carrier

The invention relates to a satellite navigation method for an interactive multi-model UKF with self-adapting factors, and belongs to the field of navigation control. The method comprises the steps that firstly, an auto-covariance matrix of a residual sequence is used as a correcting value, and a smoothing filter is designed for fusing the correcting value with the old self-adapting factor to obtain the new self-adapting factor; secondly, a covariance matrix of process noise is adjusted in real time by utilizing the self-adapting factor, and therefore positioning errors, caused by unknown noise statistics properties, in a system are effectively reduced; afterwards, a model set M is set by the adoption of the interactive multi-model (IMM) algorithm; finally, soft handover between models is achieved by adjusting model probability in real time according to measurement residual errors, so that positioning errors caused by inaccurate system models are reduced. According to the method, the positioning accuracy of a complex motor carrier in a satellite navigation system is effectively improved with models and noise statistical properties unknown.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

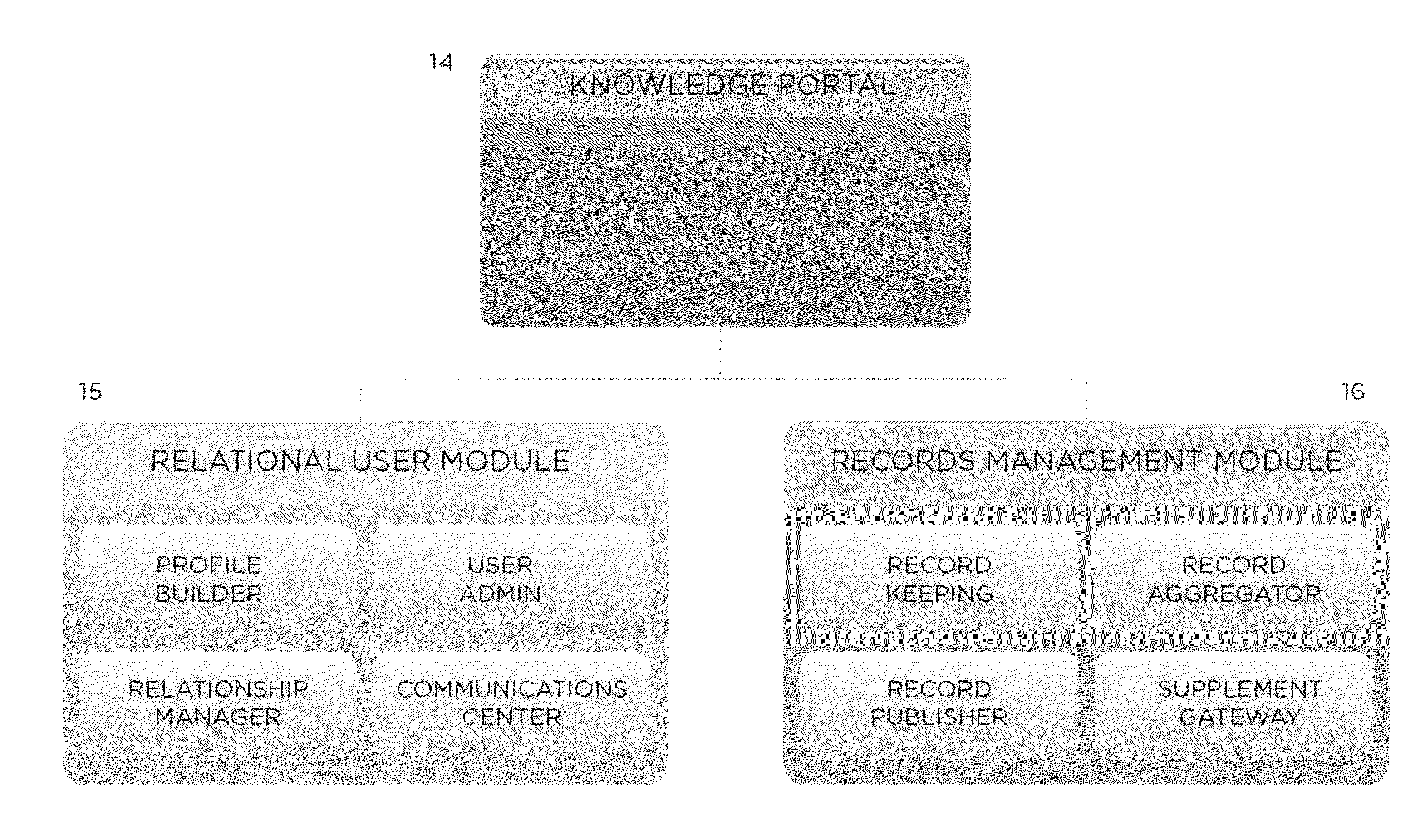

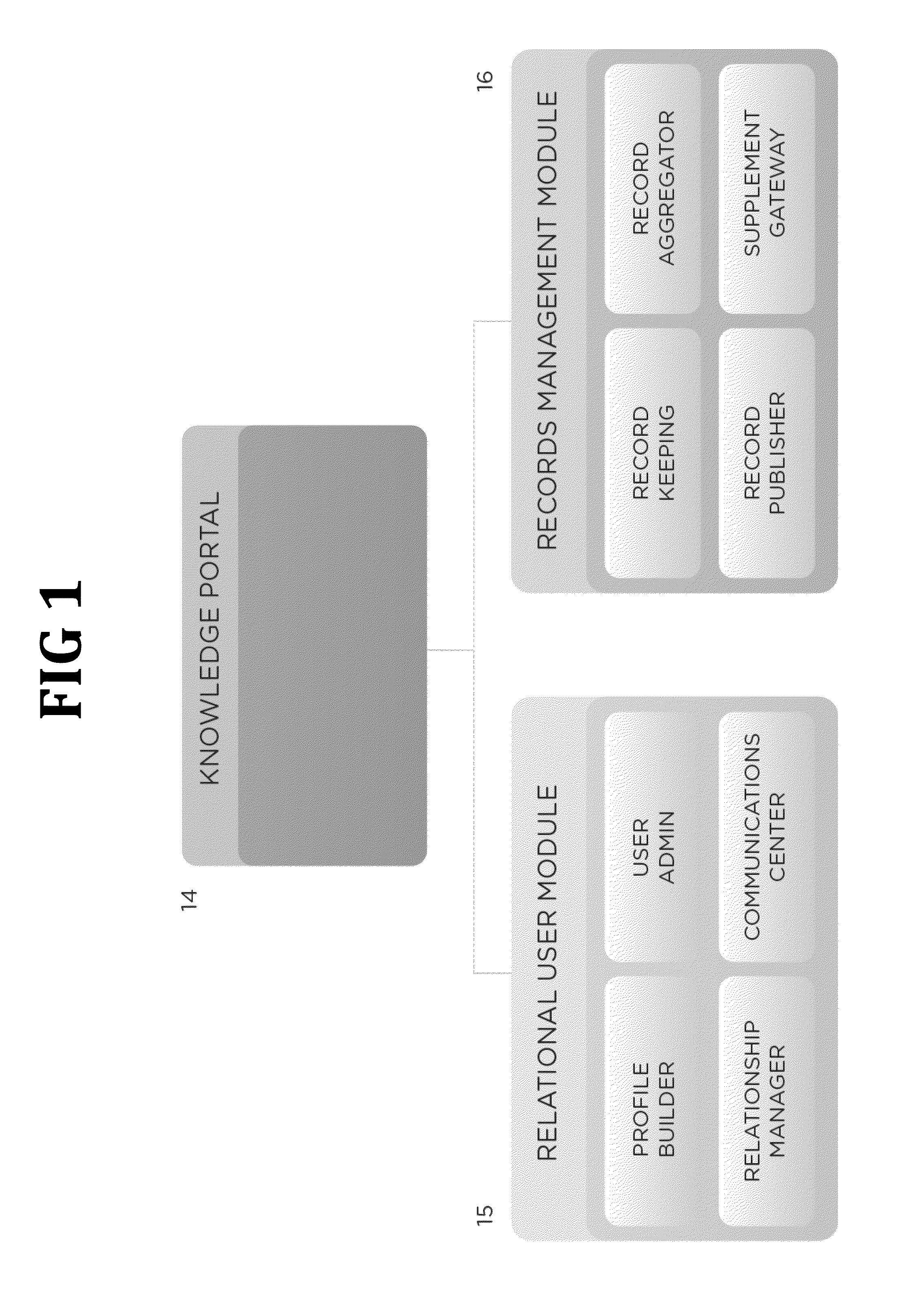

Method and apparatus for preparing, storing and recording compliant records for motor carriers, registrants, and governmental organizations

ActiveUS20150178737A1Improve efficiencyDigital data information retrievalRegistering/indicating working of vehiclesIn vehicleCloud base

A vehicle-centric cloud-based records management platform remains accessible through a web-based management portal and a mobile application, which can be integrated with vehicle devices for in-vehicle use. Regardless of the method of collection, the computerized method and system of the present invention are able to summarize the data into actionable documents for vehicle registration, fuel tax calculation / filing, and federal forms completion.

Owner:LEGATUS SOLUTIONS

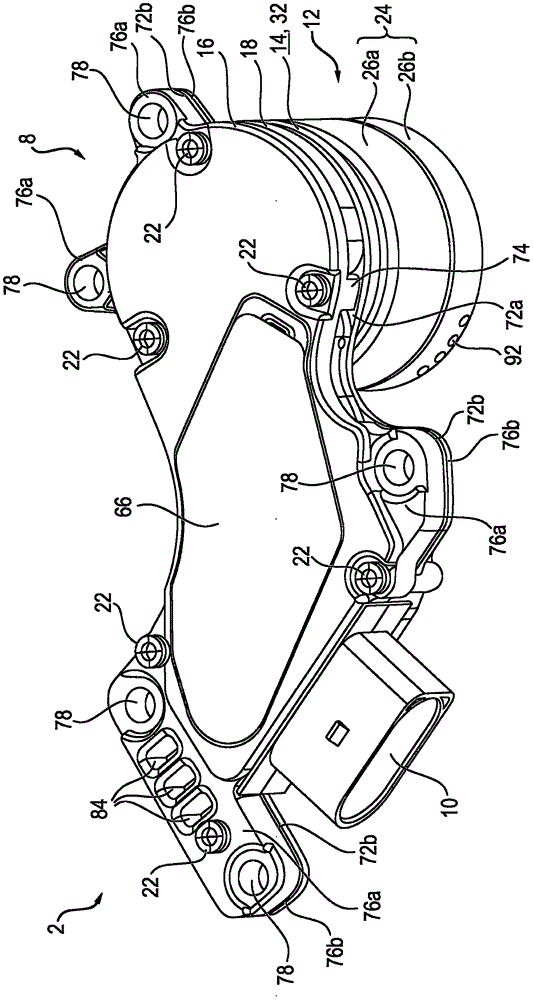

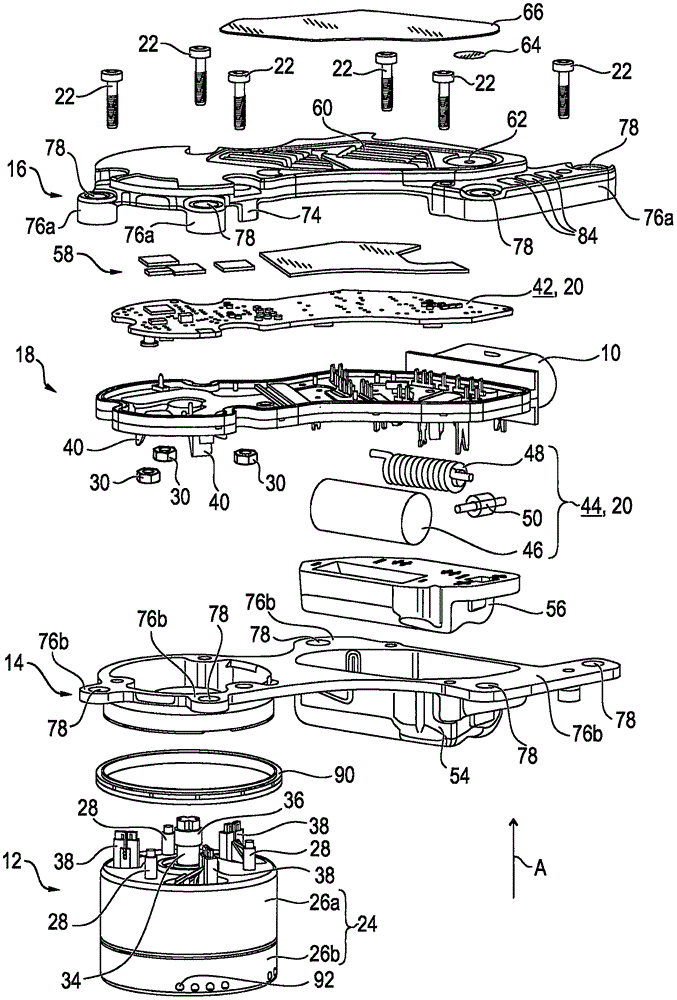

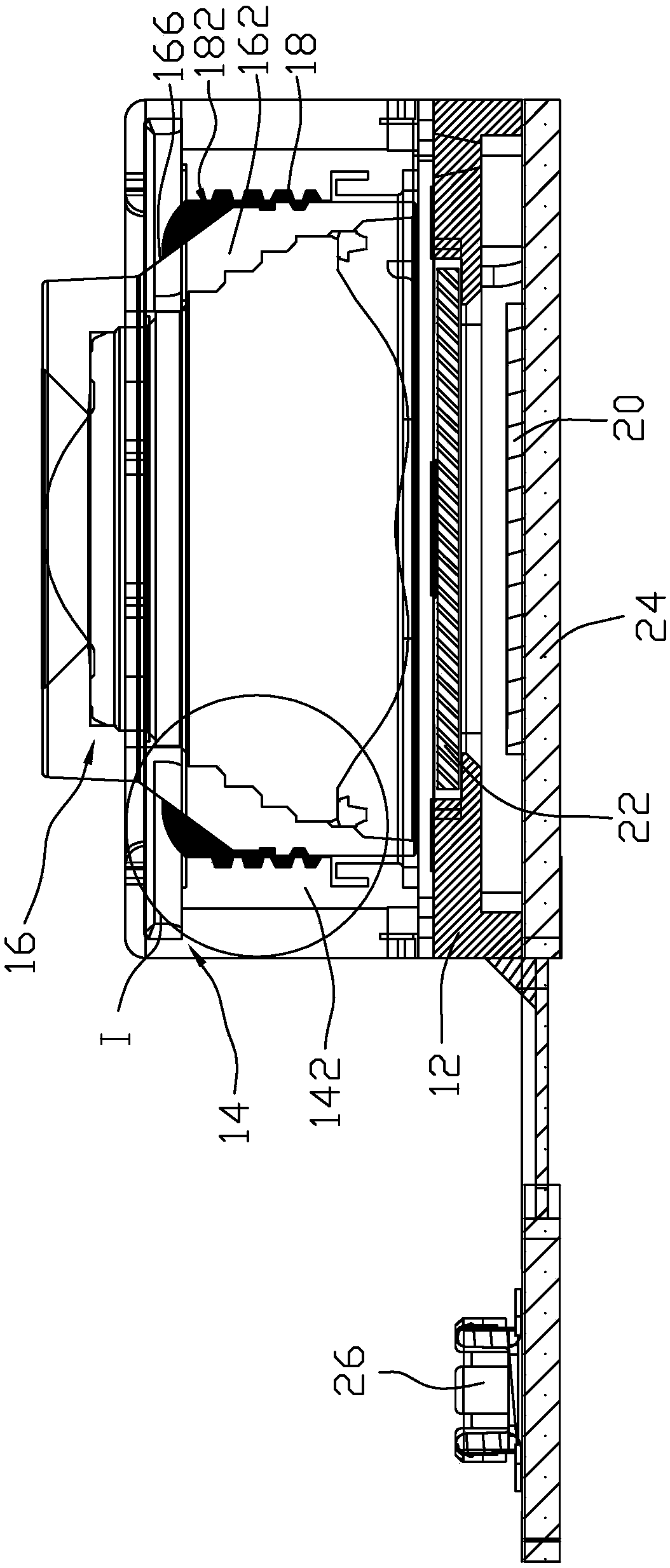

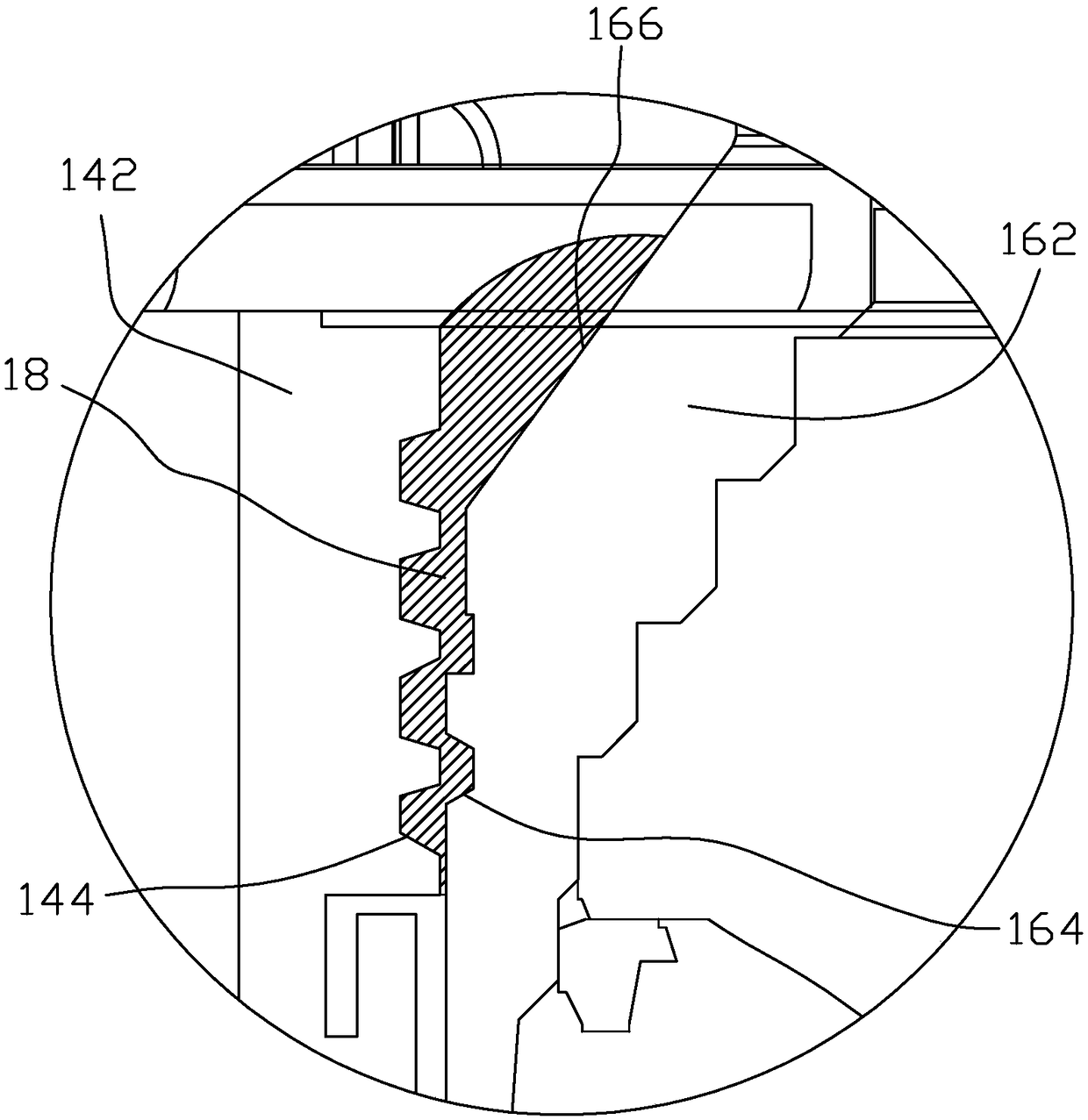

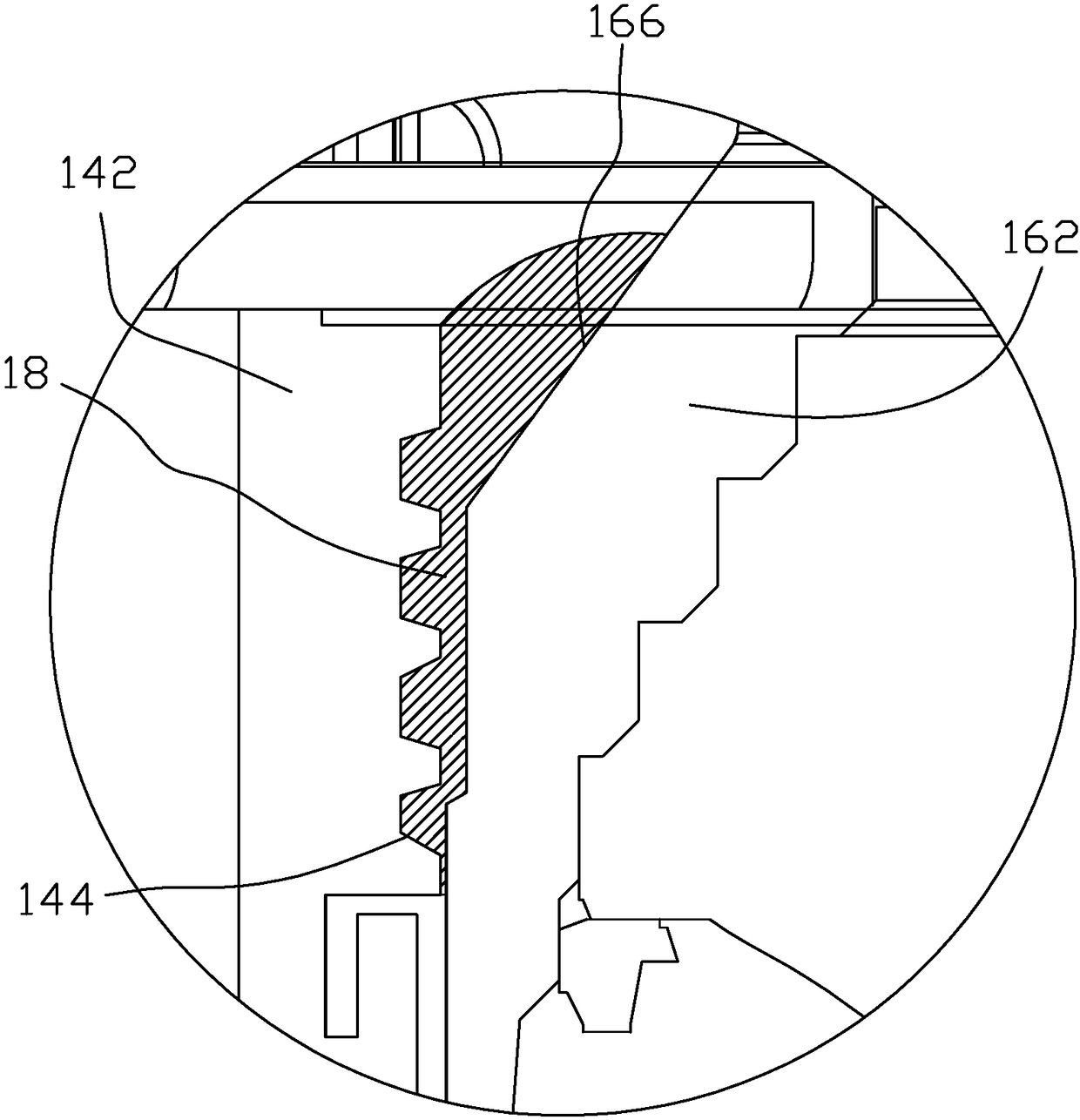

Motor Structure Assembly

ActiveCN105932810ACompact structureAffect lifeAssociation with control/drive circuitsGearing controlSandwich likeHeat conducting

A motor structure assembly 2 has an electric motor 12 with a motor housing 24 and an electronics unit 8. The electronics unit comprises a first housing shell formed as a motor carrier 14 and having the motor housing fastened to it. The electronics unit also comprises a second housing shell in the form of a cooling cover 16, and an electronics carrier 18 arranged in sandwich-like fashion between the motor carrier 14 and the cooling cover 16. The cooling cover and the motor carrier 14 exhibit greater thermal conductivity than the electronics carrier 18. The cooling cover 16 and the motor carrier 14 are coupled to one another in heat-conducting fashion at at least one abutment surface. The present invention also relates to an actuator 4 having the above motor structure assembly and a motor vehicle transmission 6 possessing the above actuator.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

