Air inlet pipe structure for dry air dehumidification and implementation method thereof

An air intake, dry air technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of low dehumidification efficiency and effect of cables, large gas pressure loss, gas pressure loss, etc., and achieve high industrial utilization value and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

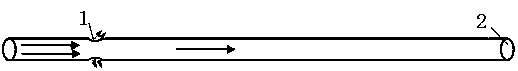

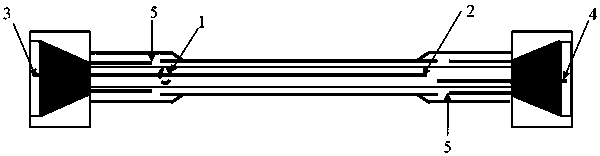

[0027] see Figure 1-3 , the present invention relates to a dry air dehumidification intake pipe structure and its implementation method, which includes the intake pipe 3 body.

[0028] The air inlet pipe 3 is provided with an air outlet 1 at the filling and anchoring surface 5 of the upper anchorage, and the outlet port 2 of the air inlet pipe 3 is close to the position of the filling and anchoring surface 5 of the lower anchorage of the cable body, that is, the upper part of the air inlet pipe 3 is provided with the air outlet 1 by using Part of the dry air in the air inlet pipe 3 dries the upper part of the cable body, while the dry air in the air outlet port 2 of the air inlet pipe 3 dries the part of the cable body near the lower anchorage.

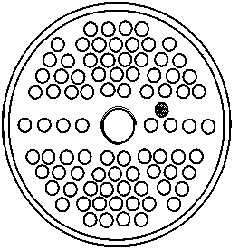

[0029] In the above structure, the length of the cable body is 11m, and the specification is 109×ø5. The air inlet pipe 3 is made of stainless steel pipe, the surface of which is the same as the galvanized aluminum alloy coating of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com