In-situ detection shearing device of loess hole

An in-situ detection and shearing instrument technology, which is applied in the direction of applying a stable shearing force to test the strength of materials, instruments, measuring devices, etc., can solve the problems of not being able to accurately and effectively obtain the shear properties of loess structural surfaces and structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

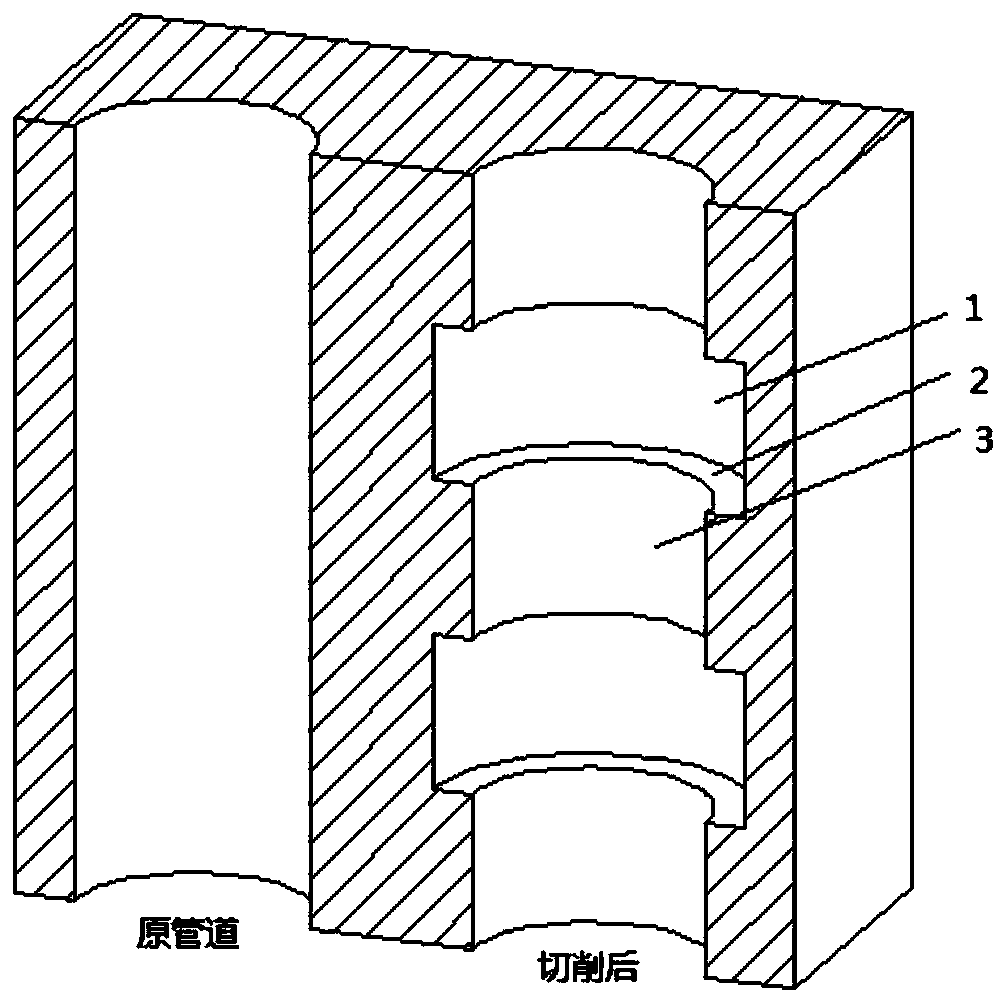

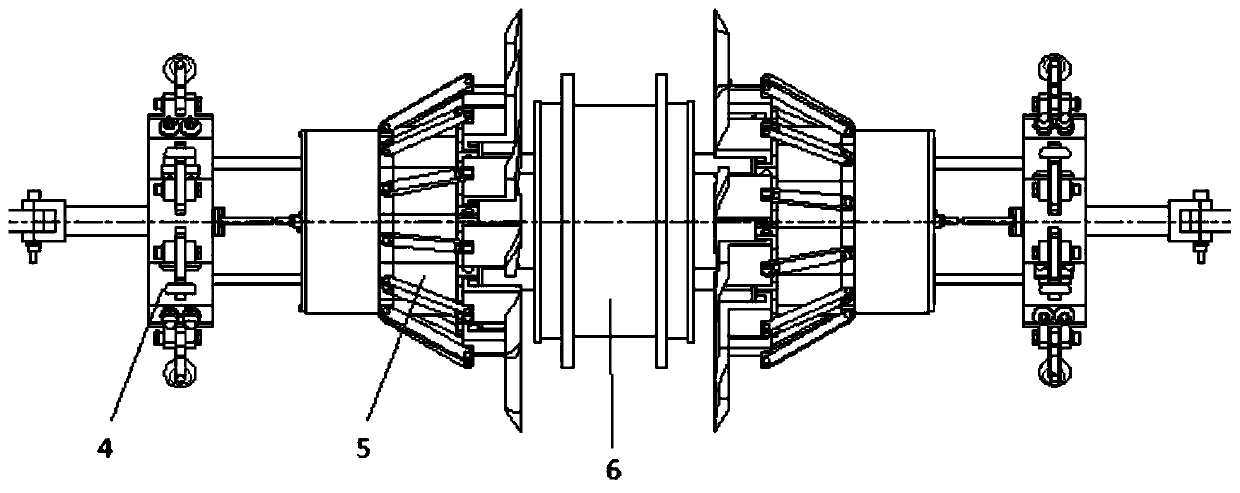

[0031] see Figure 1-8 , this embodiment provides a shearing instrument for in-situ detection of loess holes, as shown in Figure 2, which is the overall structure diagram of the instrument for measuring soil shear strength. The structure of the soil shear strength measuring instrument in the loess pipeline is symmetrically distributed, mainly composed of three parts: the moving carrier, the shearing part and the airbag carrier.

