Assembling target material for preparing composite material, manufacturing method thereof, repair method thereof and modification method thereof

A technology for composite materials and targets, which is applied to assembleable targets, the repair and modification of the above-mentioned assembleable targets, the preparation of assembleable targets of composite materials, and the manufacturing field of the above-mentioned assembleable targets, which can solve the problems of low efficiency, The problems of high film thickness of composite materials and restrictions on the large-scale application of composite materials have achieved the effect of reducing cost, reducing pollution and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

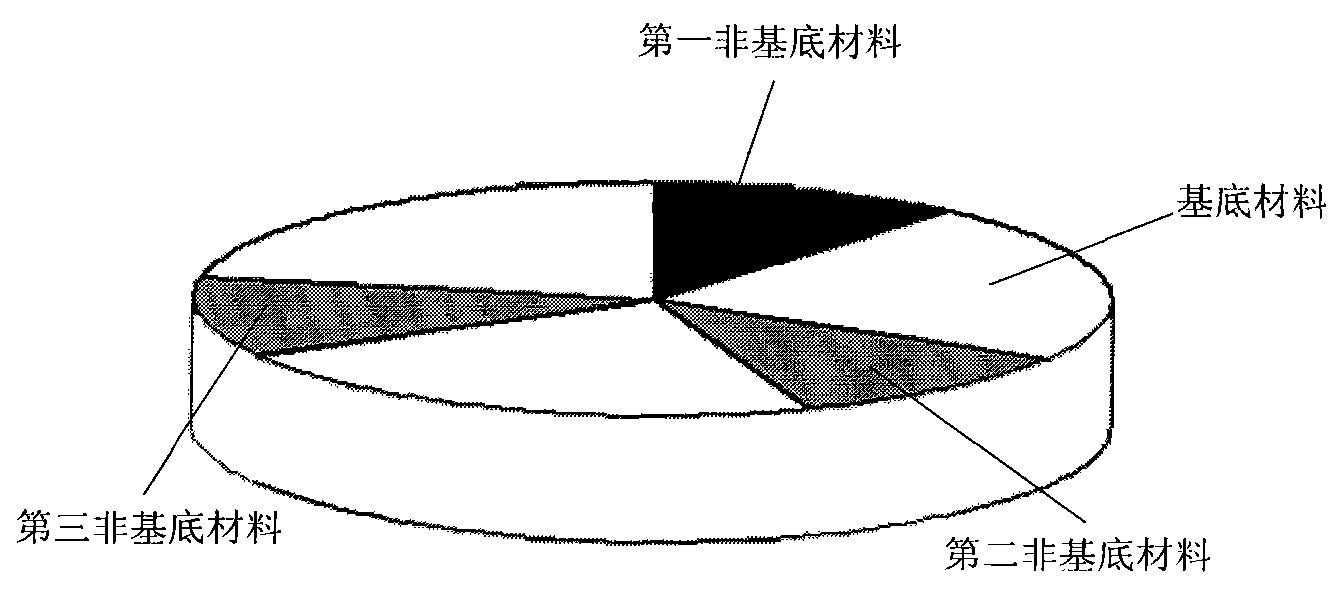

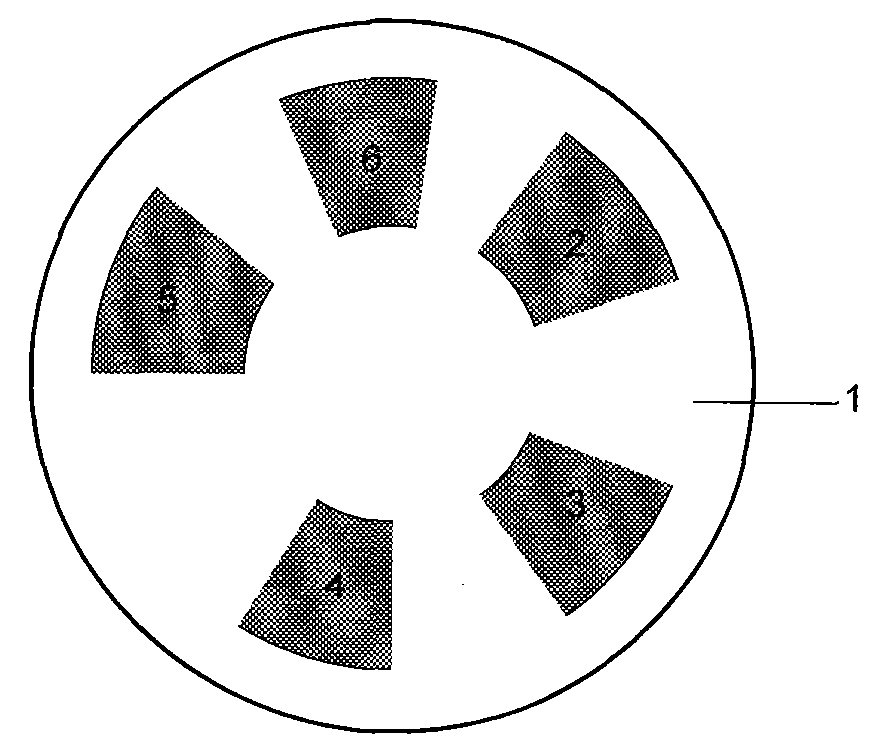

[0029] see figure 1 , figure 1 A target structure for preparing functional materials is disclosed. figure 1 The base material shown in is not a base. From the structure, it can be seen that a groove is opened in the base material (or a groove structure is formed after splicing discrete pieces of base material), and the depth of the groove is less than or equal to the thickness of the base material. After the non-substrate material is filled, at least one non-substrate material is distributed in the groove, which is obtained by subsequent filling or inlaying. The shape, material, quantity and area are not limited, and can be adjusted according to different film requirements. As a preference, the groove-filling regions are evenly distributed on the assembled target, and the shape is fan-shaped, triangular or fan-shaped. figure 1 shows the situation that there are three kinds of non-substrate materials at the same time, using a fan-shaped structure. In the figure, the total are...

Embodiment 2

