Motor Structure Assembly

A technology of motor structure and components, applied in the direction of electric components, electrical components, mechanical equipment, etc., can solve the problems of electronic device damage, overheating, heating, etc., and achieve the effect of flat structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

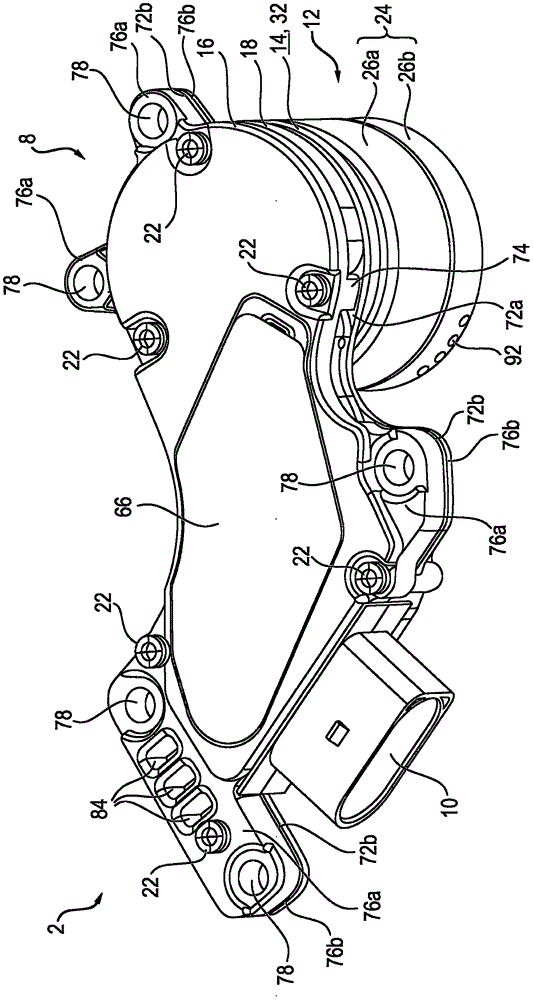

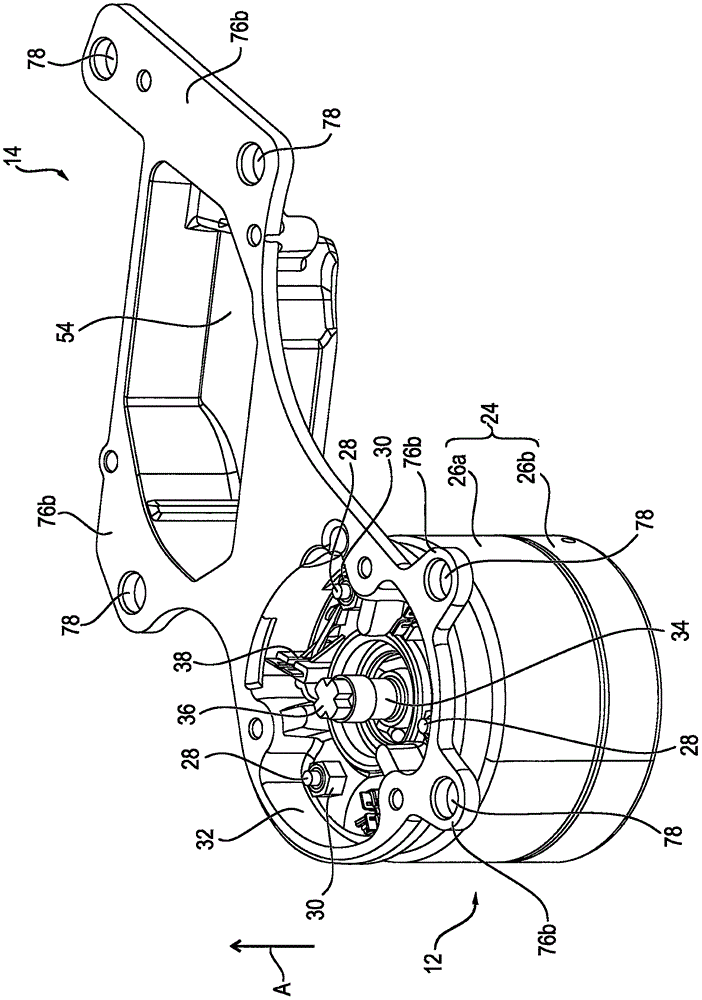

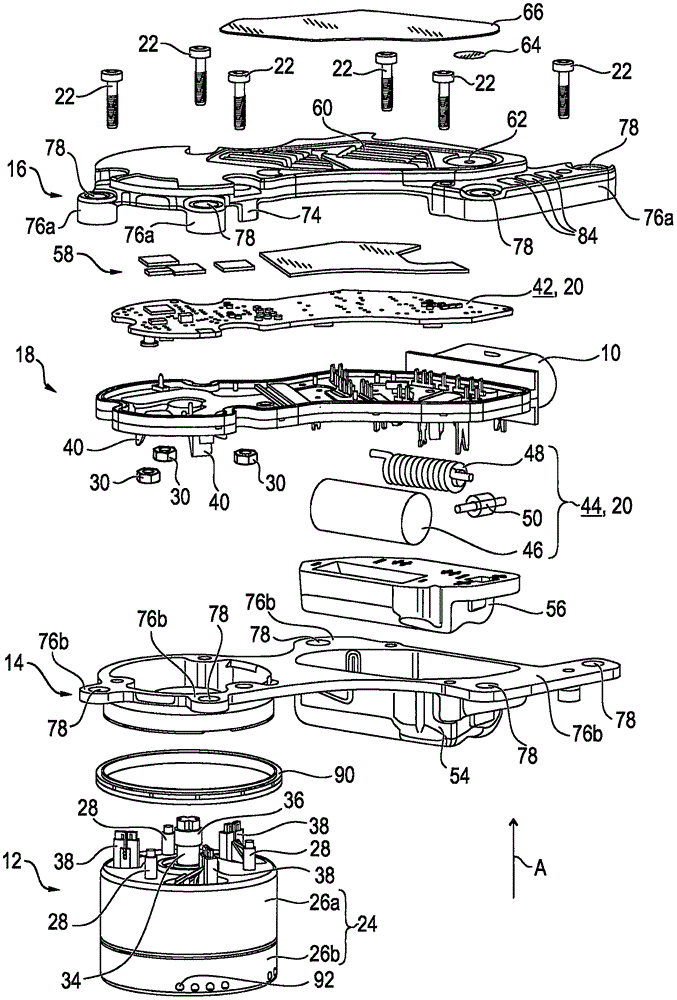

[0036] figure 1 An electrical machine assembly 2 for an actuator 4 of a motor vehicle transmission 6 , in particular a direct-shift transmission, is shown. The electromechanical assembly 2 of the actuator 4 , also referred to below as the transmission actuator, comprises an elongated electronics unit 8 with a plug-in connector 10 projecting on the narrow side, and an electric motor 12 fastened to the electronics unit 8 .

[0037] The electronics unit 8 comprises a first housing shell in the form of a motor base 14 , a second housing shell in the form of a cooling cover 16 and an electronics base 18 which is sandwiched between the motor base 14 and the cooling cover 16 . The plug-in connector 10 is here integrally formed on the end side of the electronics mount 18 . The converter circuit 20 of the electronics base 18 is connected in an electrically conductive manner by means of the plug connector 10 to a motor vehicle electronics not shown in detail, or to a motor for energiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com