Method for fabricating sole for footwear in environment protection

A production method and environmentally friendly technology, which can be applied to shoe soles, footwear, footwear, etc., can solve the problems of high cost and poor practicability, and achieve the effects of lightweight use, improved production efficiency, and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

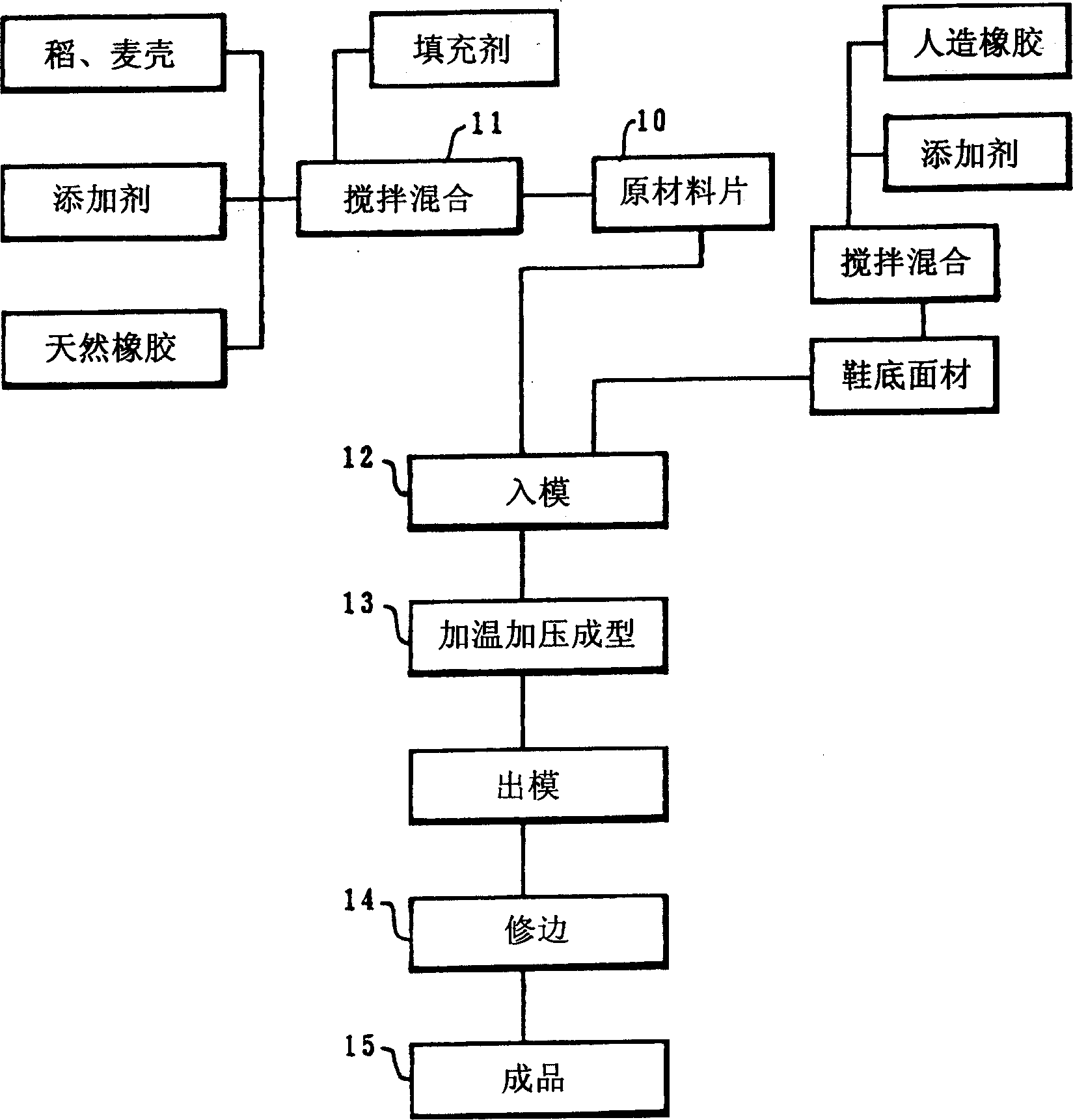

[0008] With reference to the accompanying drawings, the manufacturing method of the environmentally friendly shoe sole of the present invention will be described in detail with examples.

[0009] The manufacture method of environmental protection sole of the present invention, its flow process is as figure 1 As shown, the entire shoe sole material is mainly plant fiber materials, such as rice husks, wheat husks, etc., without special treatment, and then mixed with natural rubber materials and existing general artificial rubber materials (11) to form raw materials (10), Among them, fiber material accounts for 35-60% of the total material, natural rubber accounts for 25-45%, and artificial rubber accounts for 10-20%, and they are stirred together to form the main material. Among them, the raw material (10) is fully mixed and stirred (11) after adding auxiliary additives for molding, and then pressed into a sheet, or directly formed into a bundle of raw materials (10), which is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com