Camera module and assembly method thereof

A technology of camera module and assembly method, which is applied in the field of cameras, can solve problems such as lens group falling off, mobile phone camera function threat, lens group and voice coil motor are not firmly combined, and achieve the effect of large contact area and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

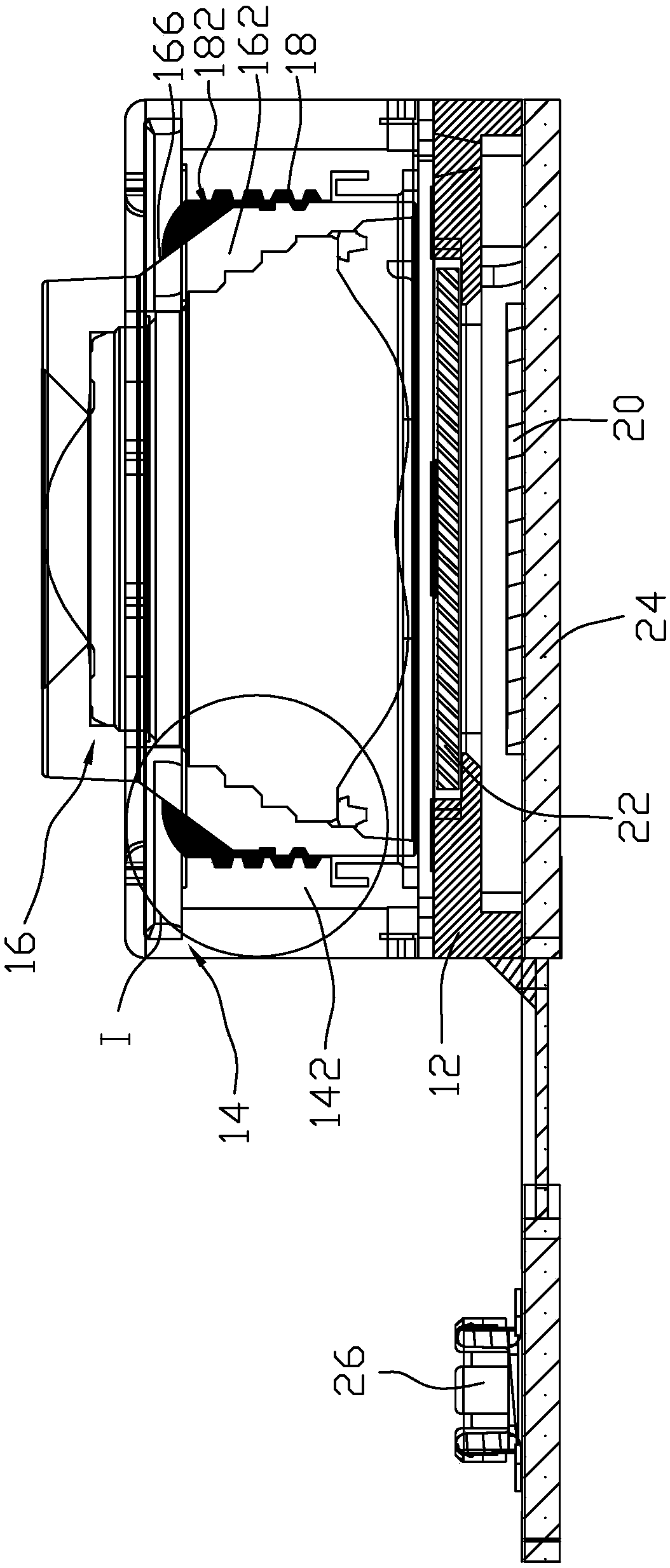

