Robot polishing equipment

A robot and equipment technology, applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of low degree of mechanization, polishing at different angles, and small application range, so as to reduce labor intensity and improve stability Sexuality, enhance the effect of polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

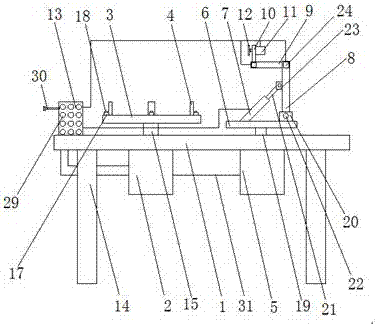

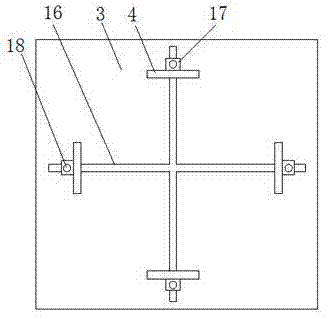

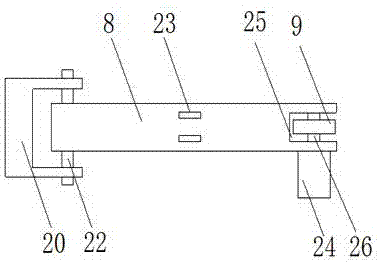

[0022] As attached Figure 1-5 As shown, a robot polishing equipment includes a console 1, a motor 1, a bearing plate 3, a limit block 4, a motor 5, a backing plate 6, a hydraulic cylinder 7, a connecting plate 8, a connecting plate 9, and a connection The board three 10, the motor three 11, the polishing disc 12 and the controller 13 are characterized in that: the operating table 1 is set on the support 14, and the motor one and the second motor 5 are respectively set on the operating table 1. And the motor one 2 and the motor two 5 are respectively provided with a transmission shaft 15 and a transmission shaft 19, the bearing plate 3 is arranged on the transmission shaft 15, and a positioning slot 16 is provided on the bearing plate 3. The limit block 4 is provided with a mounting plate 17, and the mounting plate 17 is set on the bearing plate 3 through a mounting bolt 18, and the backing plate 6 is provided on the second transmission shaft 27 and is provided on the backing p...

Embodiment 2

[0030] As attached Image 6 As shown, a robot polishing equipment includes a console 1, a motor 1, a bearing plate 3, a limit block 4, a motor 2 5, a backing plate 6, a hydraulic cylinder 7, a connecting plate 8, a connecting plate 9, and a connection The board three 10, the motor three 11, the polishing disc 12 and the controller 13, are characterized in that the operating table 1 is set on the support 14, the motor one and the two motors 5 are respectively set on the operating table 1. And the motor one 2 and the motor two 5 are respectively provided with a transmission shaft 15 and a transmission shaft 19, the bearing plate 3 is provided on the transmission shaft 15 and a positioning slot 16 is provided on the bearing plate 3. The limit block 4 is provided with a mounting plate 17, and the mounting plate 17 is set on the bearing plate 3 through a mounting bolt 18, and the backing plate 6 is provided on the second transmission shaft 27 and is provided on the backing plate 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com