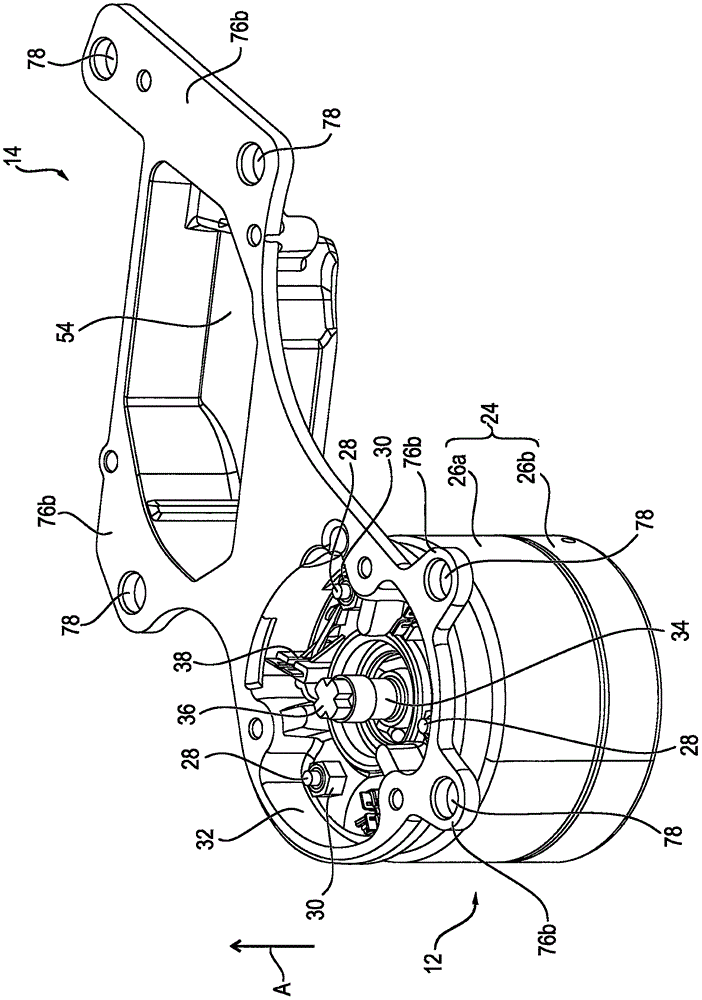

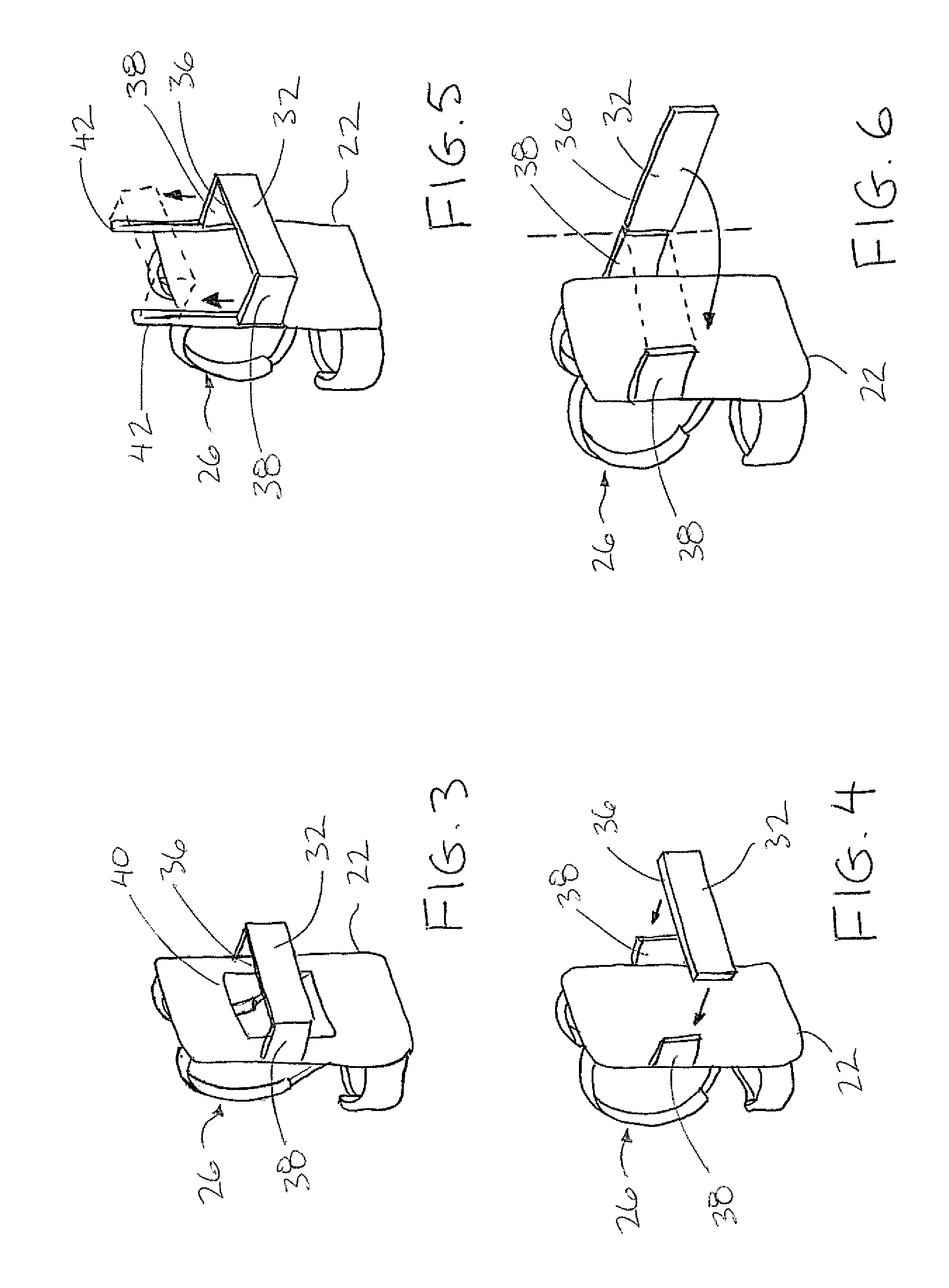

Outboard Motor Carrier

InactiveUS20100230450A1Easy to adaptPrevent movementTravelling sacksOutboard propulsion unitsMotor carrierSurface plate

An outboard motor carrier device is arranged for carrying an outboard motor including a transom bracket arranged to be clamped onto a transom of a boat. The carrier device includes an upright frame including opposing front and rear sides and a pair of shoulder straps on the front side which are arranged to be secured over respective shoulders of a user. A transom bracket mount in the form of an upright panel is supported on the rear of the frame onto which the transom bracket of the outboard motor is clamped. Typically the transom bracket mount is positioned on the upright frame such that the transom bracket mount is arranged to wholly support the outboard motor thereon without any additional securement of the outboard motor to the upright frame of the carrier device being required.

Owner:TOMBERLI MARIO

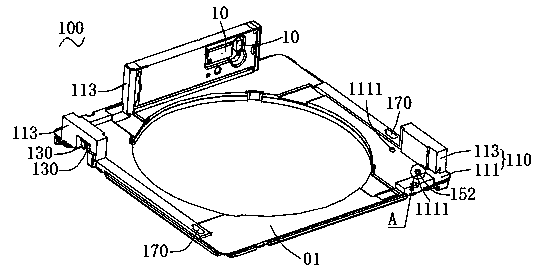

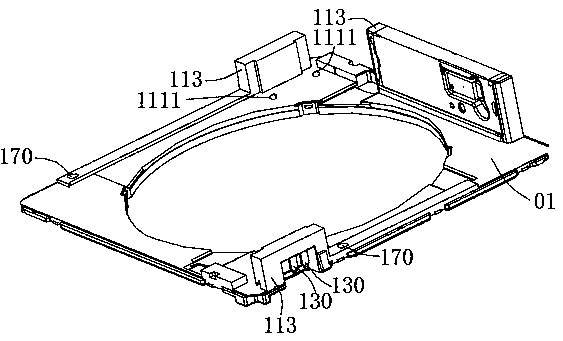

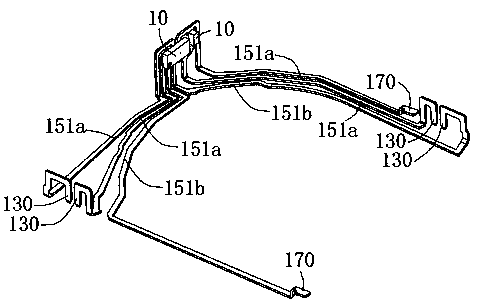

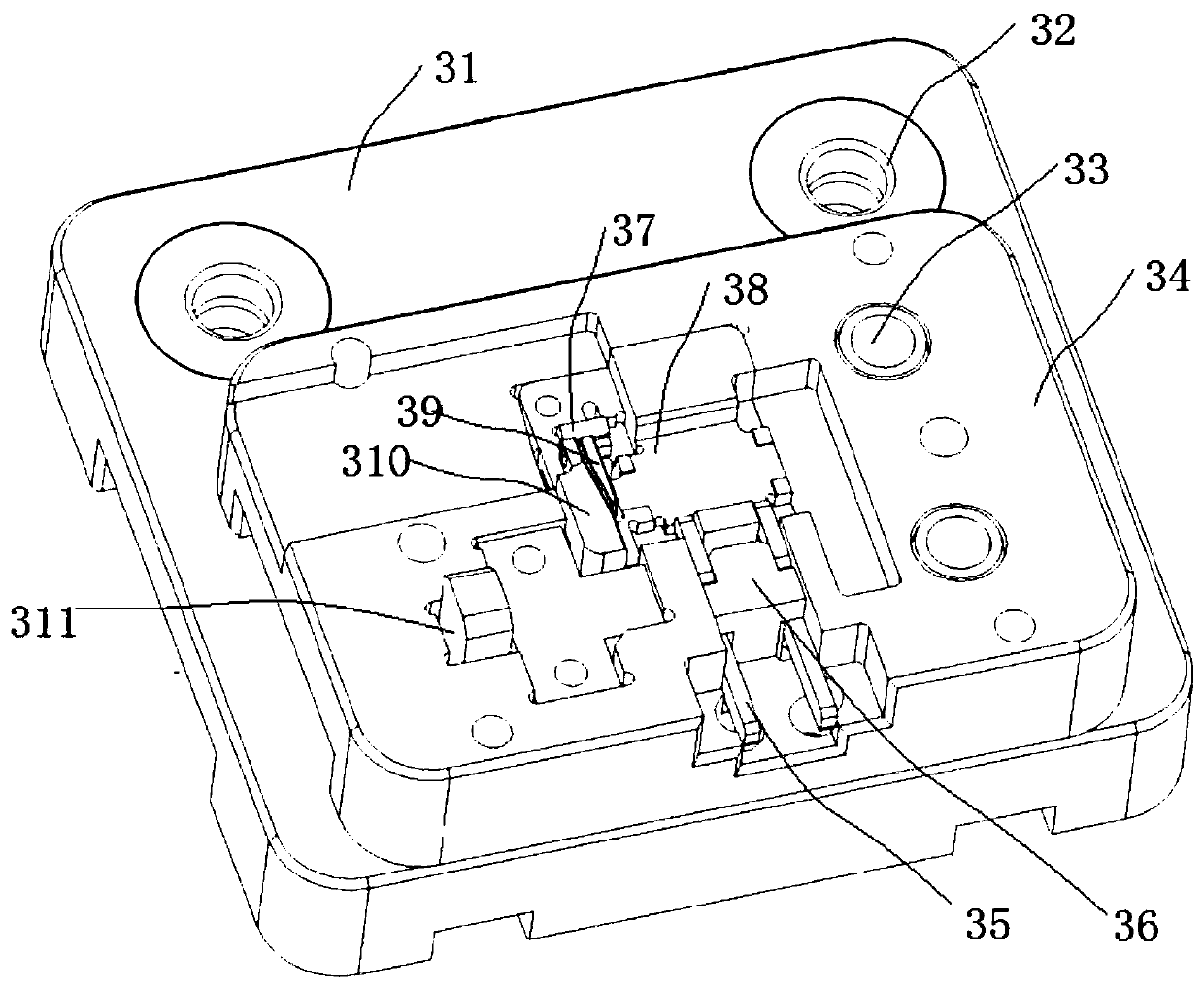

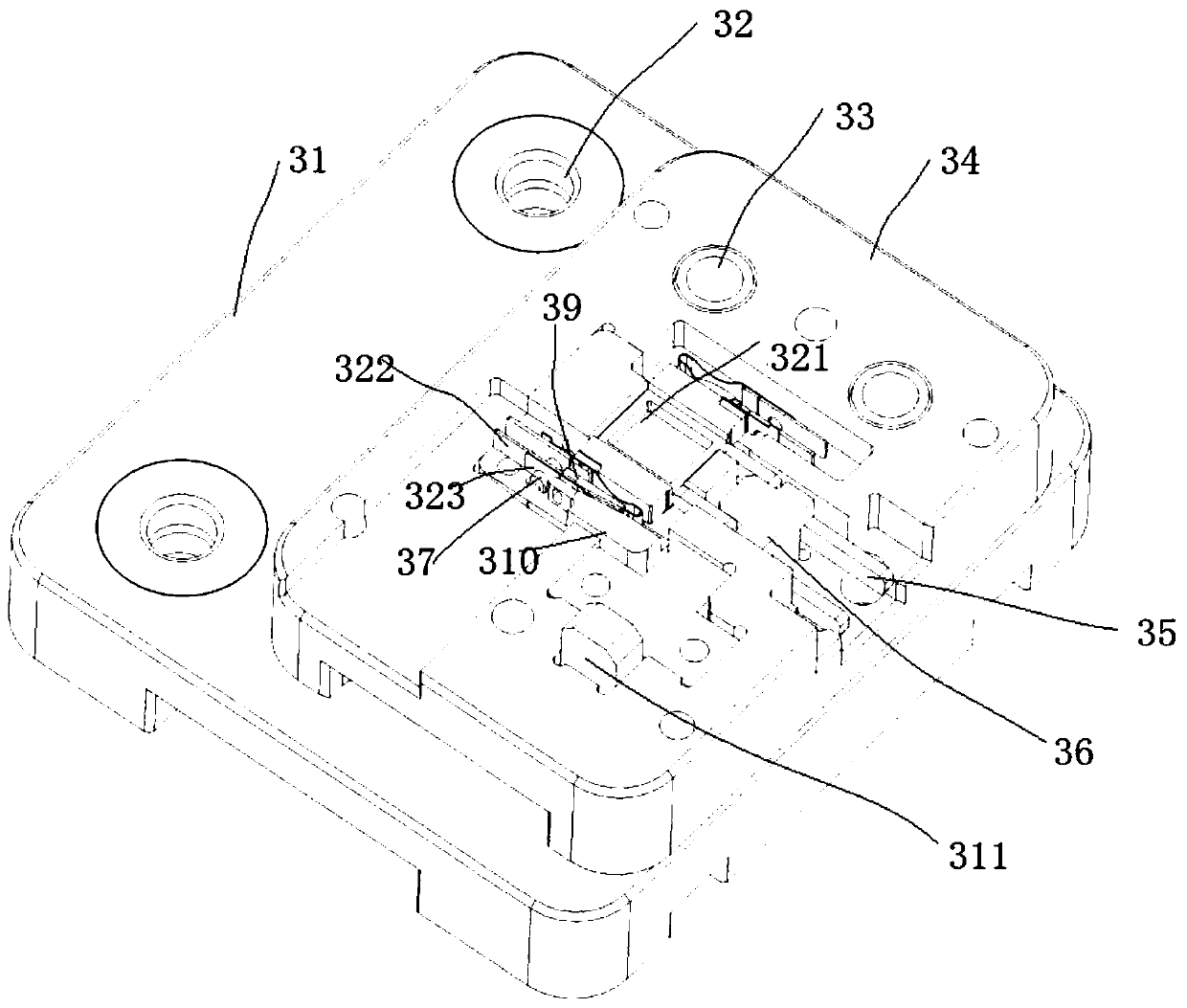

Camera module motor carrier, detection device and method thereof, and motor

ActiveCN111193856AReduce the time for electrical performance testingImprove detection efficiencyTelevision system detailsColor television detailsElectrical connectionStructural engineering

The invention relates to a camera module motor carrier, a detection device and method thereof, and a motor. The camera module motor carrier provided by the invention comprises an insulating main bodywhich comprises a bottom wall and at least two side walls which are vertically connected with different side edges of the bottom wall respectively, and the bottom wall is provided with a first surface which is vertical to the side walls. The carrier further comprises an electronic element which is fixed in the insulating main body, a plurality of first pins which are arranged on the outer surfaces of the side walls of the insulating main body in an exposed manner and are distributed on different side walls, a conductive circuit which is buried in the insulating main body and comprises a plurality of first conductive circuit branches. One end of the first conductive circuit branch is electrically connected with a pin of the electronic element, and the other end is electrically connected with a first pin. The first surface of the bottom wall is provided with a plurality of exposed grooves, and the conductive circuit is provided with a plurality of exposed points corresponding to the exposed grooves. Each first conductive circuit branch is provided with at least one exposed point. The carrier further comprises a second pin which is arranged on the first surface of the bottom wall inan exposed manner.

Owner:SUZHOU GYZ ELECTRONICS TECH CO LTD

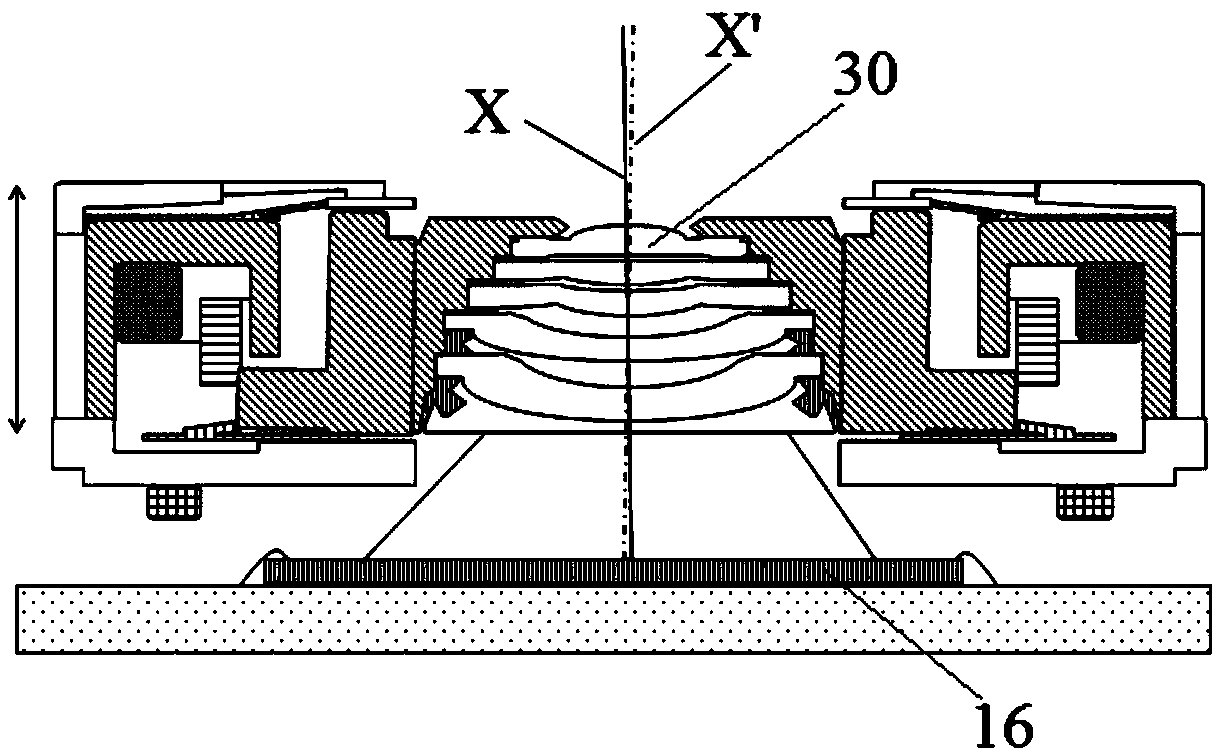

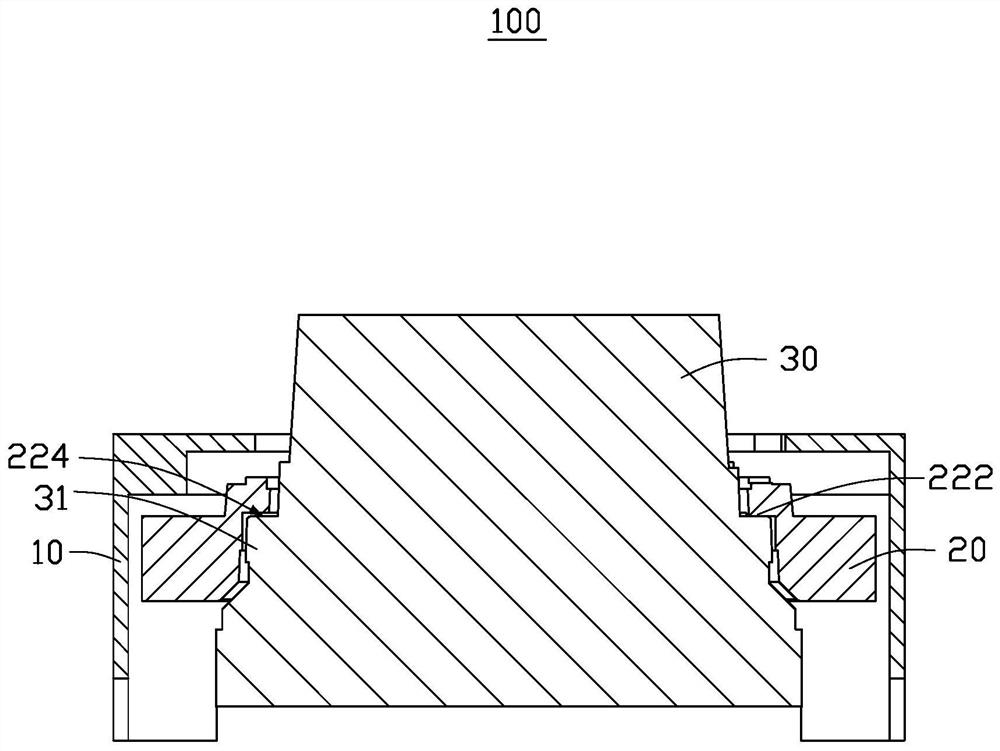

Camera module and assembly method thereof

ActiveCN108540694AIncrease contact areaImprove reliabilityTelevision system detailsMaterial gluingMotor carrierEngineering

The invention provides a camera module and an assembly method thereof. The camera module comprises a voice coil motor and a lens set, the voice coil motor comprises a motor carrier, the lens group isarranged in the motor carrier, the lens group comprises a lens cone and a lens, a gap is reserved between the motor carrier and the lens cone, a first groove is formed in an inner wall of the motor carrier by depressing toward the interior of the main body and / or a second groove is formed in an outer wall of the lens cone by depressing toward the interior of the main body, the first groove and / orthe second groove communicates with the gap between the motor carrier and the lens cone, and the first groove and / or the second groove and the gap between the motor carrier and the lens cone is filled with viscose to fix the motor carrier and the lens cone. According to the camera module and the assembly method thereof provided by the invention, due to the setting of the first and second grooves,the contact areas of the motor carrier and the lens cone with the viscose can be increased, thus improving the combination reliability, even if the viscose cracks, the viscose filled in the first groove and the second groove also limits the motor carrier and the lens cone, thereby ensuring that the motor carrier and the lens cone are not separated.

