Silane modified polyurethane sealant prepolymer and preparation method thereof and sealant

A polyurethane sealant and silane modification technology, which is applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as a large number of air bubbles, affecting the sealing effect, and destroying the concrete interface, so as to achieve colloidal compactness, Good sealing effect, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a silane-modified polyurethane sealant prepolymer, which is prepared by the following method:

[0035] Add 200g of polypropylene oxide glycol (molecular weight 1000, purchased from Dow Chemical, brand name Voranol2110TB) into the reaction kettle, stir evenly and raise the temperature to 110°C, vacuum dehydration for 2 hours, reduce the temperature to 80°C, add 220g MDI-100 Stir and react for 2 hours, then add 800g of polypropylene oxide triol (molecular weight 3000, purchased from Shandong Lanxing Dongda Chemical Co., Ltd., brand name DL-3000) and react at 80°C for 3 to 4 hours, then cool to 50°C , Add 114g of γ-aminopropyltrimethoxysilane dropwise until the NCO content is completely consumed, and stir for 2 hours to obtain a prepolymer.

Embodiment 2

[0037] This embodiment provides a silane-modified polyurethane sealant prepolymer, which is prepared by the following method:

[0038] Add 200g of polypropylene oxide glycol (molecular weight 2000, purchased from Dow Chemical, brand name Voranol2120) into the reactor, stir evenly and raise the temperature to 110°C, vacuum dehydration for 2 hours, reduce the temperature to 80°C, add 135g MDI-100 Stir and react for 2 hours, then add 700g of high activity polyether triol (molecular weight 6000, purchased from Dow Chemical, trade name Voranol6055), react at 80°C for 3 to 4 hours, cool to 50°C, add 108g γ-aminopropyl dropwise Trimethoxysilane until the NCO content is completely consumed, stir for 2 hours to obtain a prepolymer.

[0039] Performance tests were performed on the prepolymers of Examples 1 and 2, and the test results are shown in Table 1.

[0040] Table 1 shows the performance test results of the prepolymers of Examples 1 and 2

[0041] performance Example 1 Example 2 Ext...

