Method for adjusting speed of stepping motor in load state

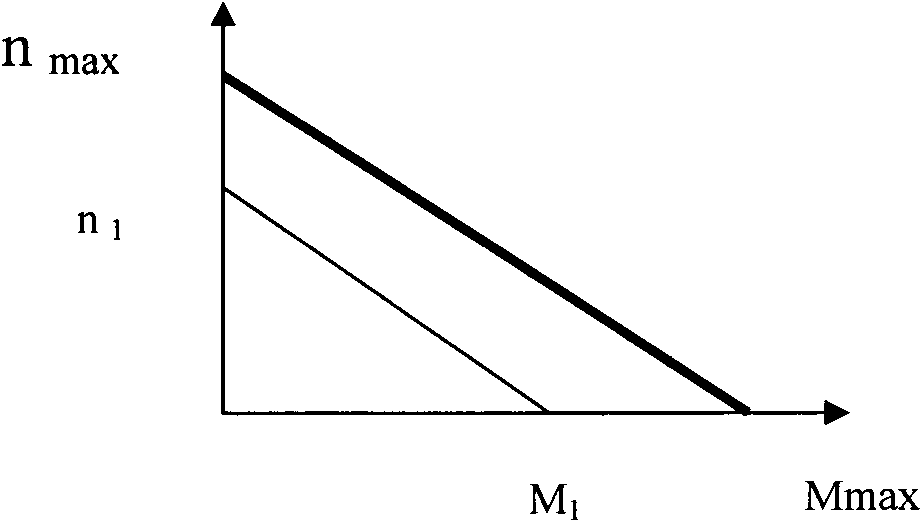

A stepping motor, speed adjustment technology, applied in the direction of motor generator control, electrical components, control systems, etc., can solve the problems of low starting speed, braking limit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method for adjusting the speed of a stepping motor under load according to the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

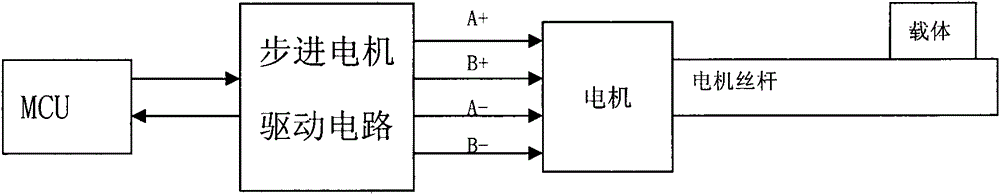

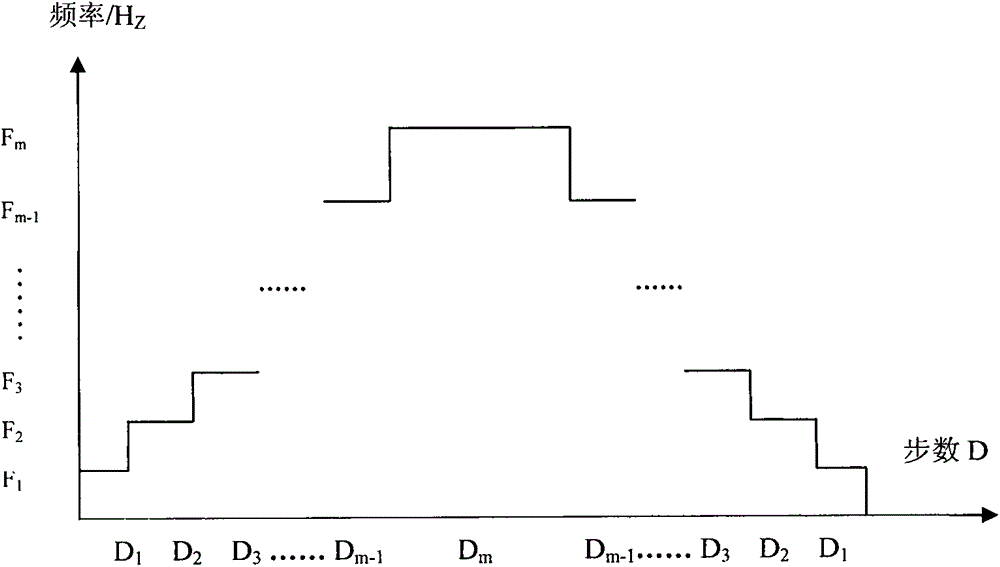

[0014] The present invention uses a frequency conversion adjustment method to adjust the relationship between the quality of the motor carrier, the signal frequency F for driving the motor, and the carrier displacement speed, thereby increasing the carrier displacement speed of the motor with the carrier.

[0015] Taking the two-phase stepping motor in the above background technology as an example, the operation method of frequency conversion regulation will be described in detail as follows. In the adjustment process, choose to use frequency conversion adjustment to accelerate the stepper motor according to the actual time used, where F max Set to the maximum starting frequency of the stepper motor itself.

[0016] Use the feedback system to calculate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com