Owner:KUNSHAN Q TECH CO LTD

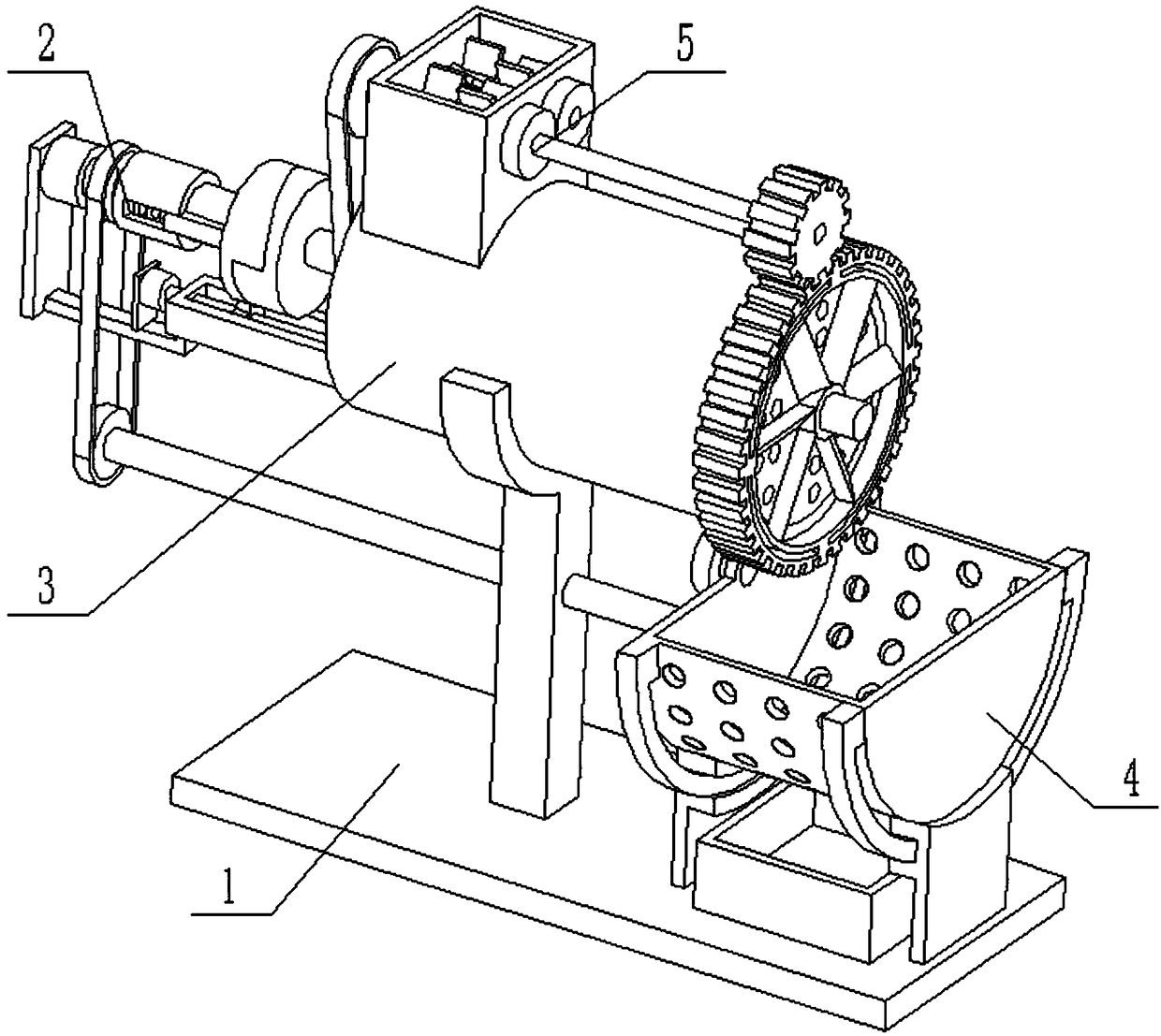

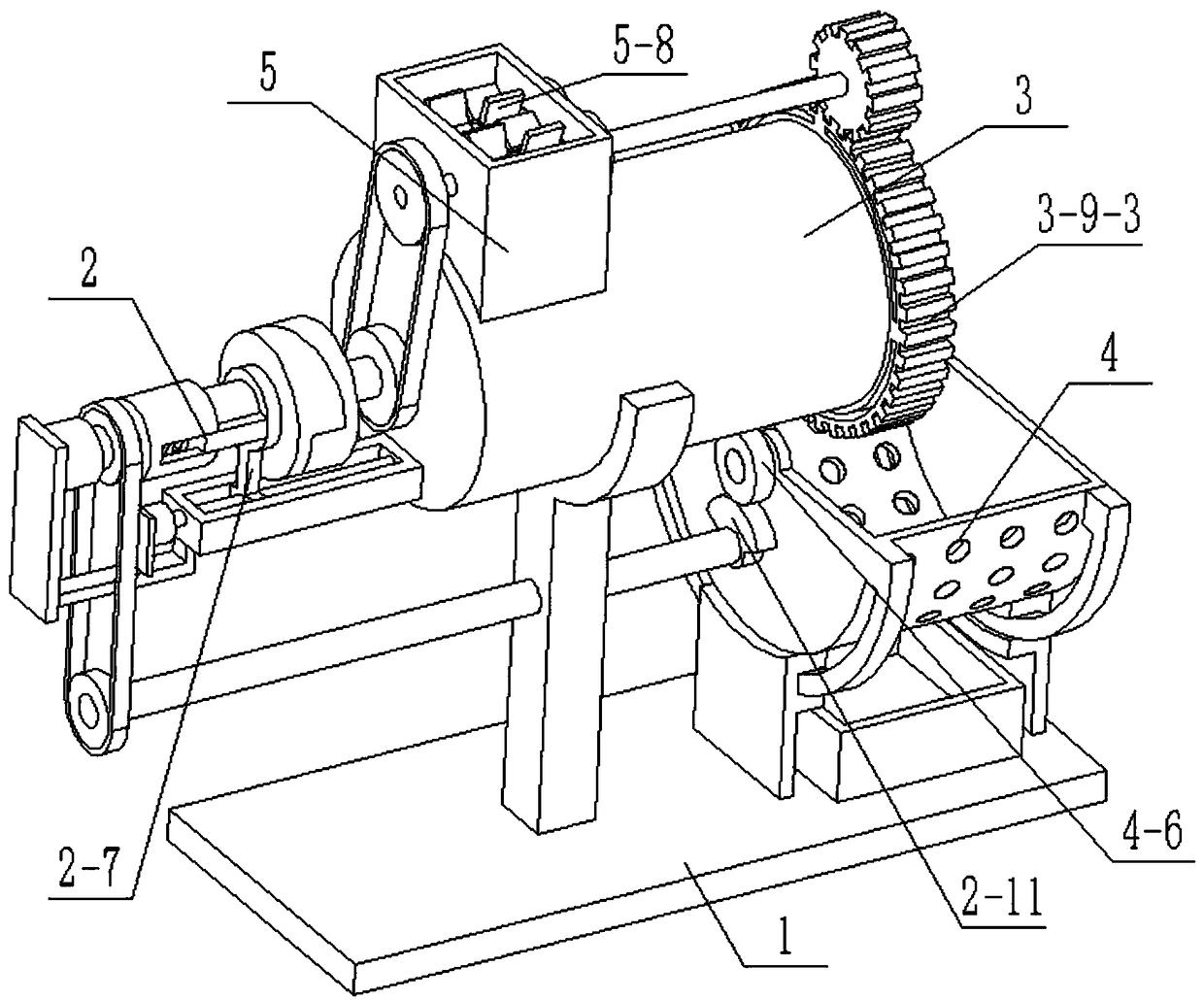

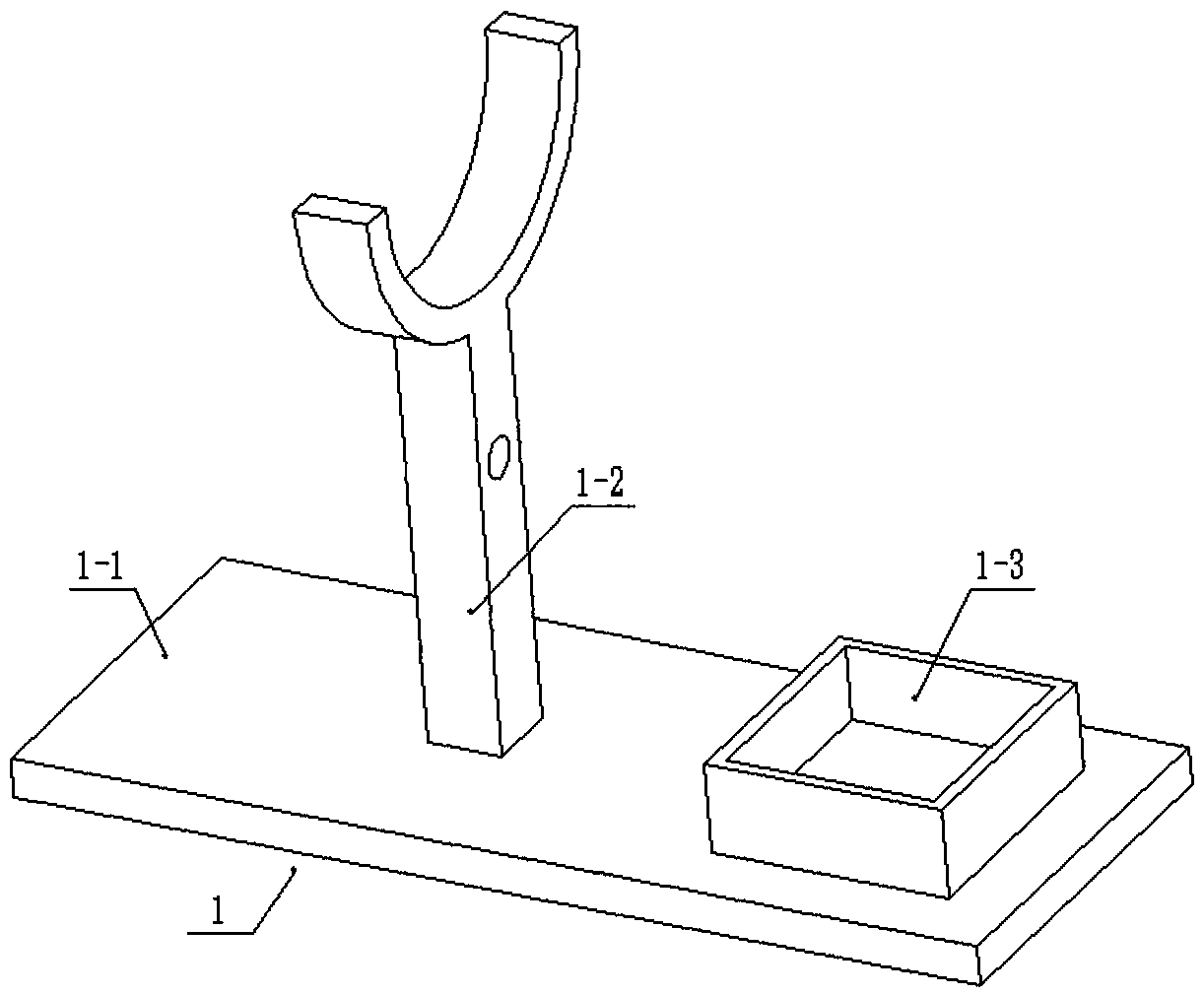

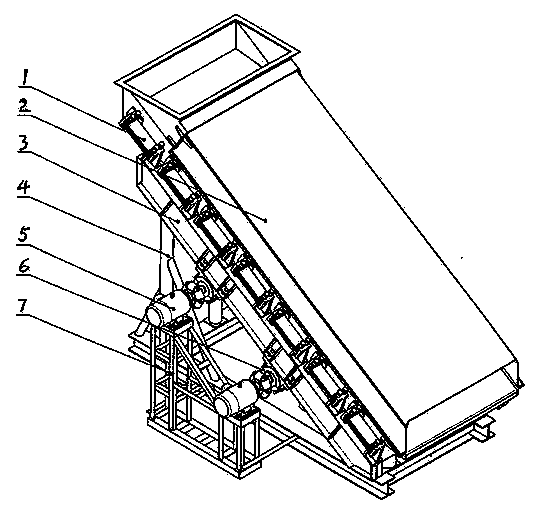

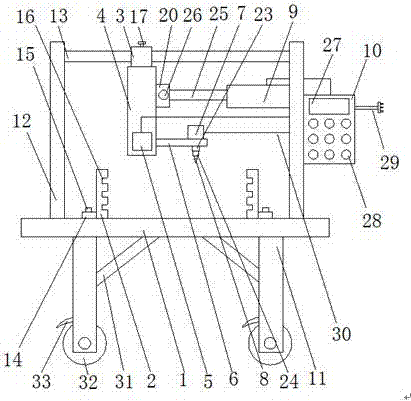

Environmental-friendly biomass fuel particle forming device

The invention relates to the technical field of production of environmental-friendly biomass fuel particles, in particular to an environmental-friendly biomass fuel particle forming device. A drum bracket is fixedly connected on a bed plate and a collecting box is arranged on the bed plate; a motor I is fixedly connected on a motor carrier I, an output shaft of the motor I is connected with one end of a central shaft through a coupling, the other end of the motor I is fixedly connected with a bushing, one end f a telescopic shaft is in slide connection in the bushing, the bushing is provided with rib slots, the telescopic shaft is provided with ribs which are in clearance fit with the rib slots, and a compression spring is arranged in the bushing. The environmental-friendly biomass fuel particle forming device has the advantages that overload jamming due to overload of the device can be avoided, blocking of a feed inlet in a feeding process can be prevented through an anti-blocking feeding pipe arranged inside, and full combustion or subsequent processing and sub-packing is facilitated since biomass fuel is in equal-quantity distribution and output materials can be ground into spherical particles uniform in size.

Owner:强胜生物质秸秆新能源(江苏)有限公司

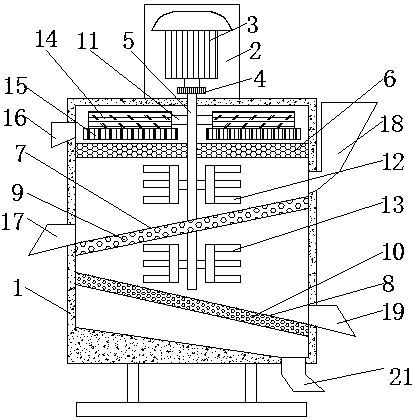

Thorough soybean washing device

The present invention discloses a thorough soybean washing device. The thorough soybean washing device comprises a washing barrel. A motor carrier box is arranged on a top part of the washing barrel;a motor is arranged inside the motor carrier box; a toothed plate is arranged on an output shaft of the motor; the center place of the toothed plate sleeves one end of a rotary shaft; the other end ofthe rotary shaft extends to the interior of the washing barrel, sequentially penetrates through a filter screen and a first filter plate, and is in overlap joint with a surface of a second filter plate; and both ends of the filter screen, first filter plate and second filter plate are fixedly connected with the inner wall of the washing barrel. By improving the soybean washing device and arranging the filter screen, the dirt-washing brushes, the brushing hairs and an impurity-removing mouth, floating dirt is effectively swept out by using the dirt-washing brushes to drive sweeping of the brushing hairs. By arranging first filtering holes, small particles of soybeans and impurities leak out. By arranging second filtering holes and a dirt-discharging mouth, the impurities leak out from theholes and are discharged from the dirt-discharging mouth after precipitation to achieve a thorough washing effect.

Owner:江苏明雨耐磨材料有限公司

Robot polishing equipment

InactiveCN107336118AImprove stabilityImprove polishing efficiencyGrinding carriagesPolishing machinesHydraulic cylinderMotor drive

The invention discloses a robot polishing device, which comprises an operating table, a motor one, a bearing plate, a limit block, a motor two, a backing plate, a hydraulic cylinder, a connecting plate one, a connecting plate two, a connecting plate three, a motor three, and a polishing disc and the controller, characterized in that: the operating table is set on the bracket, the motors 1 and 2 are respectively set on the operating table, the bearing plate is set on the transmission shaft 1, and the position limiting The block is provided with a mounting plate, the backing plate is set on the transmission shaft 2, the hydraulic cylinder is set on the backing plate, and the connecting plate 3 is connected to the rotating shaft in the upper limit groove of the connecting plate 2 , the motor three is arranged on the connection board three, and the controller is arranged on the operating table. In the present invention, a bearing plate is arranged on the transmission shaft 1 of the motor 1, and a position-adjustable limit block is arranged on the load plate, so that the stability of the workpiece in the polishing process is improved through the limit block, and the polishing quality of the workpiece is enhanced. .

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

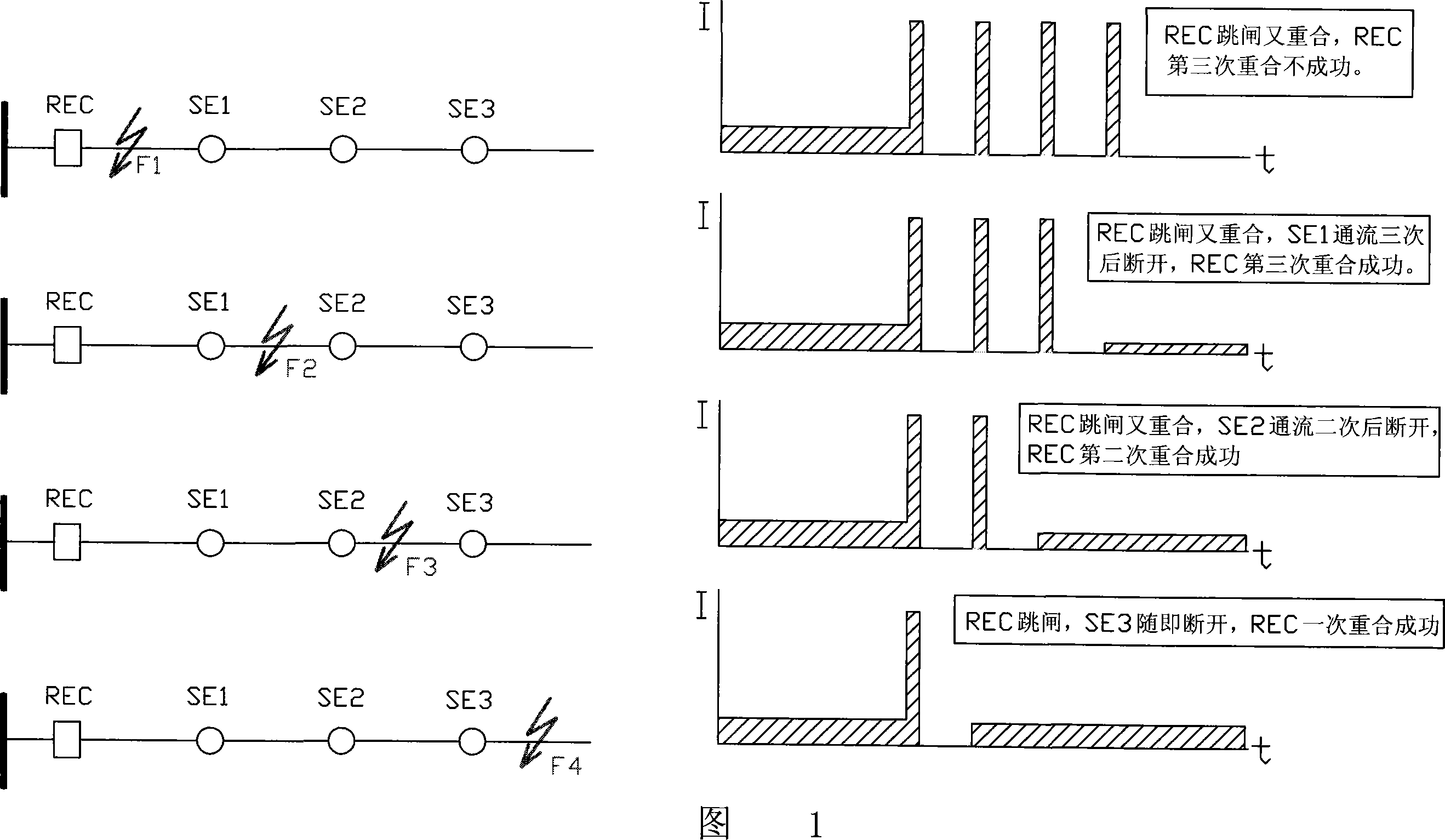

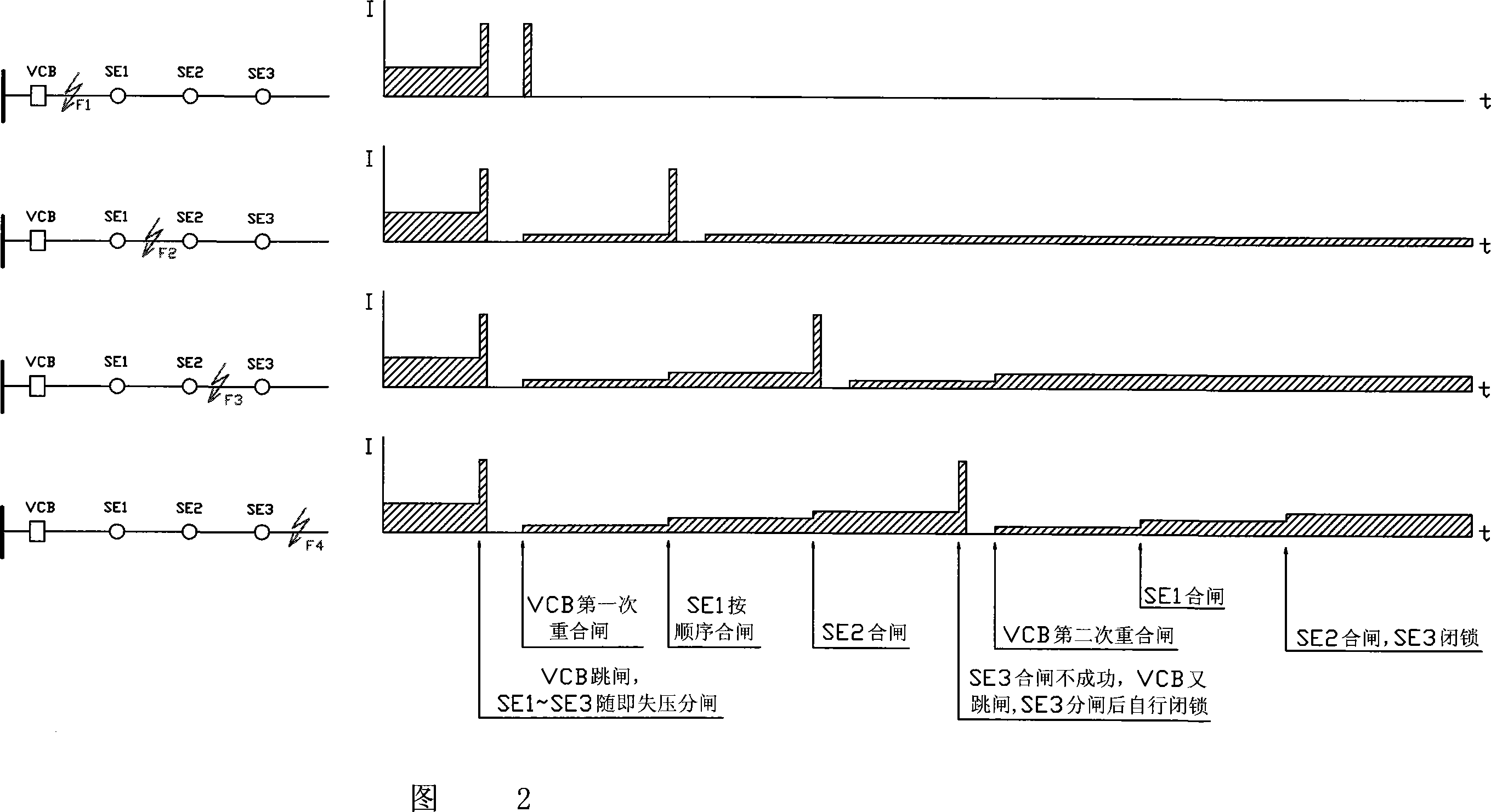

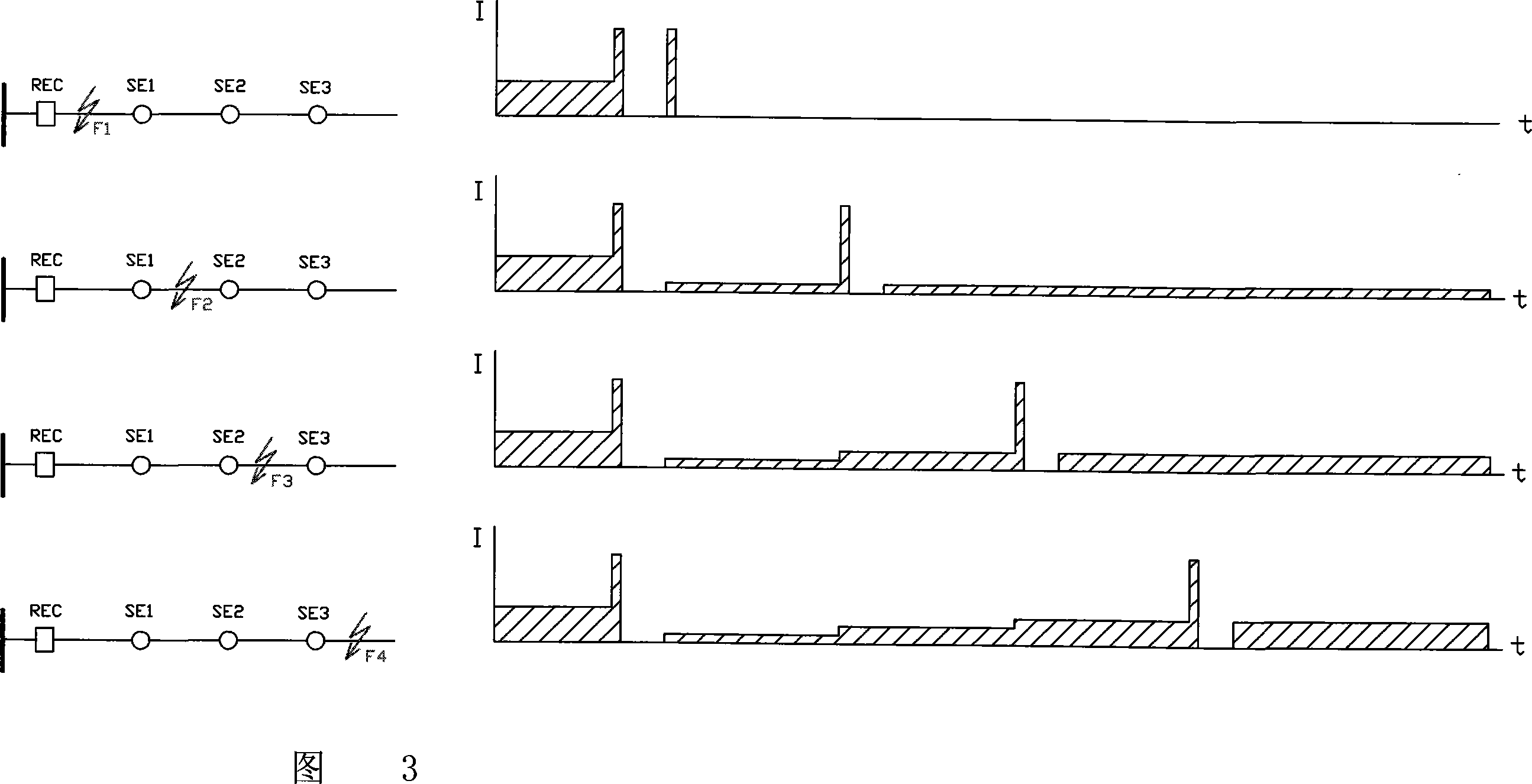

Automatic control device for differential distribution network

ActiveCN101127455AGuaranteed continuityStrong lockEmergency protective circuit arrangementsFault locationAutomatic controlEngineering

The utility model relates to an automatic control device of differential distribution network, comprising three current transformers of phase A, B, and C arranged in the lines of the distribution power network, and two sectional switches arranged on both sides of the section of the lines. The utility model also comprises a fault current collector, an address encoder, an address decoder, a carrier frequency device, a differential comparison and identification unit, and a motor carrier power supply unit. The current transformers of phase A and C are connected with the collector of faulting current, and the current transformer of phase B is connected with the motor carrier power supply unit which is connected with a trip coil of the sectional switch. Besides, the carrier frequency device is connected with the address encoder and the address decoder, and the fault current collector is connected with the differential comparison and identification unit which is connected with the trip coil of the sectional switch. The utility model has the advantages that: due to adopting the differential device to position the working section in a long distance, the faulting section can be identified quickly, the action number of the switch can be reduced, the power can be resupplied soon, and the impact caused by short circuit to the power network can be avoided.

