Patents

Literature

239results about How to "High rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

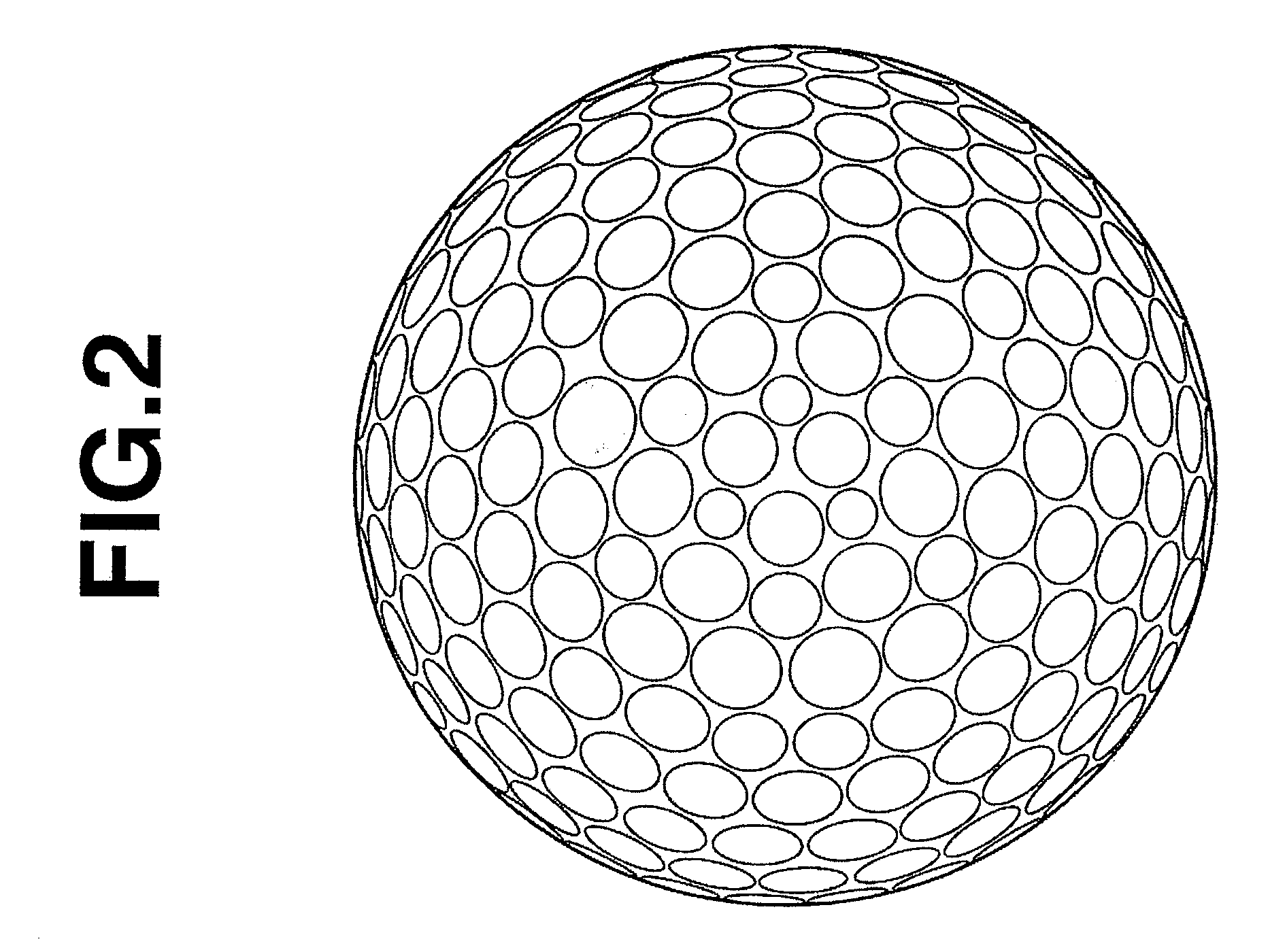

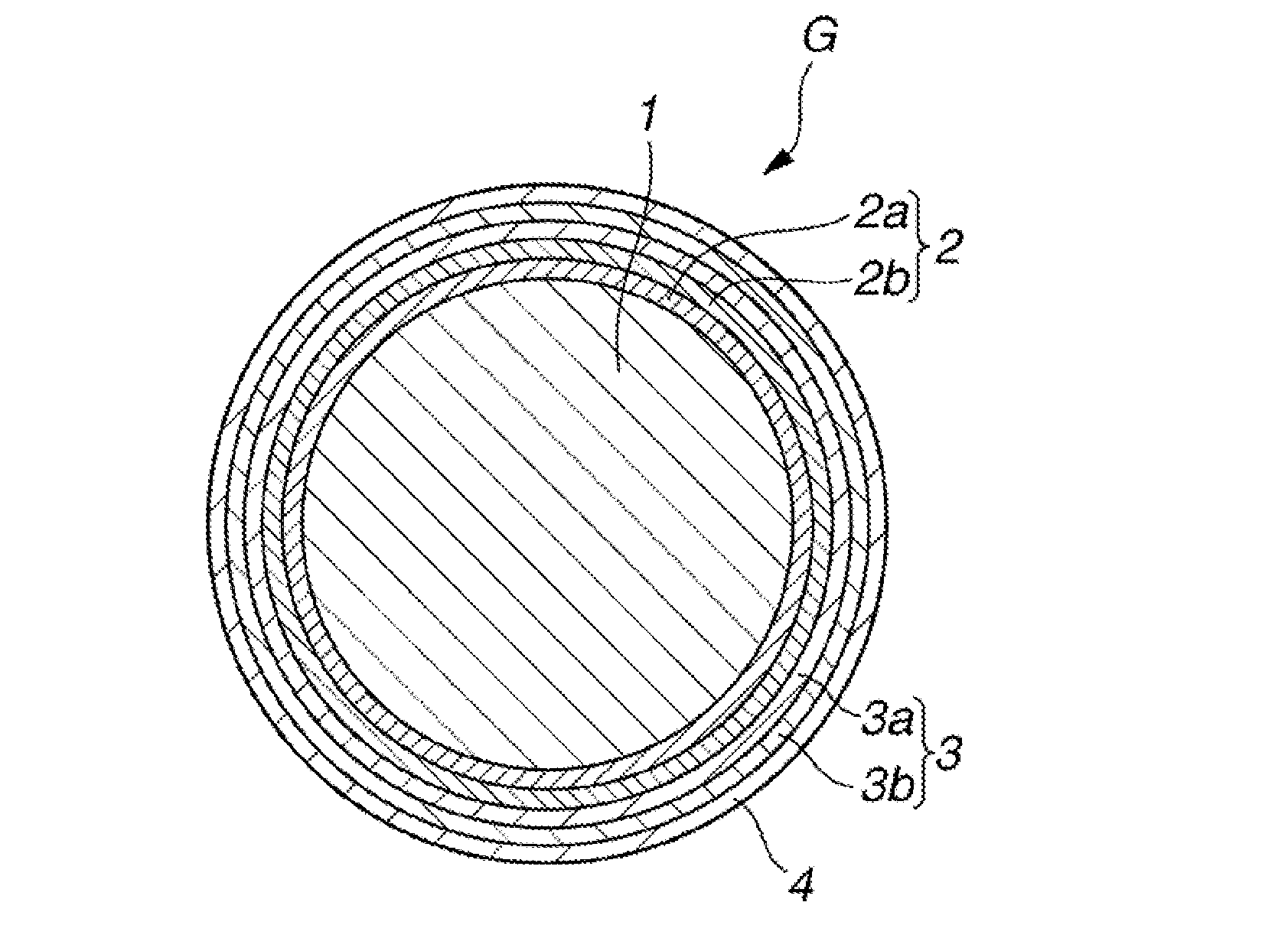

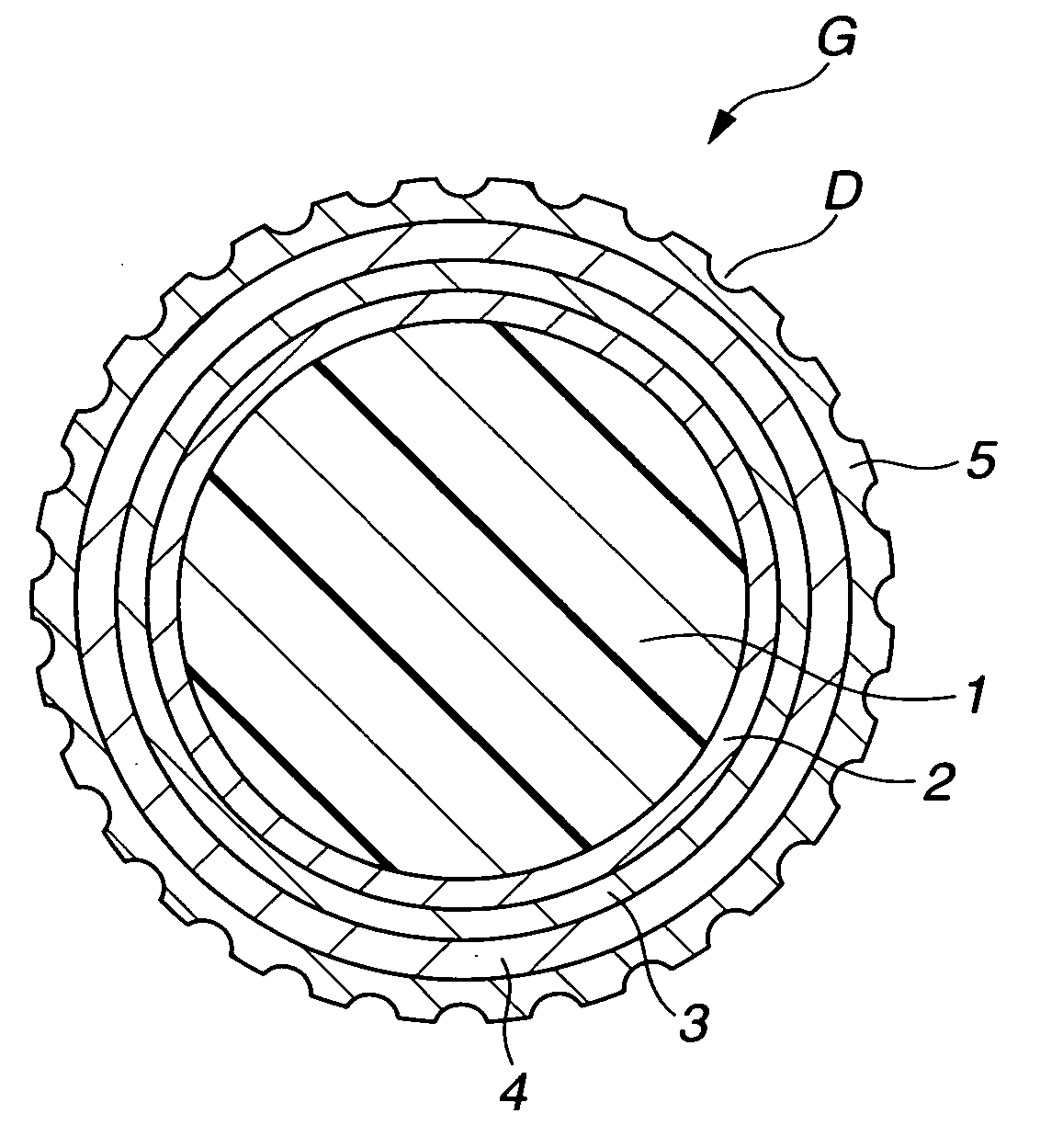

Multi-piece solid golf ball

A multi-piece solid golf ball has a solid core obtained by molding and vulcanizing a rubber composition which includes (A) a base rubber containing a polybutadiene synthesized using a rare-earth catalyst, (B) an unsaturated carboxylic acid and / or a metal salt thereof, (C) an organic sulfur compound, (D) an inorganic filler and (E) an organic peroxide. The core is enclosed within a mantle of one or more layer which is made primarily of a thermoplastic resin and has a Durometer D hardness of 30 to 70. The mantle is enclosed within a cover which is made primarily of a thermoplastic polyurethane and which has a Durometer D hardness of 40 to 60 that is lower than the Durometer D hardness of the outermost layer of the mantle. This construction provides the golf ball with an outstanding rebound.

