Camera module and motor thereof

A camera module and motor technology, applied in the field of cameras, can solve the problems of large module size, affecting the screen ratio of small electronic devices, and screen size reduction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present invention provides a motor of a camera module, which is used to drive the movement of the lens to achieve the purpose of focusing, and can be applied to small electronic devices, such as mobile phones, tablets, and smart watches.

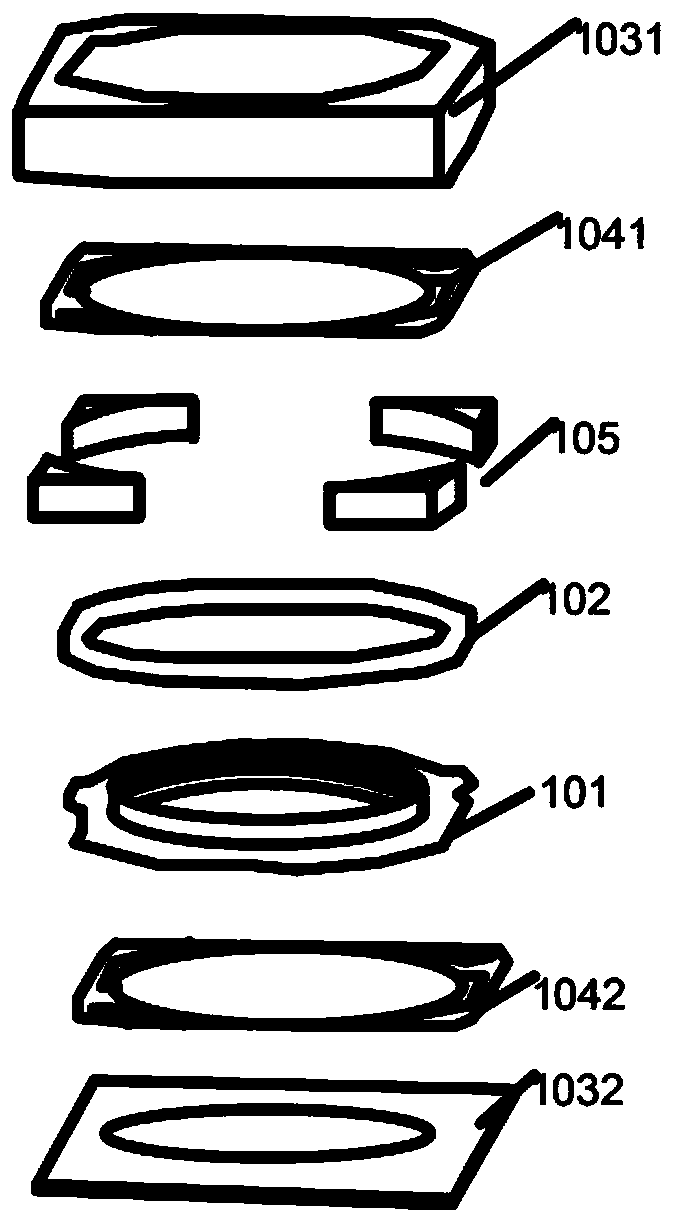

[0035] Such as figure 1 As shown, the motor of the camera module includes: a motor carrier 101, which is used to carry a multi-layer lens; a coil 102, which is sleeved outside the motor carrier; , the other end is fixed inside the casing; the magnet 105 surrounds the coil 102 and is fixed inside the casing 103, the magnet 105 is used to generate a magnetic field; wherein, when the coil 102 is energized, the coil 102 can Under the action of the magnetic field, it moves perpendicular to the direction of the magnetic field to achieve the purpose of focusing.

[0036] Since the motor is equipped with a motor carrier 101, the motor carrier 101 directly carries the lens, and the existing lens barrel structure for carryi...

Embodiment 2

[0049] Based on the same inventive concept, an embodiment of the present invention also provides a camera module, which is applied to small electronic devices, such as mobile phones, tablets, and smart watches.

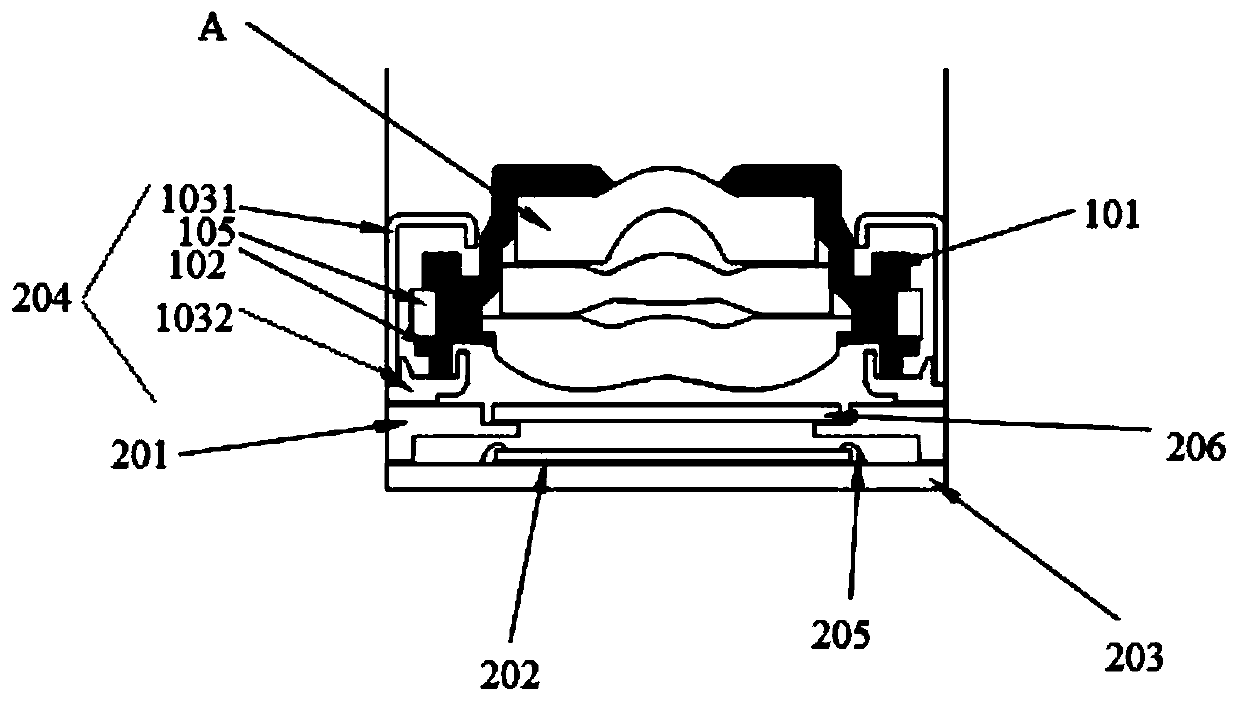

[0050] Such as figure 2As shown, the camera module includes: a bracket 201, a photosensitive chip 202, a circuit substrate 203, and any of the above-mentioned motors 204; The bottom of the bracket 201 is adhered to the circuit substrate 203 . These adhesions are fixed by glue adhesion in particular.

[0051] The motor 204 includes: a motor carrier 101, which is used to carry a multi-layer lens A; a coil 102, which is sleeved outside the motor carrier 101; a casing, which is sleeved outside the coil 102; a supporting elastic piece, one end of which is connected to the motor Carrier 101, the other end of which is fixed inside the housing; magnet 105, which surrounds the coil 102 and is fixed inside the housing for generating a magnetic field; electrifying the coil 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com