Robot device for workpiece drilling

A robot and workpiece technology, applied in the field of workpiece processing, can solve the problems that the drill bit cannot be adjusted at will, the workpiece cannot be drilled, and the applicable range is small, so as to improve the drilling quality, improve the drilling accuracy and reduce the labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

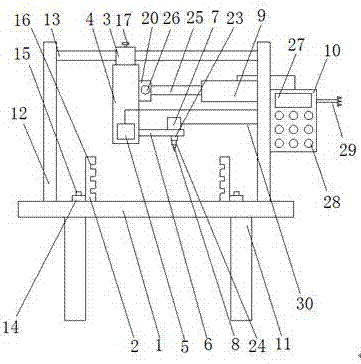

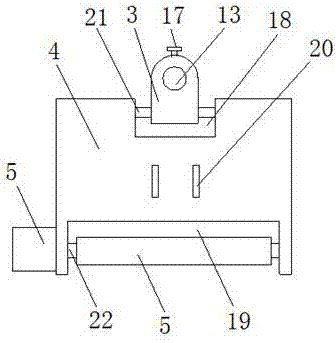

[0019] as attached figure 1 and 2 As shown, a robot device for drilling a workpiece includes an operating table 1, a positioning block 2, an adjusting block 3, an adjusting plate 4, a motor one 5, a load plate 6, a motor two 7, a drill bit 8, a cylinder 9 and a controller 10 , characterized in that: the console 1 is set on the bracket 11, the console 1 is provided with a vertical board 12, and a cross bar 13 is provided between the vertical board 12 and the vertical board 12, and the positioning block 2 is provided with a mounting plate 14, and the mounting plate 14 is set on the console 1 through the mounting bolt 15, the adjustment block 3 is set on the cross bar 13 through the fastening bolt 17, and the adjustment block 3 is provided with Connecting rod 21, described adjusting plate 4 is provided with connecting groove 18, limit groove 19, fixed plate 20, and connecting groove 18 is connected with connecting rod 21, and described motor one 5 is arranged on adjusting plate ...

Embodiment 2

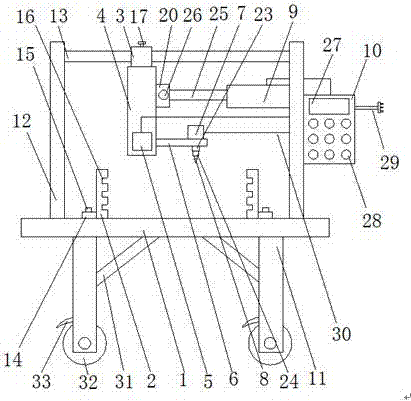

[0027] as attached image 3 As shown, a robot device for drilling a workpiece includes an operating table 1, a positioning block 2, an adjusting block 3, an adjusting plate 4, a motor one 5, a load plate 6, a motor two 7, a drill bit 8, a cylinder 9 and a controller 10 , characterized in that: the console 1 is set on the bracket 11, the console 1 is provided with a vertical board 12, and a cross bar 13 is provided between the vertical board 12 and the vertical board 12, and the positioning block 2 is provided with a mounting plate 14, and the mounting plate 14 is set on the console 1 through the mounting bolt 15, the adjustment block 3 is set on the cross bar 13 through the fastening bolt 17, and the adjustment block 3 is provided with Connecting rod 21, described adjusting plate 4 is provided with connecting groove 18, limit groove 19, fixed plate 20, and connecting groove 18 is connected with connecting rod 21, and described motor one 5 is arranged on adjusting plate 4, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com