Owner:BRIDGESTONE SPORTS

Solid golf ball

ActiveUS20070129174A1Excellent durability to crackGood impactGolf ballsSolid ballsChemistryThermoplastic

The invention provides a solid golf ball having a solid core, a cover layer that encloses the core, and a plurality of dimples formed on an outside surface of an outermost layer of the cover. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, and an unsaturated carboxylic acid or a metal salt thereof, an organic peroxide and an inorganic filler. The solid core has a deformation, when subjected to loading from an initial load of 10 kgf to a final load of 130 kg, of 2.0 to 3.5 mm, and has a specific hardness distribution. The cover layer, which is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The core has a surface hardness which is from 1 to 15 Shore D hardness units lower than the surface hardness of the core. The golf ball has a deformation, when subjected to loading from an initial load of 10 kgf to a final load of 130 kgf, of 2.0 to 2.9 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

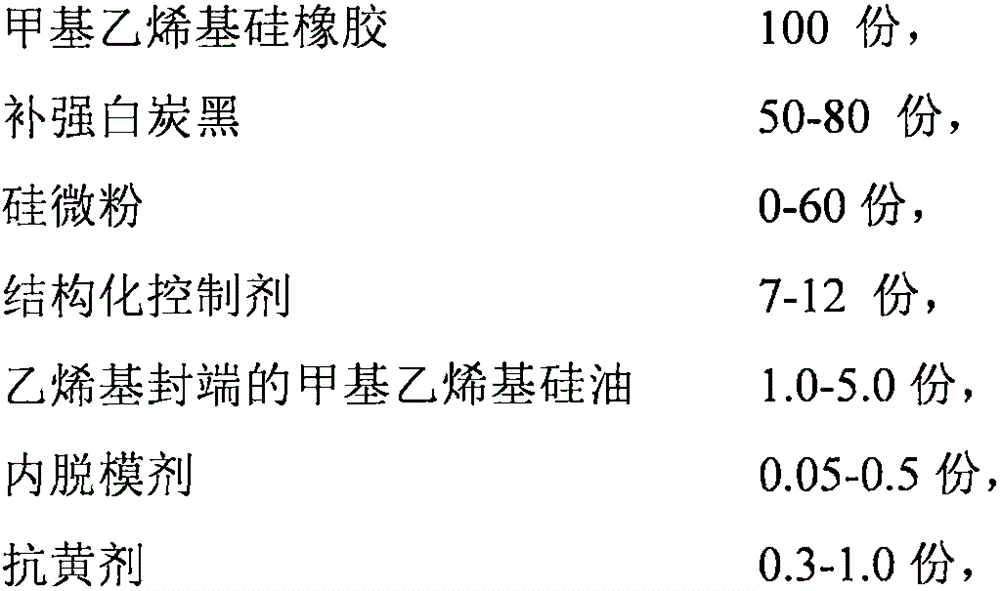

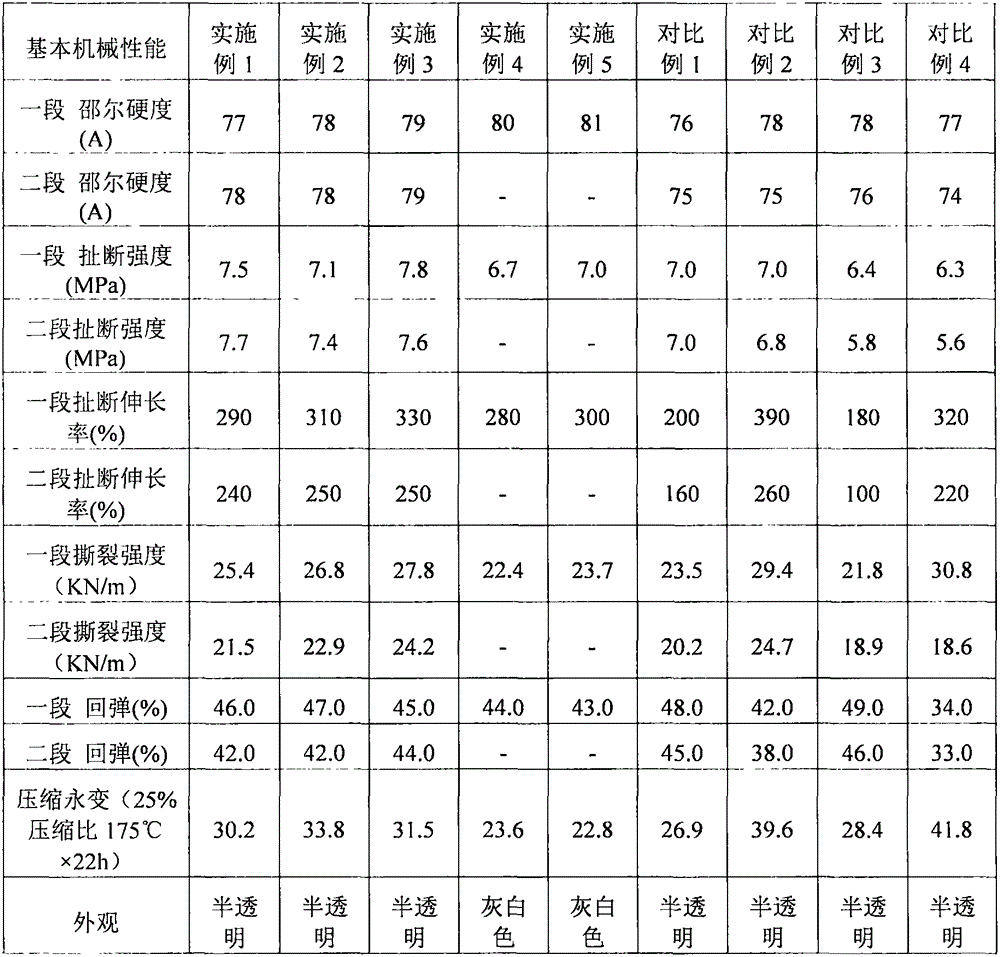

High-hardness extruded silicone rubber composition and preparation method thereof

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Foamed high resilience polyurethane wave-absorbing material and preparation method thereof

InactiveCN101519487AThe shape of the material is regularThe size of the bottom surface is accurate and consistentPliabilityFire retardant

The invention relates to a foamed high resilience polyurethane wave-absorbing material and a preparation method thereof. In the foamed high resilience polyurethane wave-absorbing material, a foamed combining material takes 4,4'-diphenylmethane diisocyanate and polyether glycol as main reaction substances, and is added with a conventional blowing promoter. The foamed high resilience polyurethane wave-absorbing material is characterized in that the foamed combing material also comprises substances such as an absorbent, a flame retardant and the like. The material is applied to full-anechoic chambers and semi-anechoic chambers, not only can achieve the effect of absorbing electromagnetic waves, but also has the characteristics of good environmental protection, flexibility, and dimensional uniformity, good mounting matrix property, beautifulness and consistency, and is particularly suitable for clean experiment environment.

Owner:NANJING BOPING ELECTRONICS TECH CO LTD

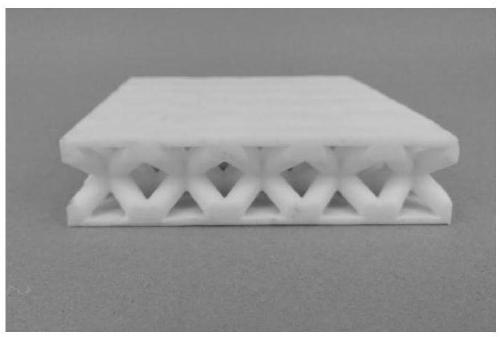

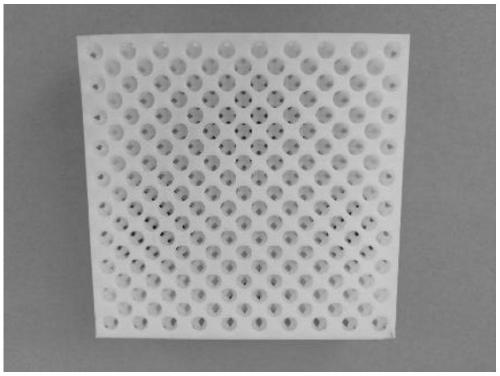

High-elastic foamed shoe insole material, and preparation method and application thereof

ActiveCN109206892AReduce weightHigh reboundAdditive manufacturing apparatusSolesCushioningThermoplastic elastomer

The invention provides a high-elastic foamed shoe insole material, and a preparation method and an application thereof, wherein the insole material is prepared by 3D-printing a thermoplastic resin compound material to form a green body, and performing supercritical fluid foaming shaping. The thermoplastic resin compound material includes: 55-100 parts of thermoplastic polyurethane resin, 0-50 parts of thermoplastic elastomer resin, 0.2-5 parts of a compatibilizer, 0.5-10 parts of a nucleating agent, 0-1.2 parts of an antioxidant, 0-1.2 parts of stearic acid, and 0-0.9 parts of a foam pore stabilizer. The insole material has a 3D structure, is light in weight, and has advantages of high resilience, low shrinking deformation and high cushioning effect. The insole material is shaped through 3D printing with the supercritical fluid impregnation and rapid pressure relief foaming. The method is green and environment-protective, is shorter in preparation process and higher in efficiency, andcan achieve customization.

Owner:ANTA CHINA

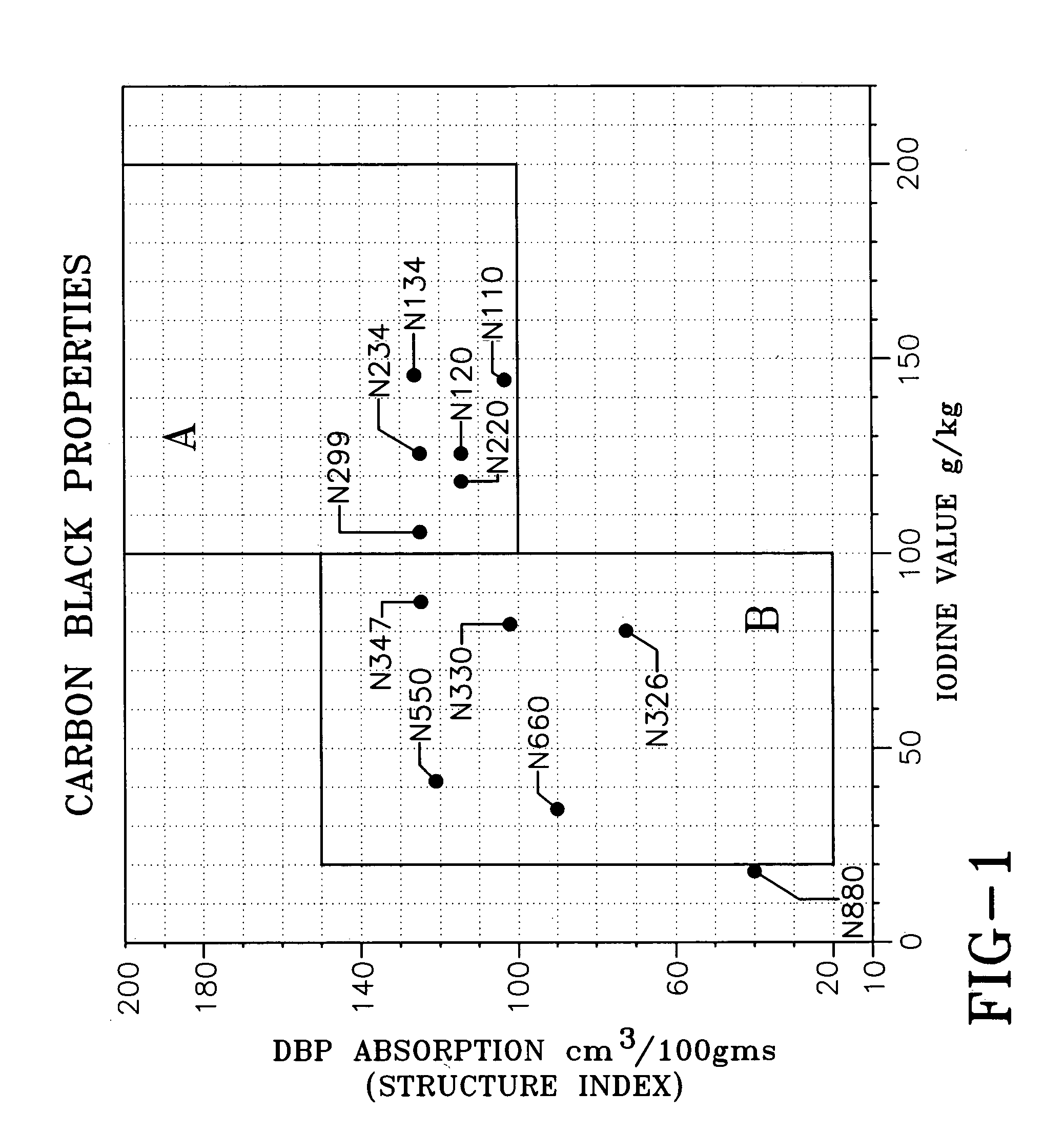

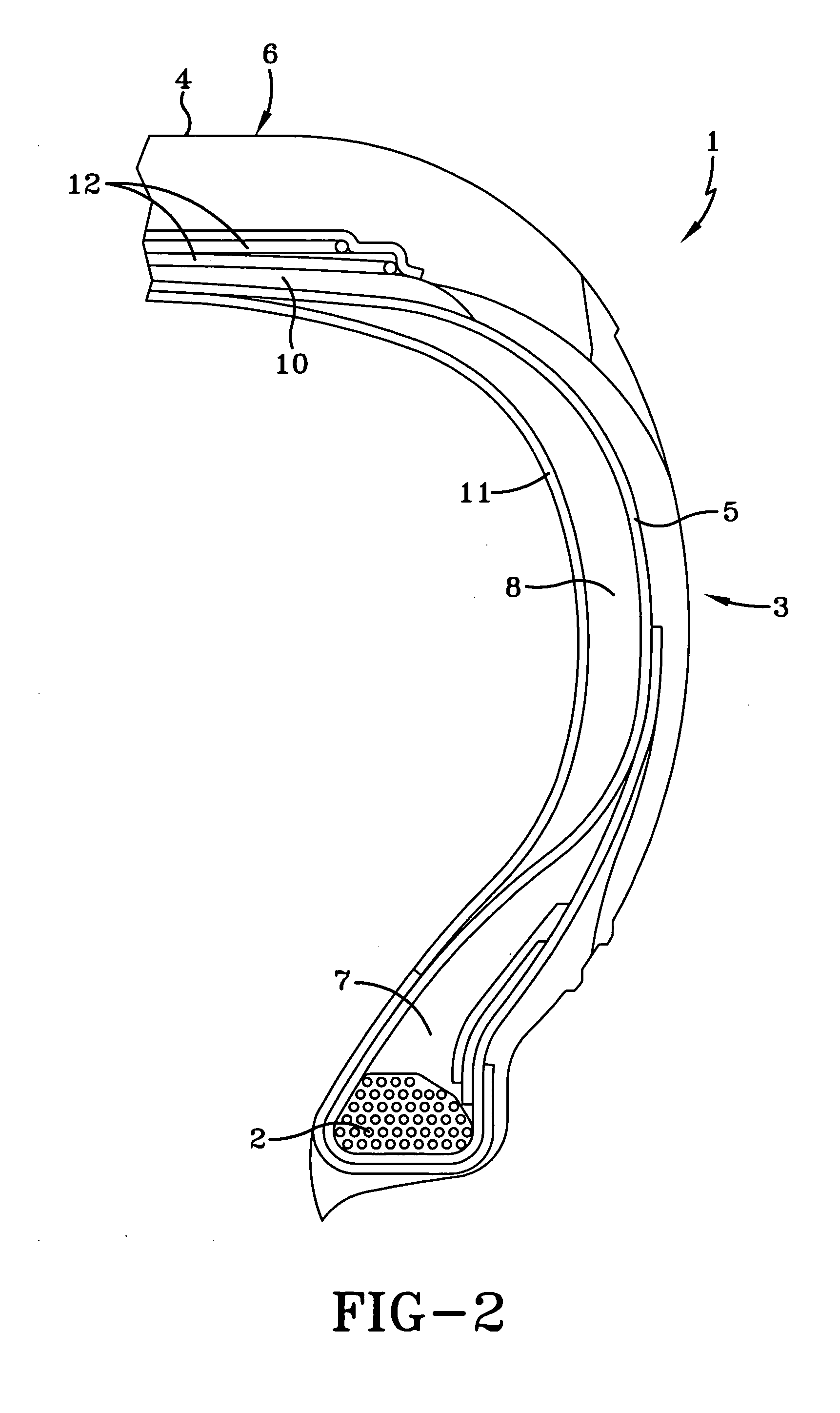

Tire with natural rubber rich tread and at least two additional rubber components with high reinforcing carbon blacks

