Patents

Literature

77results about How to "Under high pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

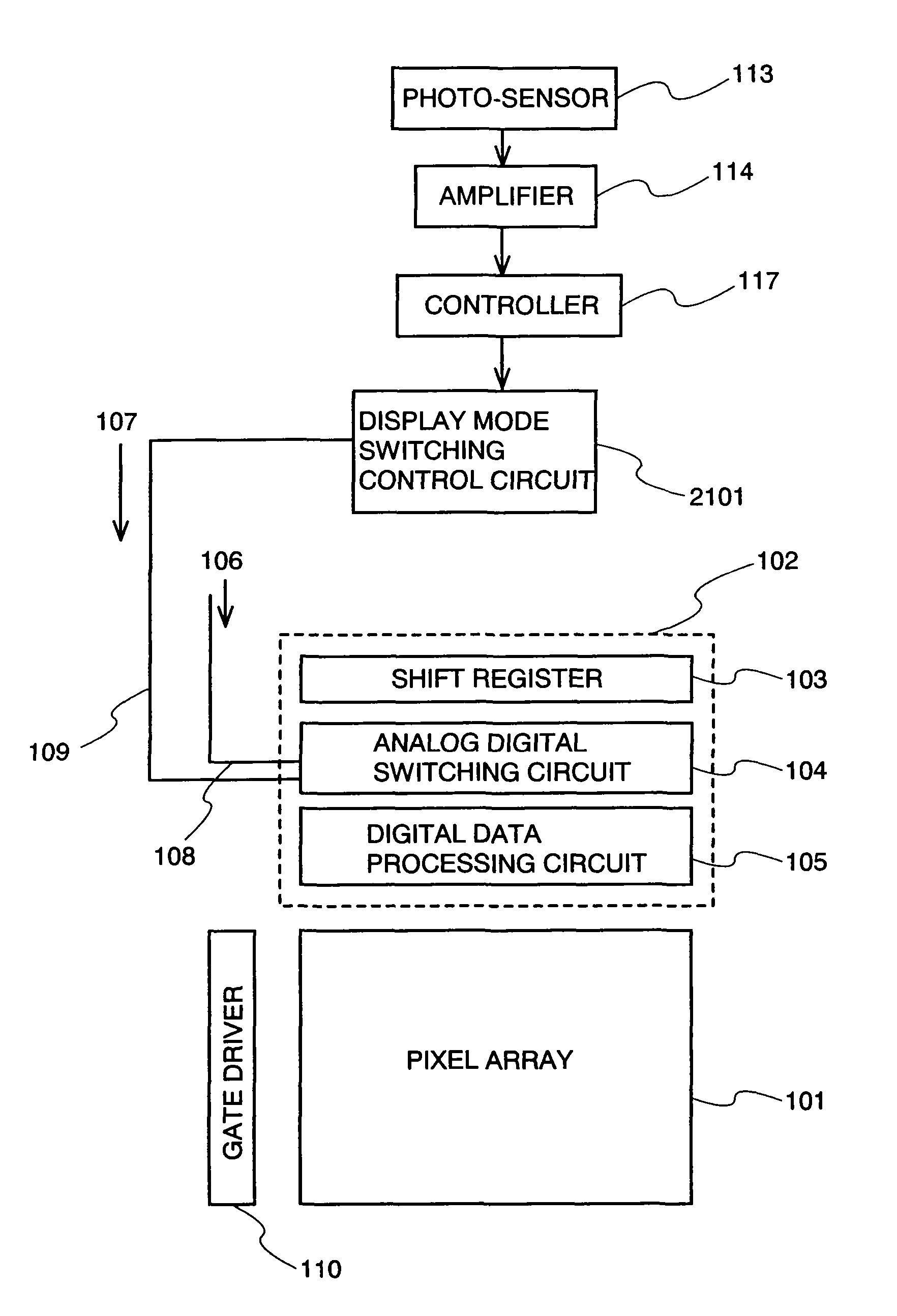

