Vibrating motor accessory feeding mechanism

A vibrating motor and accessories technology, applied in the field of vibrating motor accessories feeding mechanism, can solve the problems of inability to meet the needs of large-scale production and low mechanization efficiency, and achieve the effect of improving mechanized production efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

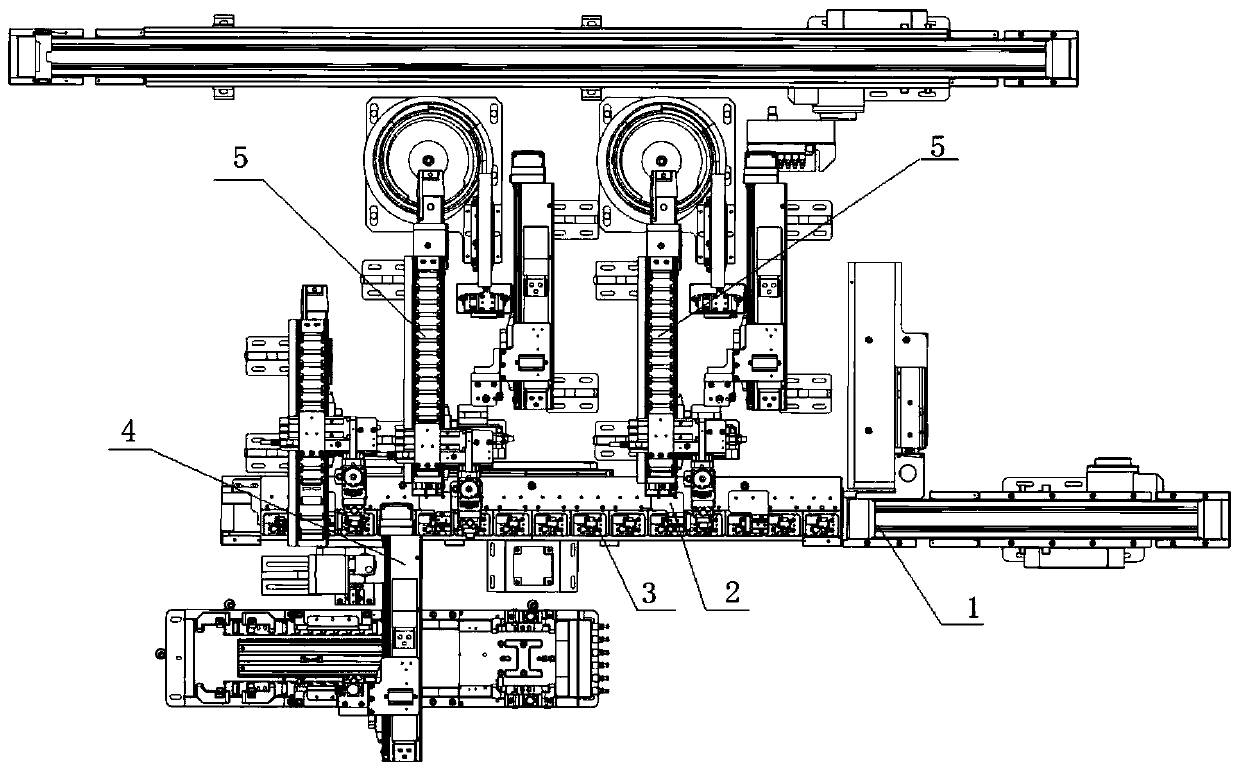

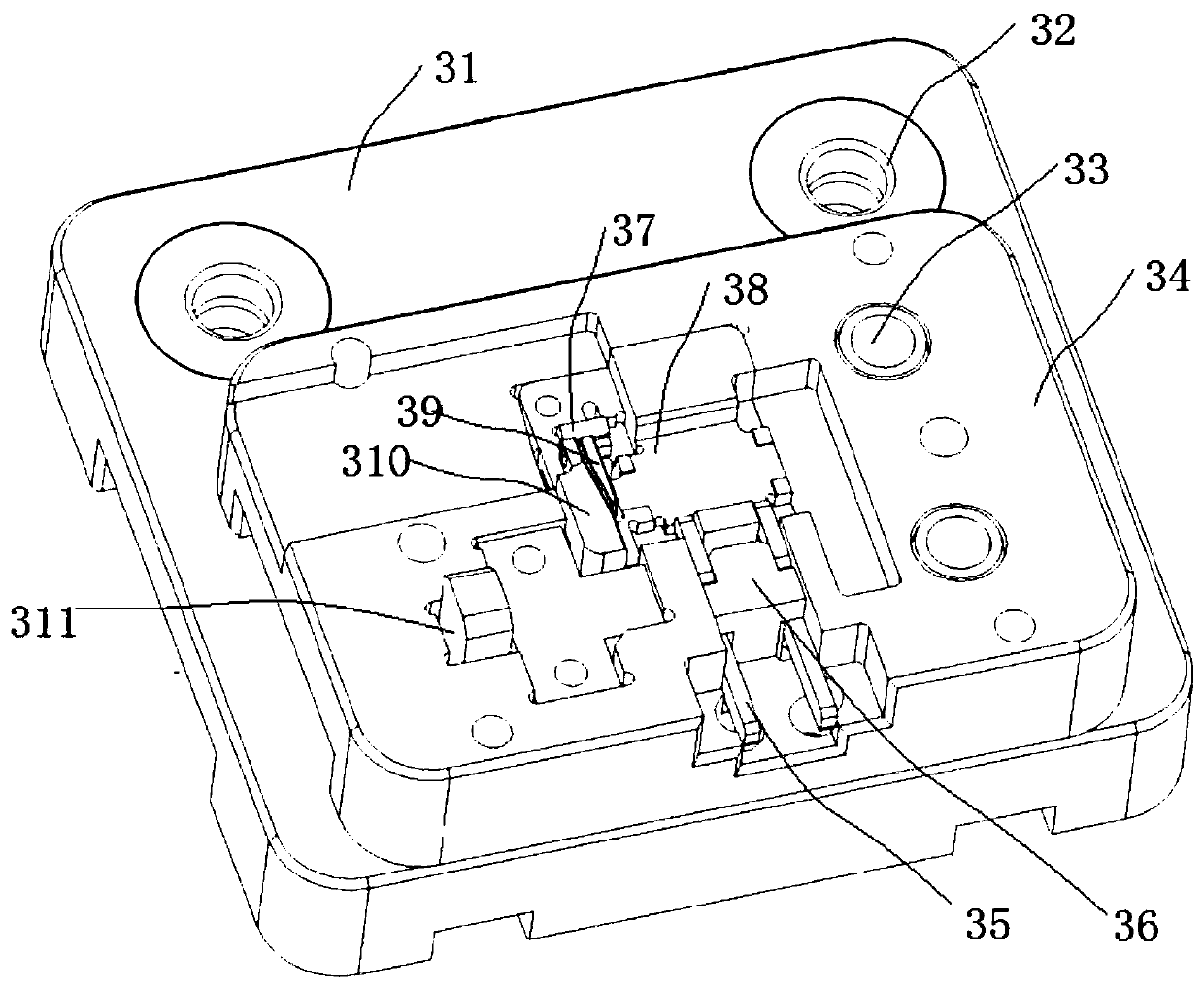