The invention relates to pneumatic tires with a focus on pneumatic tires primarily intended for use in off-the-road service at relatively slow vehicular speeds, and to large truck tires, aircraft tires and agricultural tires and therefor not primarily focused on, and in one aspect intended to be exclusive of, passenger tires and particularly smaller passenger tires, wherein the elastomer composition of the treads, and at least two additional components, of such tires are of natural rubber rich rubber compositions composed, based upon the elastomers of the rubber compositions, of at least 45, alternately at least 75 weight percent cis 1,4-polyisoprene natural rubber. For this invention, the natural rubber rich treads and at least two additional natural rubber rich rubber components of such tires contain rubber reinforcing carbon blacks comprised primarily of high reinforcing, small particle size, carbon blacks. Silica reinforcement can also be used in combination with the high reinforcing carbon black for the natural rubber rich tire components.

Owner:SANDSTROM PAUL HARRY +2

Solid golf ball

ActiveUS7273425B2Improve performanceImprove wear resistanceGolf ballsSolid ballsThermoplasticPtru catalyst

The invention provides a solid golf ball having a solid core, a cover layer that encloses the core, and a plurality of dimples formed on an outside surface of an outermost layer of the cover. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, and an unsaturated carboxylic acid or a metal salt thereof, an organic peroxide and an inorganic filler. The solid core has a deformation, when subjected to loading from an initial load of 10 kgf to a final load of 130 kg, of 2.0 to 3.5 mm, and has a specific hardness distribution. The cover layer, which is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The core has a surface hardness which is from 1 to 15 Shore D hardness units lower than the surface hardness of the core. The golf ball has a deformation, when subjected to loading from an initial load of 10 kgf to a final load of 130 kgf, of 2.0 to 2.9 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

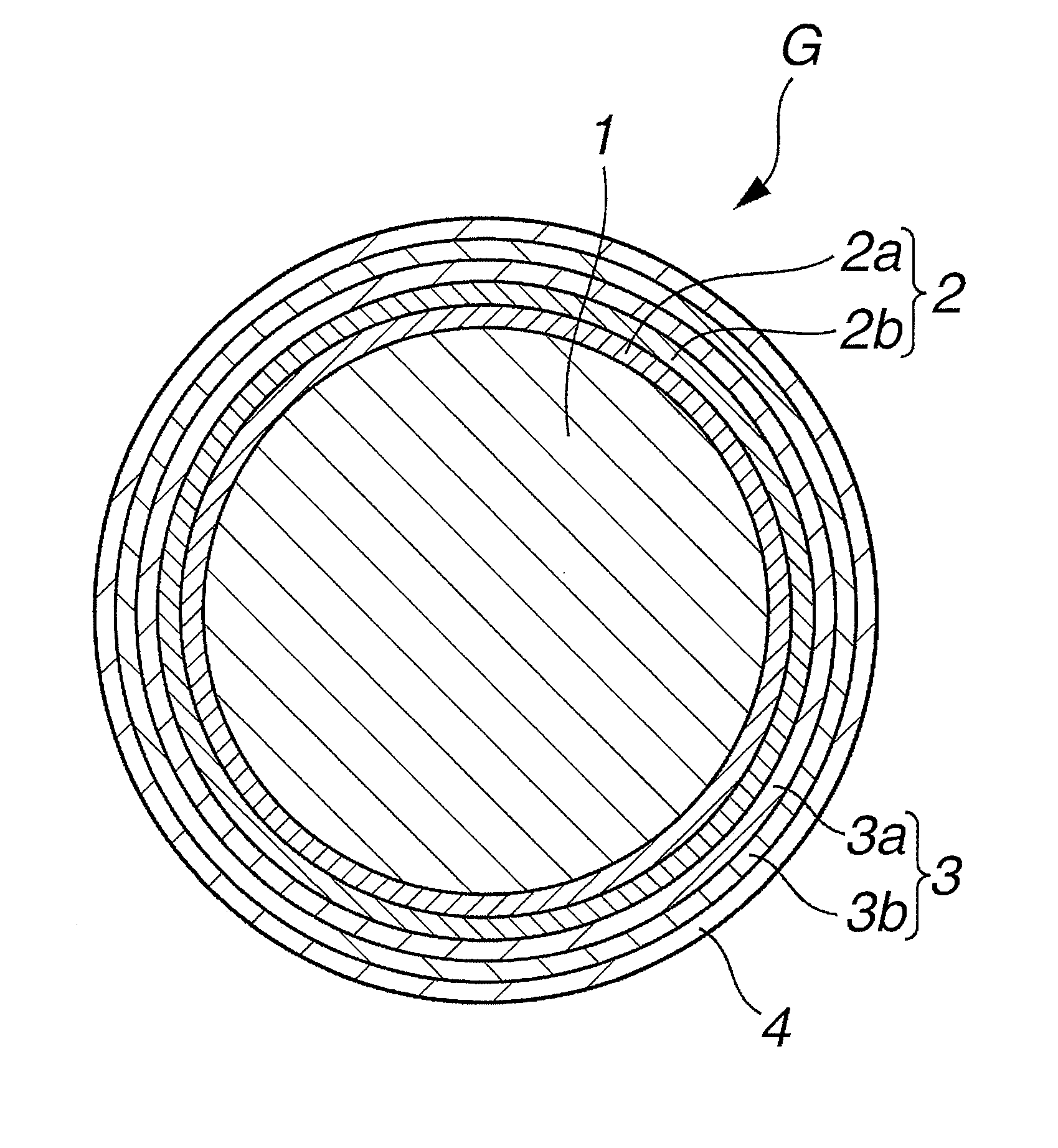

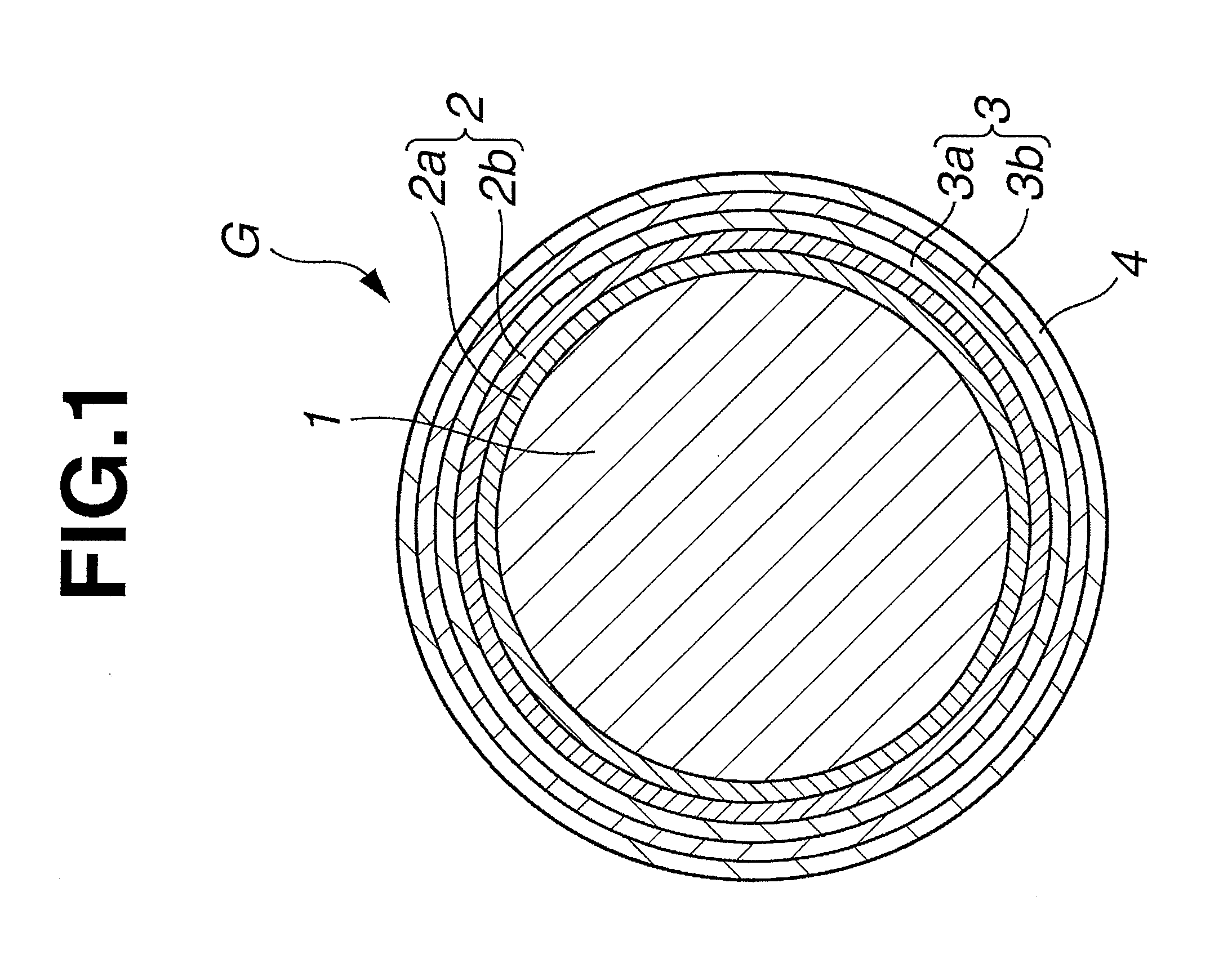

Multi-piece solid golf ball

A multi-piece solid golf ball has a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and an outer layer which encases the envelope layer and has formed on a surface thereof a plurality of dimples. The core is made of an elastomer. The envelope layer is formed of an inner envelope layer and an outer envelope layer, and the intermediate layer is formed of an inner intermediate layer and an outer intermediate layer. Letting the average hardness of the core be expressed by the following formula:average core hardness (Shore D)=[core surface hardness (Shore D)+core center hardness (Shore D)] / 2,the outer layer has a hardness (Shore D) which is higher than the average core hardness and each of the envelope layers and the intermediate layers is softer than the outer layer.The invention provides a multi-piece solid golf ball in which importance is placed on achieving an excellent flight when played by ordinary amateur golfers who do not have a very high head speed, and on having a good, soft feel on impact.

Owner:BRIDGESTONE SPORTS

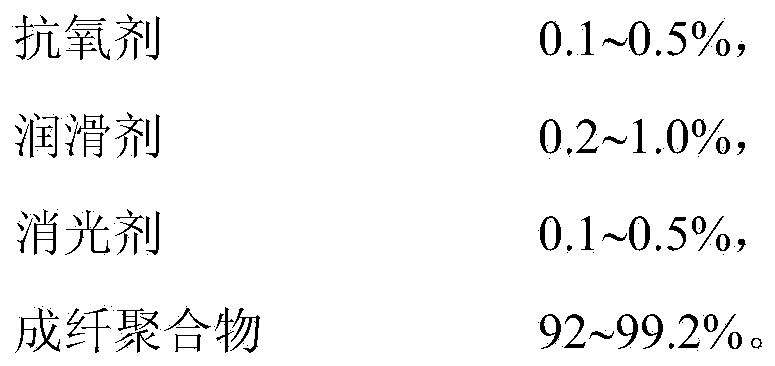

Material for rubber forming shoes and preparation method of material

The invention provides a material for rubber forming shoes and a preparation method of the material, relating to a rubber foaming material. The material for the rubber foaming shoes consists of the following raw materials in parts by mass: 100 parts of a main material, 1-5 parts of a vulcanizing agent, 1-4 parts of a vulcanizing adjuvant, 2-5 parts of a foaming agent, 8-15 parts of a plasticizer, 6-20 parts of a filler, 2-6 parts of a lubricant, 0-10 parts of an abrasion-resistant agent, 0.5-2 parts of an antioxidant, and 1.5-3 parts of pigment. The preparation method comprises the following steps of: mixing the raw materials according to the ratio into an internal mixer for mixing until a temperature of rubber is increased to 80-90 DEG C; discharging the mixed materials out the internal mixer, and pelleting through a pelleting machine; placing the pelleted material into an injection molding machine for fusing and vulcanizing; and molding through mould pressing, so as to obtain a product. The cost is low, the preparation method is simple, and the foaming rate and the rigidity are controllable; and the preparation method can be used for producing sandals, high-level beach shoes and the materials of insoles of sneakers, outsoles of leather shoes and the like. The material provided by the invention can replace the conventional shoe foaming material EVA (ethylene-vinyl acetate copolymer); and the defects of poor EVA strength, easiness of deformation, low cost performance and the like can be overcome.