Owner:COOPER NINGBO ELECTRIC

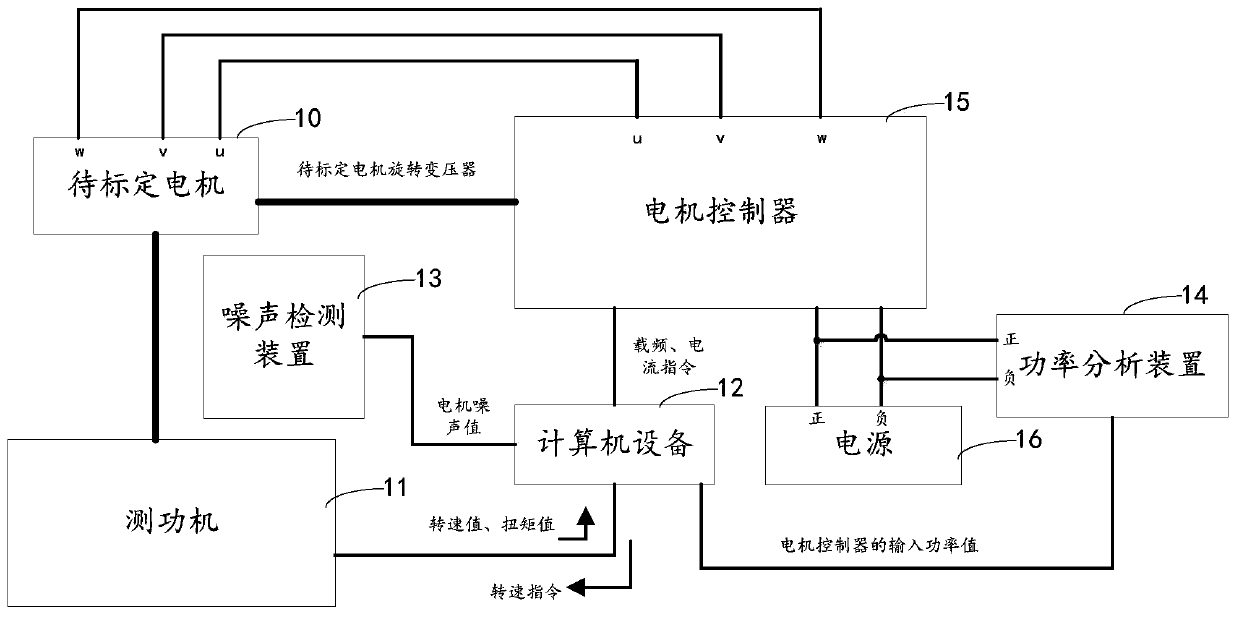

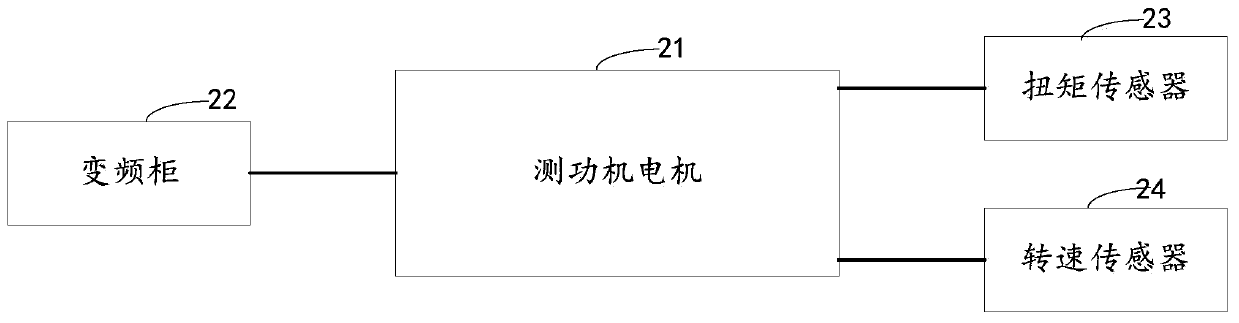

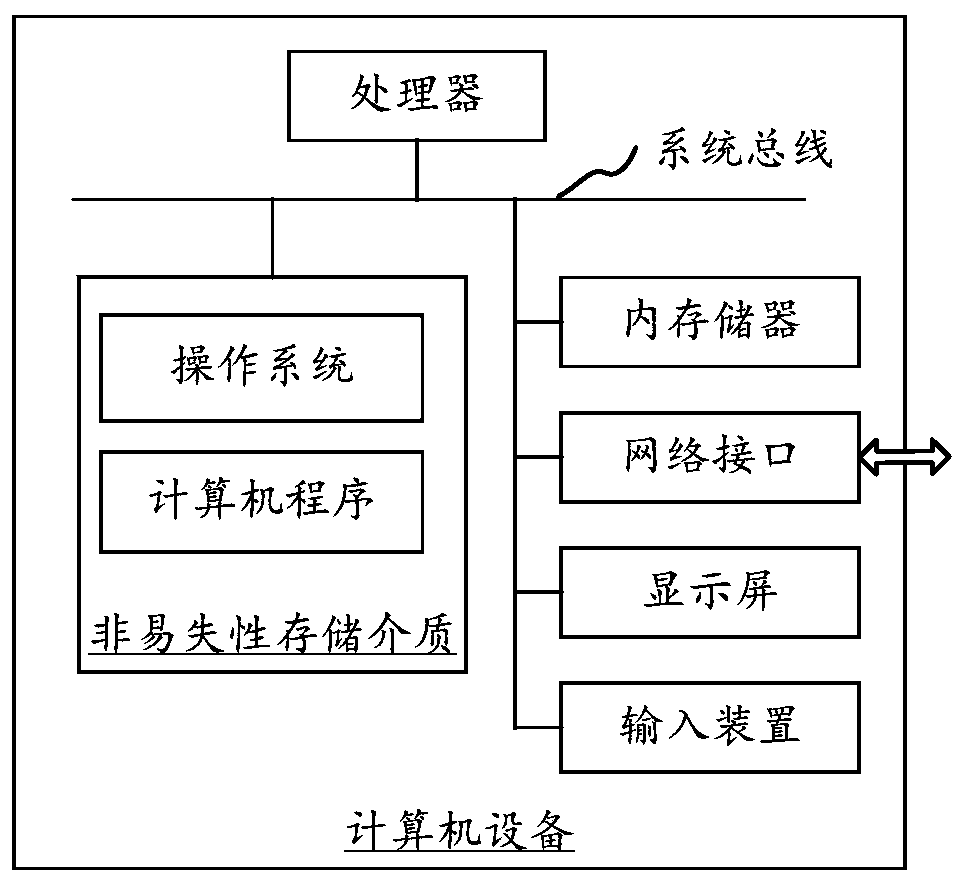

Motor carrier frequency calibration system, method and device

ActiveCN111398812AImprove accuracySimple working conditionsSubsonic/sonic/ultrasonic wave measurementPower measurement by current/voltagePower analysisElectric machine

The invention relates to a motor carrier frequency calibration system, method and device. The system comprises a dynamometer, a computer device, a noise detection device and a power analysis device. The computer device is used for sending a carrier frequency value to the motor controller and sending a given rotating speed value to the dynamometer. The dynamometer is used for controlling the rotating speed of the to-be-calibrated motor according to the given rotating speed value and returning an actual torque value and an actual rotating speed value of the to-be-calibrated motor to the computerdevice. The noise detection device and the power analysis device are respectively used for acquiring and transmitting a motor noise value and an input power value to the computer device. The computerdevice is also used for determining a system efficiency value according to the actual torque value, the actual rotating speed value and the input power value, and calibrating a target carrier frequency value corresponding to the given rotating speed value according to the carrier frequency value and the motor noise value. By adopting the system, the calibration efficiency and the calibration result accuracy can be improved.

Owner:CHONGQING JINKANG POWER NEW ENERGY CO LTD

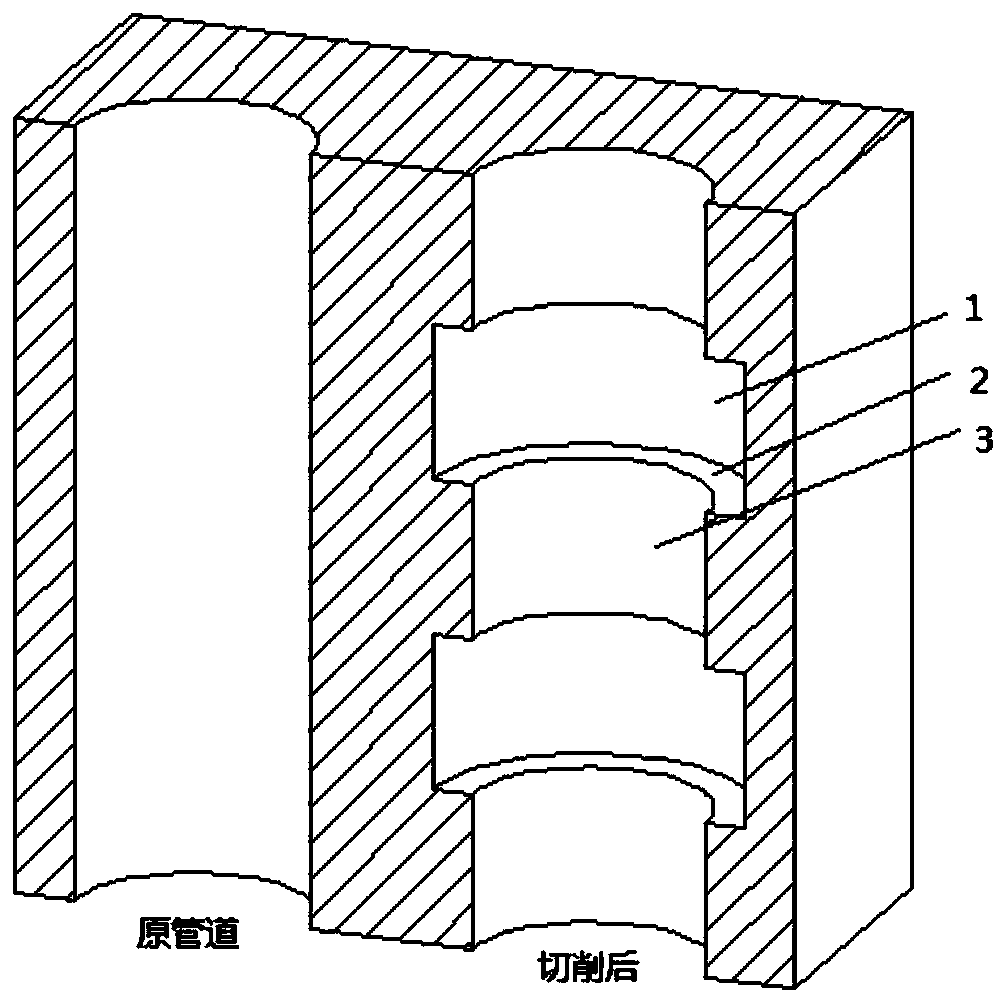

In-situ detection shearing device of loess hole

ActiveCN110646299APrecise determination of shear strengthMaterial strength using steady shearing forcesSoil scienceMeasurement test

The invention discloses an in-situ detection shearing device of a loess hole. The in-situ detection shearing device comprises a motion carrier, a shearing part and an air bag carrier, wherein the motor carrier drives the shearing part and the air bag carrier to climb a wall and walk, the loess shearing tool is borne by the shearing part, the shearing part is used for driving the shearing tool to rotate and cut after the motor carrier reaches a detection position, the air bag carrier is connected with the shearing part and comprises a main air bag carrier and a side air bag carrier, the main air bag carrier bears a main air bag and is used for solidifying hole soil, the side air bag carrier bears a side air bag, and the motion carrier and the side air bag are jointly used for measuring a shearing force. In the shearing force, in-situ measurement test of soil shear strength can be performed in a loess underground pipeline, and soil shear strength at different soil layer positions can beaccurately measured.

Owner:CHANGAN UNIV

Multi-positional flat hook bracket

InactiveUS20060153658A1Easy to manufactureFlexible elementsCargo supporting/securing componentsMotor carrierTransportation security administration

A multi-positional flat hook bracket for cargo securement is provided. The bracket allows for the securement of tie-down flat hooks in such a way as to conform to the recent regulations promulgated by the Federal Motor Carrier Safety Administration (FMCSA). Namely, the tie-down will stay inboard of the trailer's rub rails, and any loss in tension to the tie-downs will not result in the flat hook coming loose.

Owner:FONTAINE TRAILER

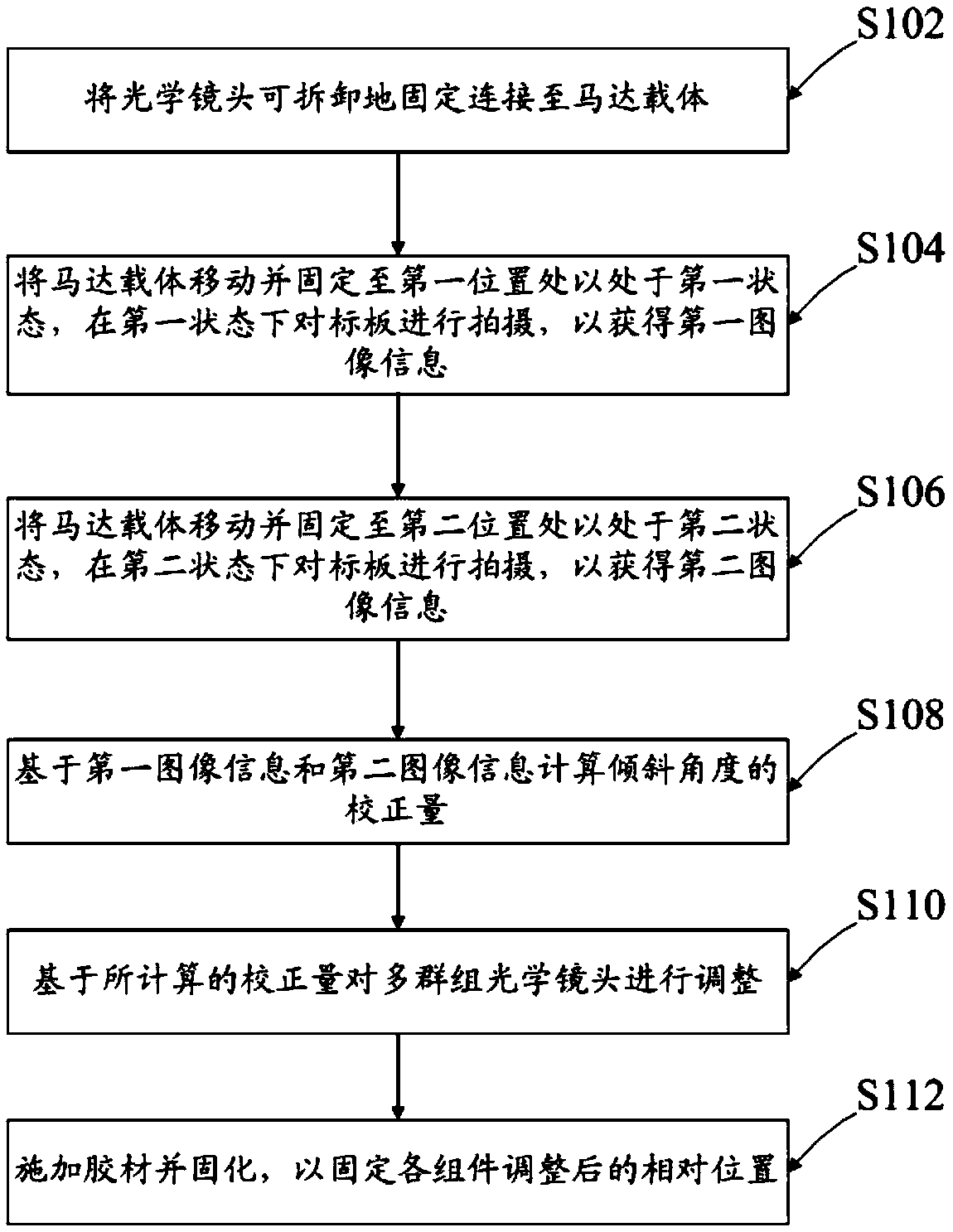

Assembling method based on multiple groups of optical lenses forming motor optical assembly

The invention discloses an assembling method based on multiple groups of optical lenses forming a motor optical assembly. The assembling method comprises the steps that the optical lenses are detachably and fixedly connected to a motor carrier; moving and fixing the motor carrier to a first position such that the carrier is in a first state; shooting the target plate in the first state to obtain first image information of the target plate; moving and fixing the motor carrier to a second position such that the carrier is in a second state; shooting the target plate in a second state to obtain second image information of the target plate; calculating a correction amount of the inclination angle based on the target plate first image information and the target plate second image information; and adjusting the multi-group optical lens based on the calculated correction amount.

Owner:NINGBO SUNNY OPOTECH CO LTD

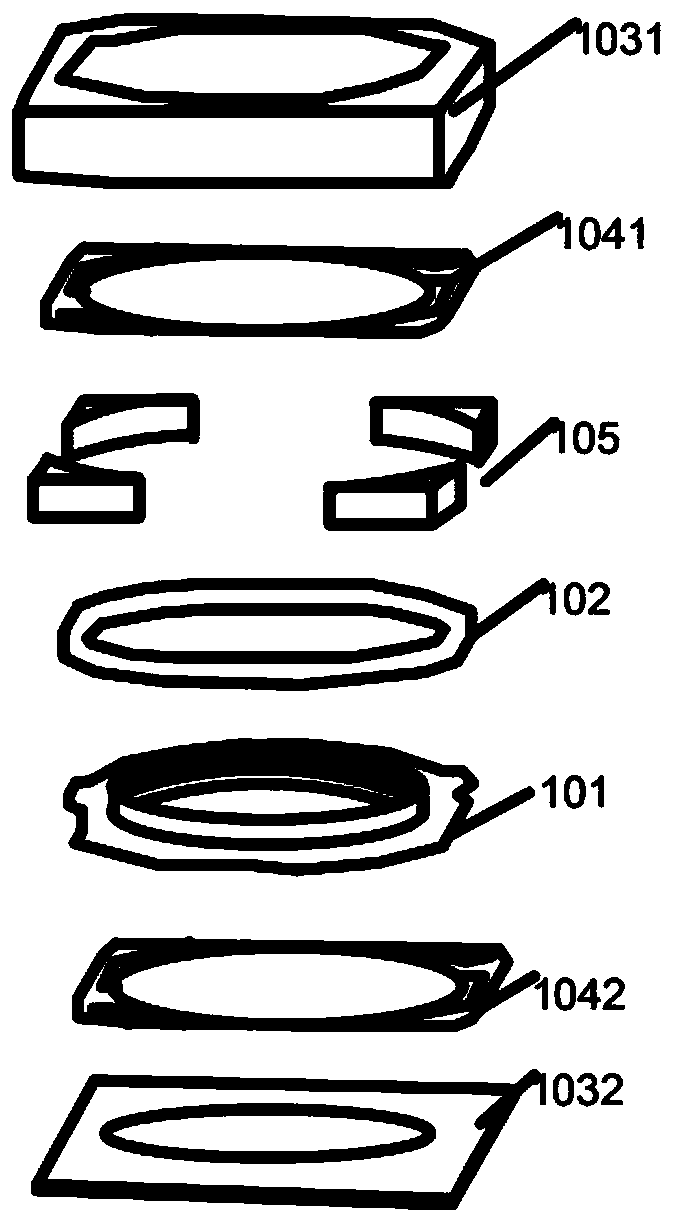

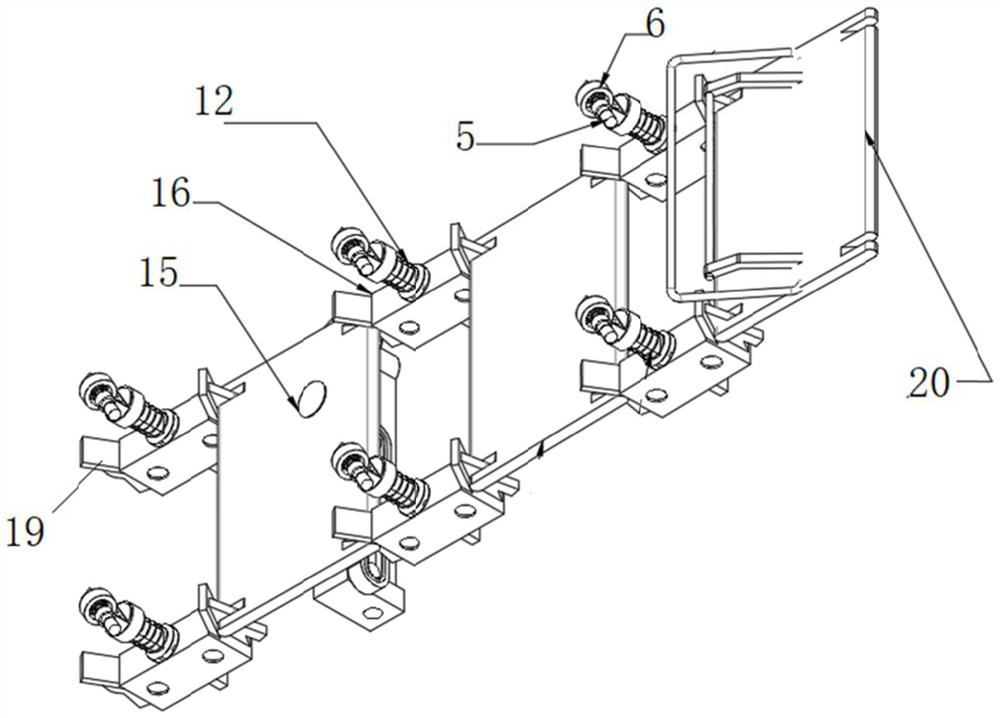

Vibrating motor accessory feeding mechanism

InactiveCN110893550AGuaranteed accuracyHigh mechanized production efficiencyAssembly machinesMetal working apparatusControl engineeringMotor carrier

The invention discloses a vibrating motor accessory feeding mechanism which comprises a vibrating motor carrier, an assembly line rail, a V-shaped spring feeding device and two blocking piece feedingdevices. The carrier is provided with a groove for placing a vibration motor accessory, a fixing block is arranged on the groove to fix a V-shaped spring, a movable positioning block is arranged between the fixing block and the mass block, a sliding block is further arranged and connected with the movable positioning block, transverse movement of the sliding block drives the movable positioning block to move, and a positioning column is further arranged at the end of the fixing block to position the V-shaped spring; the blocking piece feeding devices can place a blocking piece in the V-shapedspring; and two shifting devices are arranged on the assembly line rail and used for shifting the sliding block on the carrier to enable the sliding blocks to move horizontally. Thus, the blocking piece feeding devices and the V-shaped spring feeding device can realize feeding, the shifting devices and the carrier can be used to position the blocking piece and the V-shaped spring, and further theaccuracy of the subsequent welding and gluing process is guaranteed, and the mechanical production efficiency is improved.

