Flexible stress sensor and preparation method thereof

A stress sensor and flexible technology, applied in the field of sensors, can solve the problems of low sensitivity, harsh spinning conditions, unfavorable integration, etc., and achieve the effects of improving detection resolution and sensitivity, easy preparation conditions, and avoiding circuit manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

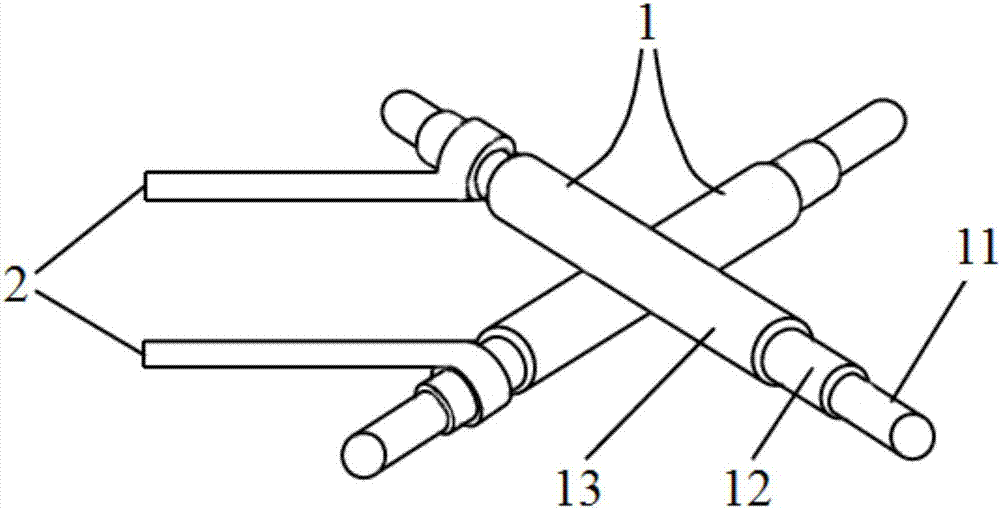

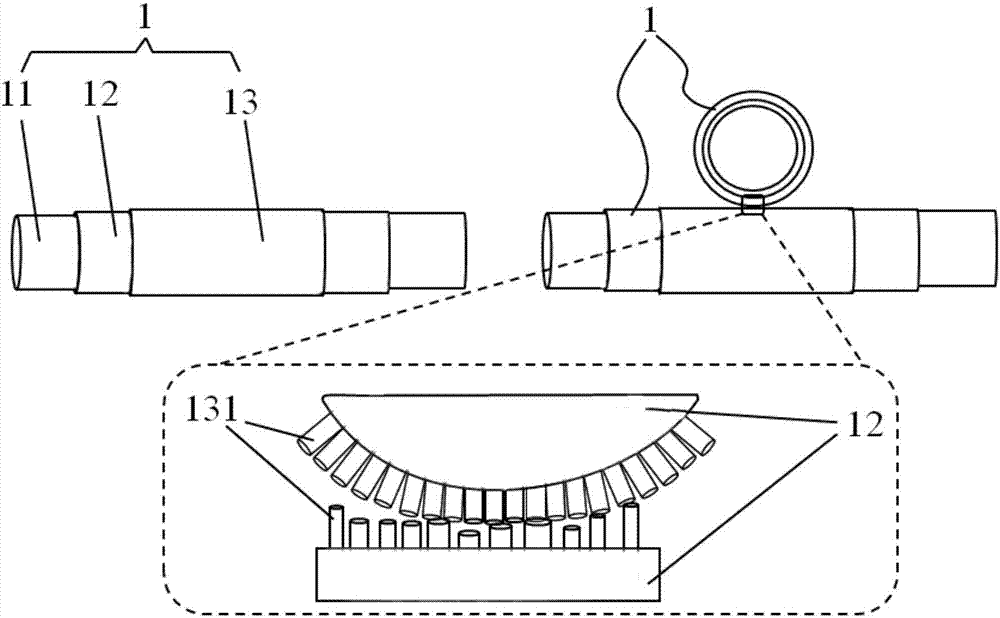

[0046] Please also see figure 2 with image 3 , the flexible stress sensor provided by this embodiment includes two sensing components 1, each sensing component 1 includes a flexible fiber filament 11 and a nanostructure film 13 covering the flexible fiber filament 11, and the flexible fiber filament 11 is a carbon fiber filament , the nanostructure film 13 is a tungsten oxide nanowire film. Each sensing component 1 is connected with a wire 2 extending outward, and the wire 2 is connected with the flexible fiber filament 11 . The two sensing components 1 are cross-stacked, and the nanostructure thin films 13 of the two sensing components 1 are in contact with each other at the intersection.

