Modified asphalt waterproof coating, preparation method for modified asphalt waterproof coating and use method thereof

A waterproof coating and modified asphalt technology, applied in the direction of asphalt coatings, coatings, etc., can solve the problems of easy settlement and stratification, uneven dispersion of sound insulation fillers and easy agglomeration, and reduce the sound insulation effect of coatings, so as to meet the requirements of sound insulation specifications, Effects of preventing agglomeration and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

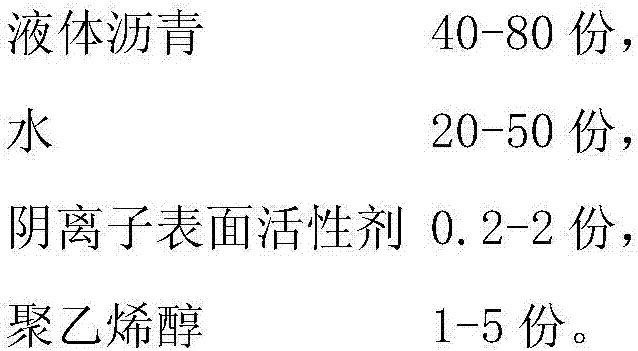

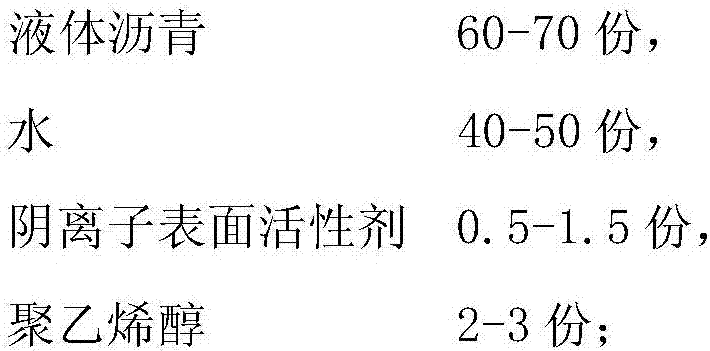

[0049] In parts by weight, prepare raw materials according to the following formula: 1 part of polyvinyl alcohol, 1 part of sodium dodecylbenzenesulfonate, 40 parts of liquid pitch, 20 parts of water;

[0050] Dissolve 1 part of polyvinyl alcohol into 20 parts of water at a temperature of 60°C to obtain a polyvinyl alcohol solution, add 1 part of sodium dodecylbenzenesulfonate to the above polyvinyl alcohol solution, and obtain soap after fully dissolving, Use a pH regulator to keep the pH of the soap solution at 9-10, and carry out high-speed dispersion and grinding of the above soap solution and 40 parts of liquid pitch in a colloid mill to obtain an anionic emulsified pitch;

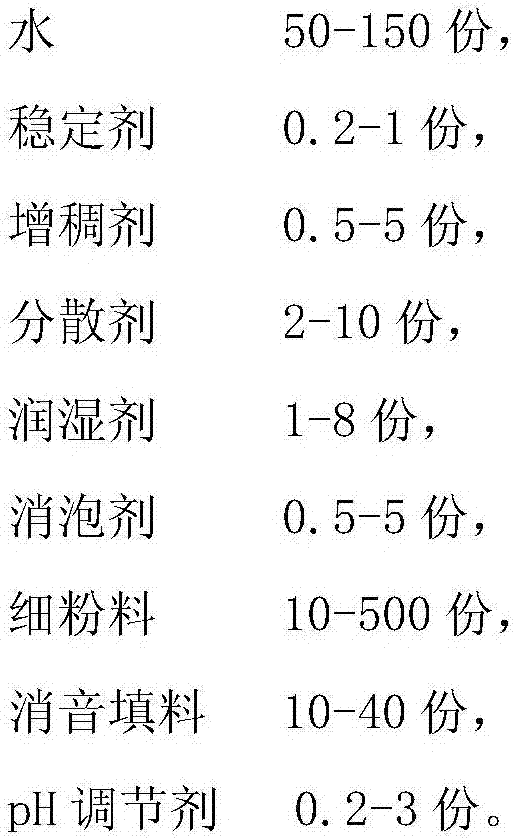

[0051] In parts by weight, prepare raw materials according to the following formula: 50 parts of water, 0.2 part of polyvinyl alcohol, 1 part of hydroxypropyl methylcellulose, 2 parts of sodium lauryl sulfate, 1 part of polyethylene glycol, 0.5 part Polyether modified silane, 10 parts of kaolin, 0.2 p...

Embodiment 2

[0058] In parts by weight, prepare raw materials according to the following formula: 2 parts of polyvinyl alcohol, 1 part of sodium dodecylbenzenesulfonate, 65 parts of liquid pitch, 50 parts of water;

[0059] Dissolve 2 parts of polyvinyl alcohol into 50 parts of water at a temperature of 60°C to obtain a polyvinyl alcohol solution, add 1 part of sodium dodecylbenzenesulfonate to the above polyvinyl alcohol solution, and obtain soap after fully dissolving, Use a pH regulator to keep the pH of the soap solution at 9-10, and carry out high-speed dispersion and grinding of the above soap solution and 65 parts of liquid pitch in a colloid mill to obtain an anionic emulsified pitch;

[0060] In parts by weight, prepare raw materials according to the following formula: 80 parts of water, 0.5 part of polyvinyl alcohol, 1 part of hydroxypropyl methylcellulose, 5 parts of sodium lauryl sulfate, 4 parts of polyethylene glycol, 1 part of Polyether modified silane, 10 parts of kaolin, 1...

Embodiment 3

[0067] In parts by weight, prepare raw materials according to the following formula: 1 part of polyvinyl alcohol, 1.5 parts of tall oil, 65 parts of liquid pitch, 50 parts of water;

[0068] Dissolve 1 part of polyvinyl alcohol into 50 parts of water at a temperature of 60°C to obtain a polyvinyl alcohol solution, add 1.5 parts of tall oil to the above polyvinyl alcohol solution, and obtain soap after fully dissolving, and use a pH regulator to maintain The pH of the soap liquid is 9-10, and the above soap liquid and 65 parts of liquid pitch are dispersed and ground at a high speed in a colloid mill to obtain an anionic emulsified pitch;

[0069] In parts by weight, prepare raw materials according to the following formula: 80 parts of water, 0.5 part of polyvinyl alcohol, 1 part of hydroxypropyl methylcellulose, 3 parts of sodium tripolyphosphate, 4 parts of polyethylene glycol, 1 part of polyether Modified silane, 30 parts of sodium bentonite, 15 parts of hollow titanium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com