Owner:常州博图自动化科技有限公司

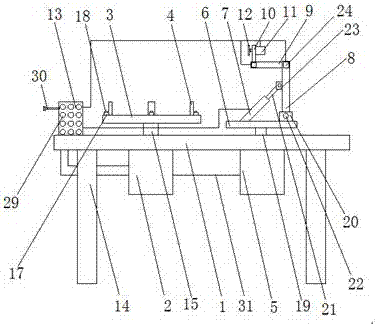

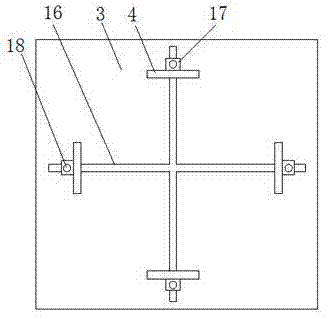

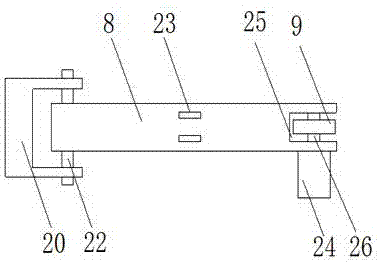

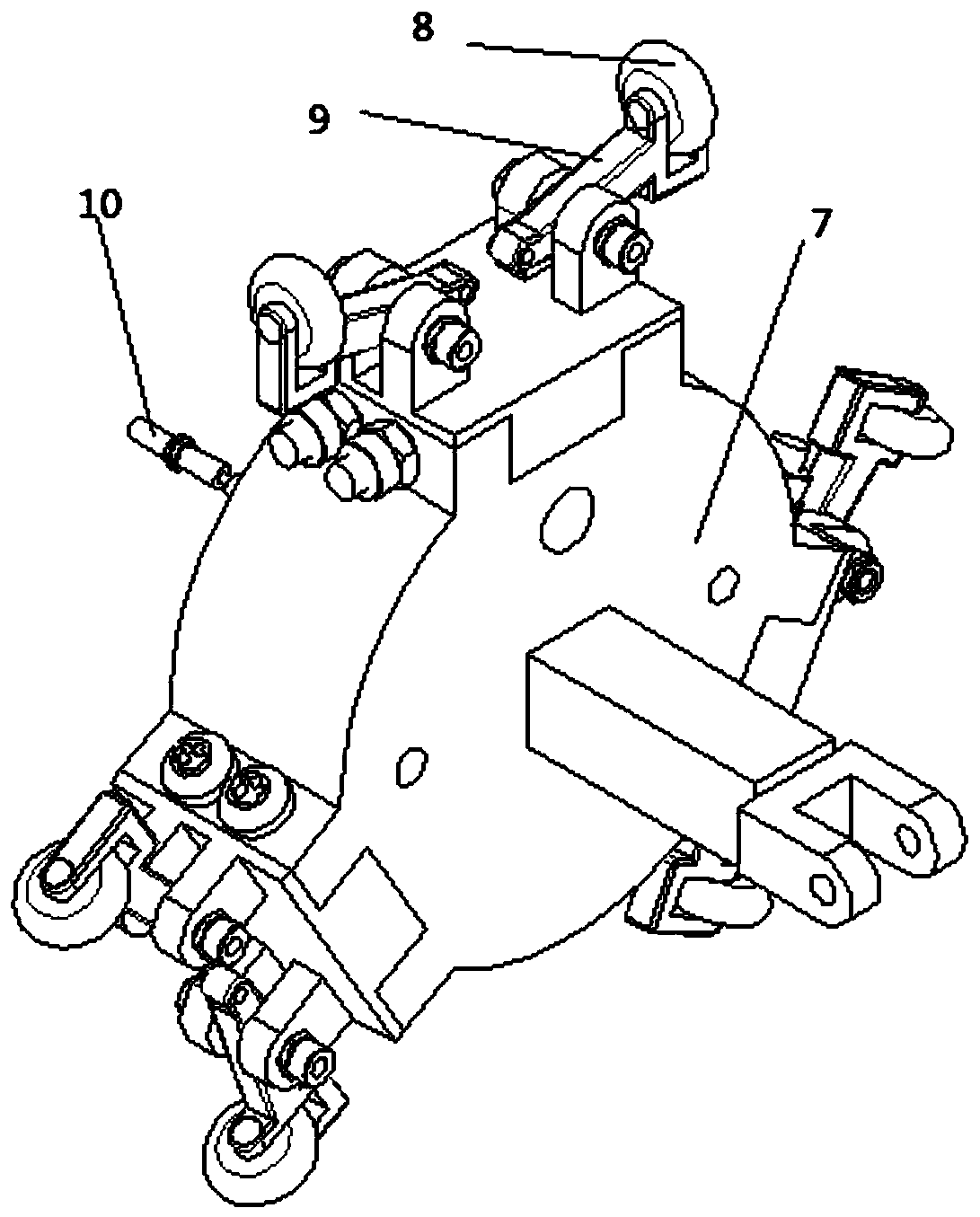

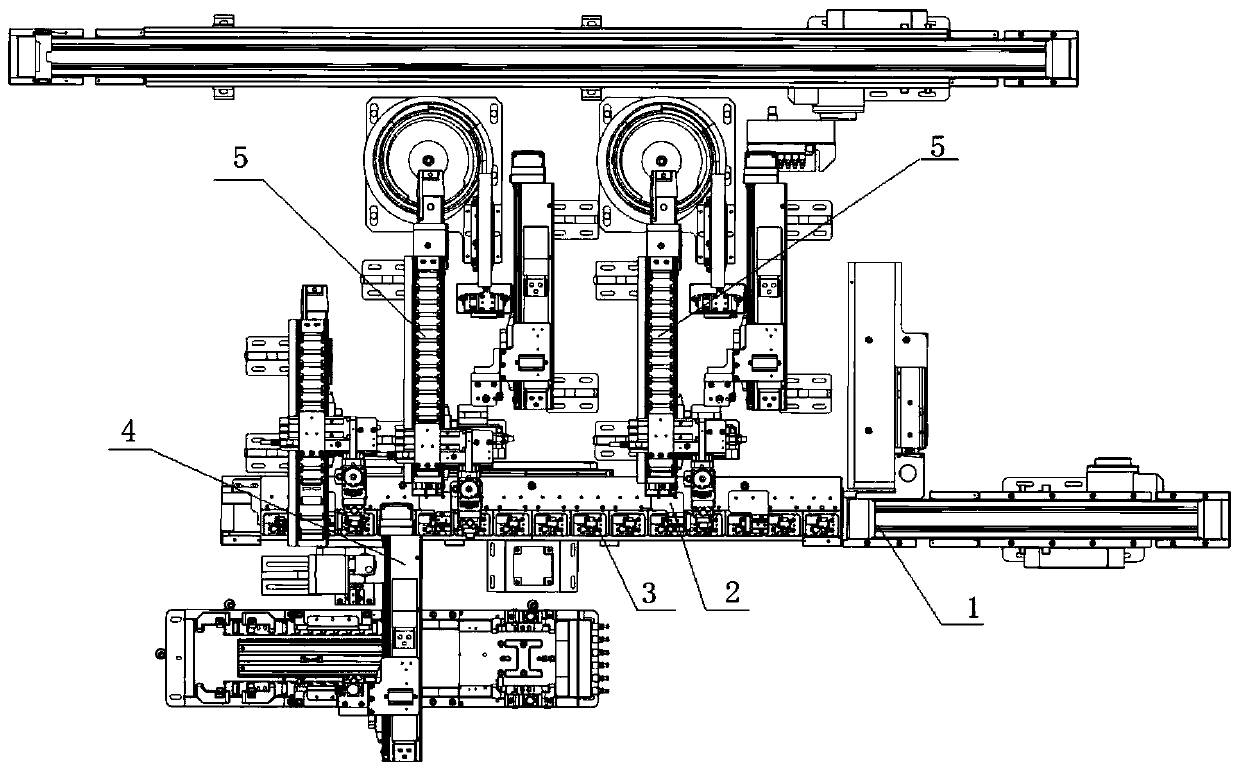

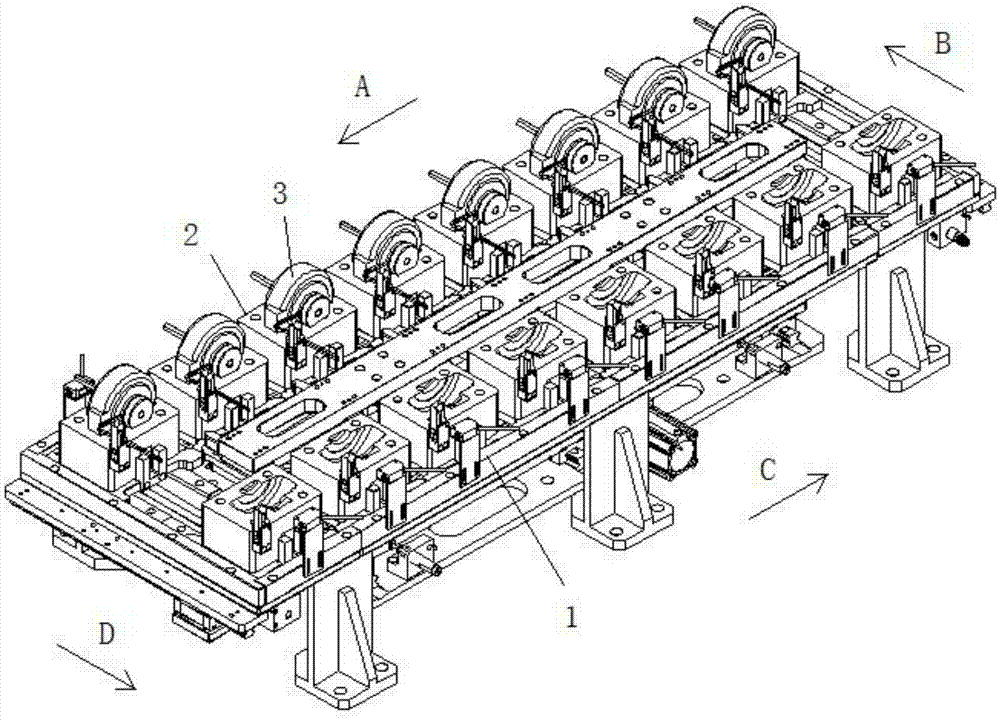

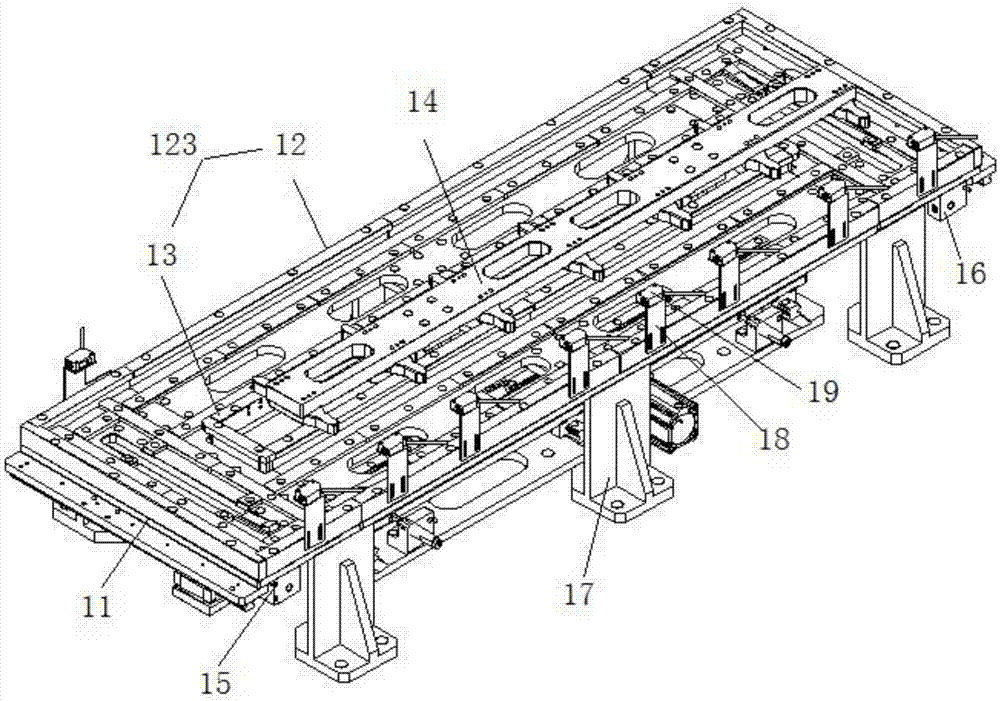

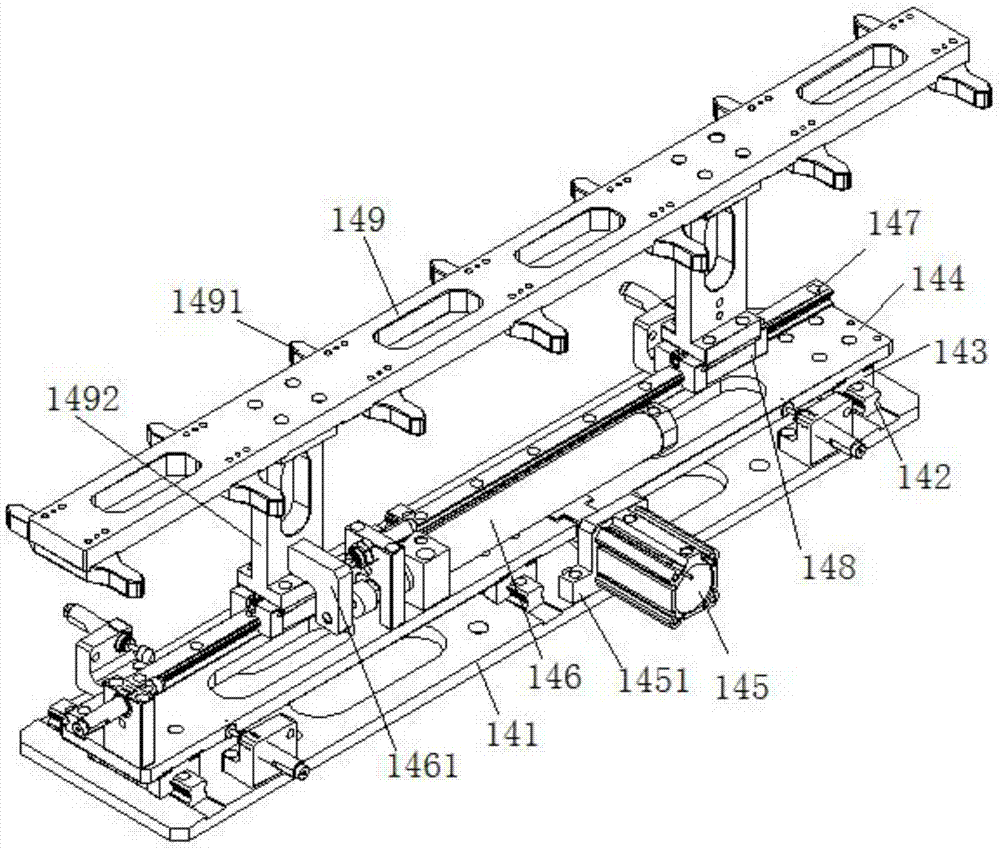

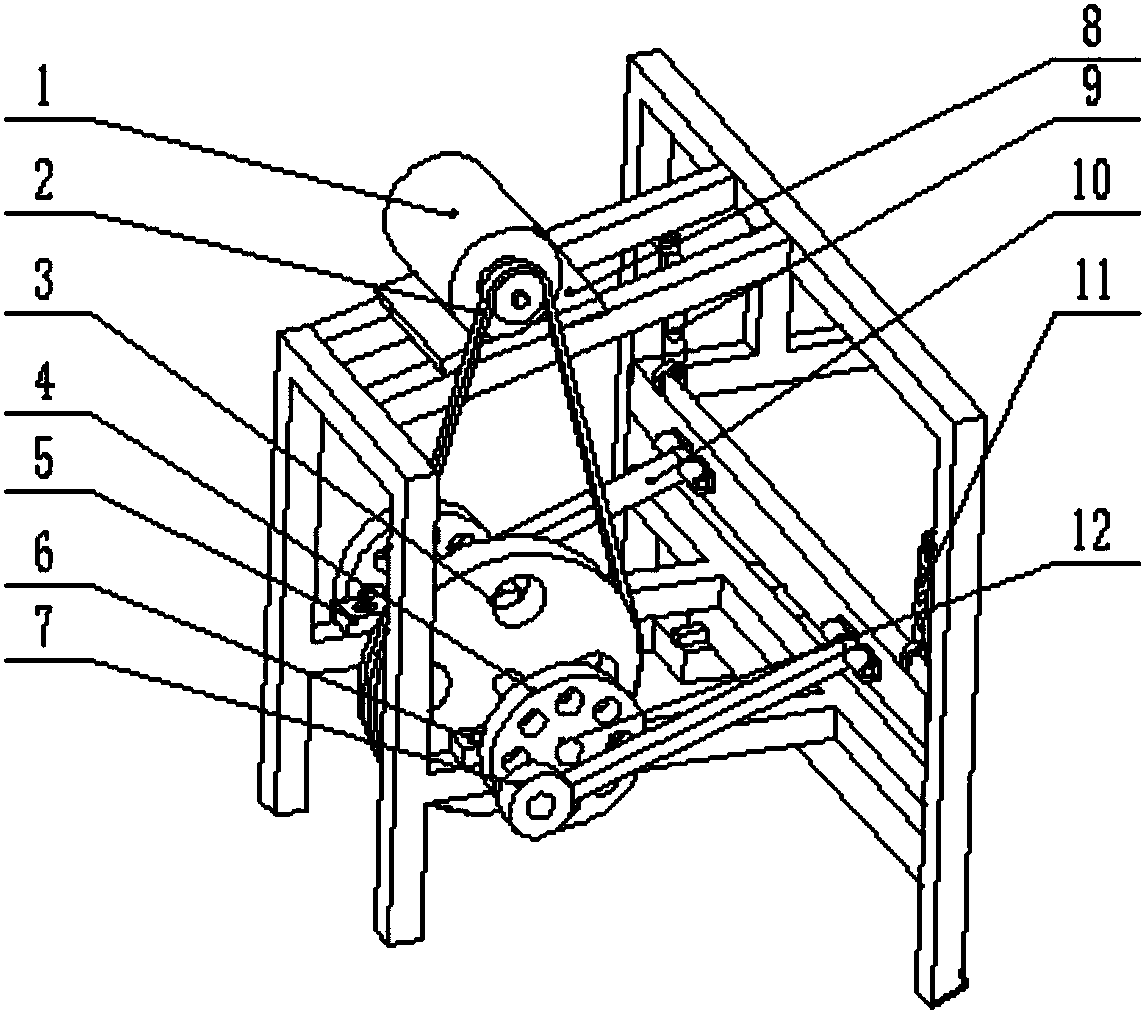

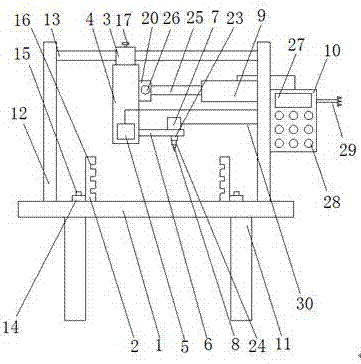

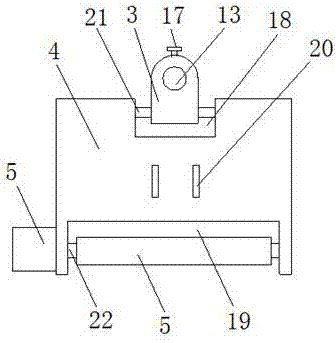

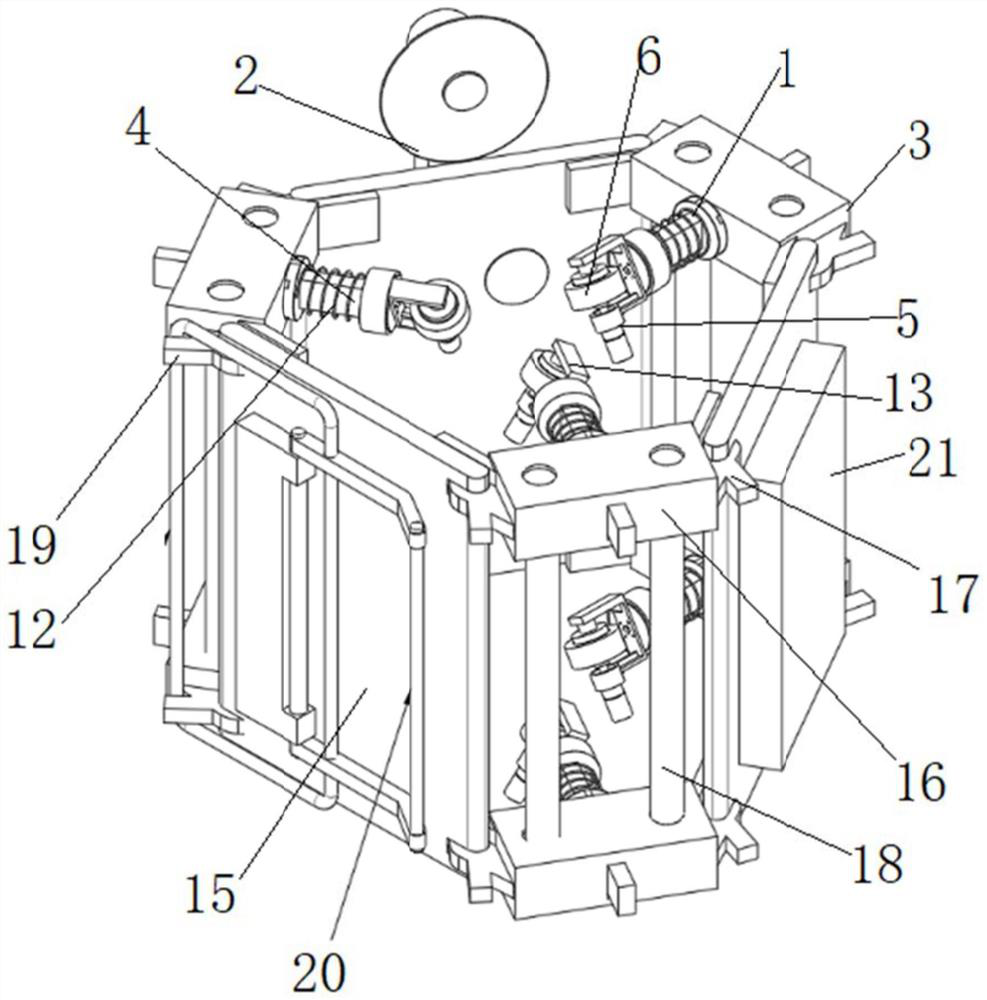

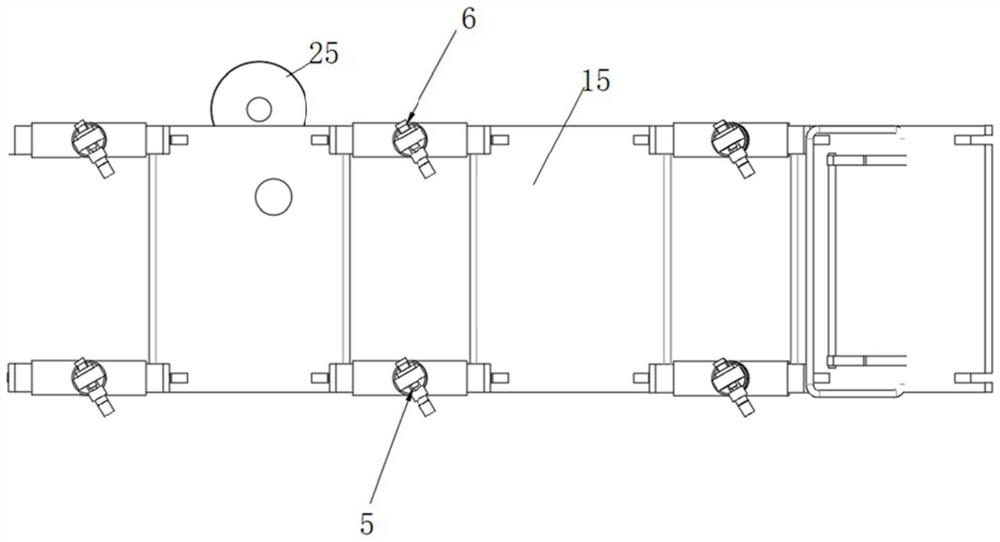

Motor carrier conveying device

The invention discloses a motor carrier conveying device which comprises a rail mounting plate and a conveying rail positioned on the rail mounting plate, and further comprises a shifting fork assembly for transversely moving a motor carrier along the conveying rail as well as a first pushing assembly and a second pushing assembly for longitudinally moving the motor carrier along the conveying rail. The conveying rail is rectangular; the first pushing assembly, the second pushing assembly and the shifting fork assembly co-drive the motor carrier to operate along the conveying rail; the shifting fork assembly comprises a shifting fork fixing plate capable of transversely and longitudinally moving; and a plurality of shifting forks which are distributed transversely at an equal distance are symmetrically arranged at the two sides of the shifting fork fixing plate. According to the motor carrier conveying device, the shifting fork assembly drives the motor carrier to transversely move, and the first pushing assembly and the second pushing assembly drive the motor carrier to longitudinally move, so that the motor carrier operates in the rectangular conveying rail; and multiple motor carriers are simultaneously moved by utilizing the multiple shifting forks, so that the efficiency is high.

