Anti-resonance vibrating screen machine

A vibrating screen and anti-resonance technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problem that the screening machine cannot run for a long time, block the screen hole, and work efficiency is low, so as to achieve high screening efficiency and prevent screening Pore clogging, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

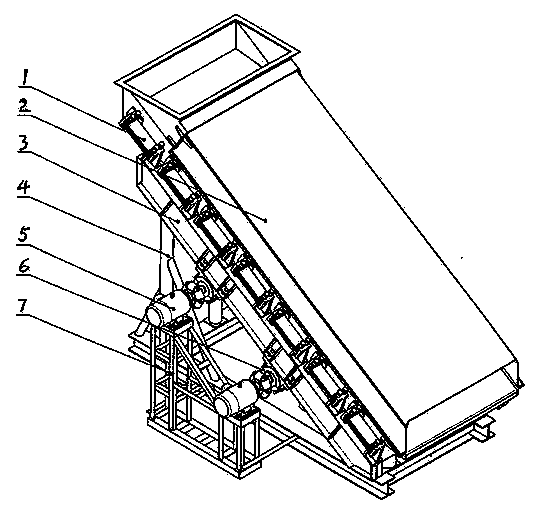

[0007] The embodiment is described in detail in conjunction with the accompanying drawings, which includes a triangular screen frame 4, a strip-shaped main vibration frame 3 is installed on the inclined surface of the screen frame through a set of vibration damping devices, and a synchronous synchronous vibration frame is installed symmetrically front and back under the main vibration frame The vibration exciter 6 is equipped with a corresponding motor 5 on one side of the screen frame and the motor frame 7 matched with the two exciters, and a screen box 2 is installed on the main vibration frame. Evenly distributed leaf springs 1 are connected therebetween. The invention utilizes the principle of anti-resonance to make the screen box anti-resonantly vibrate on the resonance frame through the leaf spring, and the screen box bears a large amplitude, while the vibration amplitude of the main vibration frame is small, so the fine, sticky and wet materials can be placed on the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com