Desanding device for shale gas exploitation

A shale gas and sand box technology, which is applied in the fields of fluid production, earthwork drilling, and liquid degassing, etc., can solve problems such as valve erosion, blockage of separator drainage pipelines, and complete removal of sand removers, thereby reducing Influence and burden reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

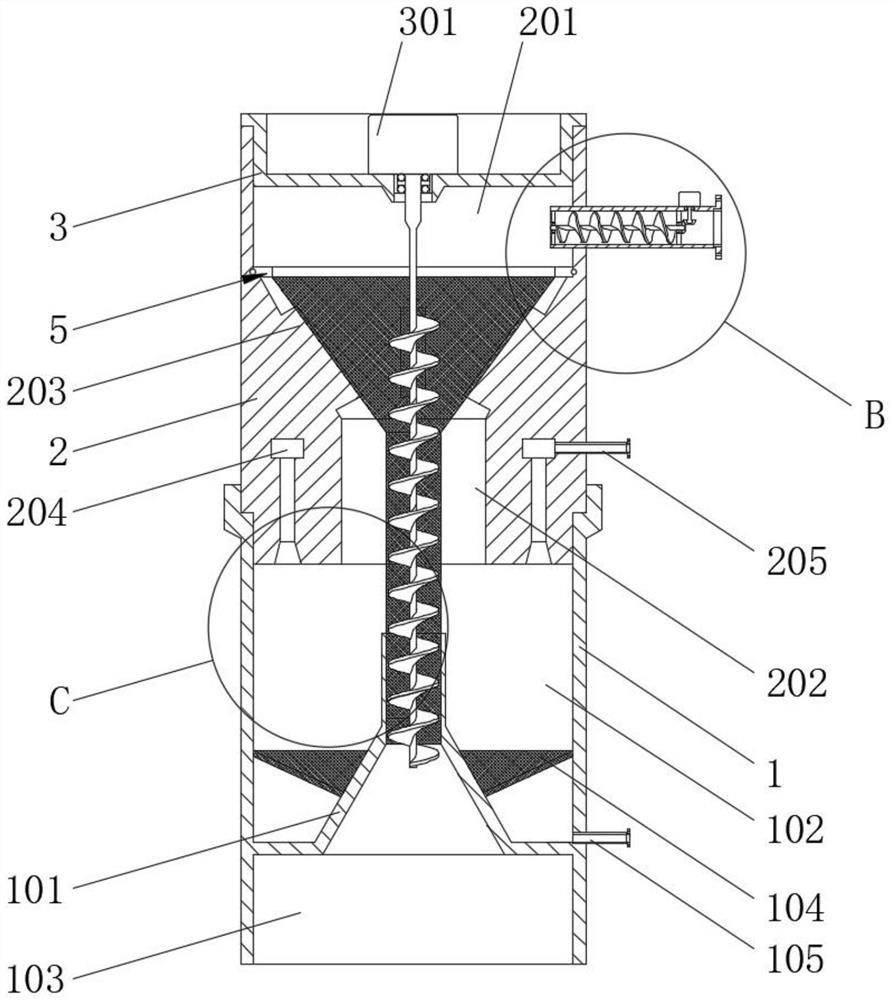

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

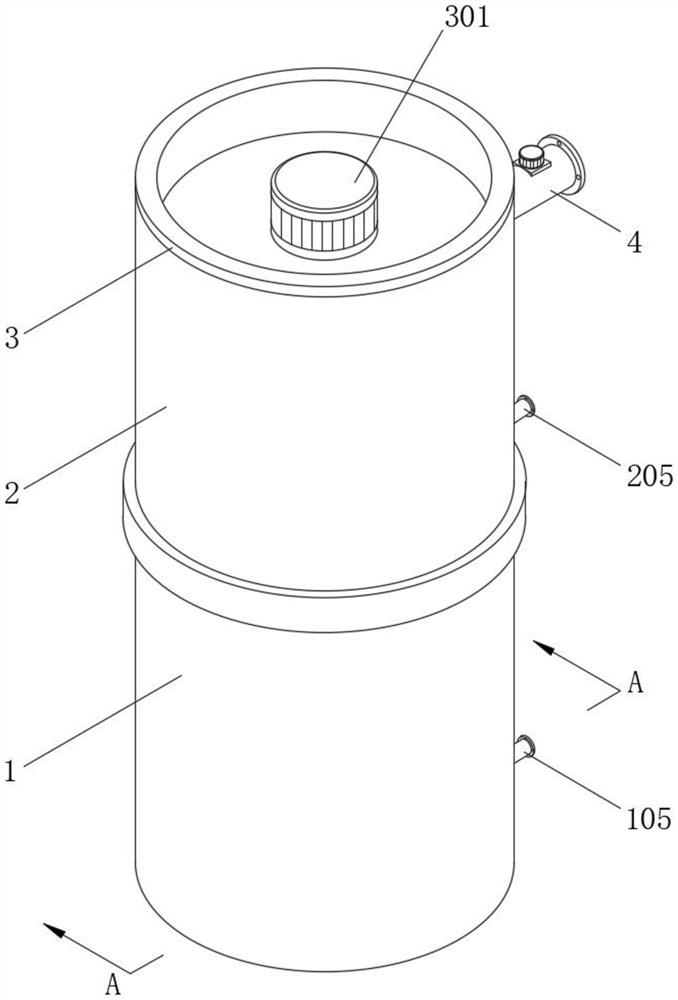

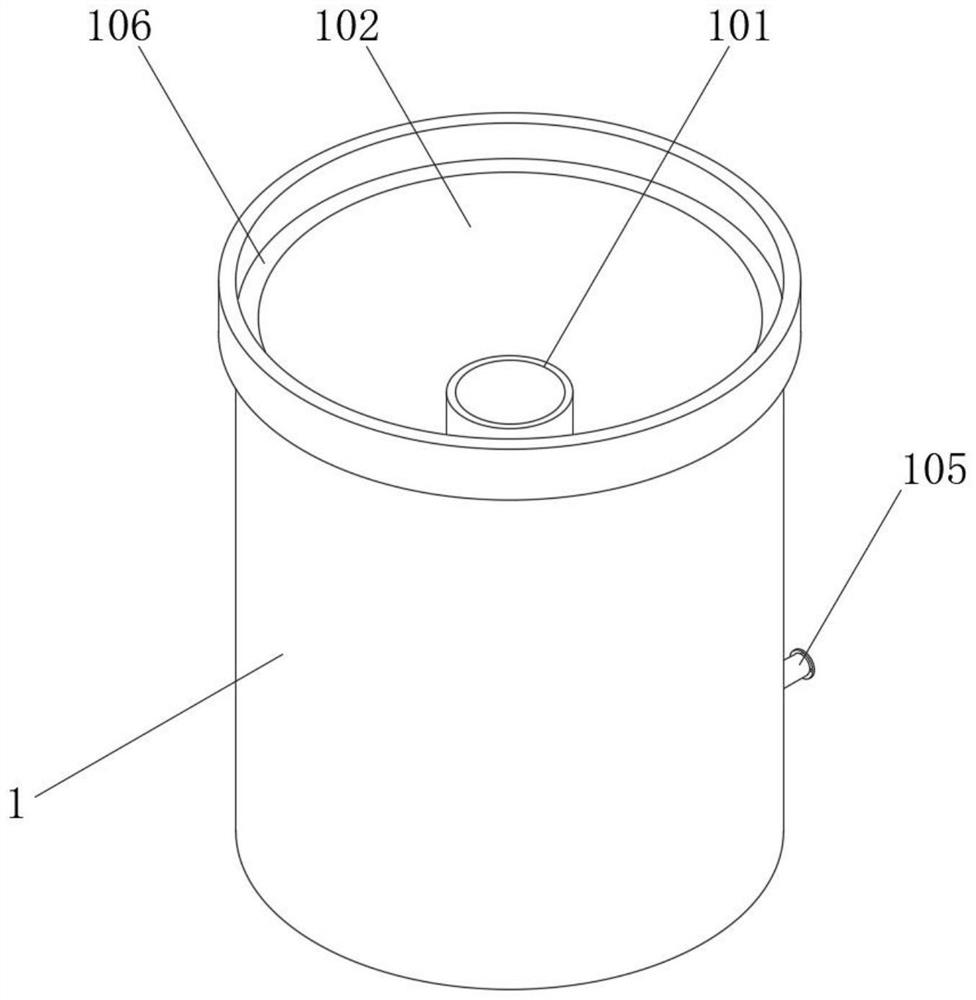

[0025] The present invention provides such Figure 1-6 The sand removal device shown for shale gas development includes a bearing box 1, a sand removal box 2, a motor carrier plate 3, a feed pipe 4 and a sand filter mechanism 5;

[0026] Both the carrying box 1 and the sand removal box 2 are cylindrical in shape, and the carrying box 1 and the sand removal box 2 are plugged and matched. The above carrying box 1 is constructed with a set of reversely docked conical buckets coaxial with the carrying box 1 101, the above-mentioned reverse docking conical bucket 101 divides the bearing box 1 into the upper drainage bin 102 and the lower sand discharge bin 103, the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com