Owner:泉州永悦新材料有限公司

High-resilience urethane elastic fiber as well as preparation method thereof

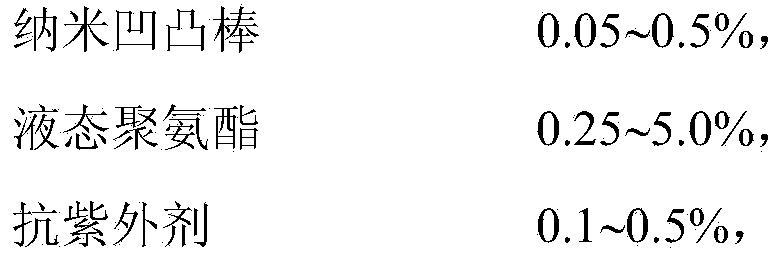

ActiveCN103436983AHigh reboundImprove the degree of microphase separation of soft and hard segmentsMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberEthylenediamine

The invention relates to a preparation method of a high-resilience urethane elastic fiber. The preparation method comprises the following steps: (1) mixing raw materials, namely, polytetramethylene ether glycol (PTMEG) and 4, 4-diphenylmethane diisocyanate (MDI) to carry out reaction so as to obtain a prepolymer; (2) adding a certain amount of a mixed diamine chain extender into the prepolymer to form polymer liquor; (3) quickly adding polyamine (the number of functional groups is greater than 2) into the polymer liquor while stirring to carry out reaction so as to form polyurethaneurea liquor; (5) carrying out reaction on MDI and polyether polyhydric alcohol and blocking with ethanediamine to prepare oligomers; (6) blending nano attapulgite with the oligomers to prepare a prepreg; and (7) mixing the polyurethaneurea liquor with the prepreg to prepare a spinning dope, and spinning to form the high-resilience urethane elastic fiber. The preparation method of the high-resilience urethane elastic fiber provided by the invention satisfies the demands on the high-resilience urethane elastic fiber in certain special fields, and the resilience of the urethane elastic fiber is improved.

Owner:ZHEJIANG HUAFENG SPANDEX

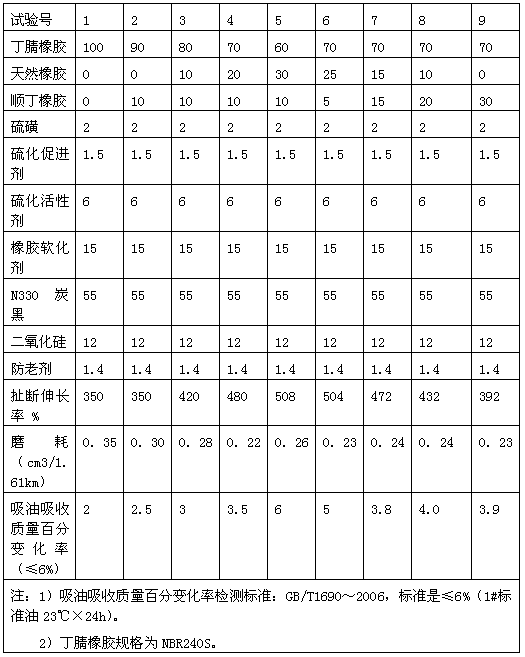

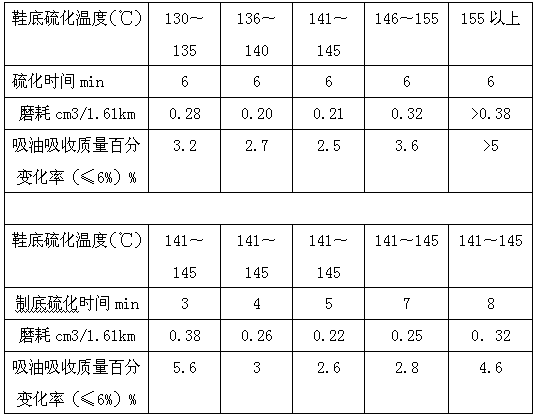

High-elongation wear-resistant oil-resistant rubber sole and preparation method thereof

The invention discloses a high-elongation wear-resistant oil-resistant rubber sole and a preparation method thereof. The rubber sole comprises 65-75 weight parts of nitrile rubber, 15-25 weight parts of natural rubber, 8-12 weight parts of butadiene rubber, 1.8-2.0 weight parts of sulphur, 1.5-2.1 weight parts of sulfuration promoter, 6-7 weight parts of sulfuration activator, 15-21 weight parts of rubber softener, 50-58 weight parts of N330 carbon black, and 8-12 weight parts of silica. According to the invention, by designing the rubber formula of the rubber sole, the processing conditions of the rubber sole and the sulfuration technology of the sole, the external force resistance of the rubber is enhanced, the elongation of the rubber is raised, the outsole rebound is raised, the requirement of wear-resistant oil resistance is realized fundamentally, the problems of bad oil resistance, low wear resistance, and low elongation existing in the present rubber soles are solved, the wear resistance and oil resistance of the rubber sole are raised, and the service life is prolonged.

Owner:际华制鞋工业有限公司

Multi-piece solid golf ball

A multi-piece solid golf ball has a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and an outer layer which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is made of an elastomer. The envelope layer is formed of an inner envelope layer and an outer envelope layer, and the intermediate layer is formed of an inner intermediate layer and an outer intermediate layer. The outer layer has a hardness which is higher than the average core hardness, and each of the envelope layers and the intermediate layers is softer than the outer layer.

Owner:BRIDGESTONE SPORTS

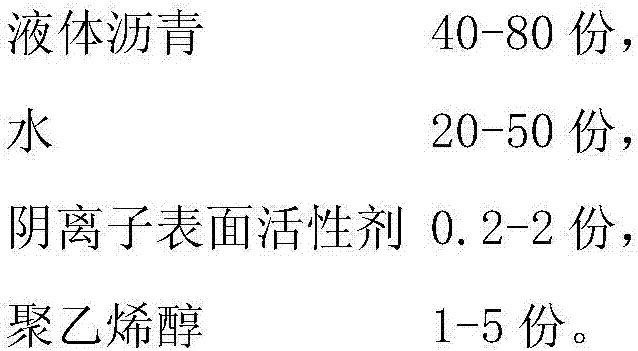

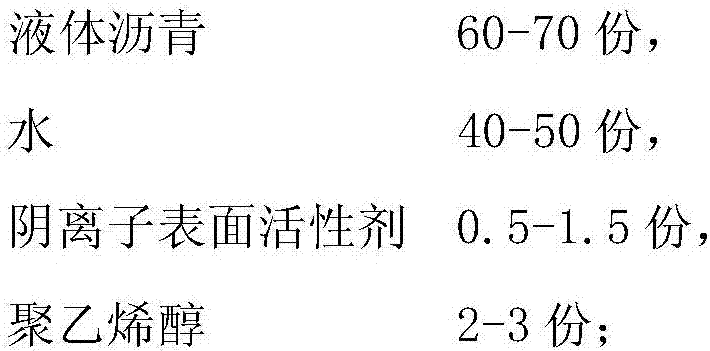

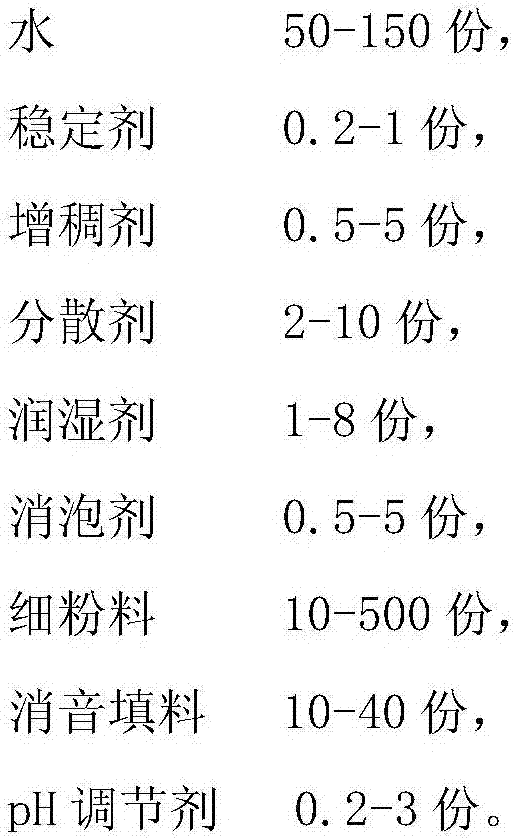

Modified asphalt waterproof coating, preparation method for modified asphalt waterproof coating and use method thereof

ActiveCN106957601AAvoid reunionTechnical effect of avoiding subsidenceBituminous coatingsBituminous waterproofingSlurry

The invention discloses a modified asphalt waterproof coating, a preparation method for the modified asphalt waterproof coating and a use method thereof and relates to the field of building materials. The problems of sound insulation and noise reduction of the waterproof coating film can be solved. The preparation method for the modified asphalt waterproof coating disclosed by the invention comprises the following steps: preparing the modified asphalt waterproof coating from a component A and a component B; mixing and uniformly stirring anion emulsified asphalt, polymer emulsion and slurry, thereby acquiring the component A; and uniformly mixing water with curing agent, thereby acquiring the component B, wherein the slurry is prepared according to the following steps: adding water, stabilizer, dispersing agent, wetting agent, de-foaming agent, fine powder and pH regulator into a dispersing device, dispersing for the first time, adding a silencing filling material soaked with a silane coupling agent solution after ending the dispersing for the first time, and then adding a thickening agent, dispersing for the second time and then ending the dispersing for the second time, thereby acquiring the slurry. The modified asphalt waterproof coating disclosed by the invention has excellent effects of sound insulation and noise reduction on the basis of excellent waterproof property.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Golf ball

A golf ball having a core, an intermediate layer enclosing the core and a cover enclosing the intermediate layer is characterized in that the intermediate layer and cover are each made from an ionomer resin-containing thermoplastic resin. The golf ball is also characterized in that the core has a diameter of at least 36.7 mm but not more than 40.7 mm, the core has a deflection when subjected to a load of 100 kg of at least 3.5 but not more than 6.0 mm, the intermediate layer has a thickness of at least 0.50 mm but not more than 1.40 mm, the intermediate layer has a Shore D hardness of at least 40 but not more than 55, the cover has a thickness of at least 0.50 mm but not more than 1.40 mm, the cover has a Shore D hardness of at least 60 but not more than 70, the golf ball has a deflection when subjected to a load of 100 kg of at least 2.8 mm but not more than 4.5 mm, and the deflection by the core under 100 kg load minus the deflection by the golf ball under 100 kg load is less than 1.0 mm.

Owner:BRIDGESTONE SPORTS

Golf Ball

A golf ball having a core, an intermediate layer enclosing the core and a cover enclosing the intermediate layer is characterized in that the intermediate layer and cover are each made from an ionomer resin-containing thermoplastic resin. The golf ball is also characterized in that the core has a diameter of at least 36.7 mm but not more than 40.7 mm, the core has a deflection when subjected to a load of 100 kg of at least 3.5 but not more than 6.0 mm, the intermediate layer has a thickness of at least 0.50 mm but not more than 1.40 mm, the intermediate layer has a Shore D hardness of at least 40 but not more than 55, the cover has a thickness of at least 0.50 mm but not more than 1.40 mm, the cover has a Shore D hardness of at least 60 but not more than 70, the golf ball has a deflection when subjected to a load of 100 kg of at least 2.8 mm but not more than 4.5 mm, and the deflection by the core under 100 kg load minus the deflection by the golf ball under 100 kg load is less than 1.0 mm.

Owner:BRIDGESTONE SPORTS

Antibacterial and moldproof polymer modified spray asphalt waterproof paint and application method thereof

ActiveCN105462496AWon't breedReduce secondary pollutionAntifouling/underwater paintsPaints with biocidesPolymer modifiedBituminous waterproofing

The invention provides antibacterial and moldproof polymer modified spray asphalt waterproof paint and an application method thereof. The paint is composed of a component A and a component B. The component A is prepared from, by weight, 90-120 parts of anionic emulsified asphalt, 40-90 parts of polymer emulsion, 0.5-5 parts of a thickening agent and 10-60 parts of filler. The component B is prepared from, by weight, 100 parts of water, 5-15 parts of a curing agent and 0.5-5 parts of an antibacterial agent. The invention further provides the application method of the antibacterial and moldproof polymer modified spray asphalt waterproof paint. The antibacterial and moldproof polymer modified spray asphalt waterproof paint has high ductility, high resilience and high adhering strength, is antibacterial and moldproof, excellent in low-temperature performance and high in construction speed and can be closely connected with a basic layer, and influences of deformation of the basic layer on the waterproof performance of a material can be effectively resisted; meanwhile, the situation that bacteria are bred on the surface of a coating film, and the coating function of a waterproof layer is damaged can be effectively prevented, and the possibility that an antibacterial agent has secondary pollution on water is reduced.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

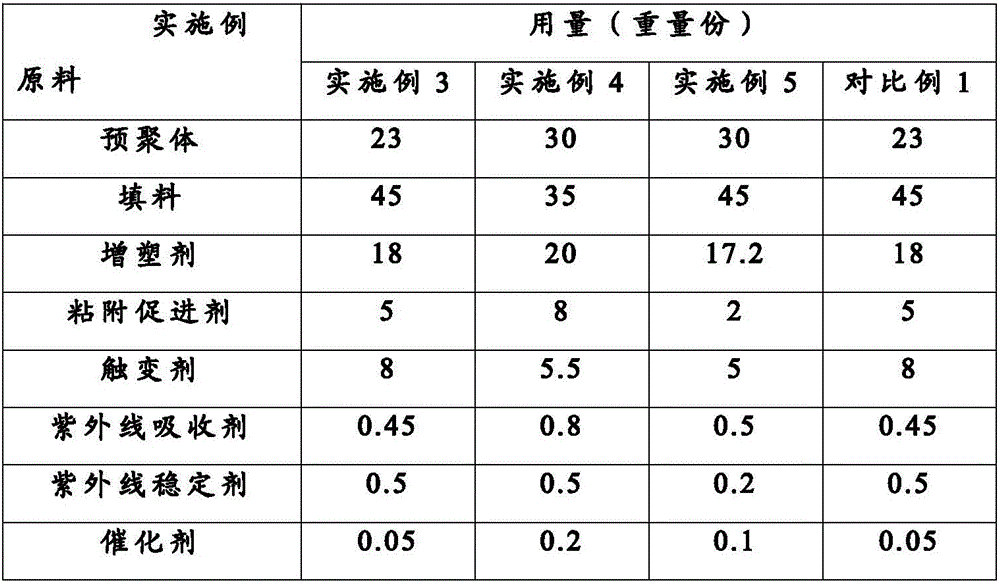

Silane modified polyurethane sealant prepolymer and preparation method thereof and sealant

The invention relates to a silane modified polyurethane sealant prepolymer and a preparation method thereof and a sealant. The prepolymer is prepared from, by mass, 70%-80% of polyether polyol, 10%-20% of isocyanate and 5%-15% of silane coupling agent, wherein polyether polyol is a mixture of polyether polyol A and polyether polyol B according to the mass ratio of 0.2 to 0.3, the polyether polyol A is polyether diol, and the polyether polyol B is polyether triol. The prepolymer is end-capped with silane, the molecular structure of the prepolymer has polyether segments with carbamate as nodes and chain segments end-capped with silane, the characteristics of silane and polyurethane are combined, the prepolymer is used for preparing the sealant, and the sealant has the performance of low modulus and high resiliency.