Owner:BOZHON PRECISION IND TECH CO LTD

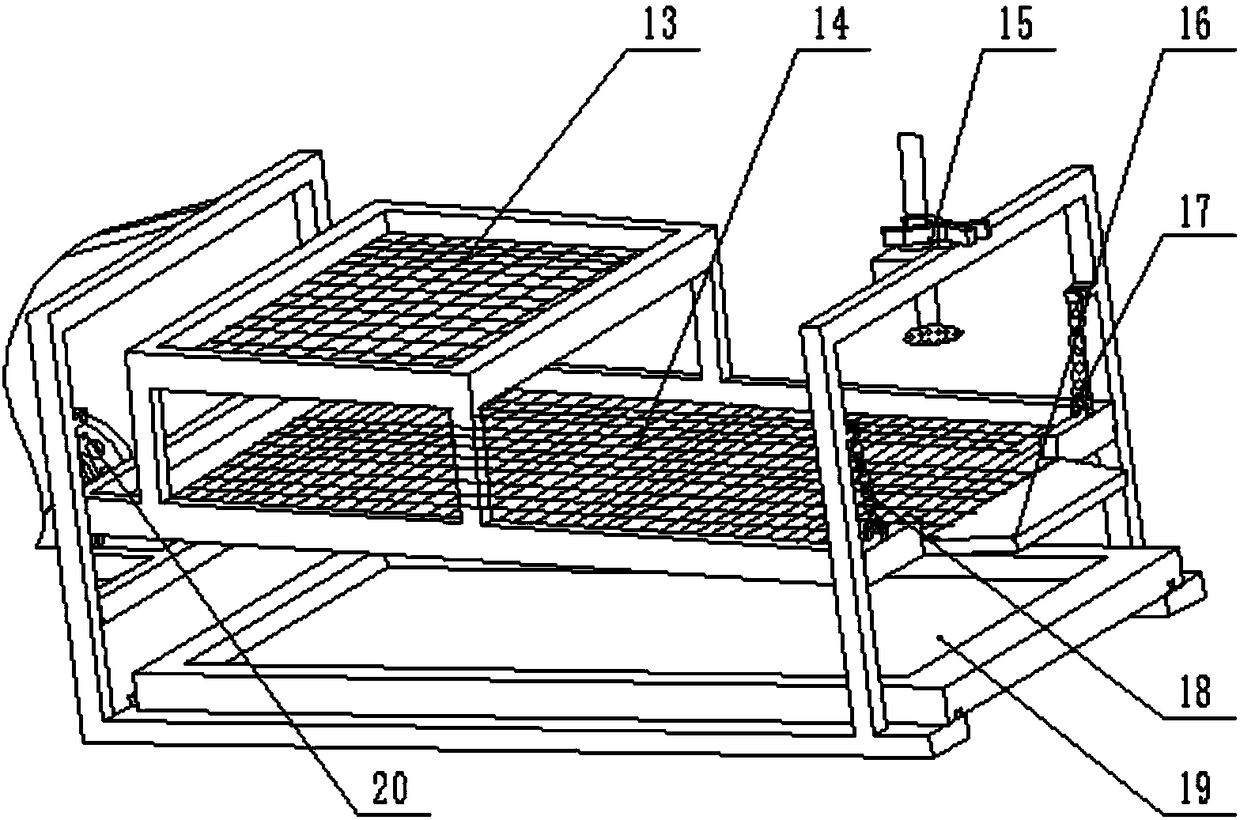

Automatic escargot screening and washing device

The invention relates to an automatic escargot screening and washing device, belongs to the field of aquatic product processing machines and particularly provides a device which adopts a motor to drive a reciprocating mechanism to screen and wash escargots automatically. The device is composed of the motor, a belt, a belt wheel, a first flange disc, a first flange disc fixing plate, a first connecting rod, a motor carrier plate, a second flange disc, a second flange disc fixing plate, a second connecting rod, a rotating shaft, an upper screen, a lower screen, a shower head spring clamp, an outlet carrier plate, a treating box, a shower head installing plate, a first guide rail, a second guide rail and a shower head spraying head. The motor works to drive two eccentric wheel connecting rodstructures, the connecting rods are connected with the lower screen, the upper face of the lower screen is connected with the upper screen, left and right reciprocating motion of the screens is formed, by means of different sizes of grids of the upper screen and the grids of the lower screen, the escargots are layered, the shower head spraying head at the outlet sprays water to wash the escargots,finally, the escargots which are moderate in size, free from sundries and suitable for people to use are obtained, labor is saved, and use is convenient.

Owner:梁化斌

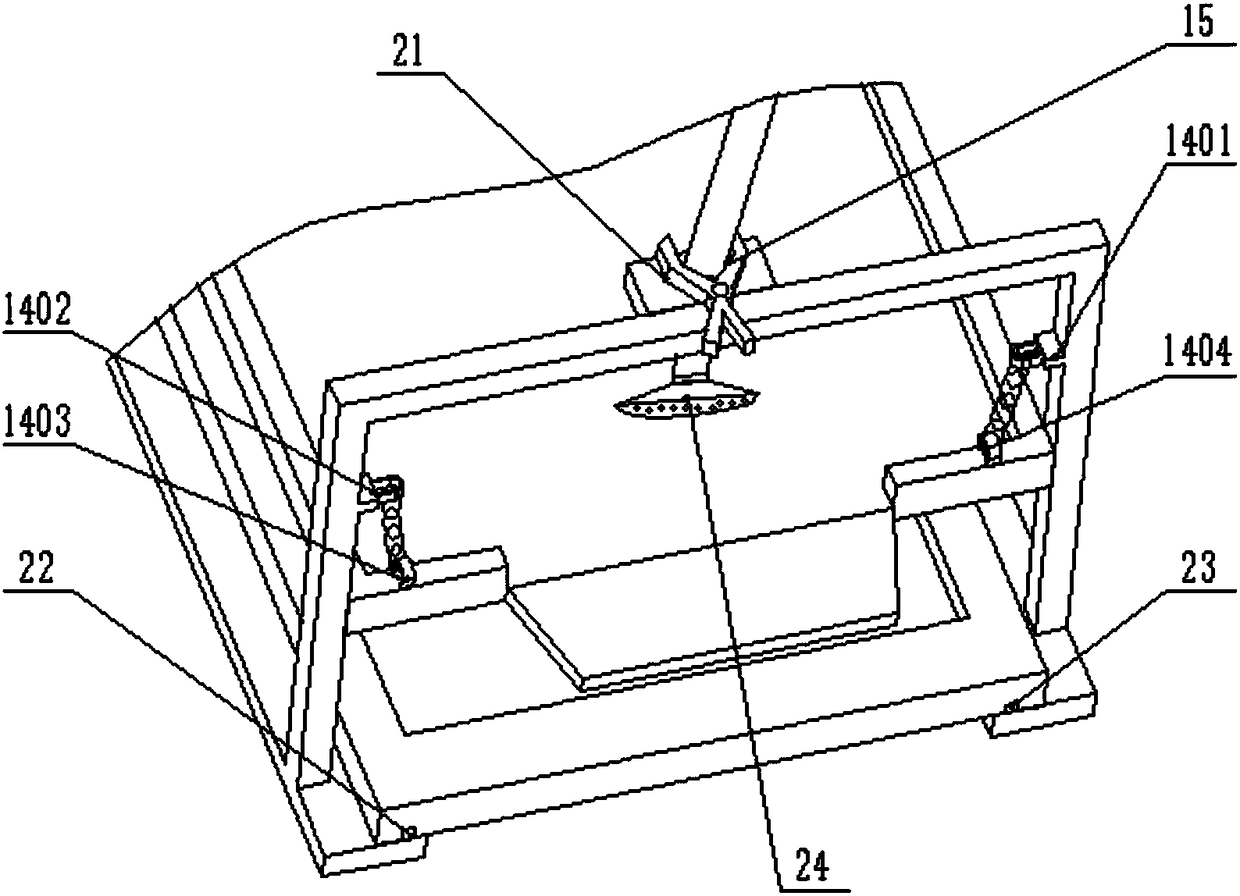

Anti-resonance vibrating screen machine

InactiveCN103611681AHigh acceleration vibration frequencyAvoid cloggingSievingScreeningHigh accelerationElectric machinery

The invention discloses an anti-resonance vibrating screen machine comprising a triangular screen frame. An elongated main vibrating frame is mounted on a slope of the triangular screen frame through a set of shock absorbers. Two synchronous vibration exciters are mounted below the main vibrating frame in a front-back symmetric manner. One side of the screen frame is provided with a motor through a motor carrier, and the motor is used with the vibration exciters. A screen box is mounted on the main vibrating frame. Evenly distributed leaf springs are connected between the screen box and the main vibrating frame. Through the adoption of the high-elasticity leaf springs, the resonance screen box is imparted high acceleration vibrating frequency, and jamming of screen holes can be prevented effectively. The anti-resonance vibrating screen machine is especially suitable for screening fine, sticky and wet ore materials, screening is efficient, and energy is saved.

Owner:HENAN TAIHANG VIBRATING MACHINERY

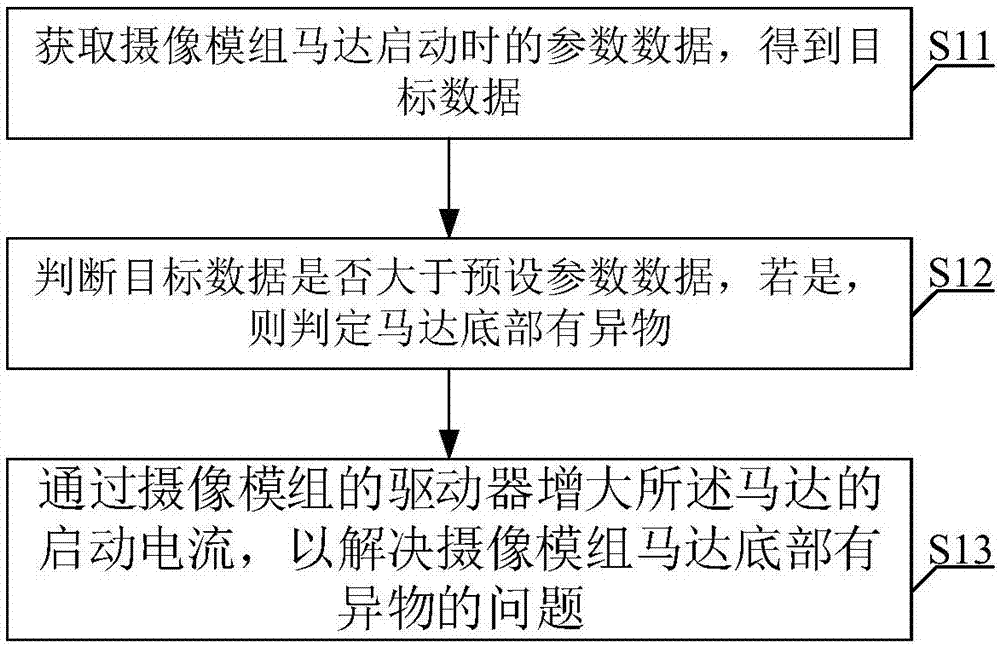

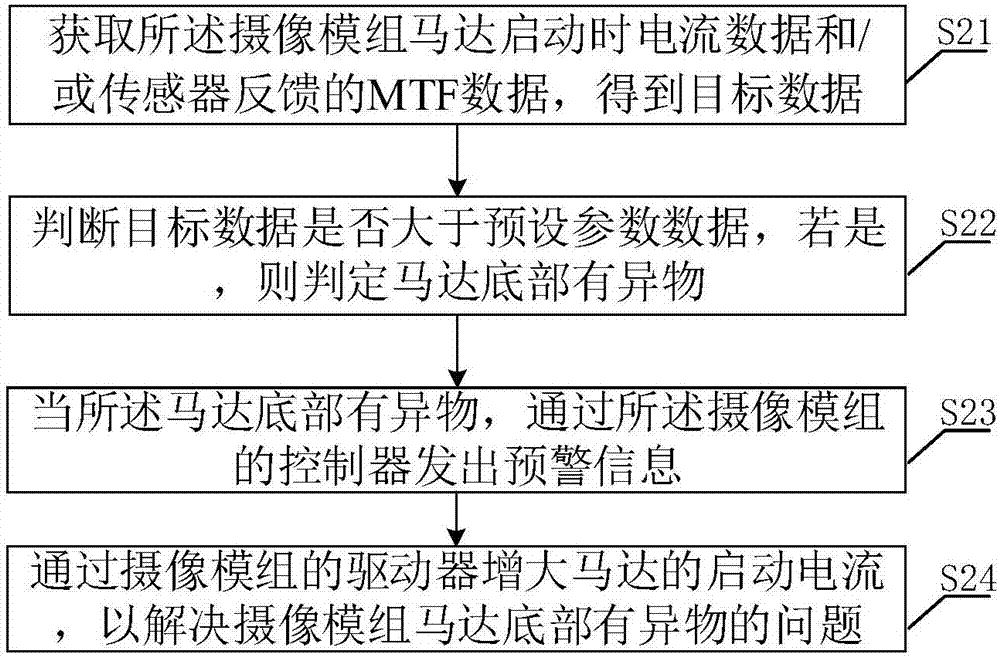

Method, system and equipment for solving foreign matter at motor bottom of camera module

InactiveCN108012145ALarge starting currentAchieve normal startupDynamo-electric motors/converters startersTelevision systemsForeign matterDriving current

The application discloses a method, system and equipment for solving foreign matter at motor bottom of a camera module. The method comprises the following steps: acquiring parameter data when the motor of the camera module is started to obtain target data; judging whether the target data is greater than preset parameter data; if the target data is greater than the preset parameter data, judging that the foreign matter is existent at the motor bottom; increasing the starting current of the motor through a driver of the camera module to solve the problem that the foreign matter is existent at the motor bottom. Visibly, the driving current of the motor is regulated through the driver of the camera module through the method for solving foreign matter at the motor bottom of the camera module provided by the invention, specifically, the starting current for driving the motor is increased, so that the force for moving a motor carrier and a lens is greater than the force for adhering the foreign matter, and the normal starting of the motor is realized under the situation that the foreign matter is existent at the bottom of the motor module motor.

Owner:TRULY OPTO ELECTRONICS

Robot device for workpiece drilling

InactiveCN107335825AImprove stabilityImprove drilling qualityLarge fixed membersPositioning apparatusDrive shaftEngineering

The invention discloses a robot device for drilling workpieces, comprising an operation table, a positioning block, an adjustment block, an adjustment plate, a first motor, a carrier plate, a second motor, a drill bit, a cylinder and a controller, and is characterized in that: the operation The platform is set on the bracket, the positioning block is provided with a mounting plate, and the mounting plate is set on the operating table through the mounting bolts, and the adjustment block is set on the cross bar through the fastening bolts, and the adjustment plate A connecting slot, a limiting slot and a fixing plate are arranged on the upper part of the motor. The first motor is arranged on the adjustment plate, the bearing plate is arranged on the rotating shaft, the second motor is arranged on the bearing plate, and the drill bit is arranged on the bearing plate. Set on the drive shaft through a mounting ring. In the invention, a positioning block with adjustable position is arranged on the operating table, and a positioning groove is arranged on the positioning block, so that the workpiece to be drilled is placed between the positioning groove and the positioning groove, so as to improve the stability of the workpiece during the drilling process properties, thereby improving the drilling quality of the workpiece.

Owner:ANHUI HAITUO ZHIYONG INTELLIGENT EQUIP CO LTD

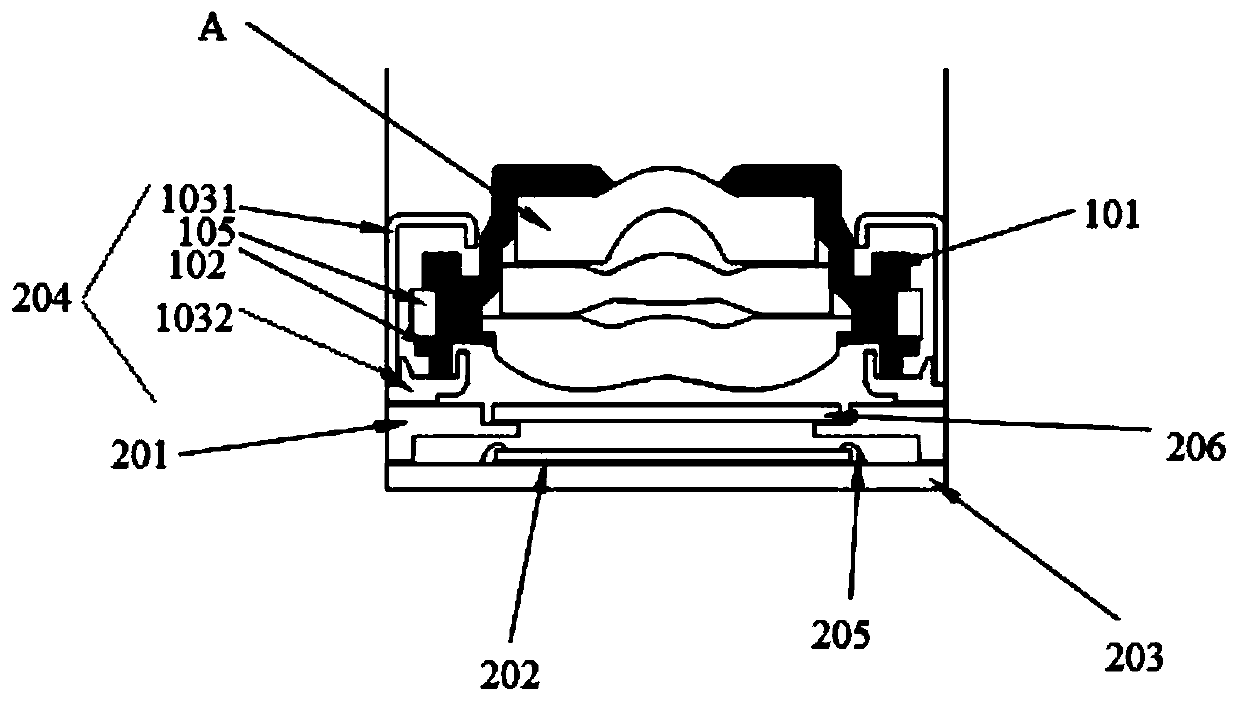

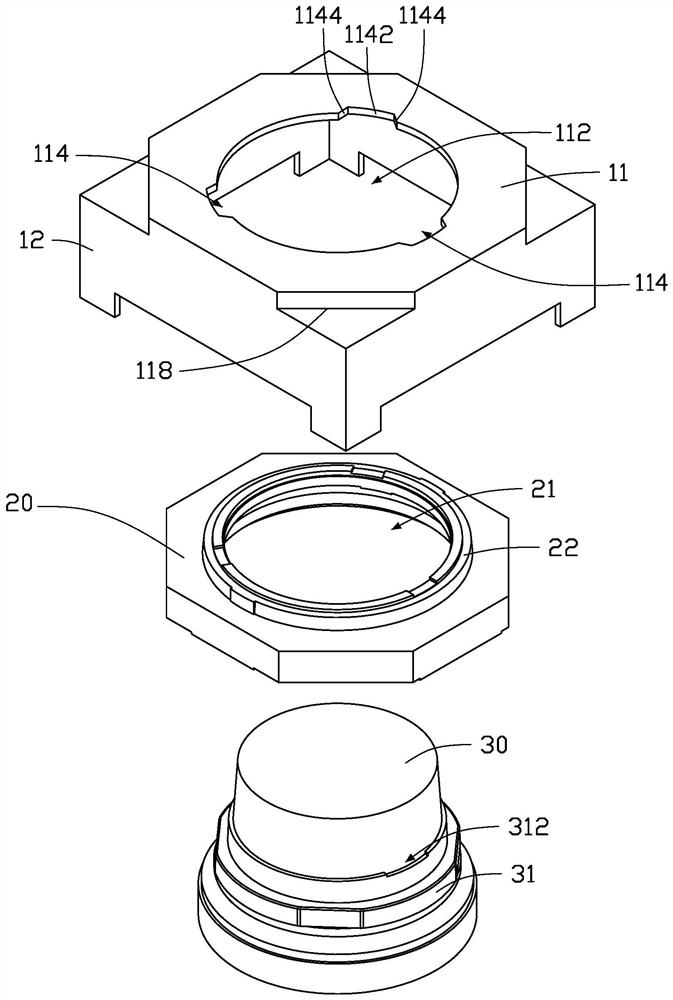

Camera module and motor thereof

PendingCN111510601ASmall sizeReduce volumeTelevision system detailsColor television detailsEngineeringCamera module

The invention relates to the technical field of cameras, in particular to a camera module and a motor thereof. The motor comprising a motor carrier, a coil, an outer shell, a supporting elastic sheetand magnets, wherein the motor carrier is used for bearing multiple layers of lenses; the coil is arranged outside the motor carrier in a sleeving manner; the outer shell is arranged outside the coilin a sleeving manner; one end of the supporting elastic sheet is connected with the motor carrier, and the other end of the supporting elastic sheet is fixed in the outer shell; the magnets surround the coil, are fixed on the inner side of the outer shell and are used for generating a magnetic field. When the coil is powered on, the coil can move in the direction perpendicular to the magnetic field under the action of the magnetic field of the magnets, so as to achieve the focusing purpose, further, a lens barrel of lenses in the prior art is abandoned, the size of the motor of the camera module is effectively reduced, namely, the size of the camera module is reduced, enough space is reserved for accommodating other assemblies, and the performance of all device structures is guaranteed while the size of small equipment is reduced.

Owner:KUNSHAN Q TECH CO LTD

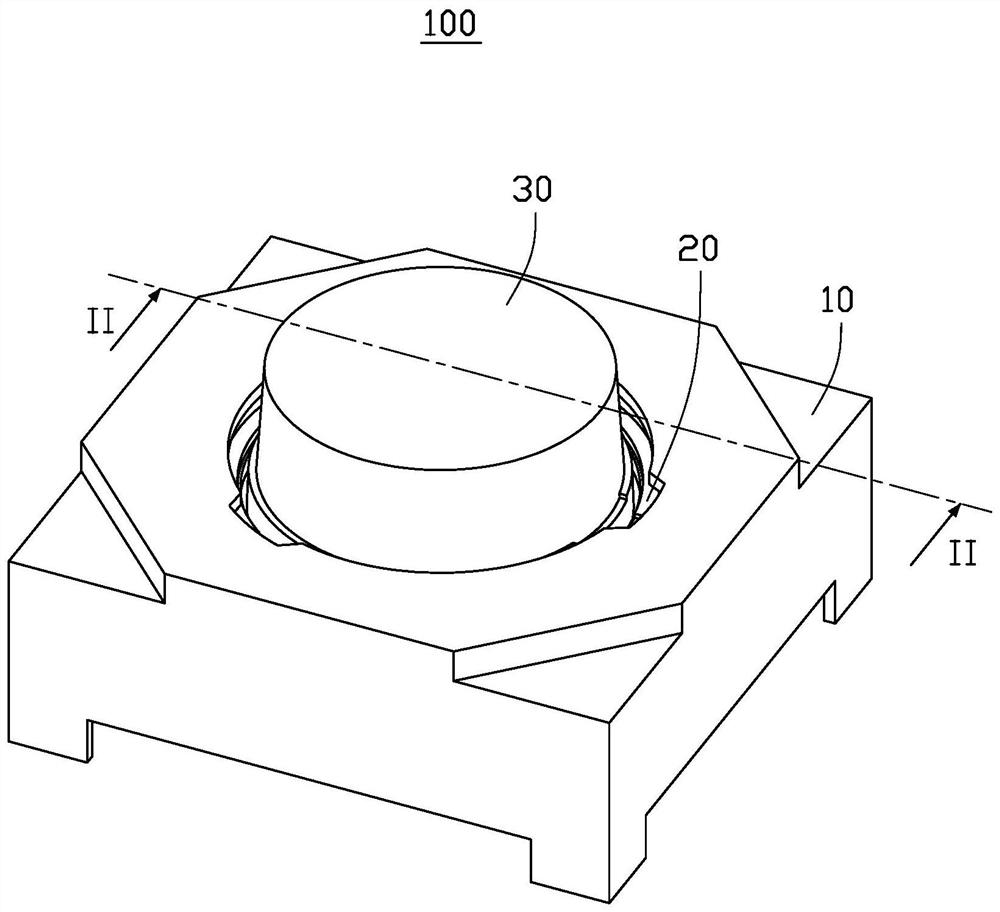

Voice coil motor carrier, voice coil motor, camera device, and lens mounting method

PendingCN112213839AProblems affecting tiltAvoid accessMountingsPropulsion systemsAdhesive glueEngineering

The invention provides a voice coil motor carrier, a voice coil motor, a camera device and a lens mounting method. The voice coil motor carrier is used for bearing a lens, the voice coil motor carriercomprises a shell and a bearing body, the shell is provided with a first opening, the bearing body is arranged in the shell, the bearing body is provided with a second opening, the peripheral side ofthe second opening extends in the axis direction of the second opening to form a limiting part, the limiting part is provided with a boss, the lens sequentially penetrates through the second openingand the first opening, the peripheral side of the lens is clamped in the limiting part, and the lens further abuts against the boss. A gap between the lens and the boss is filled with an adhesive layer. The voice coil motor carrier, the voice coil motor, the camera device and the lens mounting method effectively solve the problem that the inclination of the lens is influenced by uneven shrinkage of glue after constant-temperature curing, and also have the advantages of tight connection and miniaturization of the bearing body and the lens.