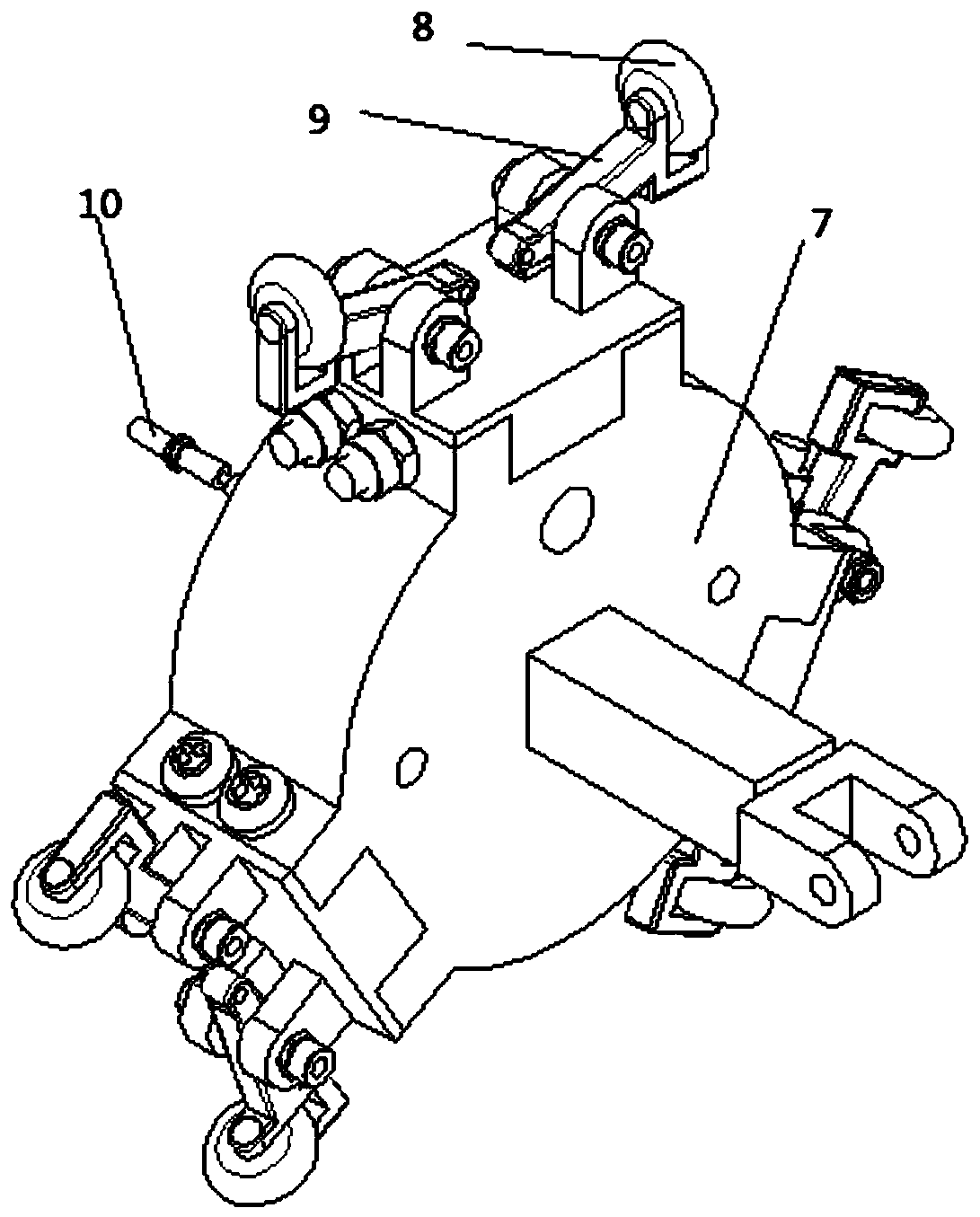

[0032] Further, motion vector 4 such as image 3 Shown, mainly be made up of main body 7, wheel 8 and wheel support 9 of fixed cylinder, be connected by spring between every pair of wheel support 9, motion carrier 4 just possesses certain self-adaptability when motion like this.

[0033] Further, cut part 5 as Figure 4 As shown, it is mainly composed of feed bearing 11, rotary bearing 12, connecting rod 13 and cutter 14.

[0034] Further, feed bearing 12 such as Figure 5 As shown, it consists of an inner ring, an outer ring and rollers. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com