Owner:JIANGSU CANLON BUILDING MATERIALS

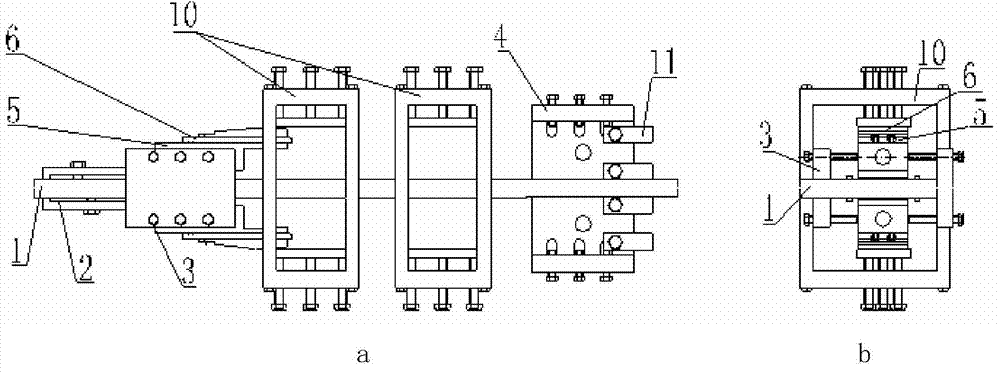

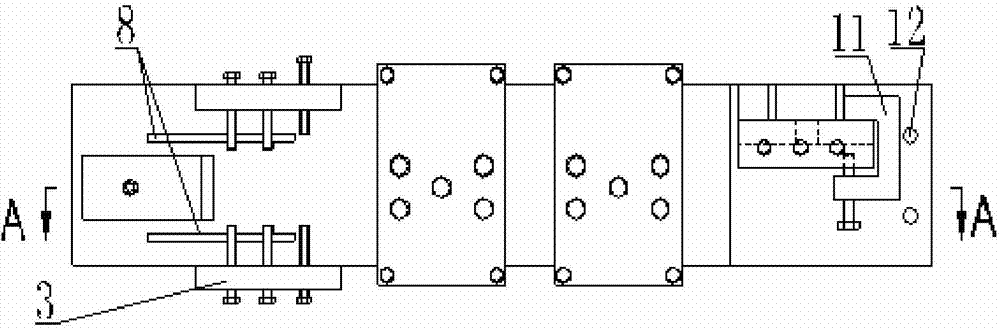

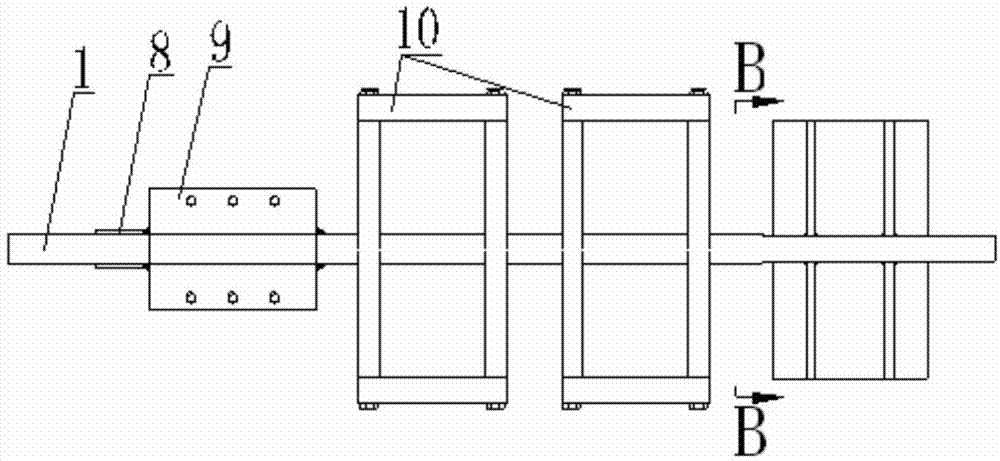

Device for heat shaping of thin-walled titanium alloy parts

The invention relates to a device for heat shaping of thin-walled titanium alloy parts. A first pressing mechanism is fixed at one end of a body, and a second pressing mechanism is fixed at the other end of the body. Two clamping mechanisms are mounted in the middle of the body. Two clamping plates of a lateral ejection mechanism are fixed on two lateral surfaces of the body respectively and located between the first pressing mechanism and the clamping mechanisms. A width inner-supporting mechanism is located between the two clamping plates of the lateral ejection mechanism, one end of the width inner-supporting mechanism is mounted in a to-be-shaped part, and cavity inner-supporting mechanisms are mounted on the upper surface and the lower surface of the width inner-supporting mechanism. One ends of the cavity inner-supporting mechanisms are mounted in the clamping mechanisms, so that a support body with a wedge-shaped inner cavity is formed in the to-be-shaped part. By the device, utilization rate of a heat treatment furnace is increased, and cost of vacuum heat shaping is lowered. Since the to-be-shaped parts are clamped symmetrically, main stresses of a tooling are symmetric in direction and offset each other, stress state of the tooling is improved, and deformation resistance of the tooling is enhanced indirectly.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Multi-piece solid golf ball

ActiveUS20080146376A1Improve wear resistanceFlight performance and controllabilityGolf ballsSolid ballsRubber materialInter layer

The invention provides a multi-piece solid golf ball having a core, an envelope layer which encases the core and is composed of an inside layer and an outside layer, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is formed primarily of a rubber material, and the envelope layer, intermediate layer and cover are each formed primarily of the same or different resin materials. The envelope layer, intermediate layer and cover have thicknesses which satisfy the relationship: cover thickness<intermediate layer thickness<envelope layer total thickness. The envelope layer, intermediate layer and cover have material hardnesses (Durometer D hardness) which satisfy the relationship: hardness of envelope inside layer material<hardness of envelope outside layer material<hardness of intermediate layer material>hardness of cover material. The envelope outside layer material has a Durometer D hardness of at least 53. The golf ball of the invention has an excellent flight and controllability which are acceptable to professional and skilled amateur golfers, and also has an excellent durability to cracking on repeated impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

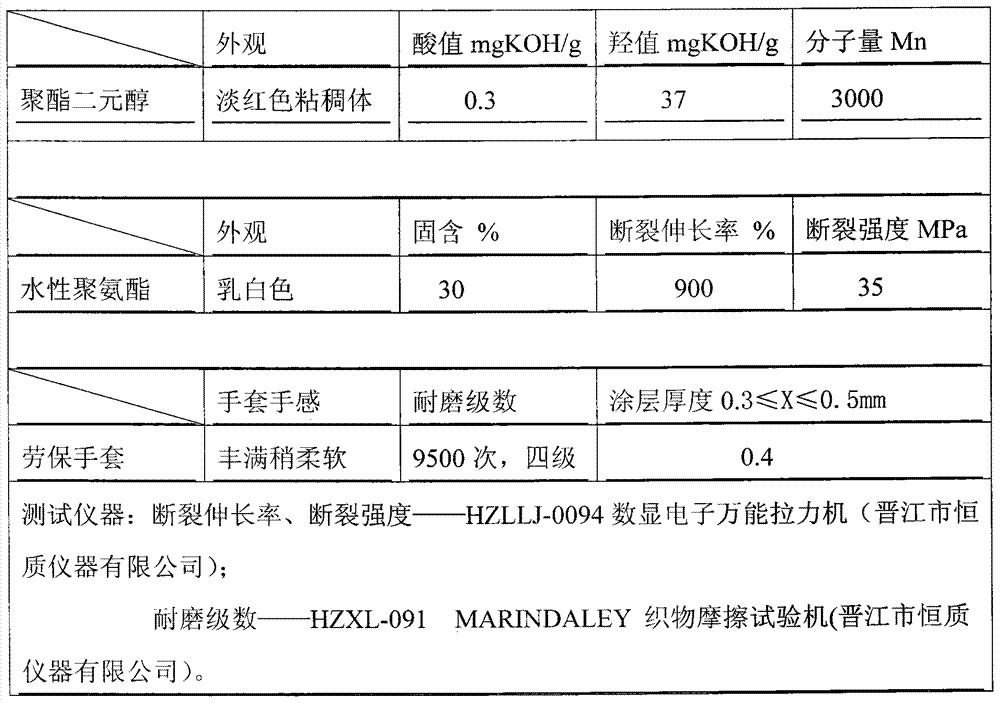

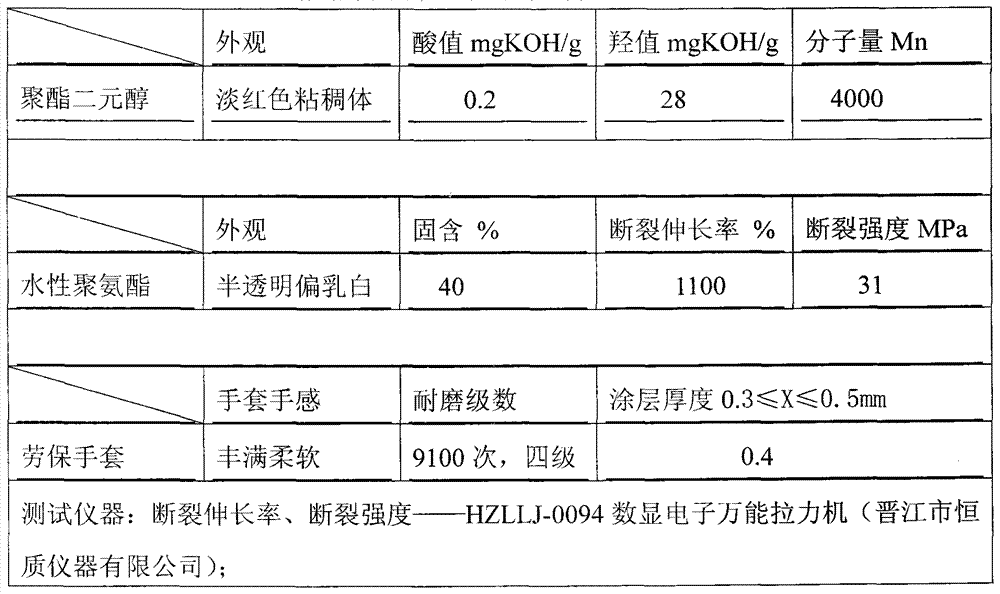

Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

InactiveCN104497258ASolve the hard feelingSolving Elasticity ProblemsAbrasion resistant fibresPolyesterSlurry

The invention discloses super-elastic wear-resisting waterborne polyurethane resin which is prepared by polymerizing polyester glycol and polyisocyanates. The invention further discloses a preparation method of the resin. By adopting the super-elastic wear-resisting waterborne polyurethane resin disclosed by the invention, slurry can be prepared to coat the surfaces of knitted gloves, so that the problems that in the prior art, knitted gloves made by using a conventional method are hard in hand feeling, poor in resilience, low in wearing resistance, and the like.