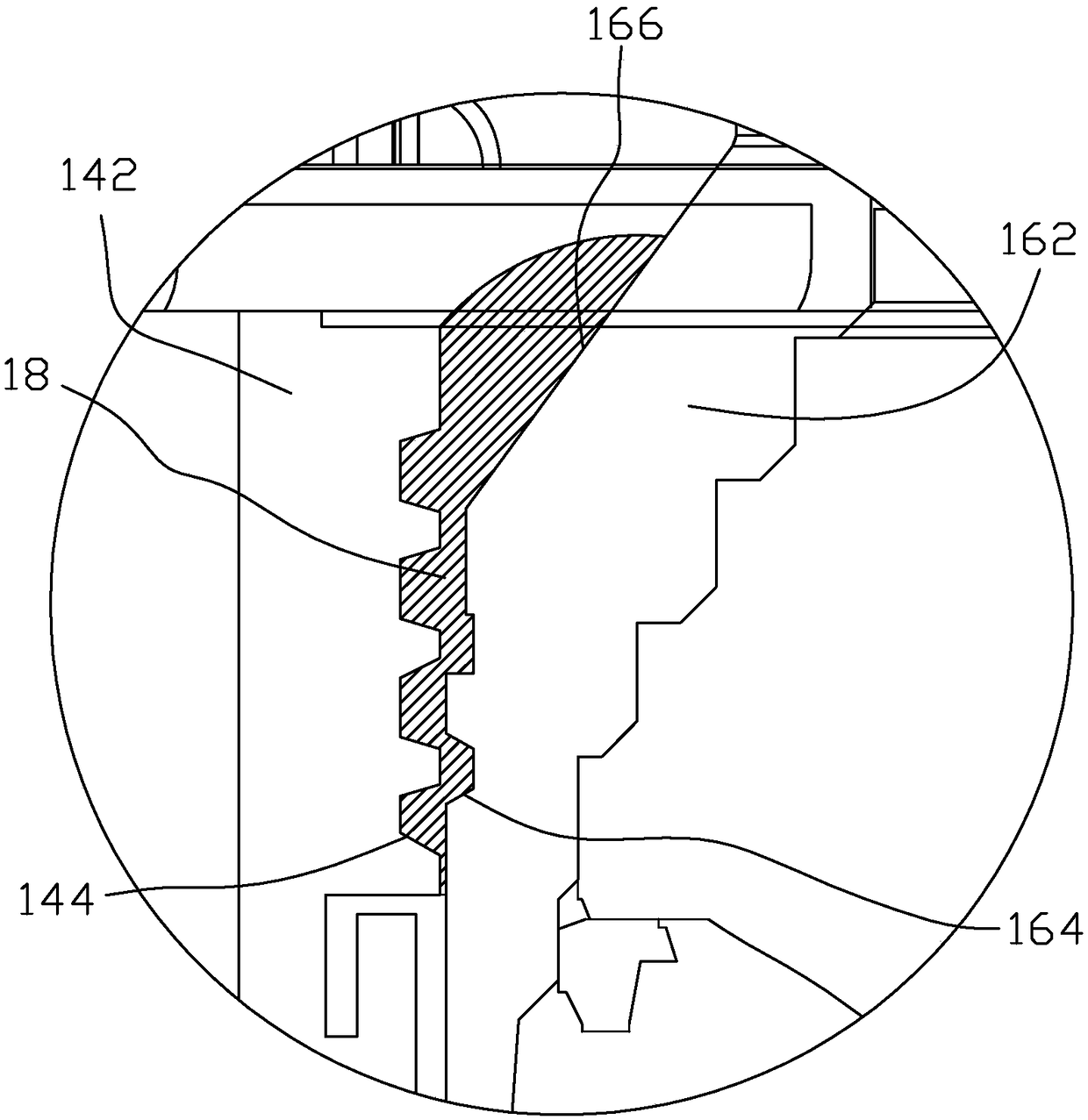

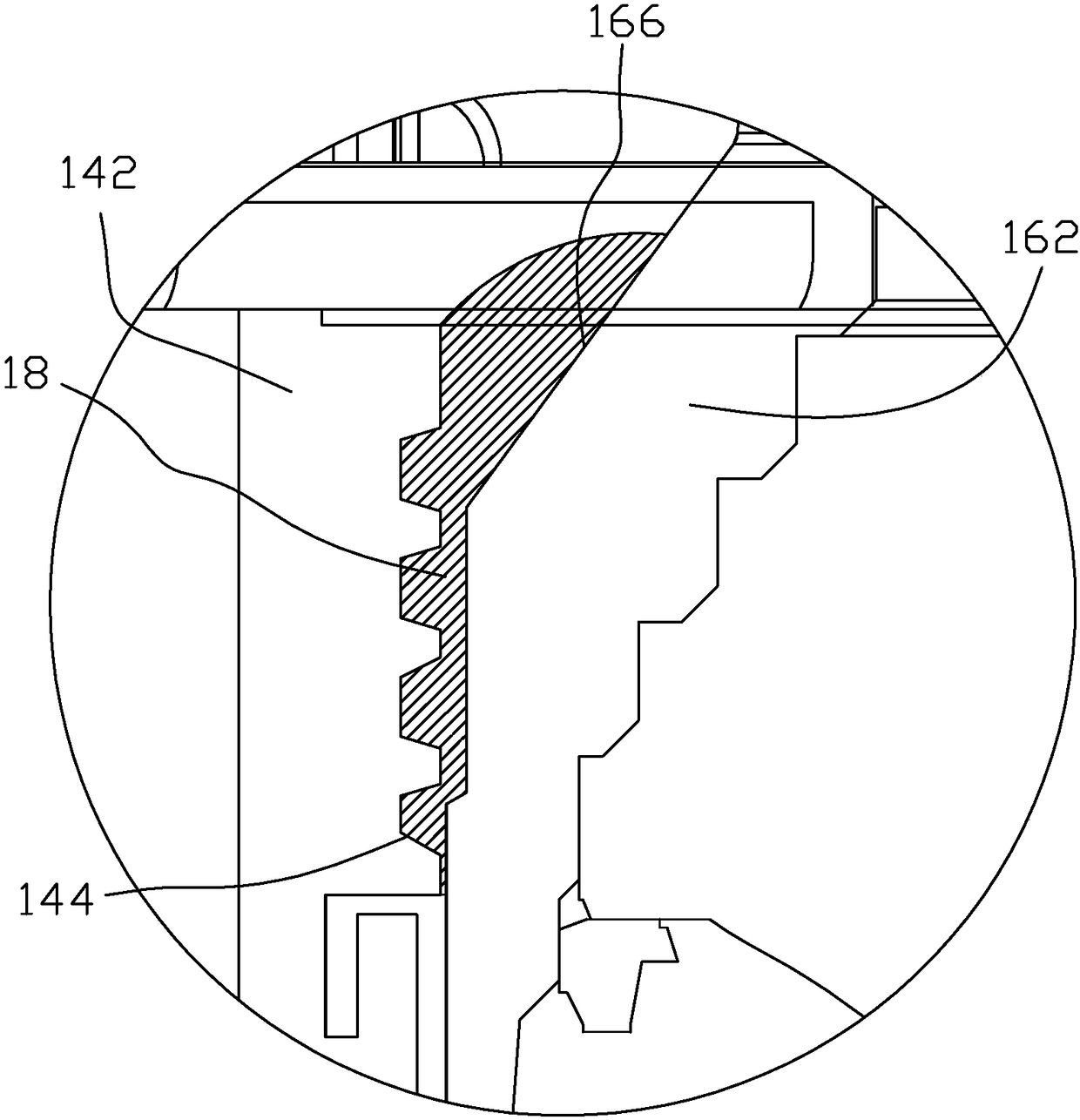

[0024] Such as figure 1 with figure 2 As shown, an embodiment of the present invention provides a camera module, including a lens mount 12, a voice coil motor 14 and a lens group 16, the voice coil motor 14 is arranged on the lens mount 12, and the lens group 16 is arranged in the voice coil motor 14 , the voice coil motor 14 is used to drive the lens of the lens group 16 to move telescopically relative to the lens holder 12 . The voice coil motor 14 includes a motor carrier 142, the lens group 16 is arranged in the motor carrier 142, the lens group 16 includes a lens barrel 162 and a lens arranged in the lens barrel 162, there is a gap between the motor ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com