Motor carrier conveying device

A technology for conveying devices and vehicles, applied in conveyors, transportation and packaging, etc., can solve problems such as low efficiency and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

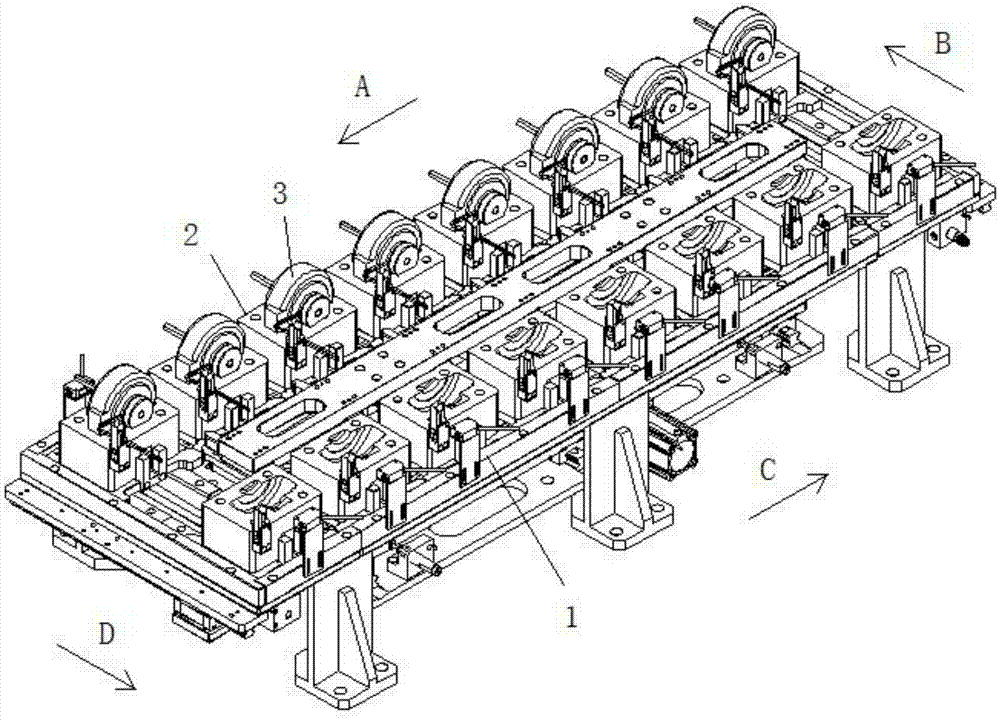

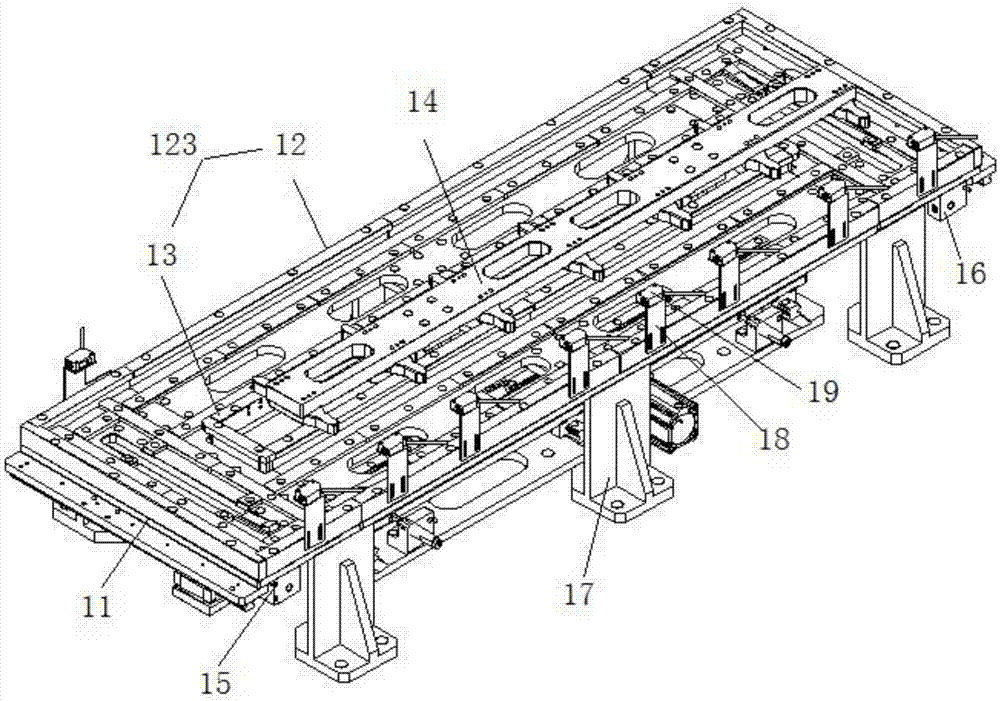

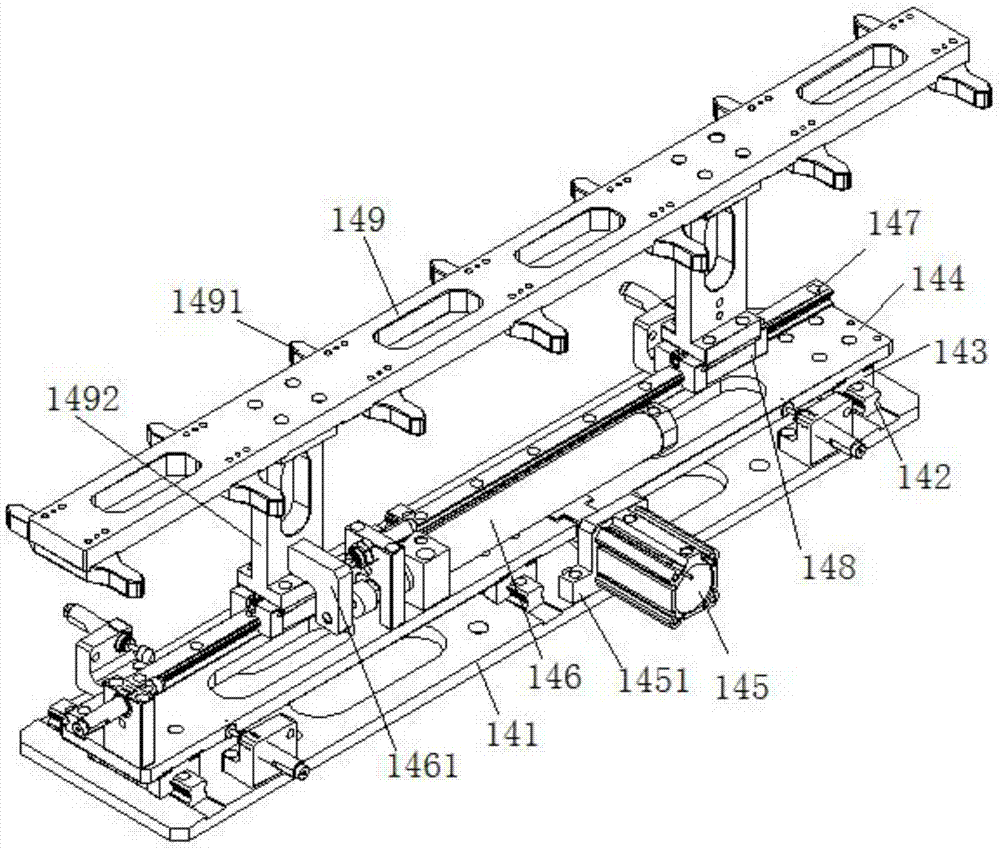

[0021] see Figure 1 to Figure 5 , motor carrier conveying device 1, comprises track mounting plate 11, outer track 12 and inner track 13 that are positioned on track mounting plate 11, outer track 12 and inner track 13 are rectangular, and inner track 13 is positioned at the space that outer track 12 closes The inner and outer tracks 12 and the inner track 13 together form a rectangular delivery track 123, on which a plurality of motor carriers 2 are arranged, the motors 3 are placed in the motor carrier 2, and the motor carriers 2 run along the rectangular delivery track 123 The motor carrier conveying device 1 also includes a shift fork assembly 14 and a first push assembly 15 and a second push assembly 16 located on both sides of the shift fork assembly. The first push assembly 15 and the second push assembly 16 have the same structure and are related to the The center of the conveying track is distributed symmetrically, and the first pushing assembly 15 and the second pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com