Owner:ANHUI LINGDA CHEM TECH

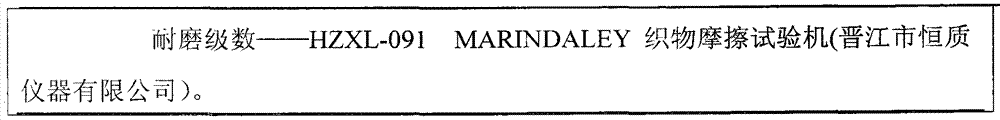

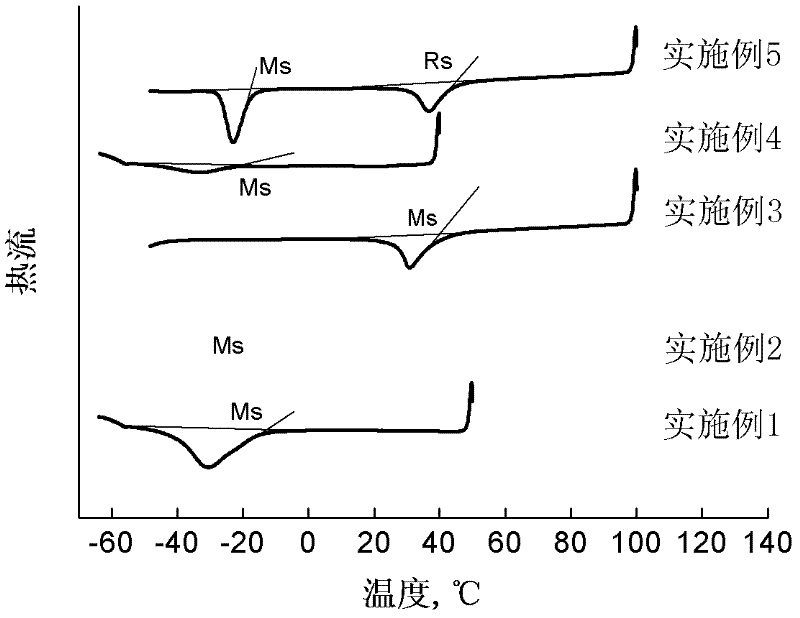

Shape memory alloy sealing gasket and production technology thereof

InactiveCN102409197AUnder high pressureGuaranteed anti-agingFlanged jointsNiti alloyShape-memory alloy

The invention discloses a shape memory alloy sealing gasket. The sealing gasket is characterized in that the material comprises the following components in parts by weight: 53.25-58.42 parts of Ni, 41.63-45.82 parts of Ti, 0.1-0.2 part of Al, 0.01-0.03 part of Cu and 0.015-0.12 part of V. The shape memory alloy sealing gasket utilizes the superelasticity and shake-suction performance of the NiTi alloy and has the advantages of good compression elasticity, corrosion resistance, fatigue resistance, high pressure resistance and good safe reliability.

Owner:NANJING UNIV OF TECH

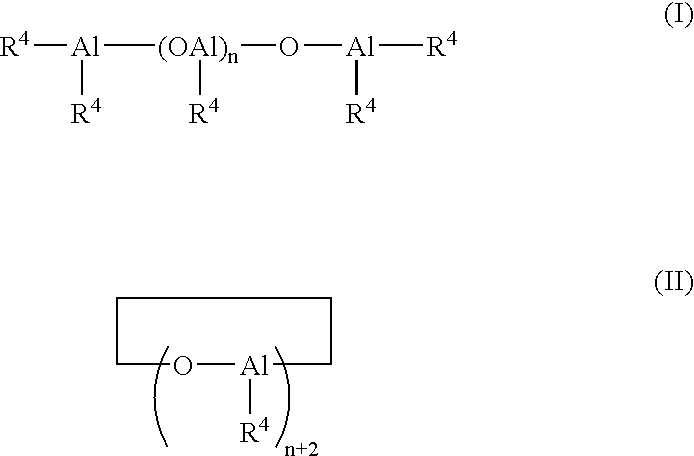

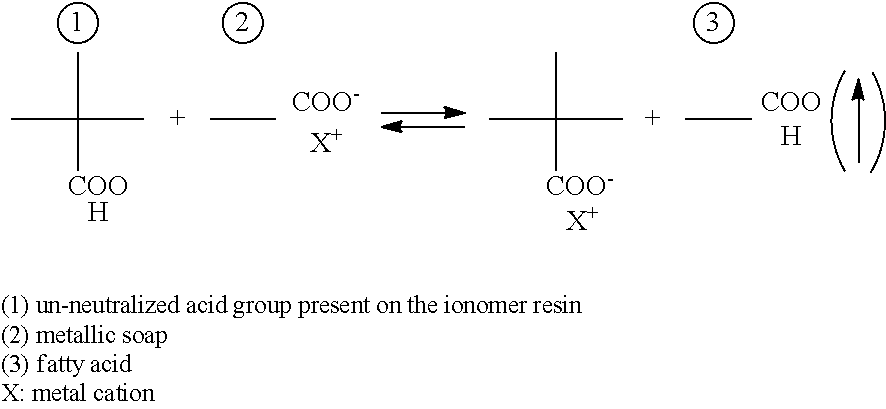

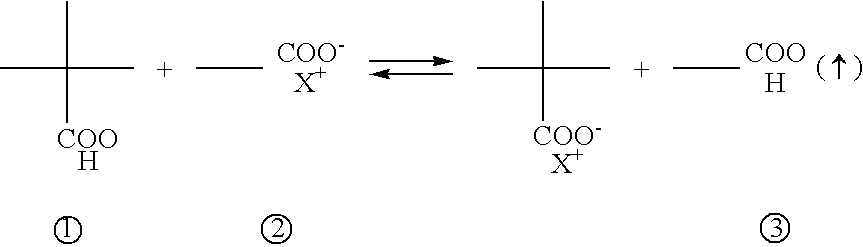

Golf ball material and method of preparing the same

ActiveUS20120029130A1Increase elasticityIncreased durabilityLiquid surface applicatorsConductive materialOrganic acidHardness

The invention provides a golf ball material which is a resin mixture composed of (a) a nonionic olefin-unsaturated carboxylic acid copolymer and / or olefin-unsaturated carboxylic acid-unsaturated carboxylic acid ester copolymer, (b) a nonionic olefin-unsaturated carboxylic acid copolymer and / or olefin-unsaturated carboxylic acid-unsaturated carboxylic acid ester copolymer, (c) an organic acid or a metal salt thereof, (d) a basic inorganic metal compound for neutralizing at least 70 mol % of acid groups in components (a) to (c), and (e) a spherical inorganic filler, which resin mixture has a Shore D hardness of from 40 to 60. The golf ball material of the invention provides an excellent rebound resilience and durability while maintaining the flow properties essential for injection molding.

Owner:BRIDGESTONE SPORTS

Golf ball

Owner:DUNLOP SPORTS CO LTD

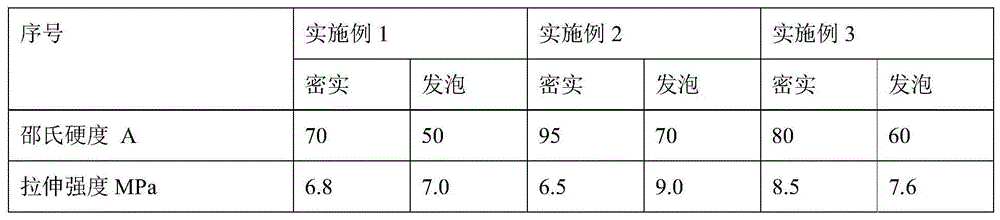

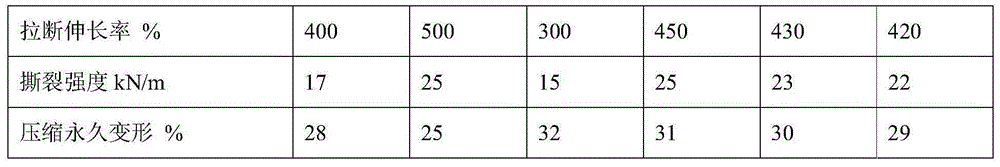

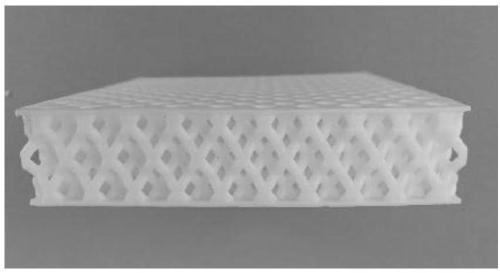

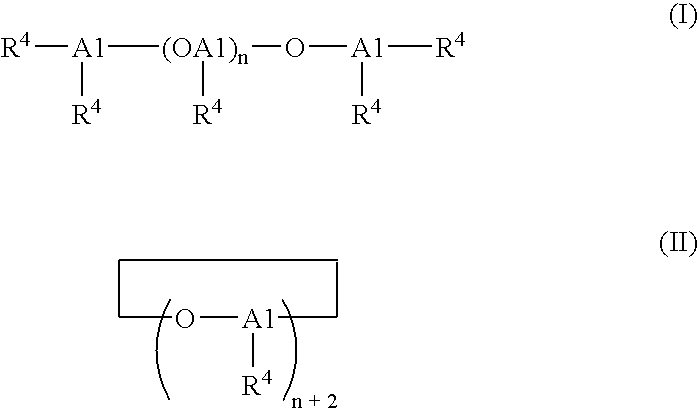

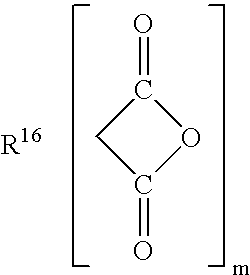

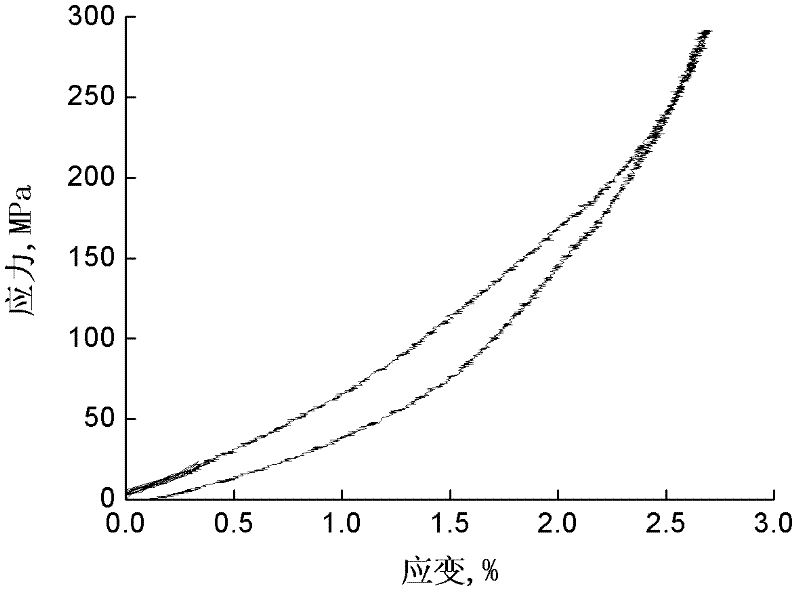

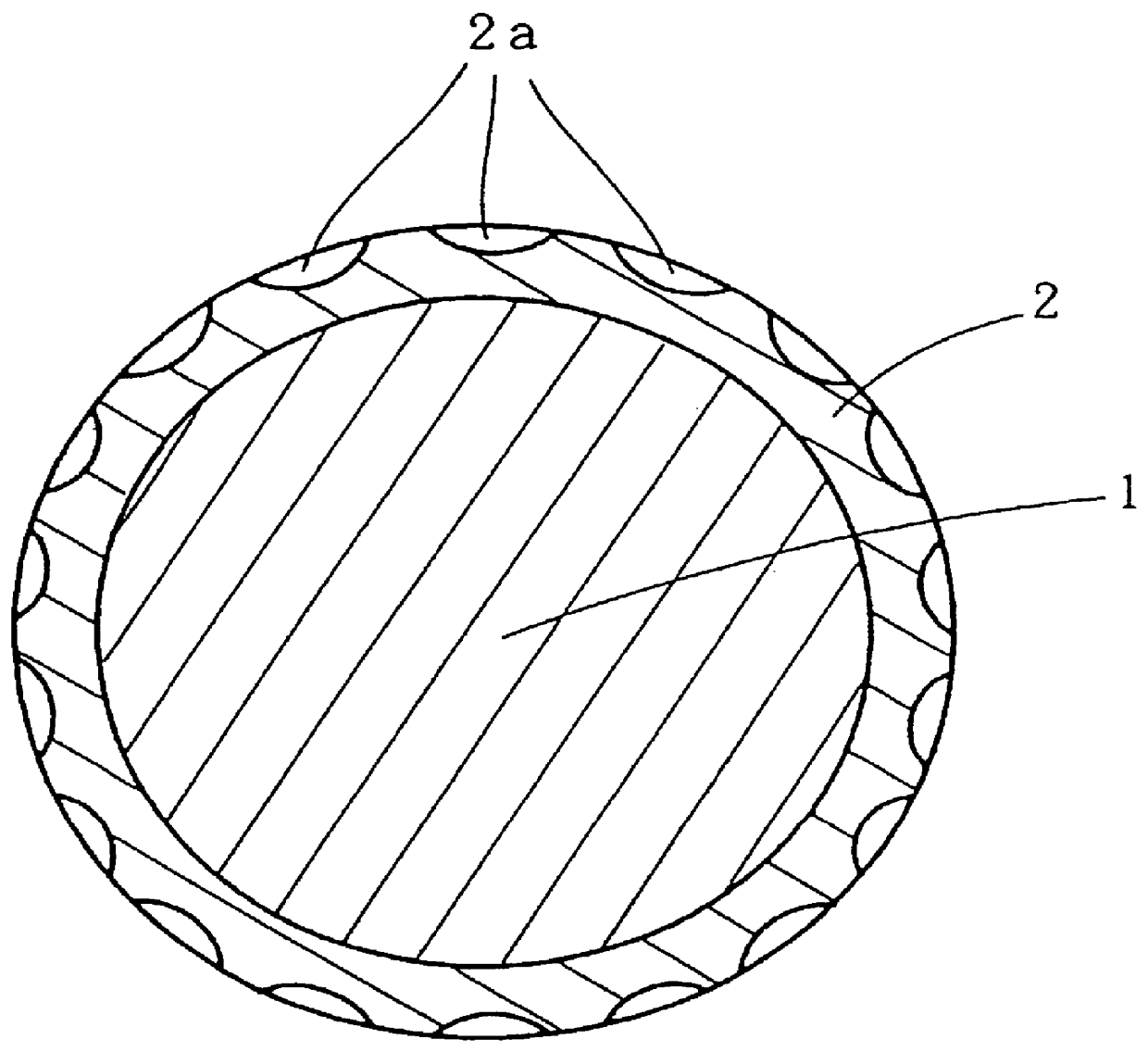

Dynamic polymer foam composite material[v]

The invention discloses a dynamic polymer foam composite material. The dynamic polymer foam composite material contains polymer foam particles with skins and a dynamic polymer, wherein the polymer chain of the dynamic polymer contains dynamic covalent bonds and / or supramolecular interaction; wherein the polymer foam particle with the skin is prepared from an expandable polymer (composition) or anexpandable polymer precursor (composition) through direct foaming and / or 3D printing, and has a skin structure; wherein the skinned polymer foam particles are compounded with the dynamic polymer and other optional components to form the composite material. The composite material has the characteristics of low density, lightness, heat insulation, sound insulation, buffering, shock absorption and dynamic property, and can be widely applied to manufacturing of packaging materials, building materials, impact-resistant protective materials, shock absorption materials, buffering materials, sound attenuation materials, heat preservation materials, shape memory materials, electronic and electrical appliance materials, medical supplies and the like.

