Assembling method based on multiple groups of optical lenses forming motor optical assembly

An optical lens and assembly method technology, applied in electrical components, color TV parts, TV system parts and other directions, can solve the problems of ignoring the assembly error of the optical lens and the carrier, vignetting and blurring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

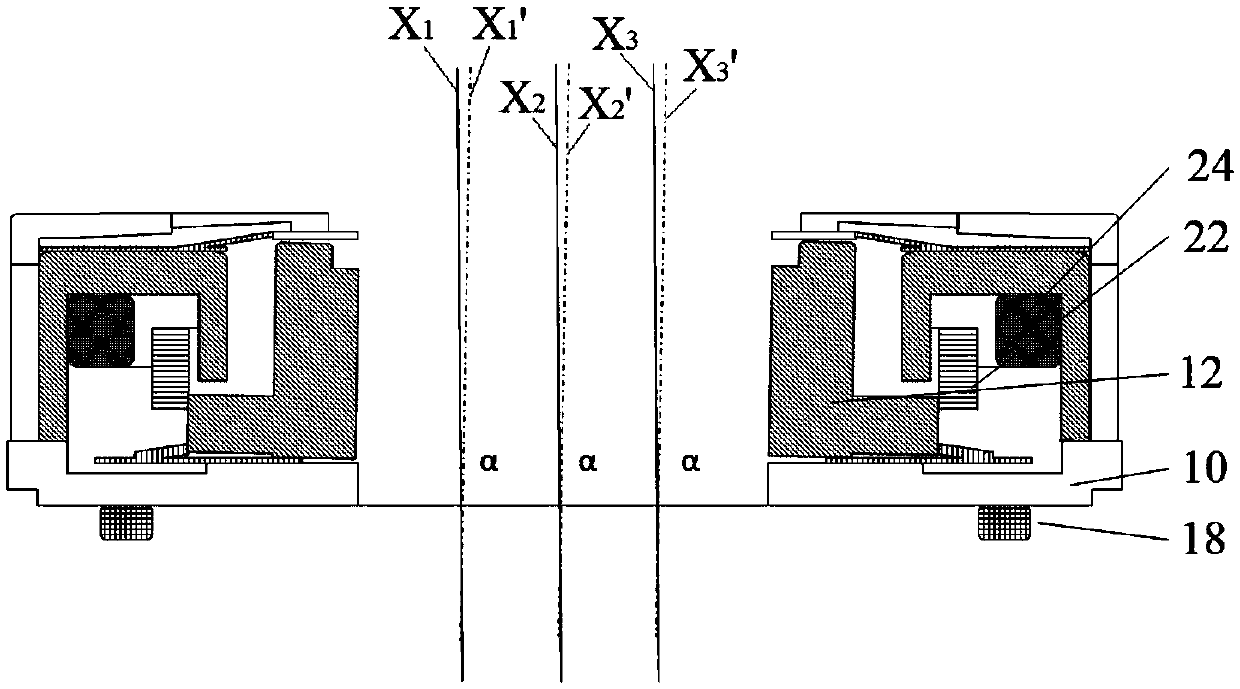

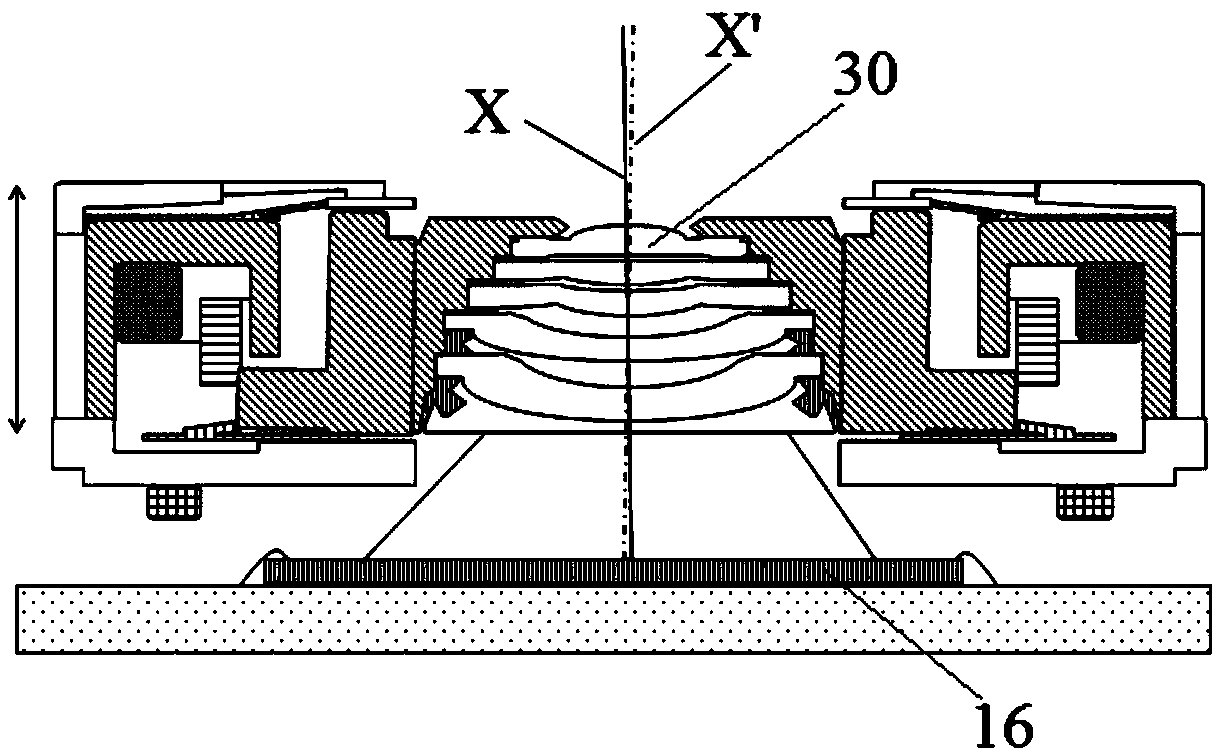

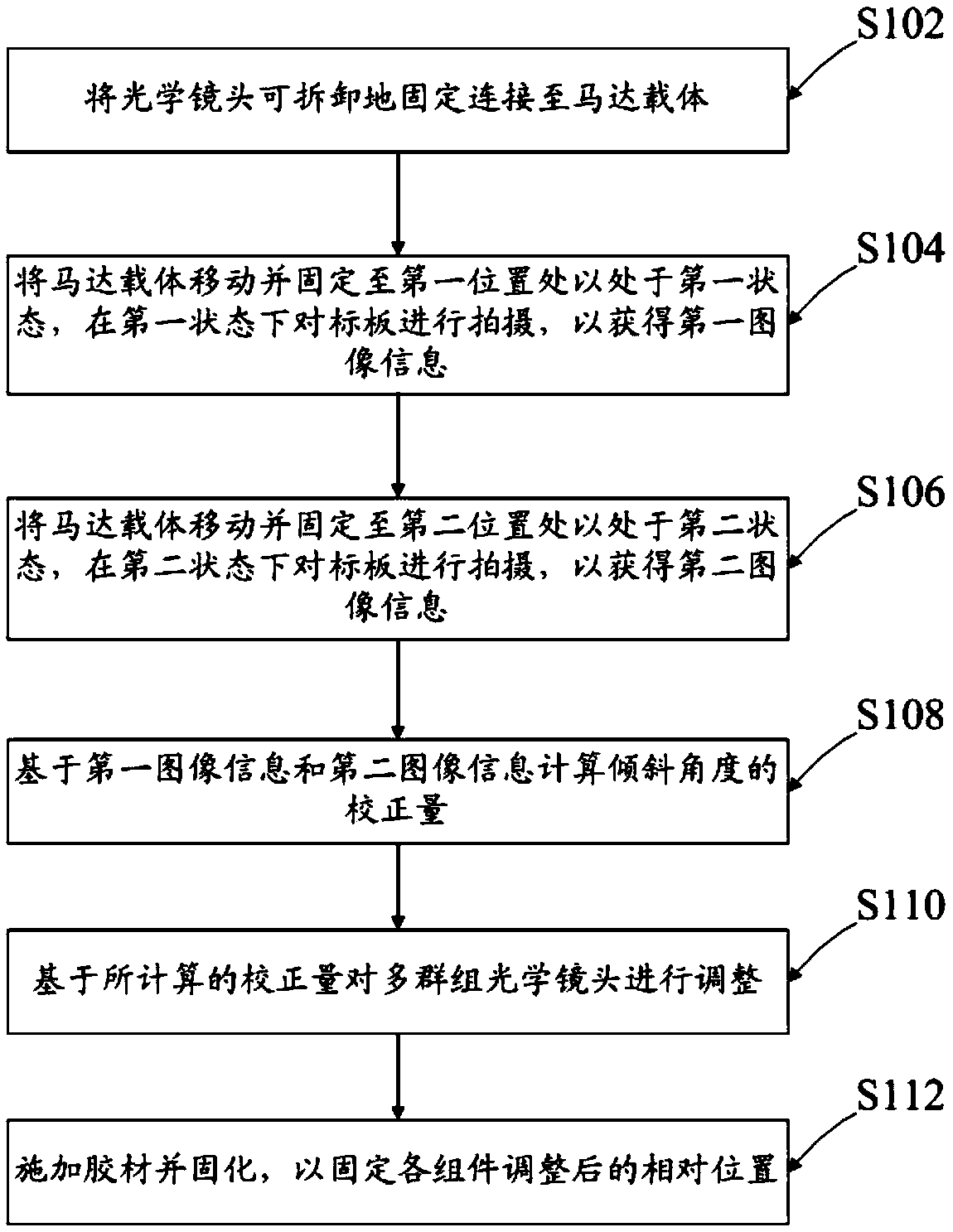

[0047] Such as image 3 As shown, in step S102 , the optical lens 30 is detachably fixedly connected to the motor carrier 12 . According to an exemplary embodiment of the present application, for example, the static tilt of the motor can be adjusted. In this case, there is no need to conduct a power test on the motor, only to test the rest position of the motor under different strokes. For example, it is possible to limit the position of the motor at different strokes (for example, use a jig for positioning). According to another exemplary embodiment, the distance from the target plate 16 to the camera test module can also be adjusted by using an existing height-adjustable bracket. For example, but not limited to, the method for testing a modular motor through MTF curves disclosed in Patent Application No. 201310063935.X.

[0048] After the optical lens 30 is installed in the motor carrier 12, in step S104, the motor carrier 12 can be moved and fixed to the first position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com