Environmental-friendly biomass fuel particle forming device

A biomass fuel and granule molding technology, which is applied in the direction of biofuel, waste fuel, raw material extrusion granulation, etc., can solve problems such as machine jamming, achieve the effects of reducing costs, reducing labor intensity, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

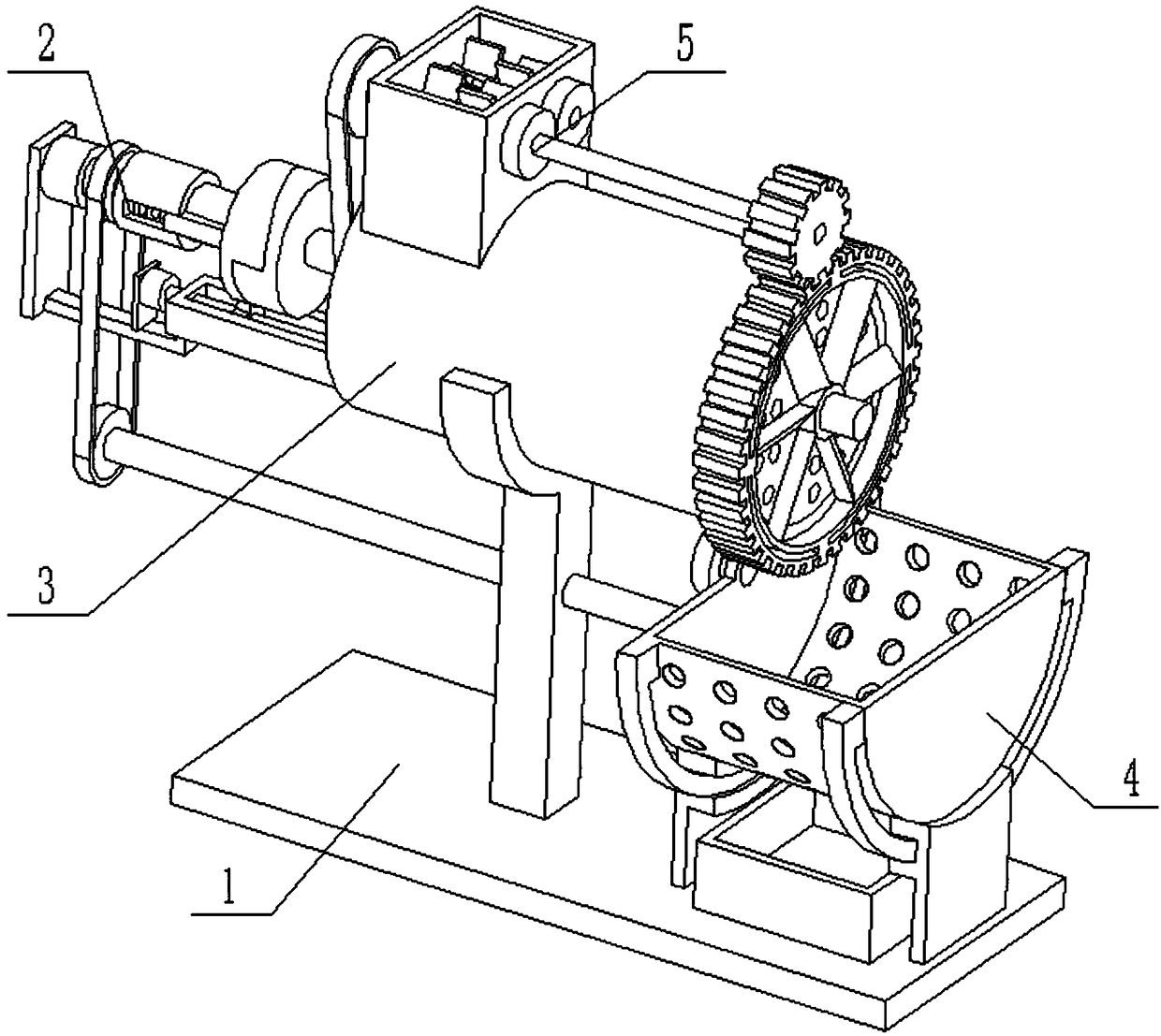

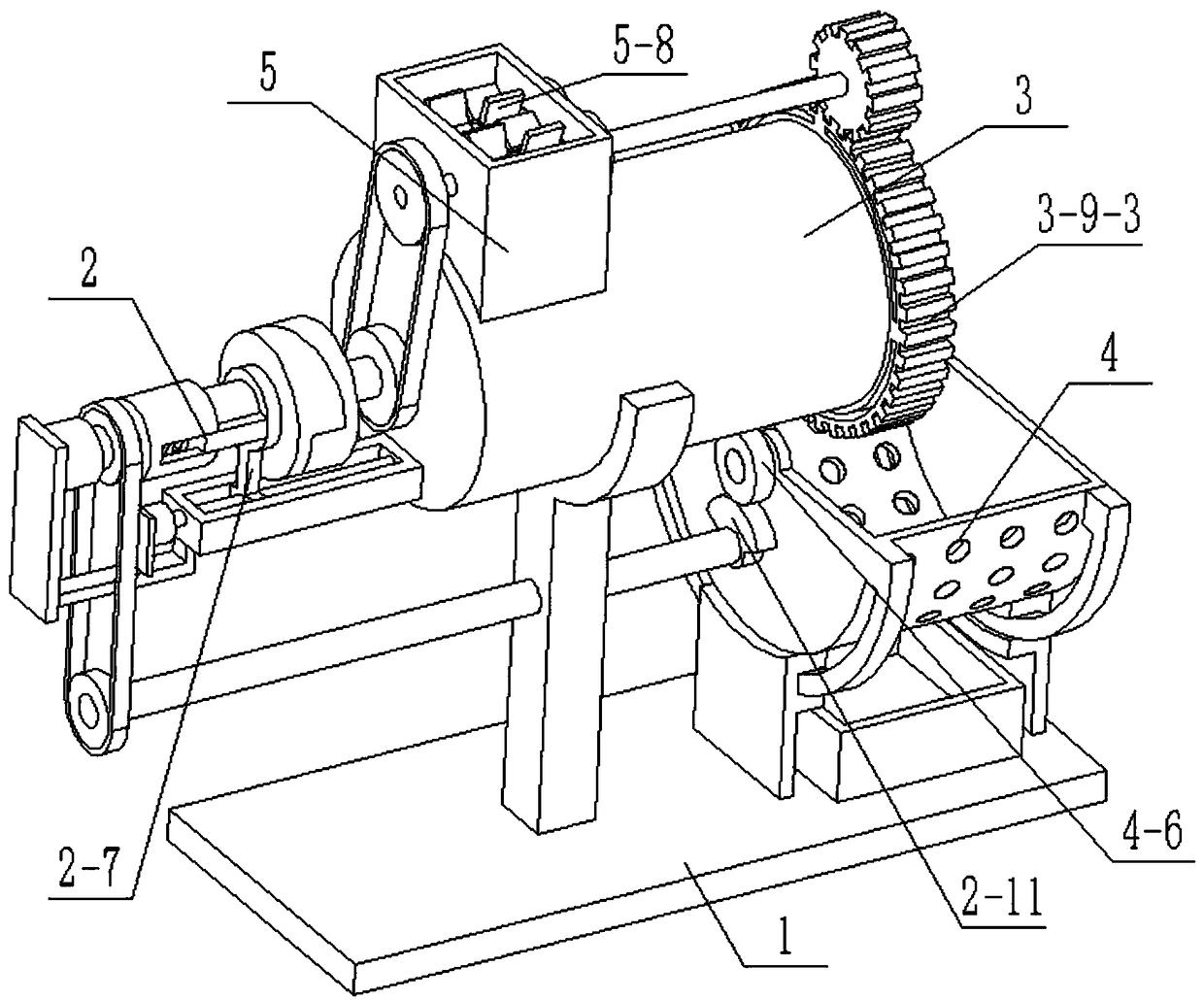

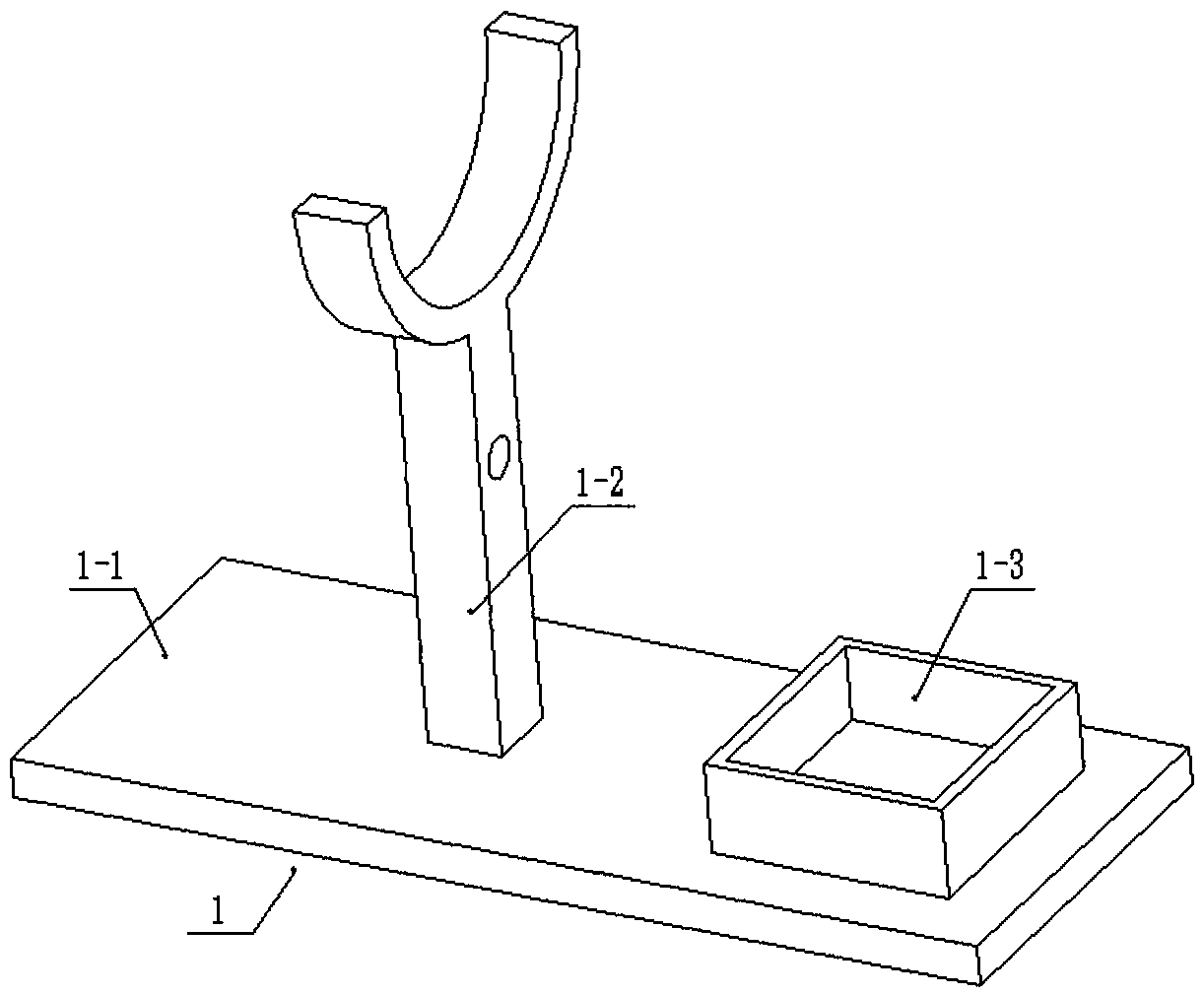

[0036] Combine below Figure 1-17Describe this embodiment, an environment-friendly biomass fuel particle forming device, including a base 1, a power transmission wheel 2, a feeding cylinder 3, a particle forming screen seat 4 and an anti-clogging feeding pipe 5, and the base 1 includes a bottom plate 1 -1. The barrel frame plate 1-2 and the collecting box 1-3; the barrel frame plate 1-2 is fixedly connected to the bottom plate 1-1, and the collecting box 1-3 is placed on the bottom plate 1-1;

[0037] The power transmission wheel 2 includes a motor I2-1, a central shaft 2-2, a shaft sleeve 2-3, a telescopic shaft 2-4, a compression spring 2-5, a power transmission wheel I2-6, a dial 2-7, Driving