[0047] The flexible fiber filament 11 in this embodiment is a conductive carbon fiber filament, so no additional conductive layer 12 is provided on its surface.

[0048] The preparation method of the flexible stress sensor specifically includes the following steps:

[0049] S11: In a...

Embodiment 2

[0055] Please also see figure 2 with image 3 , the structure of the flexible stress sensor provided by this embodiment is basically the same as that of Embodiment 1, the difference is that: the surface of the flexible fiber filament 11 is provided with a conductive layer 12, and each sensing component 1 is connected with an outwardly extending The wire 2 is connected, and the wire 2 is connected to the conductive layer 12 of the flexible fiber filament 11 .

[0056] The preparation method of the flexible stress sensor comprises the following steps:

[0057] S00: Prepare a conductive layer 12 on the surface of the flexible fiber 11 by thermal evaporation coating method or magnetron sputtering method.

[0058] S10: Prepare a layer of nanostructure thin film 13 on the surface of the conductive layer 12 of the flexible fiber filament 11 by thermal evaporation coating method, and manufacture the sensing component 1 .

[0059] S20: Lay the two sensing components 1 up and down s...

experiment example

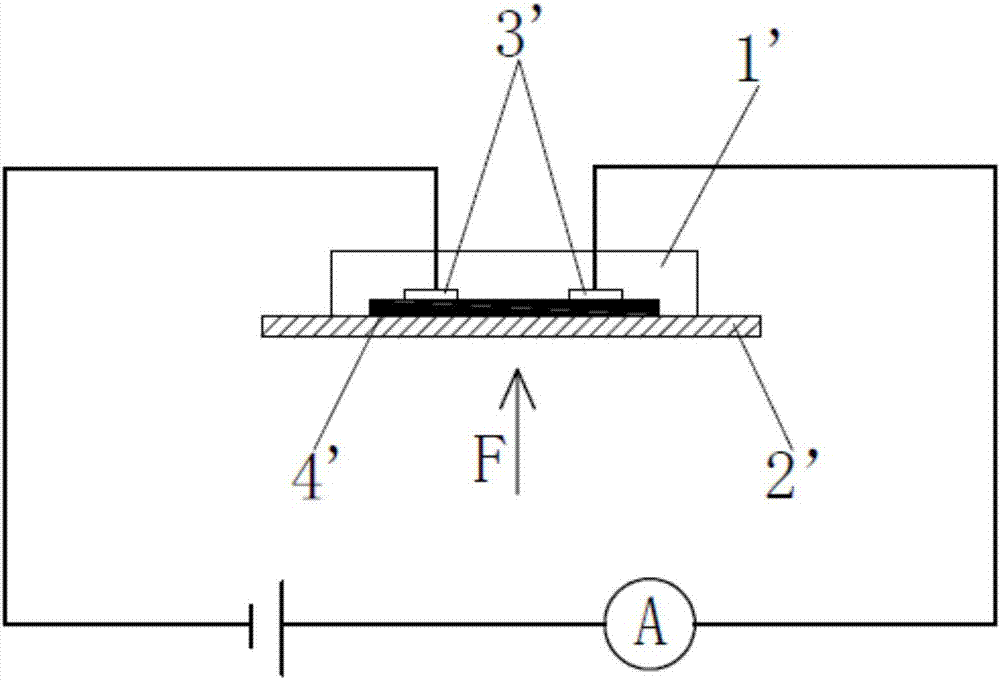

[0061] Such as Image 6 As shown, the flexible stress sensor of embodiment 1 is connected to the test circuit, Image 6 U represents the voltage of the power supply, R s Represents the resistance of the flexible stress sensor, and R represents a resistor connected in series with the flexible stress sensor. Such as Figure 7 As shown, an external force F is applied to the intersection of the two sensing components in the flexible stress sensor during the test, and a multimeter is used to monitor the voltage across the series resistor R in real time.

[0062] Please refer to Figure 8 , which is a performance test result diagram of the flexible stress sensor of the present invention, the ordinate in the figure is the voltage value at both ends of the series resistance R, when the external force F is applied to the flexible stress sensor, R s The resistance changes accordingly, which in turn changes the current in the circuit, and finally manifests as a change in the voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com