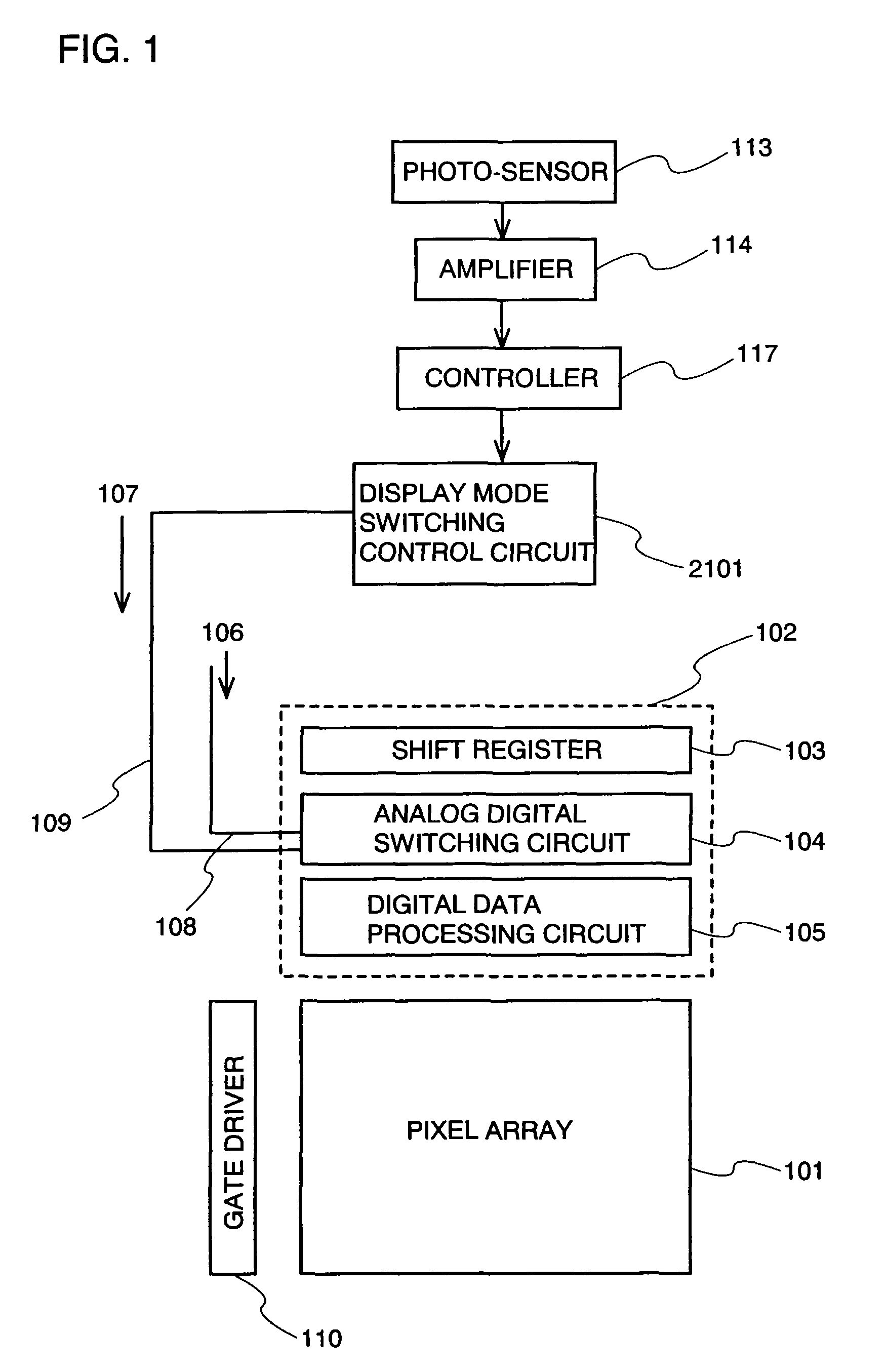