pulley 2-8, driven pulley 2-9, drive shaft 2-10, incomplete gear 2-11 and motor frame I2-12; motor I2-1 is fixedly connected to motor frame I2-12, and the central shaft One end of 2-2 is connected to the output shaft of the motor I2-1 through a coupling, the central shaft 2-2 has axia...

specific Embodiment approach 2

[0040] Combine below Figure 1-17 To illustrate the present embodiment, the feeding cylinder 3 also includes a drive pulley 3-10, the drive pulley 3-10 is fixedly connected to the rotating shaft 3-2, the drive pulley 3-10 has axial positioning, and the drive pulley 3-10 -10 is located between the rotating shaft 3-2 and the barrel 3-1.

[0041] The described a kind of environment-friendly biomass fuel particle forming device also includes an anti-clogging feeding pipe 5, and the described anti-clogging feeding pipe 5 includes a feeding seat 5-1, a transmission shaft 5-2, and a transmission pulley 5-3 , driving gear 5-4, driving gear 5-5, driven gear 5-6, driven shaft 5-7 and stirring blade 5-8; transmission shaft 5-2, driving pulley 5-3, driving gear 5-4 Both coincide with the axes of the driving gear 5-5, and both have axial positioning, and both the axes of the driven gear 5-6 and the driven shaft 5-7 coincide with each other, and both have axial positioning, and the feeding...

specific Embodiment approach 3

[0044] Combine below Figure 1-17 To illustrate this embodiment, the shearing cutter head 3-9 includes an outer circular knife rest 3-9-1, a rib plate 3-9-2, a ring gear 3-9-3, and a cutting knife 3-9-4 And inner circular knife rest 3-9-5; Outer circular knife rest 3-9-1, ring gear 3-9-3 and inner circular knife rest 3-9-5 are all coaxial with rotating shaft 3-2, And have axial positioning, between the right end of inner circular knife rest 3-9-5 and outer circular knife rest 3-9-1, be fixedly connected with a plurality of cutting knives 3-9-4, inner circular knife rest 3 -9-5 clearance fit on the rotating shaft 3-2, the left end of the outer circular tool rest 3-9-1 is connected to the cylinder 3-1 through bearings with seats, and the ring gear 3-9-3 passes through multiple ribs The plate 3-9-2 is fixedly connected to the outer ring of the outer circular knife holder 3-9-1, and the ring gear 3-9-3 is engaged with the driving gear 5-4 for transmission; the left end face of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com