Owner:O FILM IMAGE TECH (GUANGZHOU) CO LTD

Coconut picking device

According to the coconut picking device, a crawling assembly and a cutting assembly are adopted, a plurality of supporting rods in an annular array are arranged on a supporting body, driving motors are installed at the ends of the multiple supporting rods, crawling wheels are arranged on output shafts of the driving motors, the surfaces of the multiple crawling wheels make contact with a trunk of a coconut tree, the lengths of the multiple supporting rods are adjustable, and the cutting assembly is arranged on the supporting body; the cutting assembly comprises a mechanical arm, one end of the mechanical arm is fixed to the supporting body, a cutting saw is fixedly installed at the other end of the mechanical arm, the supporting body serves as a driving motor carrier, and meanwhile a supporting structure can be formed on the outer side of a tree trunk in cooperation with a clamping structure formed by the circumferential array of the supporting rods; then the driving motor is used for driving the crawling wheels to achieve vertical crawling of the whole device on a tree trunk, the cutting assembly is used for achieving the purpose of cutting and picking, the device is simple in structure, manual crawling is not needed, and the picking efficiency and working safety are greatly improved.

Owner:LINGNAN NORMAL UNIV

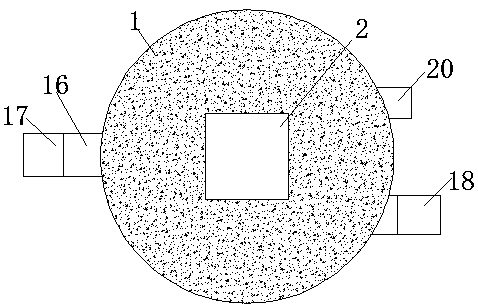

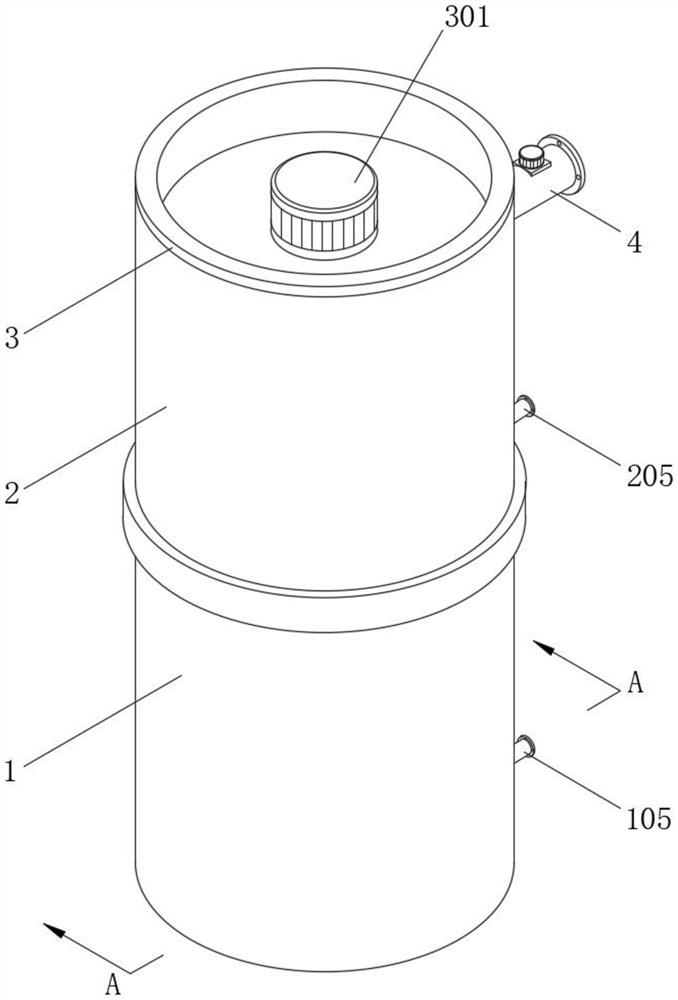

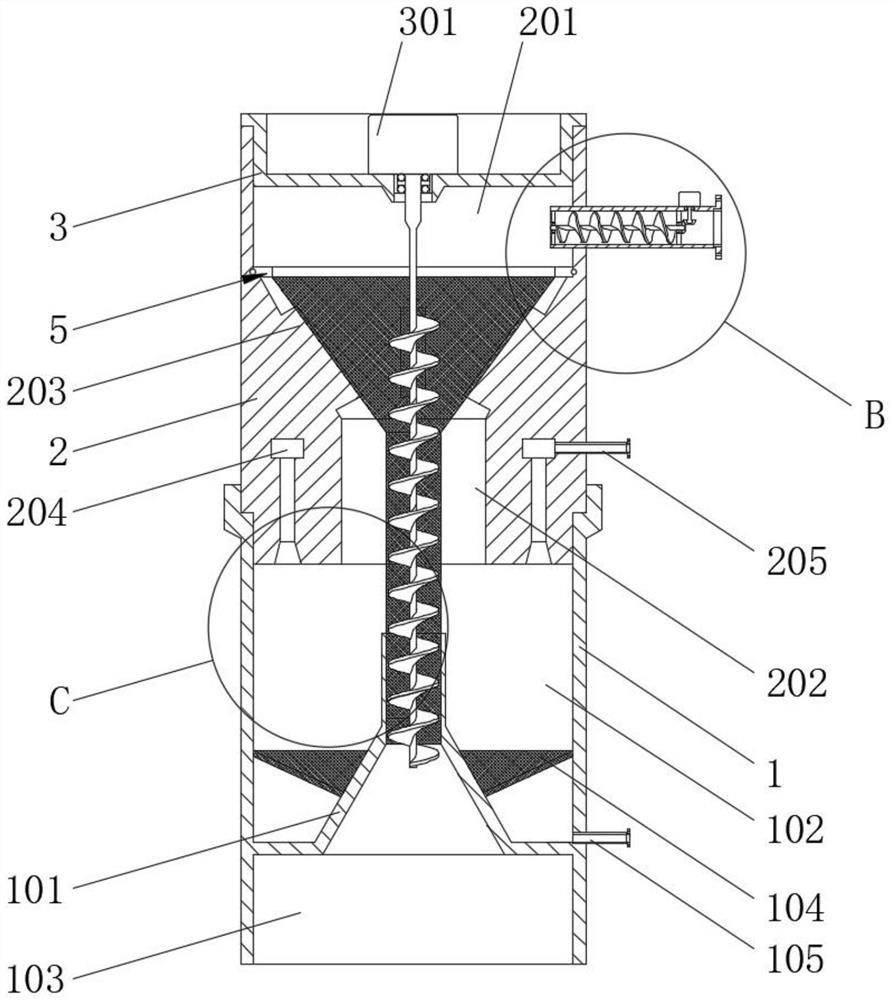

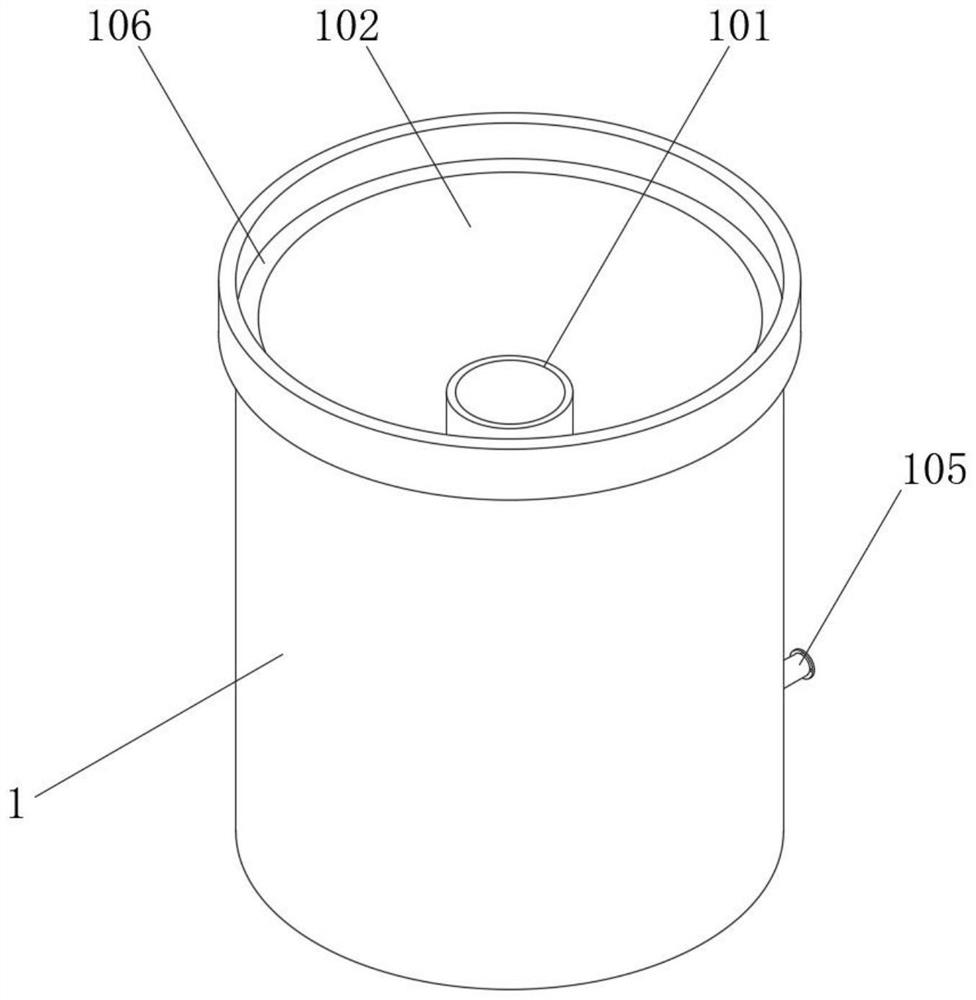

Desanding device for shale gas exploitation

PendingCN113274795AEasy to transportAchieve separationLiquid degasificationFluid removalThermodynamicsElectric machine

The invention discloses a desanding device for shale gas exploitation. The desanding device comprises a bearing box, a desanding box, a motor carrier disc, a feeding pipe and a sand filtering mechanism; the bearing box and the desanding box are both constructed to be cylindrical; the bearing box and the desanding box are matched in an inserted connection mode; and a set of reverse butt joint conical hoppers coaxial with the bearing box are constructed in the bearing box; the bearing box is divided into an upper drainage bin and a lower sand discharging bin through the reverse butt joint conical hoppers; the desanding box is installed above the bearing box; a feeding bin is formed above the desanding box; a funnel-shaped separation bin is formed below the desanding box; and the funnel-shaped separation bin is communicated with the feeding bin and the drainage bin of the bearing box; the motor carrier disc is installed on the top of the desanding box and seals the feeding bin; a set of grooves for installation of a first driving motor is formed in the upper end of the motor carrier disc; and a set of auger feeding rods are arranged at the bottom end of the first driving motor. The desanding device for shale gas exploitation is reasonable in structure, easily achieves desanding work of fracturing fluid, reduces the workload of follow-up equipment and is recommended to be widely used.

Owner:戴牛根

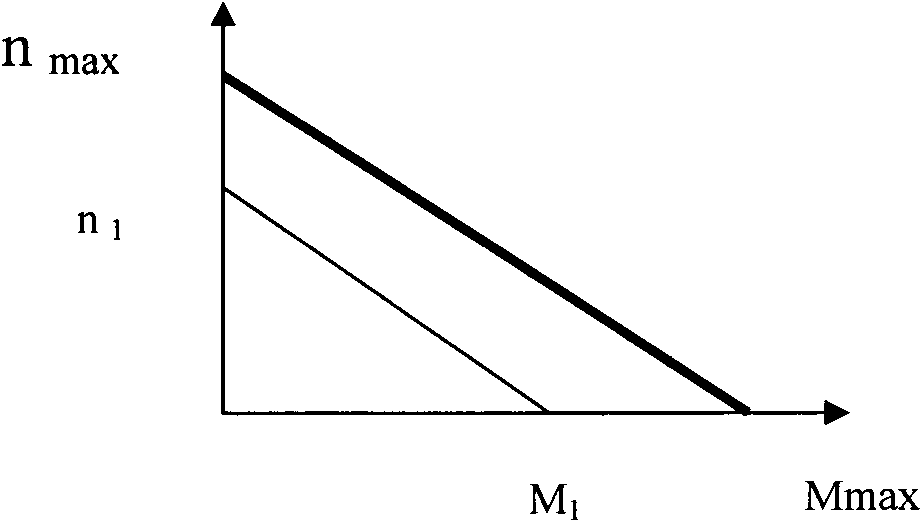

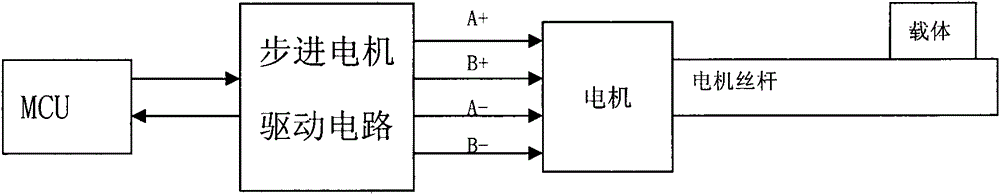

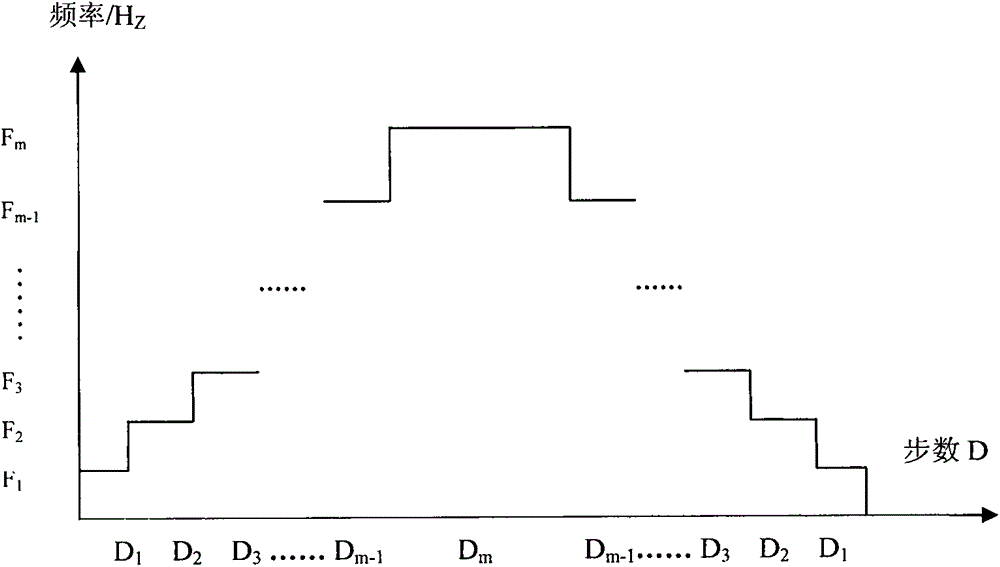

Method for adjusting speed of stepping motor in load state

InactiveCN104426442AFlexible adjustment of the number of stepsFlexible frequency adjustmentDynamo-electric converter controlStep numberDrive motor

The invention provides a method for adjusting speed of a stepping motor in a load state. Relation between the mass of a motor carrier and start signal frequency and carrier displacement speed of a driving motor is adjusted by a frequency-changing adjusting method. The method is characterized by comprising the following steps that at first, the step number Dn required to step by the stepping motor is calculated, and within the range that the stepping motor steps for D1 steps, stepping motor pulse is provided according to frequency F1 to brake a carrier; within the range that the stepping motor continuously steps for D2 steps, stepping motor pulse is provided according to frequency F2 to brake the carrier; by parity of reasoning, within the range that the stepping motor steps for Dm steps, stepping motor pulse is provided according to frequency Fmax to brake the carrier. The problem on the requirement on speed limitation required when the actual using time T0 is greater than time limit T is solved.

Owner:O NET COMM (SHENZHEN) LTD

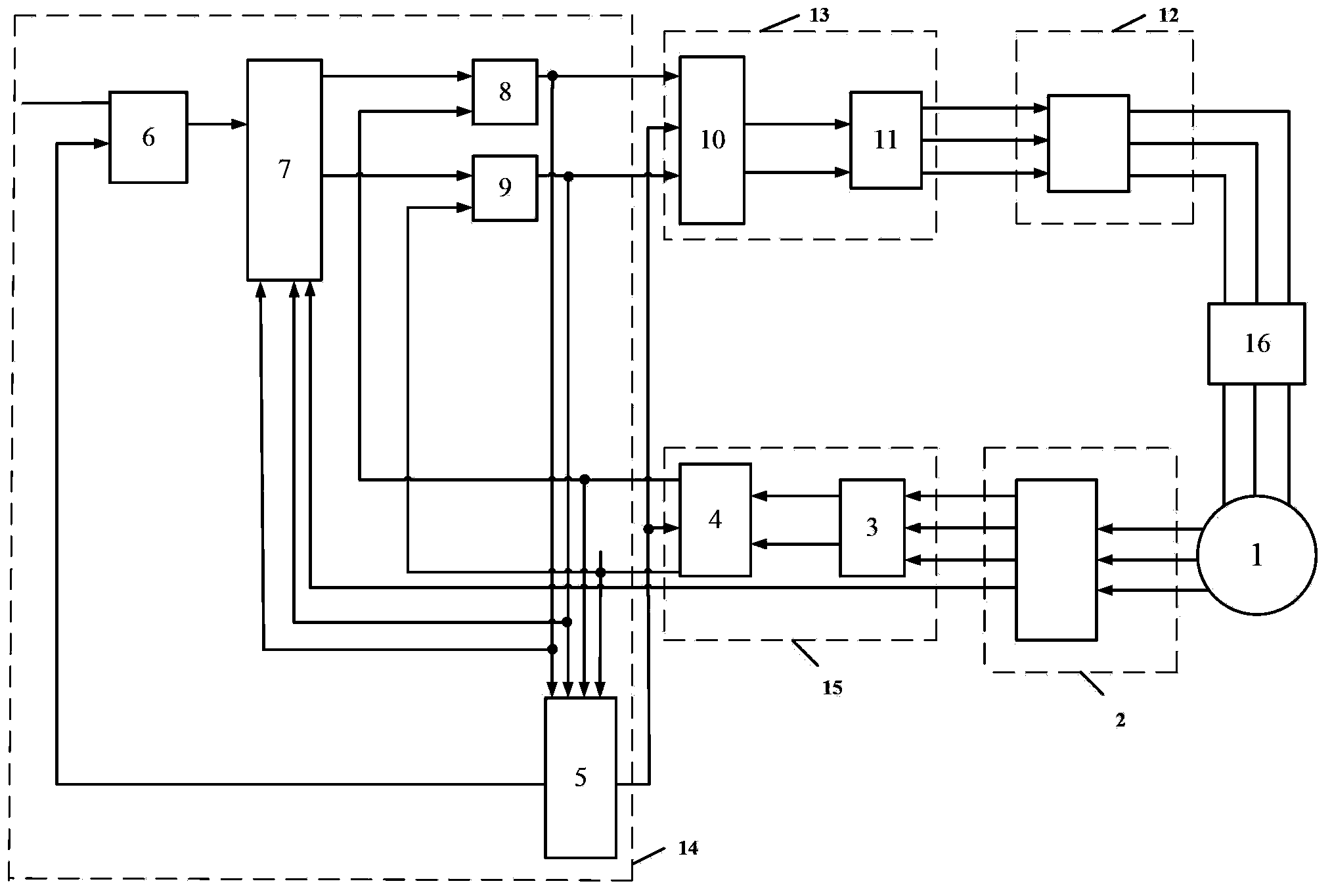

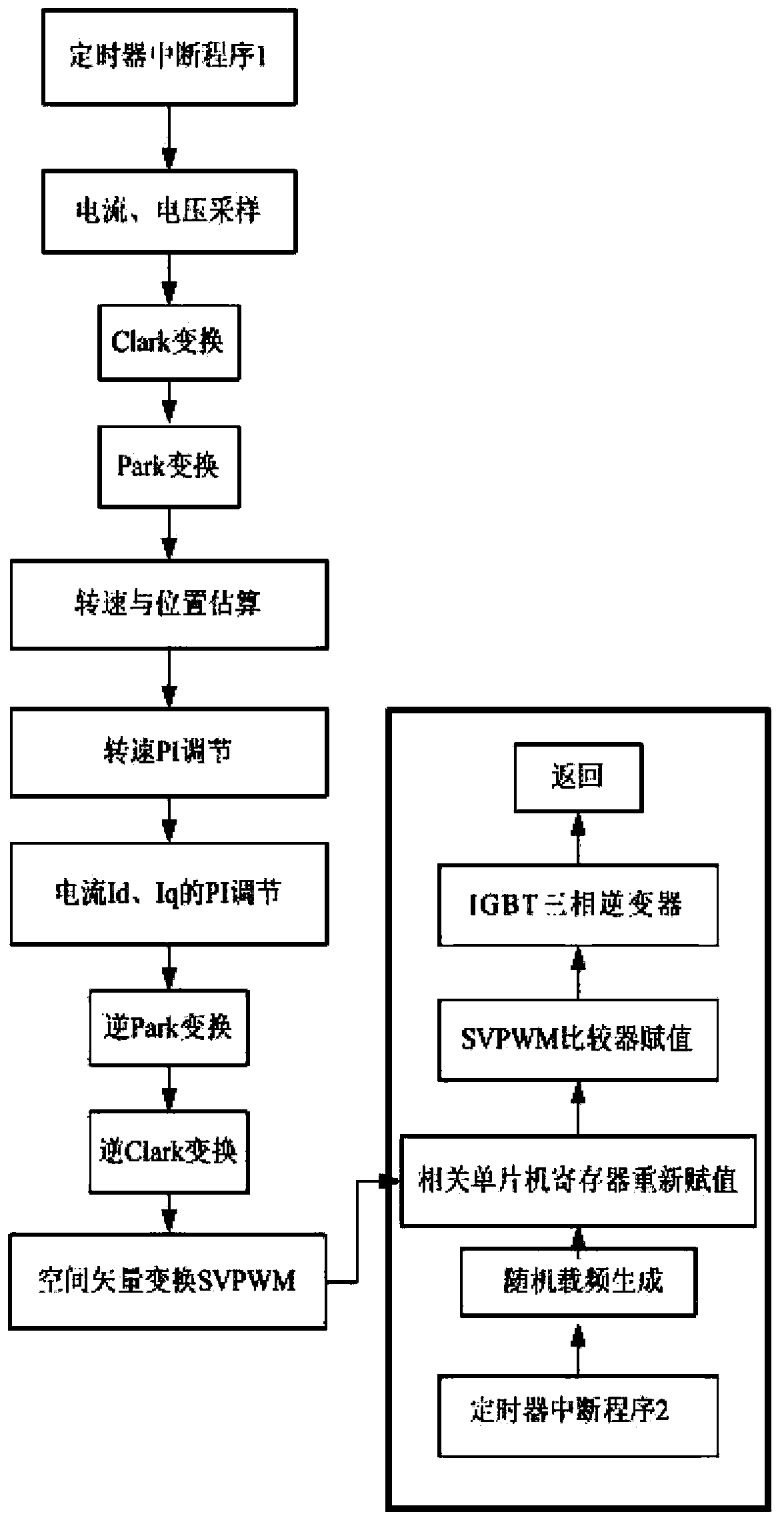

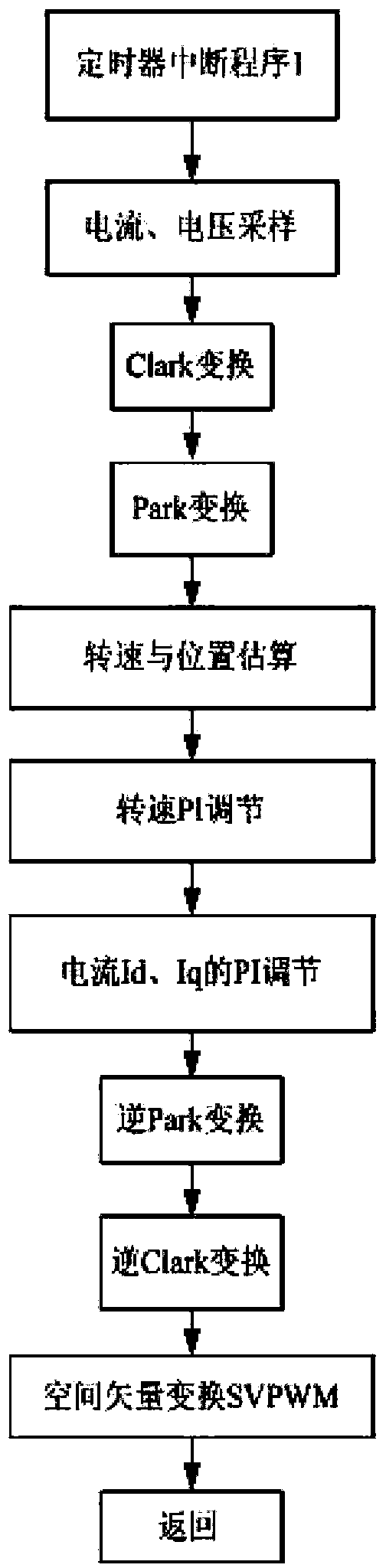

Variable carrier frequency motor controller

ActiveCN103414420ASimple internal structureImprove stabilityElectronic commutation motor controlVector control systemsControl vectorClosed loop

The invention relates to a variable carrier frequency motor controller. The variable carrier frequency motor controller comprises a motor vector control module, an analog-digital conversion module, a closed loop PI speed-regulating module, a space vector pulse width modulation module and a three-phase inverter, wherein the motor vector control module, the analog-digital conversion module, the closed loop PI speed-regulating module, the space vector pulse width modulation module and the three-phase inverter are electrically connected in sequence. A coordinate transformation module is arranged between the analog-digital conversion module and the closed loop PI speed-regulating module, and an inverse coordinate transformation module is arranged between the closed loop PI speed-regulating module and the space vector pulse width modulation module. The variable carrier frequency motor controller further comprises a random carrier frequency generating module, and the output end of the random carrier frequency generating module is respectively connected with the space vector pulse width modulation module and the motor vector control module electrically. By changing the motor carrier wave frequency in real time, the signal interference brought by turning on or turning off a driving module in a fixed period is reduced, and the motor control quality is improved.