[0036] In this embodiment, the circular target and fan-shaped groove filling are still used as examples to illustrate the repair method of the composite material target, such as Figure 3A Shown is a composite material target material, four evenly distributed triangular areas are opened above the base target material 12 which is relatively difficult to consume, and the triangular areas are filled with target material 13 which is relatively easy to consume, as above As mentioned above, neither the shape nor the area of the target material and the trench is a feature that limits the present invention.

[0037] The projection along the A-A direction in the target is as follows Figure 3B As shown, while the projection along the B-B direction is as Figure 3C As shown, it can be seen that the thickness of the filled target material 13 is smaller than the thickness of the base target material 12 , obviously, its thickness can also be equal to the thickness of the target material...

Embodiment 3

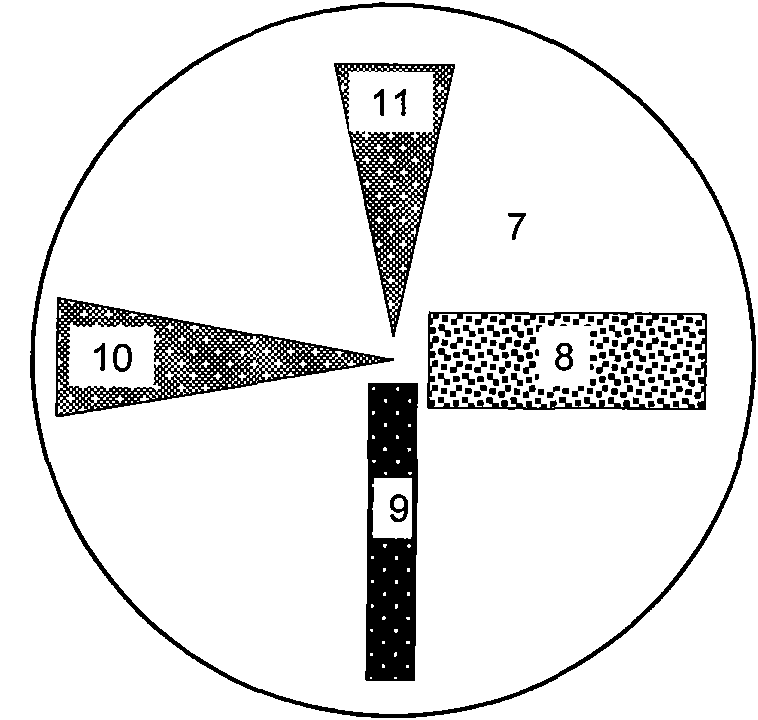

[0042] This embodiment, as shown in FIG. 4, illustrates a method in which the first material is used as the target substrate (not the base), the second material is used as the covering material, and there is a certain area of hollowing above the covering of the second material. During the deposition process of the film, The first material and the second material are simultaneously deposited on the substrate and combined to form a composite material.

[0043] Manufacture the hollow structure 18 of W by machining, the material is the sheet 16 of W, have a plurality of hollow structures 17 above the sheet 16, the shape of the hollow structure can be any shape (not limited to) including the fan shape At Figure 4A shape shown). With Ti as the base target 20, Cu as the base 19, and the W hollow structure 18 placed above the Ti base, the resulting final structure is as follows Figure 4C As shown, during the use of the target, Ti and W are co-deposited on the substrate to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com