Owner:厦门天策材料科技有限公司

Formula and production technology of polyurethane low-speed solid tire

The invention relates to a formula and a production technology of a polyurethane low-speed solid tire and belongs to the technical field of high-polymer material products. The formula is characterized by comprising the following raw materials in parts by weight: 0.8-1.5 parts of polyester polyol, 0.15-0.25 parts of toluene diisocyanate, and 0.1-0.15 parts of curing agent component. The production technology is characterized by specifically comprising the following steps: dehydrating the polyester polyol and adding toluene diisocyanate to firstly obtain a prepolymer; and respectively feeding the prepolymer and the curing agent components into tanks A and B of a casting machine, mixing according to the weight parts and casting into a tire casting die, performing casting forming, and performing secondary vulcanization. The integrated solid tire having completely identical internal material, external material and performances is prepared by virtue of the formula technology and the formula, and the technology can be realized by performing primary cast forming through the tire casting die, and the production technology of the tire can be greatly simplified.

Owner:日照悍马轮胎股份有限公司

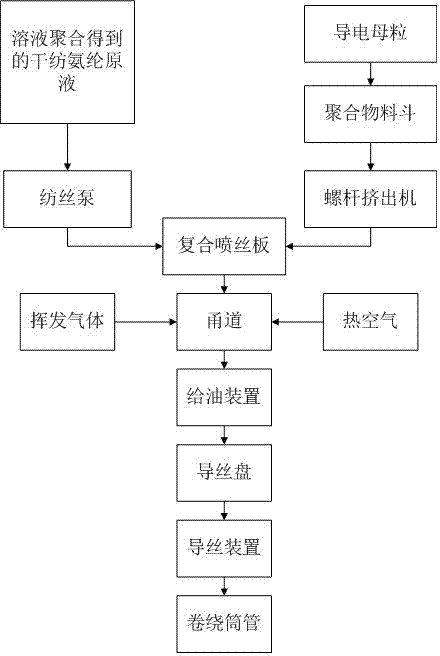

Conductive spandex fiber and preparation method thereof

InactiveCN106868614AImprove conductivityConductivity has no effectElectroconductive/antistatic filament manufactureFilament/thread formingFiberSurface layer

The invention discloses a conductive spandex and a production method. The production method attaches a layer of melt-spun spandex skin layer containing a certain proportion of conductive particles on the outside of the dry-spun spandex, so that the polyurethane elastic fiber can maintain high elongation and high resilience. At the same time, it has good electrical conductivity. Fabrics using conductive spandex have good antistatic properties. The conductive spandex produced by this method has excellent durability and stability, and friction, bending and washing have no effect on its conductive performance.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

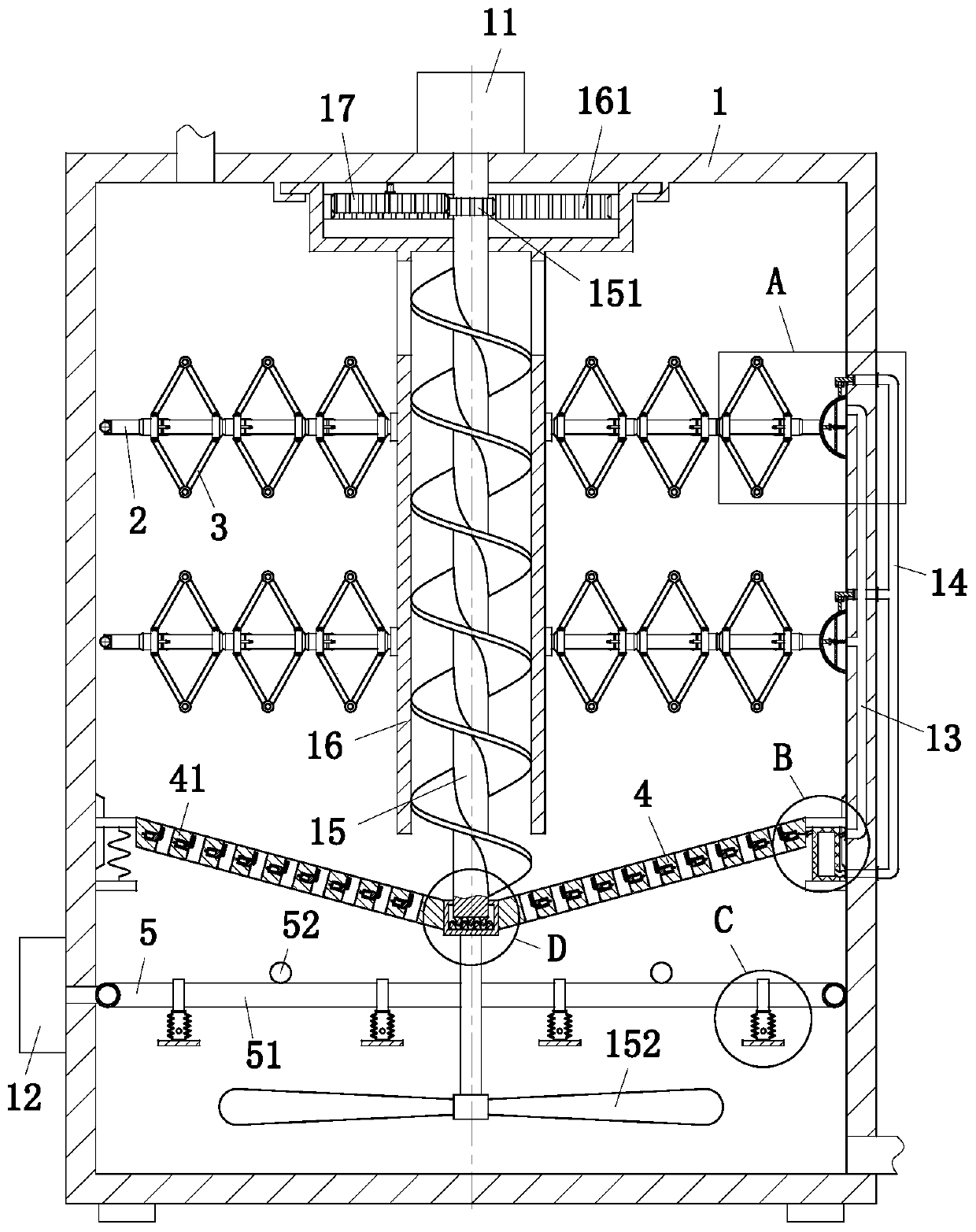

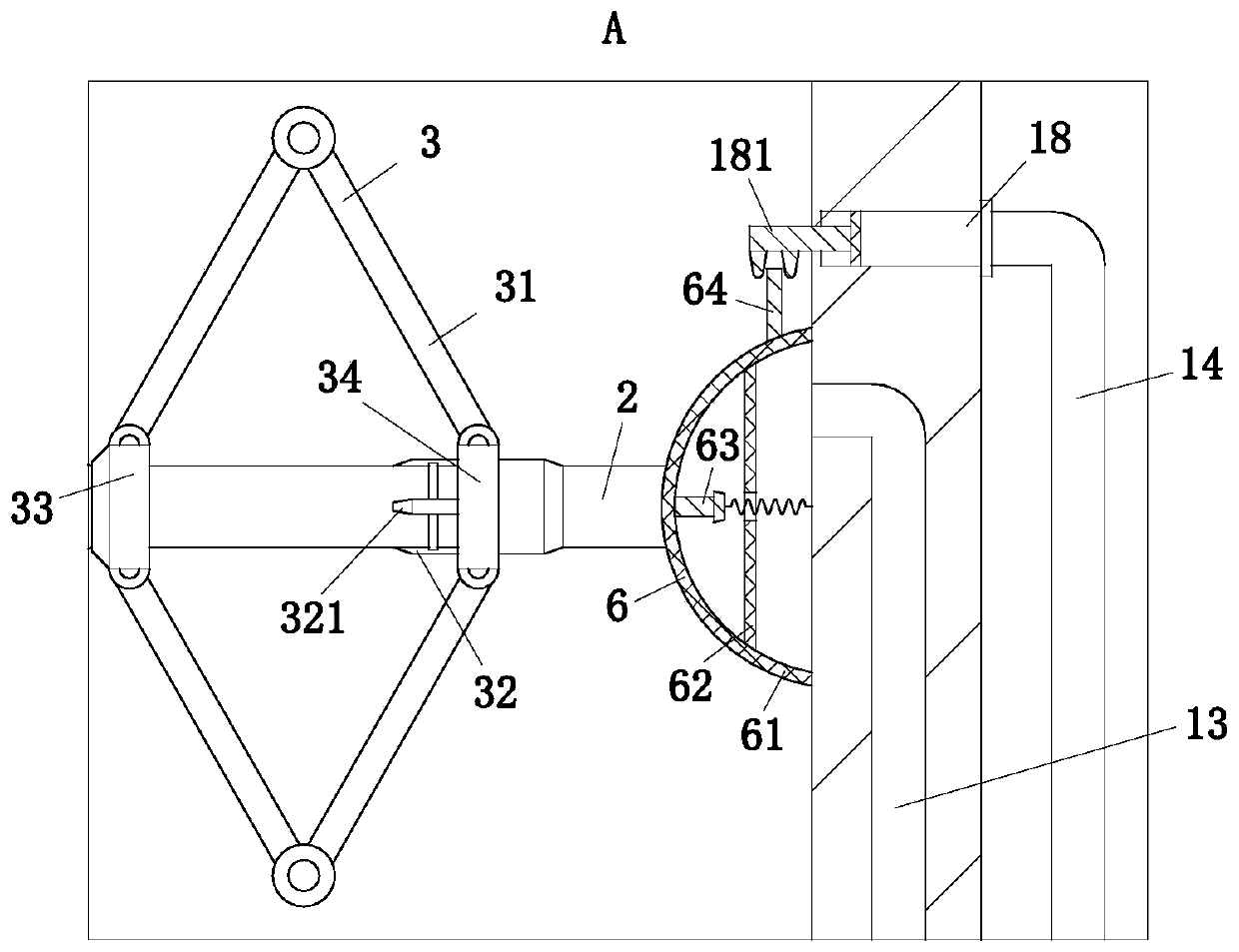

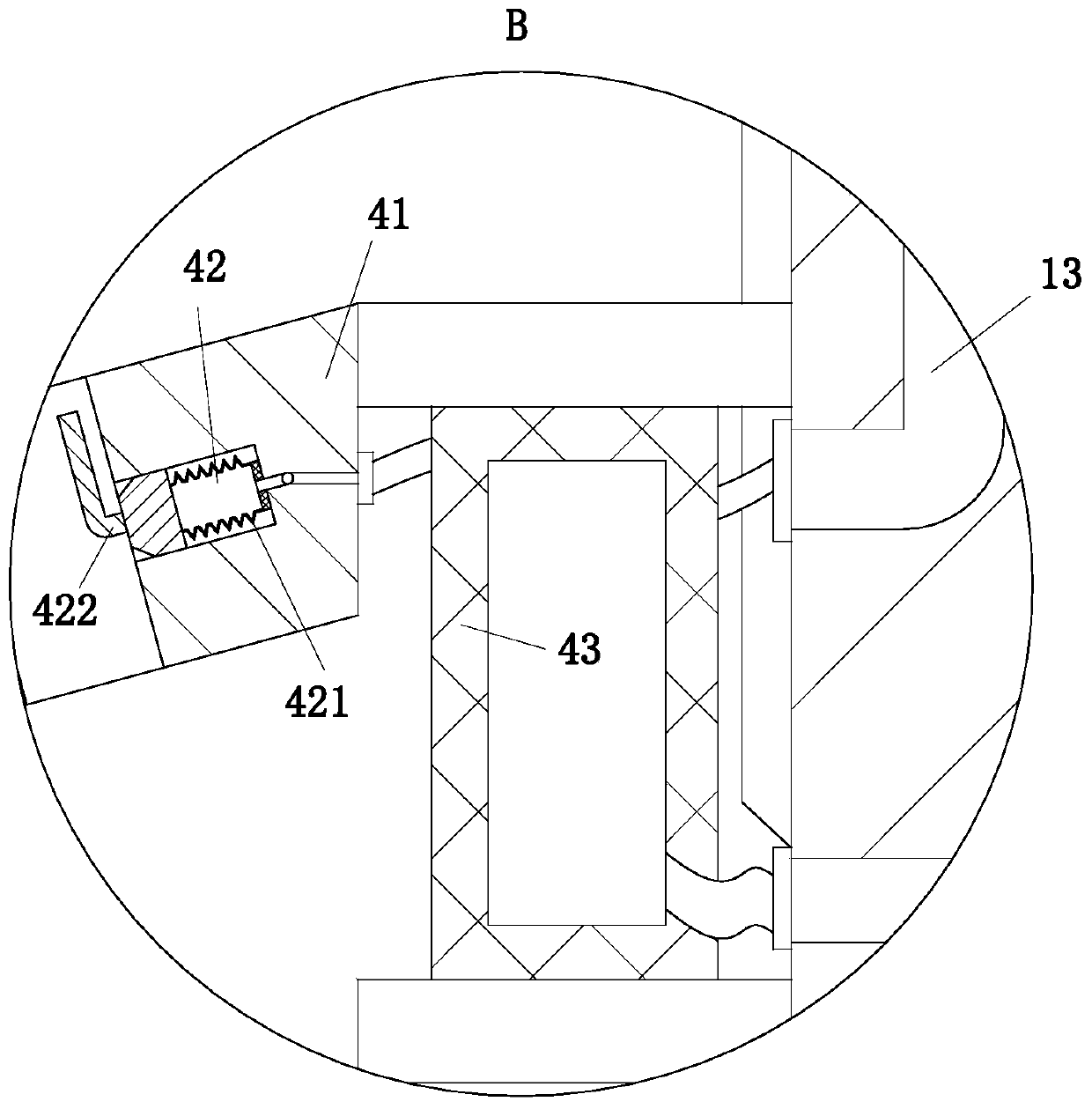

Heavy metal contaminated soil remediation device

InactiveCN109731895AImprove repair efficiencyImprove screening efficiencyContaminated soil reclamationSoil mixingSoil remediation

The invention belongs to the technical field of soil remediation devices, and particularly discloses a heavy metal contaminated soil remediation device which comprises a tank, an outer barrel, a spiral conveying shaft and smashing rods. A motor is mounted on the top of the tank, the spiral conveying shaft is arranged inside the tank, the outer barrel is rotationally connected into the tank and ispositioned on the outer side of the spiral conveying shaft, the inner wall of the outer barrel is in contact with the edges of the spiral conveying shaft, a screening module is mounted on the inner wall of the tank and corresponds to the lower side of the spiral conveying shaft, a spray module is arranged inside the tank and is positioned at the bottom of the screening module, and two squeezing modules are mounted on a side of the inner wall of the tank; the motor is in transmission connection with the spiral conveying shaft; the four smashing rods are arranged on two sides of an outer cylindrical surface of the outer barrel and correspond to the two squeezing modules, three smashing modules are arranged on each smashing rod, and the smashing rods and the smashing modules are used for crushing soil blocks. The heavy metal contaminated soil remediation device has the advantages that the screening efficiency of funnel-shaped sieve plates can be improved, and the soil remediation chemicaland soil mixing efficiency can be improved.