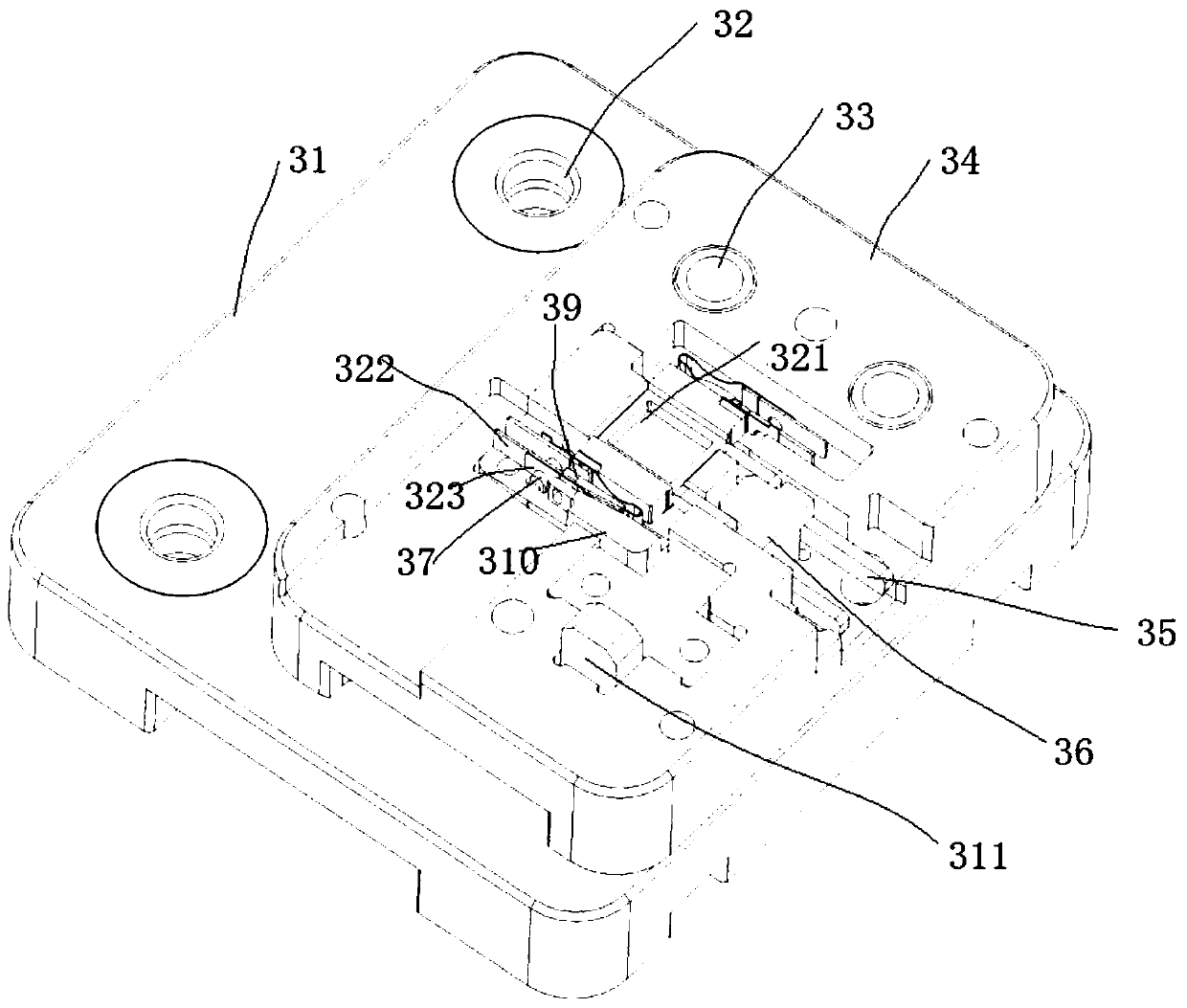

[0019] Such as figure 1 and Figure 9 As shown, the vibrating motor accessory feeding mechanism of the present invention includes a vibrating motor carrier 3, an assembly line track 1, a V spring feeding device 4 and two baffle feeding devices 5, the carrier is used to place the vibrating motor accessories, and it follows the assembly line track moves. The specific structure of the carrier is as figure 2 and 3 As shown, it includes a base 31, a base block 34 is arranged on the base 31, a groove 38 is set on the base block 34 for placing a vibration motor, a positioning block 312 is set on one side of the groove 38, and a clip is set on the other side. The clamping device cooperates with the positioning block 312 to position the mass block. The concrete structure of tightening device is as follows, it comprises a group of rotating arm 35,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com