Owner:HANGZHOU ZHOUJU ELECTRONICS TECHNOLOGICAL

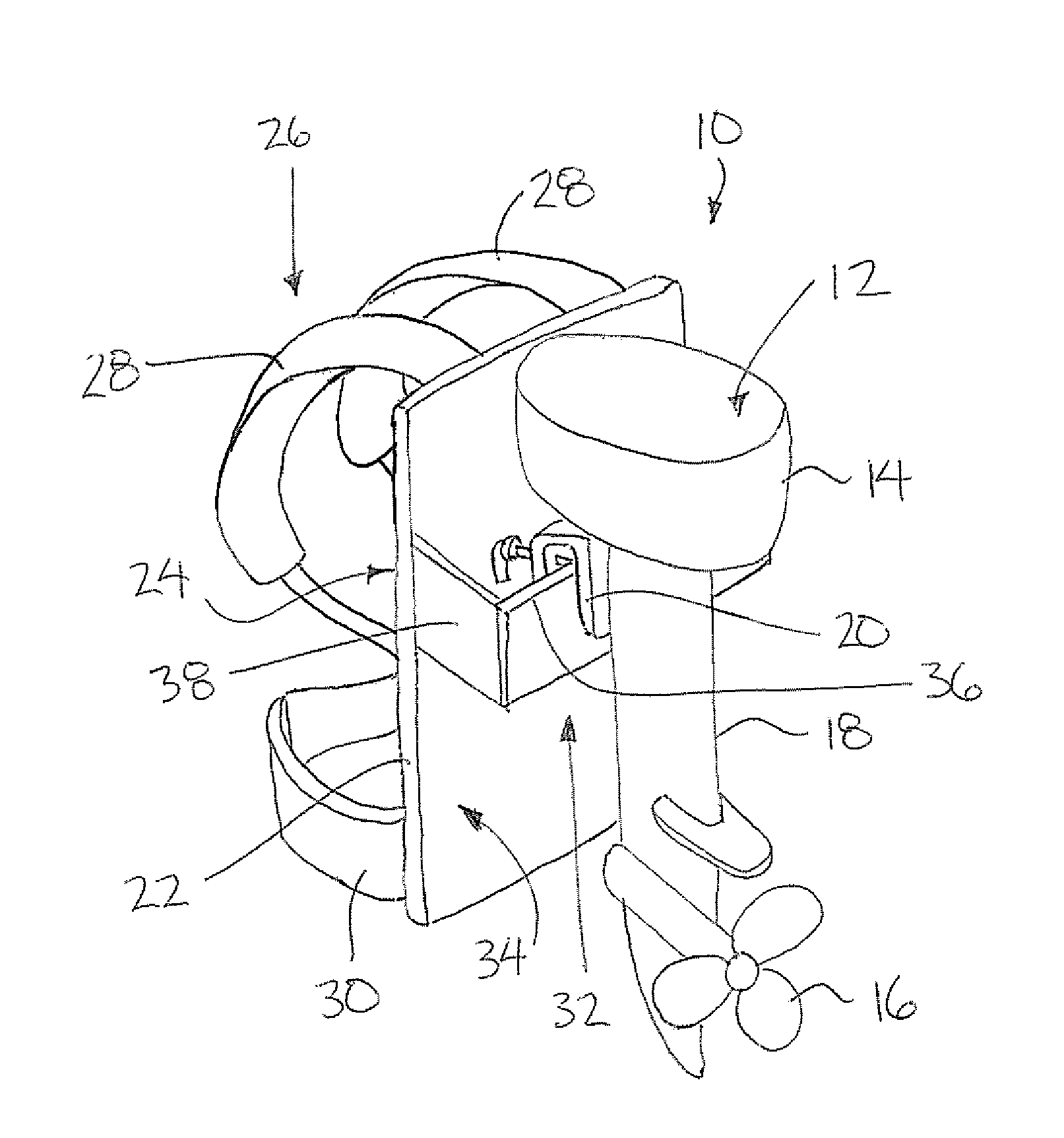

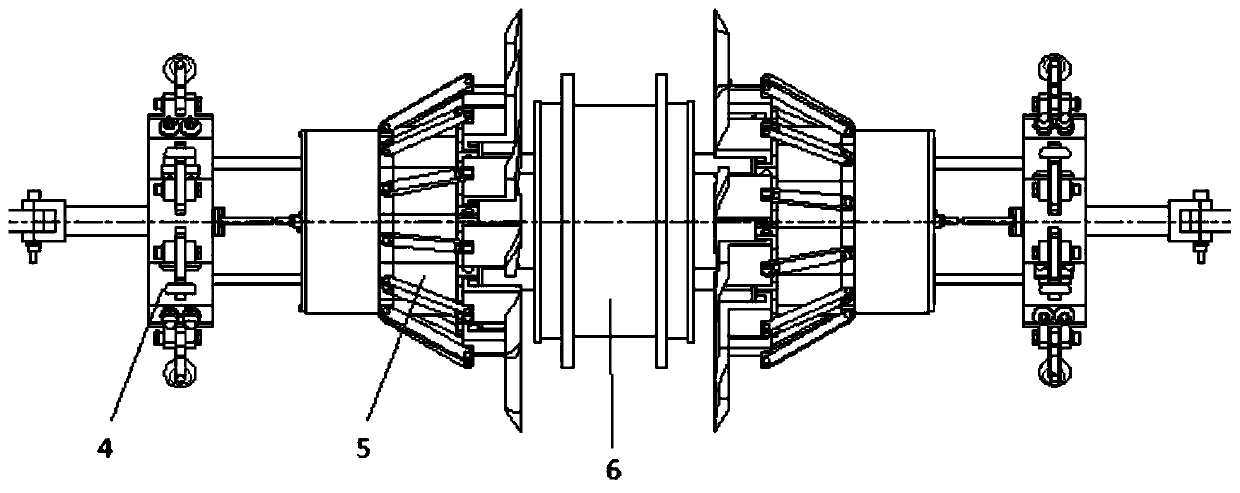

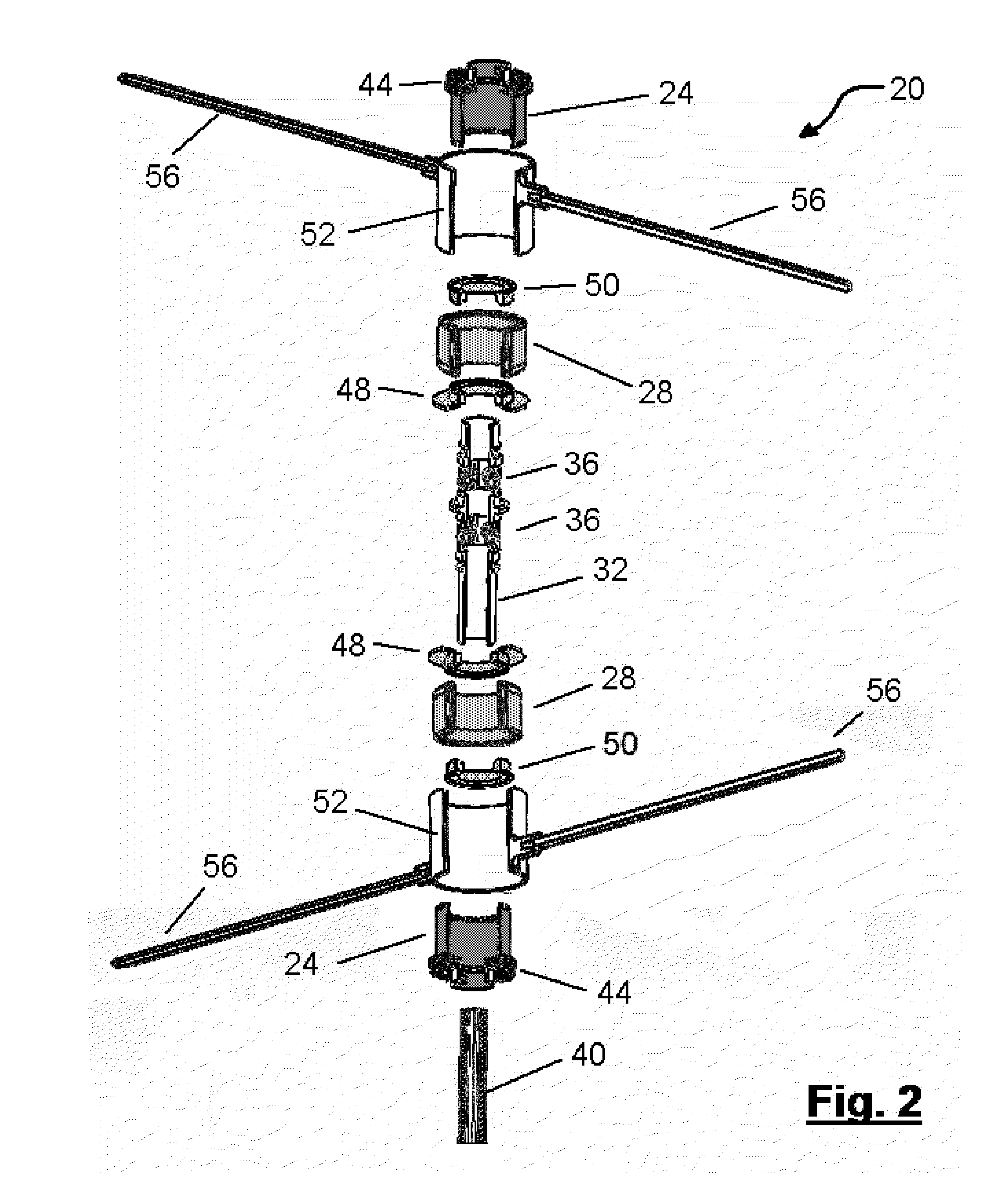

Coaxial direct drive system

A coaxial direct drive system includes at least two prime movers mounted to a motor carrier member about a common axis. Each prime mover includes a stator affixed to the motor carrier member, and each prime mover further includes a rotor which can rotate about the common axis. Each rotor has a driven member affixed to it, which rotates with the respective rotor, and to which driven objects, such as aero foil blades, etc. can be affixed. The motor carrier member can be directly mounted to an object to be propelled by the coaxial direct drive system, or can be hollow to receive a support mast which is mounted to the object to be driven. The driven objects can have different rotational senses, such that when the prime movers counter rotate, the driven objects generate trust in the same direction.

Owner:LIVINGSTON EDWARD

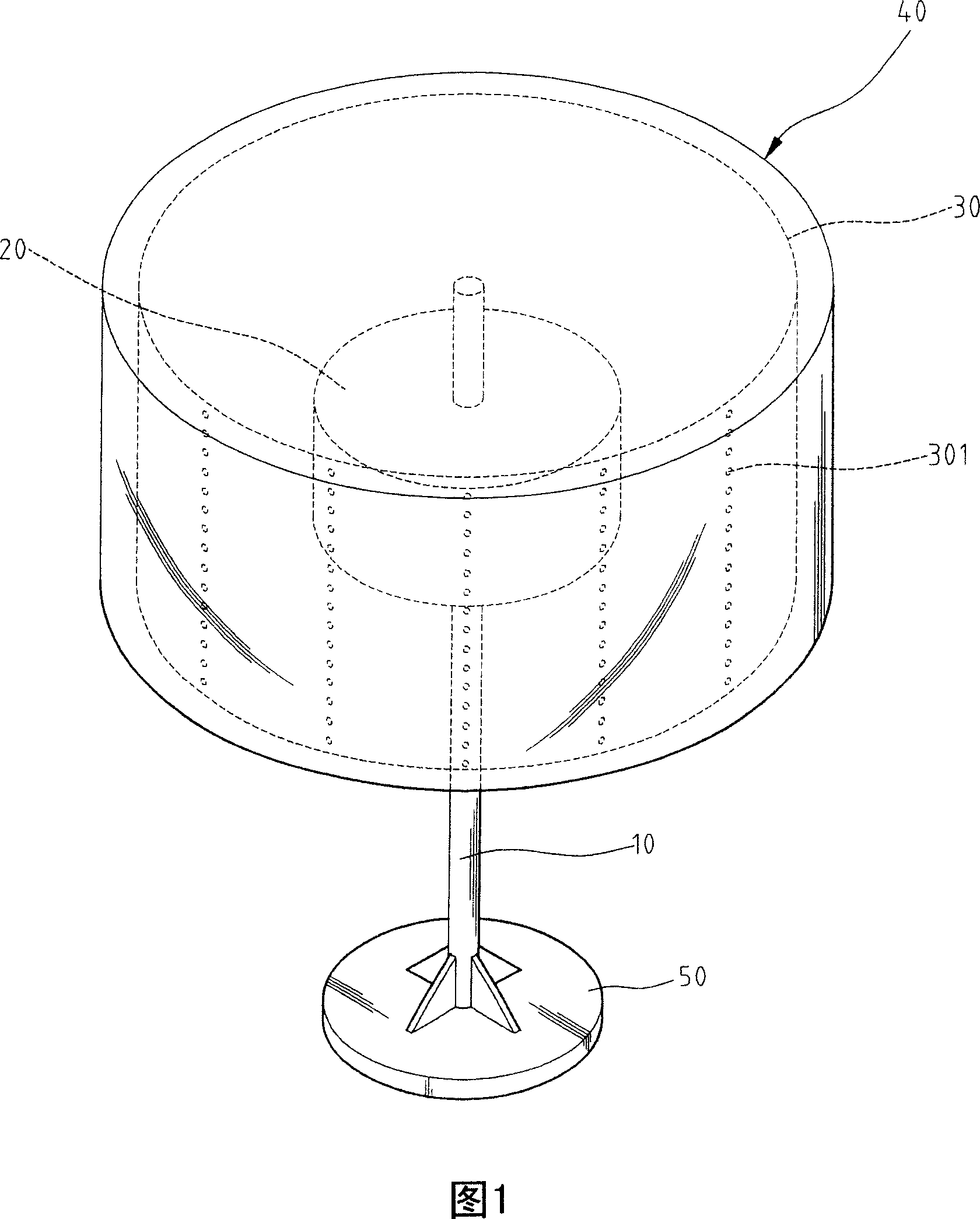

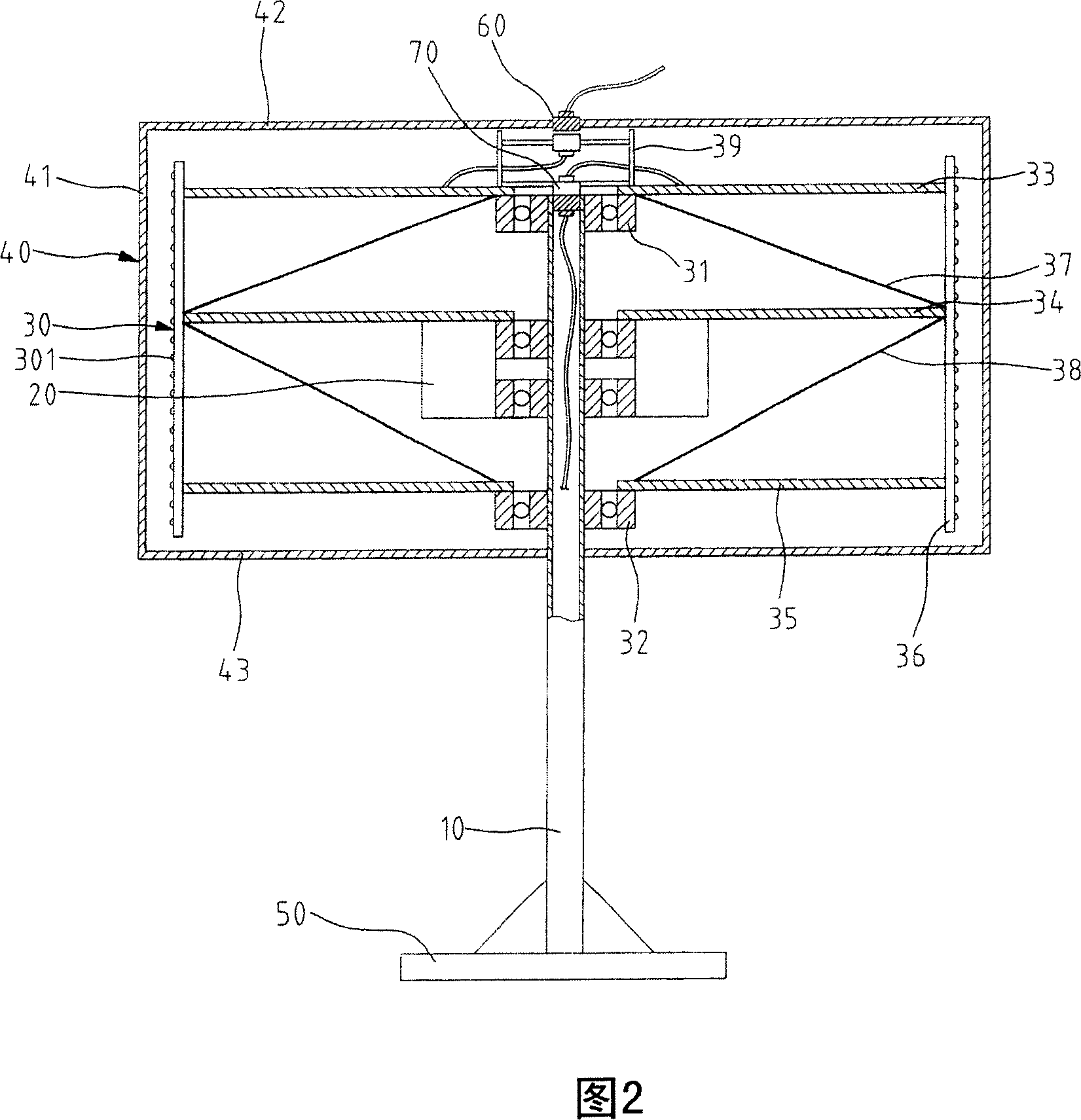

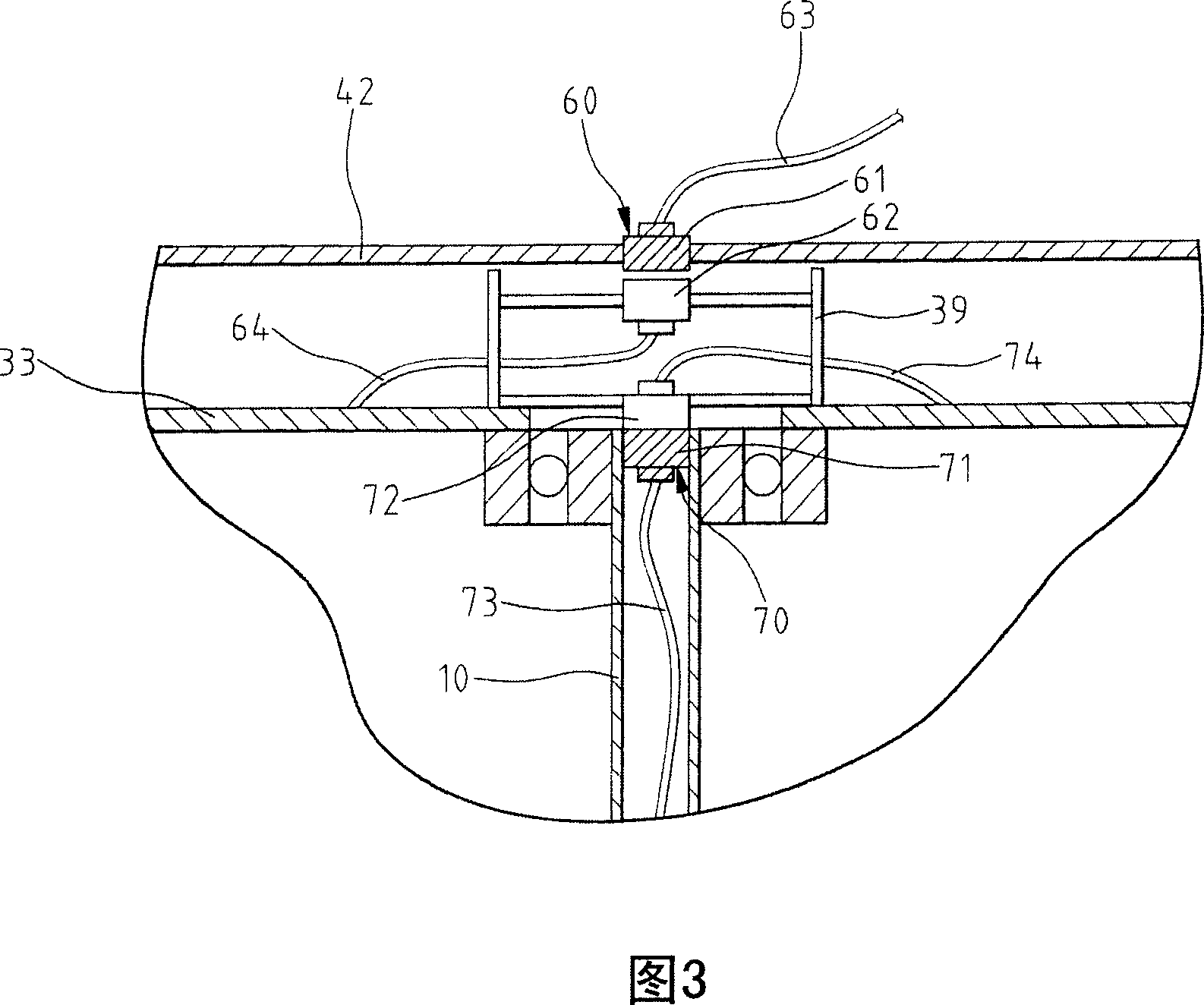

Cylindrical display screen

InactiveCN1971675AImprove efficiencyImprove stabilityStatic indicating devicesAdvertisingArray data structureMotor carrier

The invention relates to a revolving column form display driven directly by outward turning motor carrier. The column form display includes: a support dead axle; a motor which is an outward turning motor is rested and fixed on the support dead axle; a rotation carrier which is connected with the motor, rotated by the rotation of motor and at least one lightening array are mounted on the surface of the rotation carrier; a protection frame which covers the rotation carrier and is mounted on the support dead axle. In the invention the motor and the rotation carrier rotates with same axle to improve the stability of rotation carrier, and make the display show pictures with great quantity.

Owner:DYNASCAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com