Embodiment 3

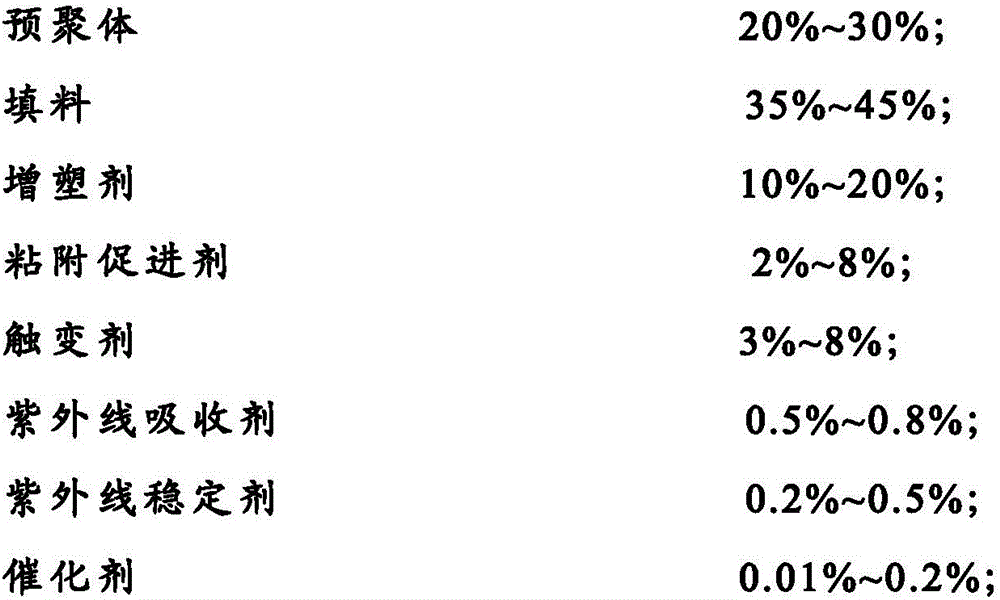

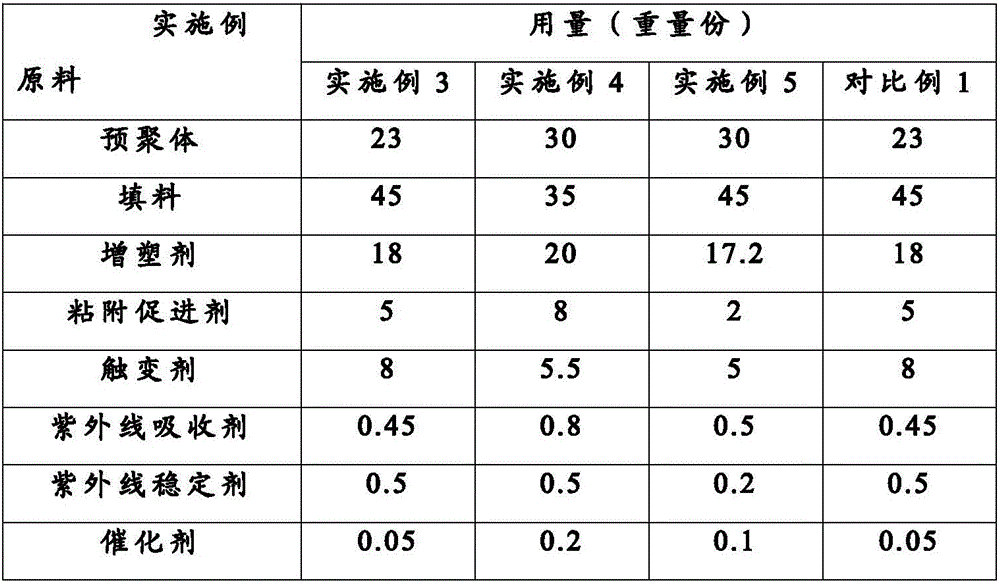

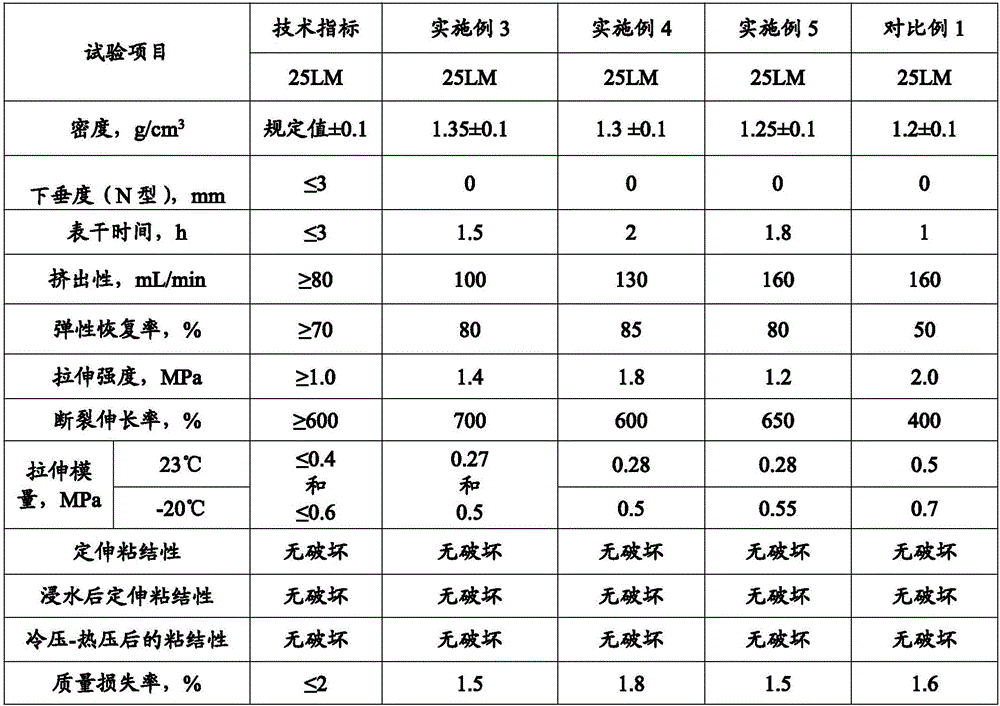

[0044] This embodiment provides a one-component silane-modified polyurethane sealant for construction. The raw materials and dosages used are shown in Table 1.

[0045] Wherein, the prepolymer adopts the prepolymer of Example 1;

[0046] The filler is heavy calcium carbonate;

[0047] The plasticizer is DINP;

[0048] Adhesion promoter is γ-aminopropyltrimethoxysilane, which is purchased from Xinyue Silicone, the brand name is KBM-903;

[0049] The thixotropic agent is fumed silica, purchased from Deshan Chemical, the brand is PM-20L;

[0050] The ultraviolet absorber is UV-1;

[0051] The ultraviolet stabilizer is UV-P;

[0052] The catalyst is dibutyl tin dilaurate.

[0053] The preparation method of the sealant is: adding prepolymer, dried filler, plasticizer and thixotropic agent into a biaxial planetary dispersing kettle, dispersing at a low speed for 15 minutes, vacuuming, filling with nitrogen, and dispersing at a high speed for 30 minutes, followed by Add adhesion promoters, ultrav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com