Owner:叶淑源

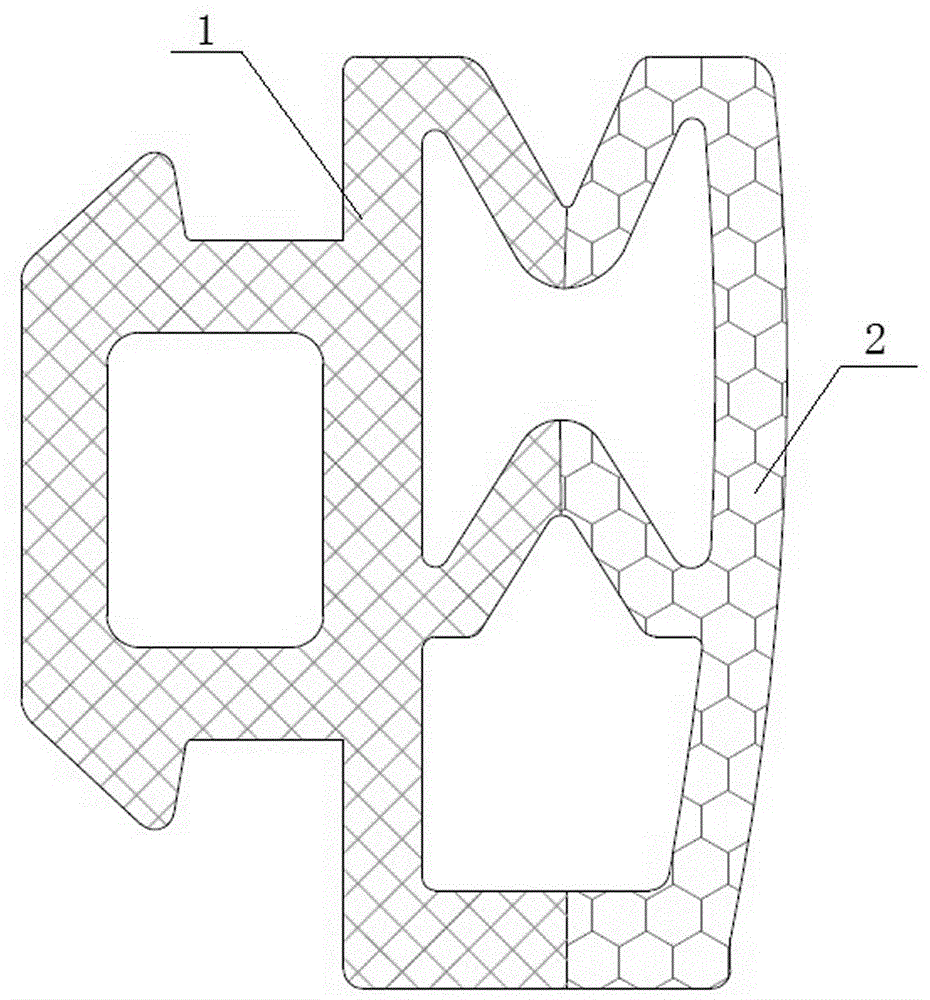

Soft-hard co-extrusion composite silicone rubber strip

The invention discloses a soft-hard co-extrusion composite silicone rubber strip, the composite silicone rubber strip is composited by dense mixed stock film and foaming mixed stock film; the dense mixed stock film comprises the following components by weight part: 100 parts of dense mixed stock, 1-3 parts of vulcanizing agent and 0.5-1.5 parts of masterbatch; the foaming mixed stock film comprises the following components by weight part: 100 parts of foaming mixed stock, 2-5 parts of vulcanizing agent, 1-3 parts of masterbatch and 1-4 parts of foaming agent. The installation part of the soft-hard co-extrusion composite silicone rubber strip is dense glue with high hardness and fixed size, fixing is convenient, and installation is easy, the sealing part is foaming glue with good elasticity and rapid rebound performance, and has advantages of high compression ratio and good sealing performance, and sealing performance of door and window can be increased.

Owner:浙江凌志新材料有限公司

Method for producing golf ball

InactiveUS20060249880A1High reboundExcellent manufacturabilityDomestic articlesSolid ballsSolventN-Butylamine

A method of manufacturing golf balls composed of a core and a cover of one or more layer that encloses the core, at least one cover layer being made of a thermoplastic polyurethane composition characterized by including at least 90 wt % of a thermoplastic polyurethane obtained by a polyurethane-forming reaction of an organic diisocyanate compound with a long-chain polyol and a chain extender, which thermoplastic polyurethane composition cover layer has an inherent viscosity in a DMF solvent of larger than 1.5 dl / g and an inherent viscosity in a 0.05 mol / L n-butylamine-containing DMF solution of larger than 0.5 dl / g, the golf ball manufacturing method being characterized by: conditioning the thermoplastic polyurethane to a pre-processing moisture content of 500 ppm or less, then injection molding the moisture-conditioned thermoplastic polyurethane to form the thermoplastic polyurethane composition cover layer. Golf balls produced by this method have a high rebound and excellent spin characteristics and scuff resistance, are recyclable in a molding operation, and have excellent manufacturability.

Owner:KURARAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

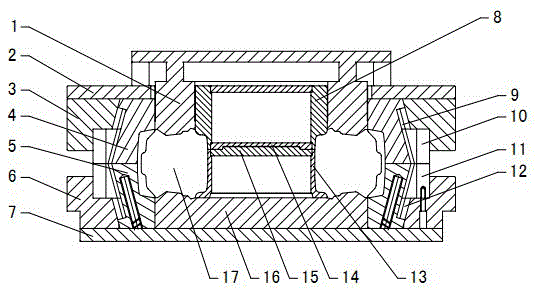

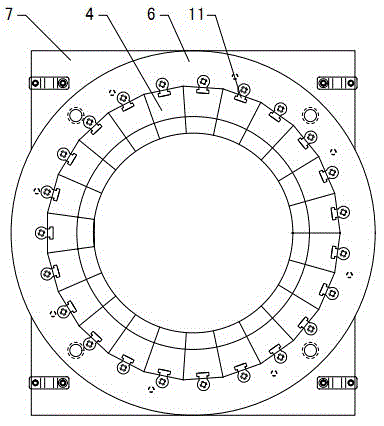

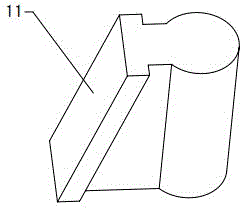

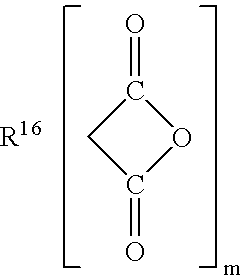

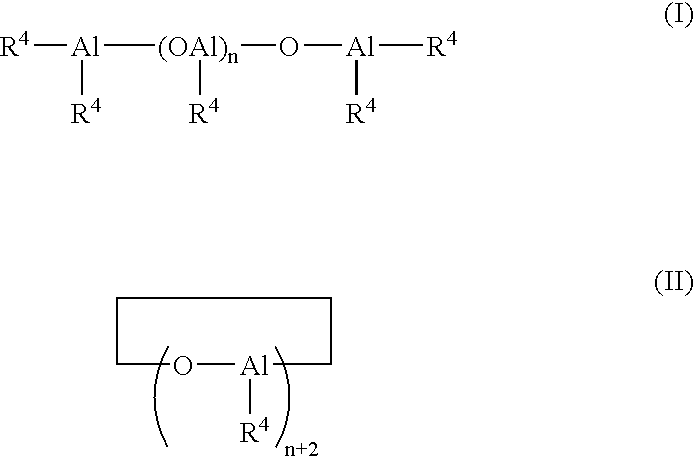

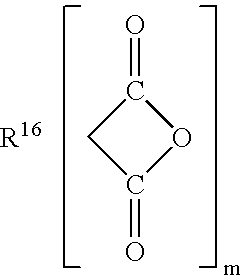

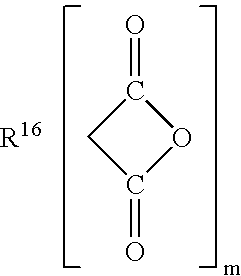

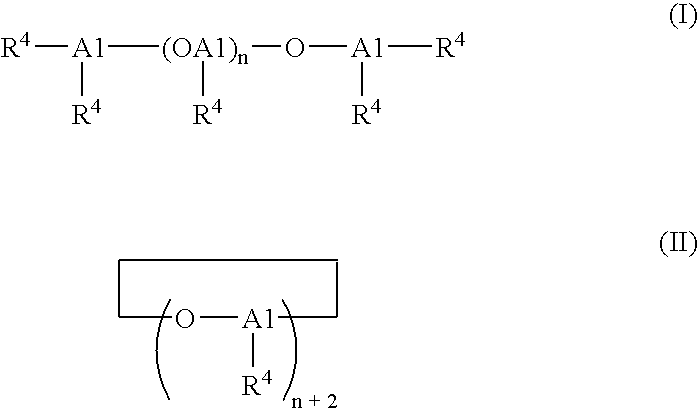

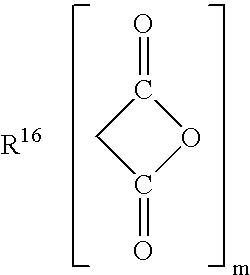

![Dynamic polymer foam composite material[v] Dynamic polymer foam composite material[v]](https://images-eureka.patsnap.com/patent_img/99ea6426-cf37-4df0-84aa-70038529320d/FDA0002376569720000021.png)

![Dynamic polymer foam composite material[v] Dynamic polymer foam composite material[v]](https://images-eureka.patsnap.com/patent_img/99ea6426-cf37-4df0-84aa-70038529320d/BDA0002376569730000021.png)

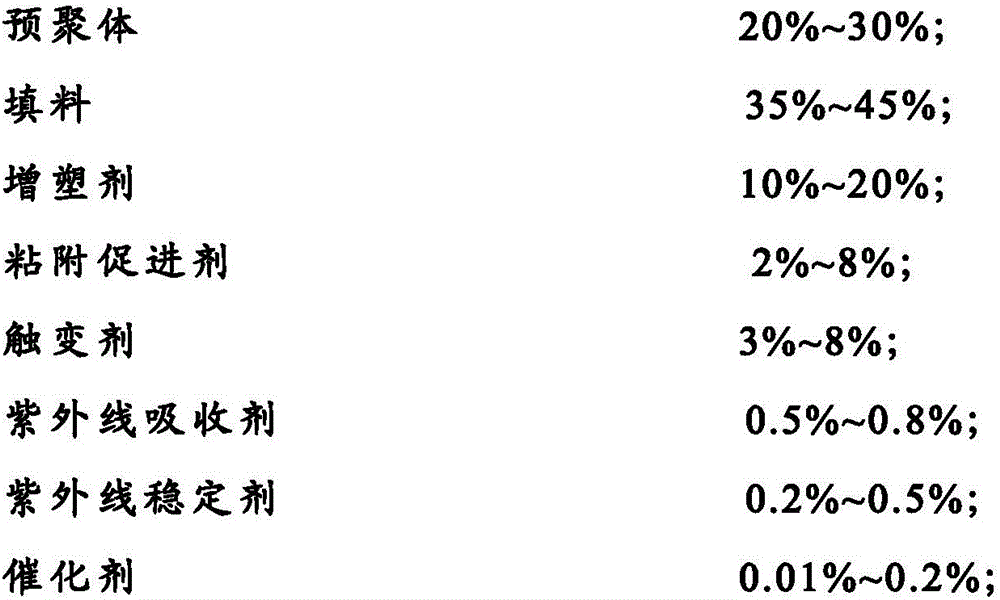

![Dynamic polymer foam composite material[v] Dynamic polymer foam composite material[v]](https://images-eureka.patsnap.com/patent_img/99ea6426-cf37-4df0-84aa-70038529320d/BDA0002376569730000071.png)