Embedded brake pad

A brake pad, embedded technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve the problems of difficulty in adding buffer pads to brake pads, complex structure of brake pads, and high manufacturing costs. Reliable performance, simple structure, easy to assemble, disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

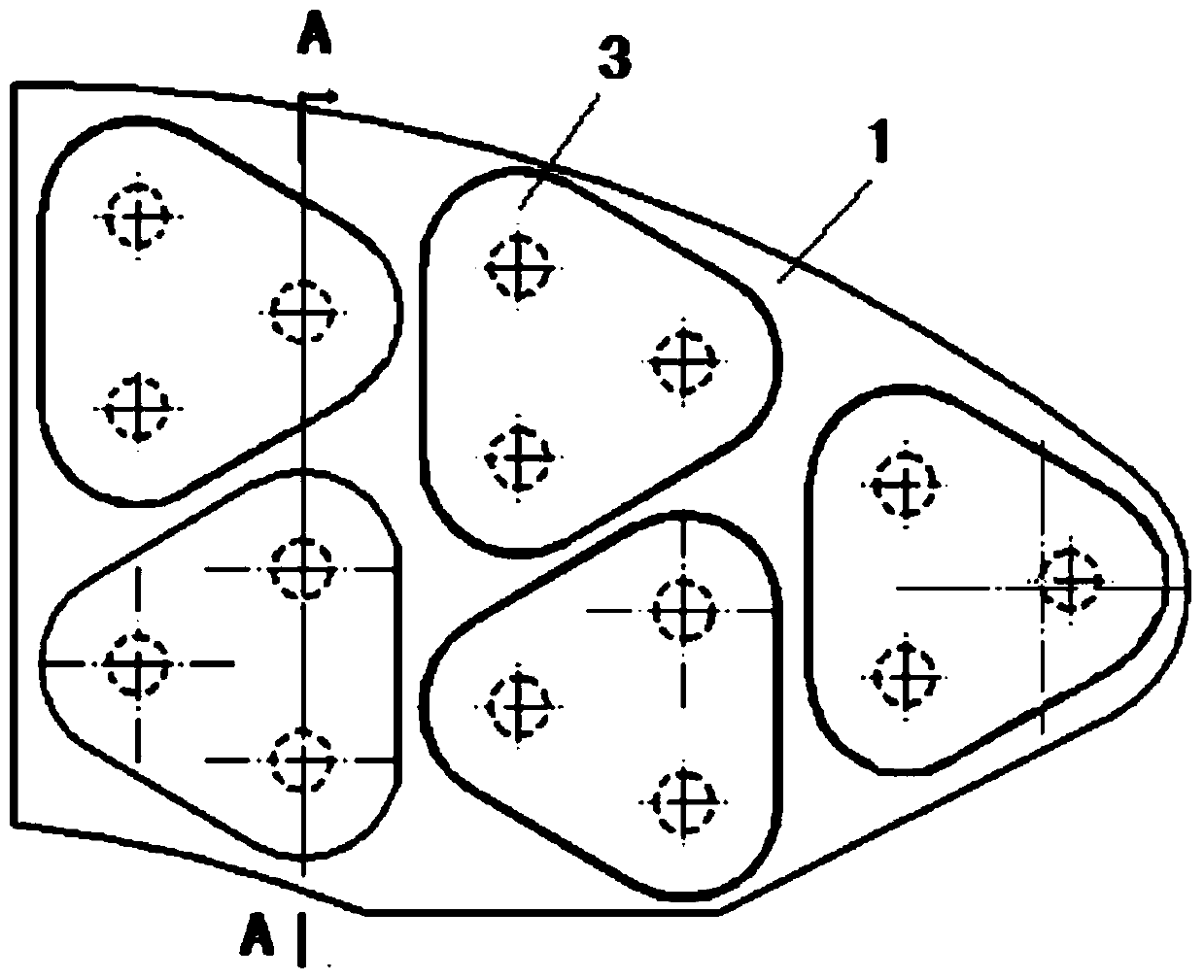

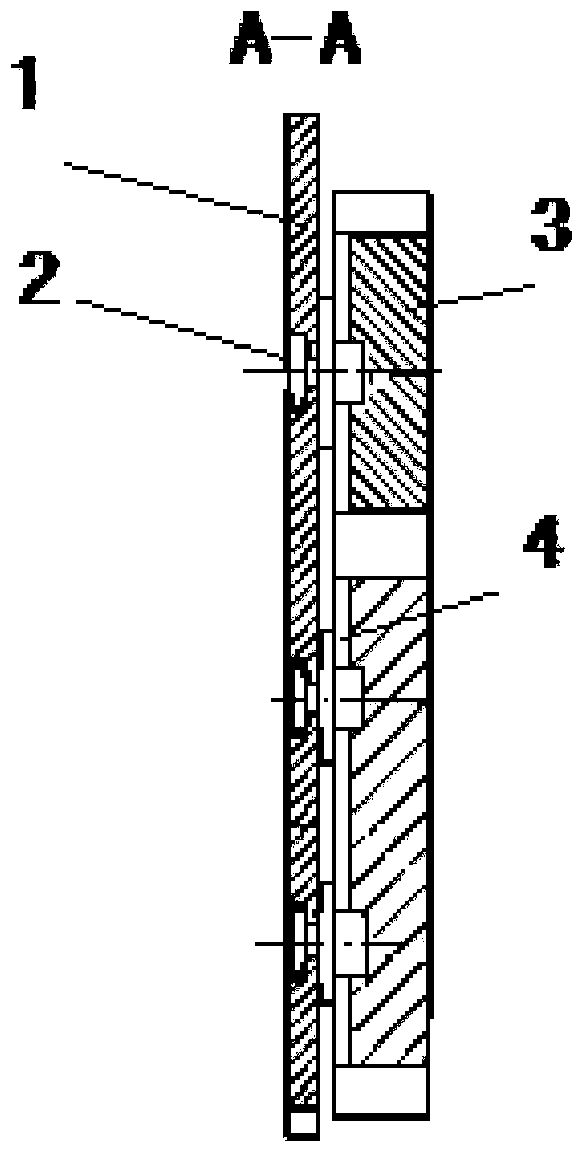

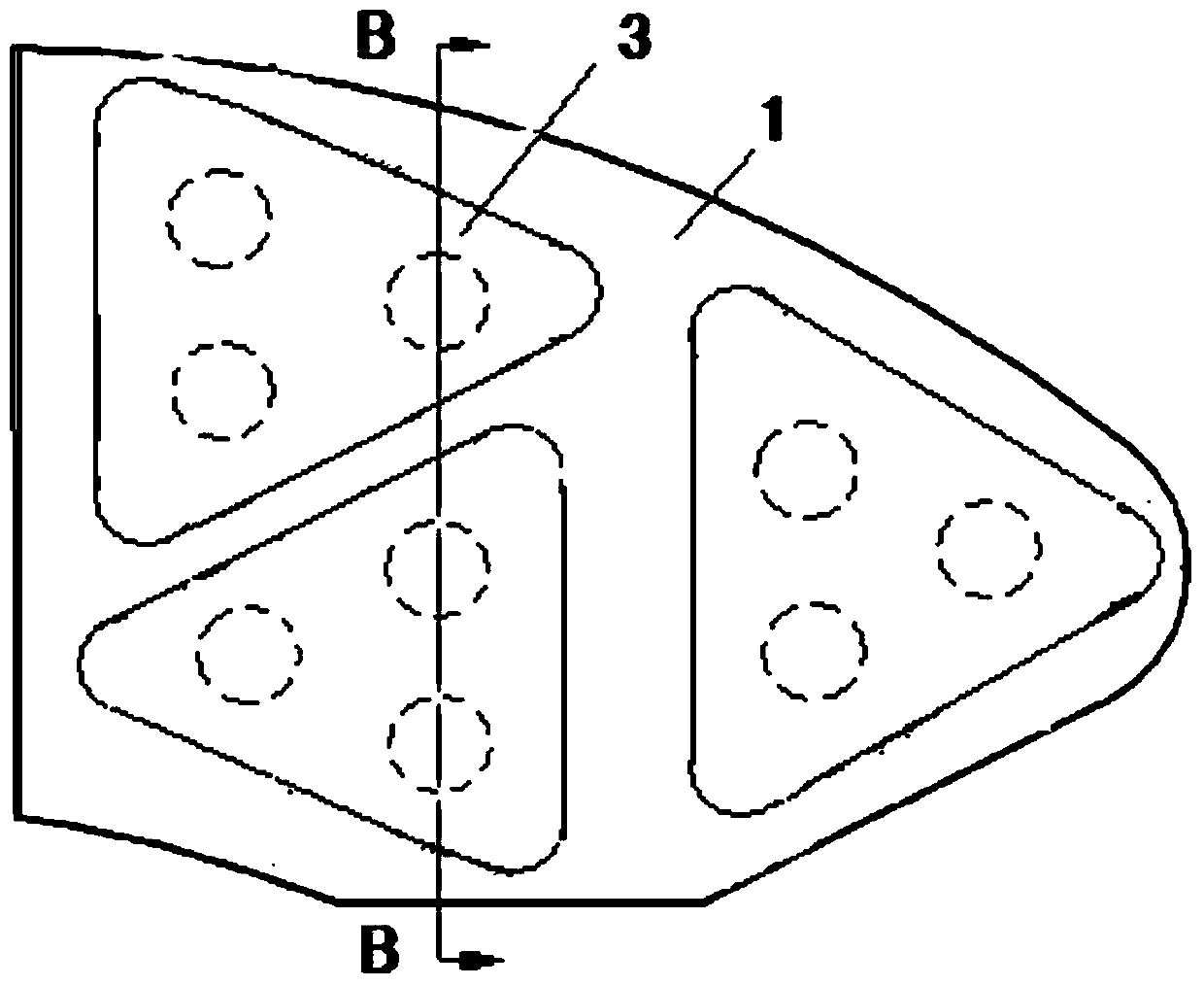

[0021] figure 1 , 2 Shown is one of the embodiments of the present invention, and it is the built-in brake pad that is installed on the disc brake of high-speed train; Its structure comprises backplate 1, the friction block 3 that metal powder metallurgy makes, its characteristic That is: each brake pad adopts an embedded friction body type brake pad, and the embedded friction body type brake pad is arranged and distributed on the back plate 1 and installed with 5 triangular shaped pads that rub against the brake disc. Friction block assembly, each of the triangular friction block assemblies is embedded with a backing plate combination type friction block assembly on the back plate 1; the backing plate combination type friction block assembly is made of metal powder metallurgy friction block 3. The backing plate 4 and the embedded pin 2 are composed; the friction side of the friction block 3 is in contact with the brake disc, and the other side of the friction block 3 is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com