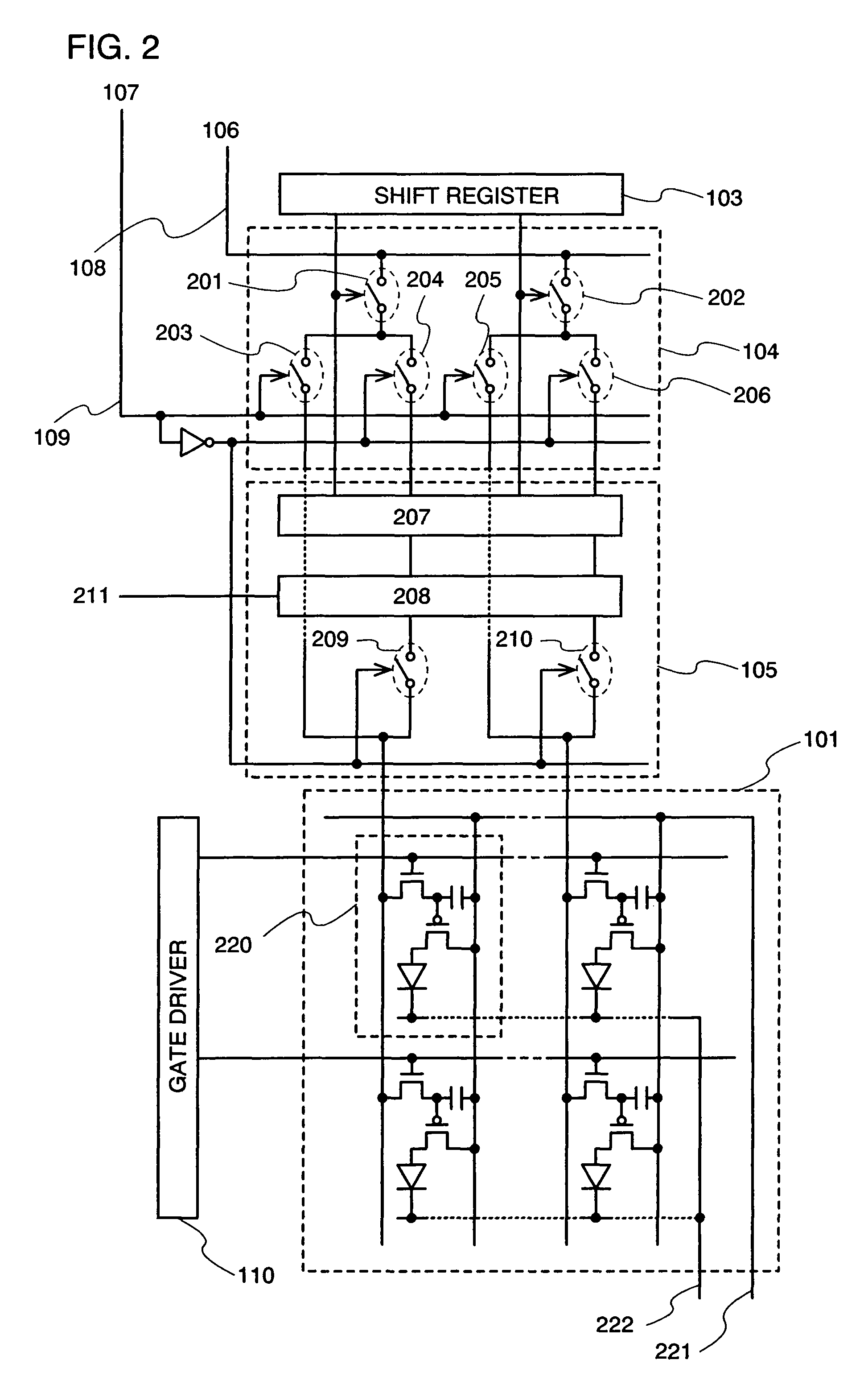

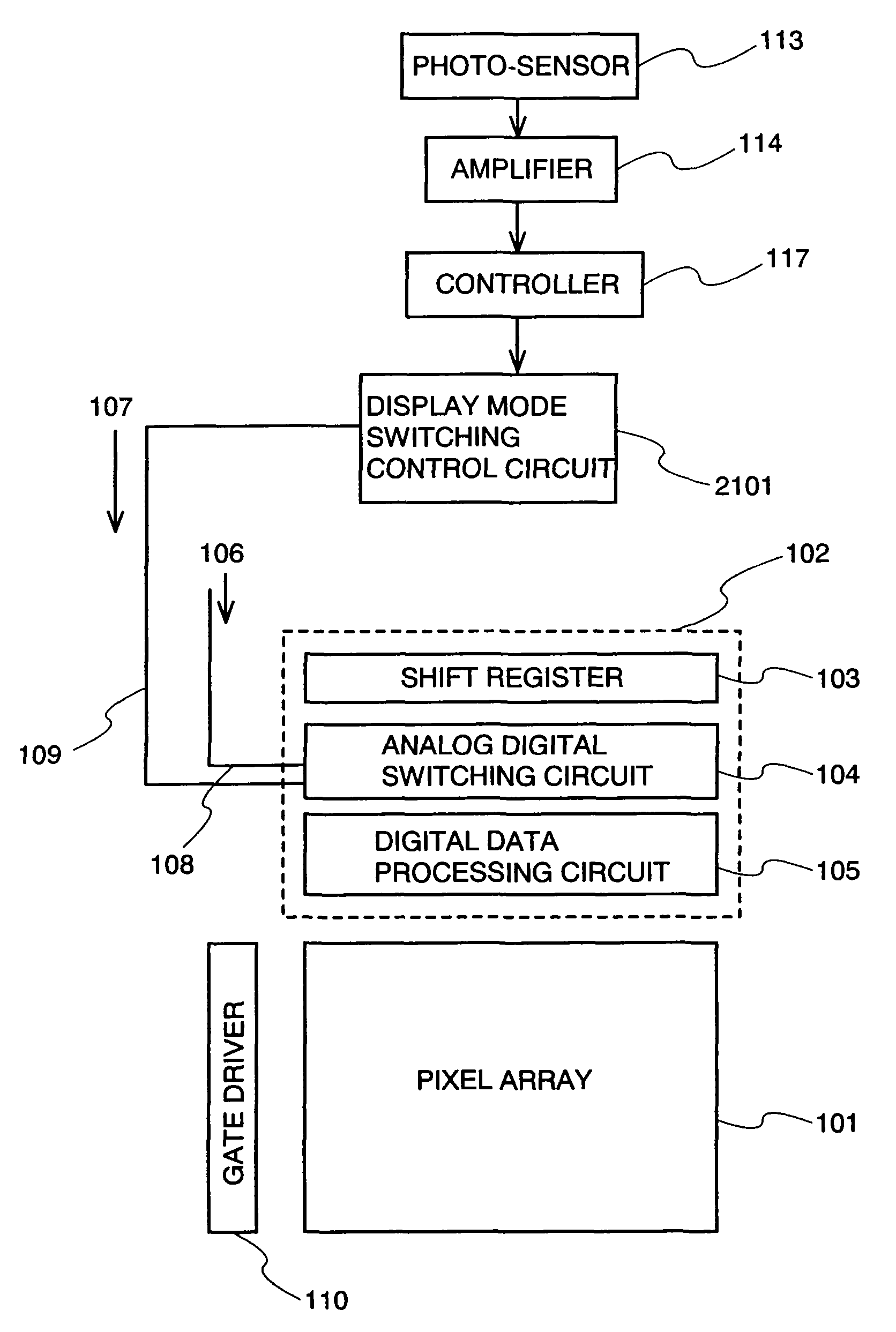

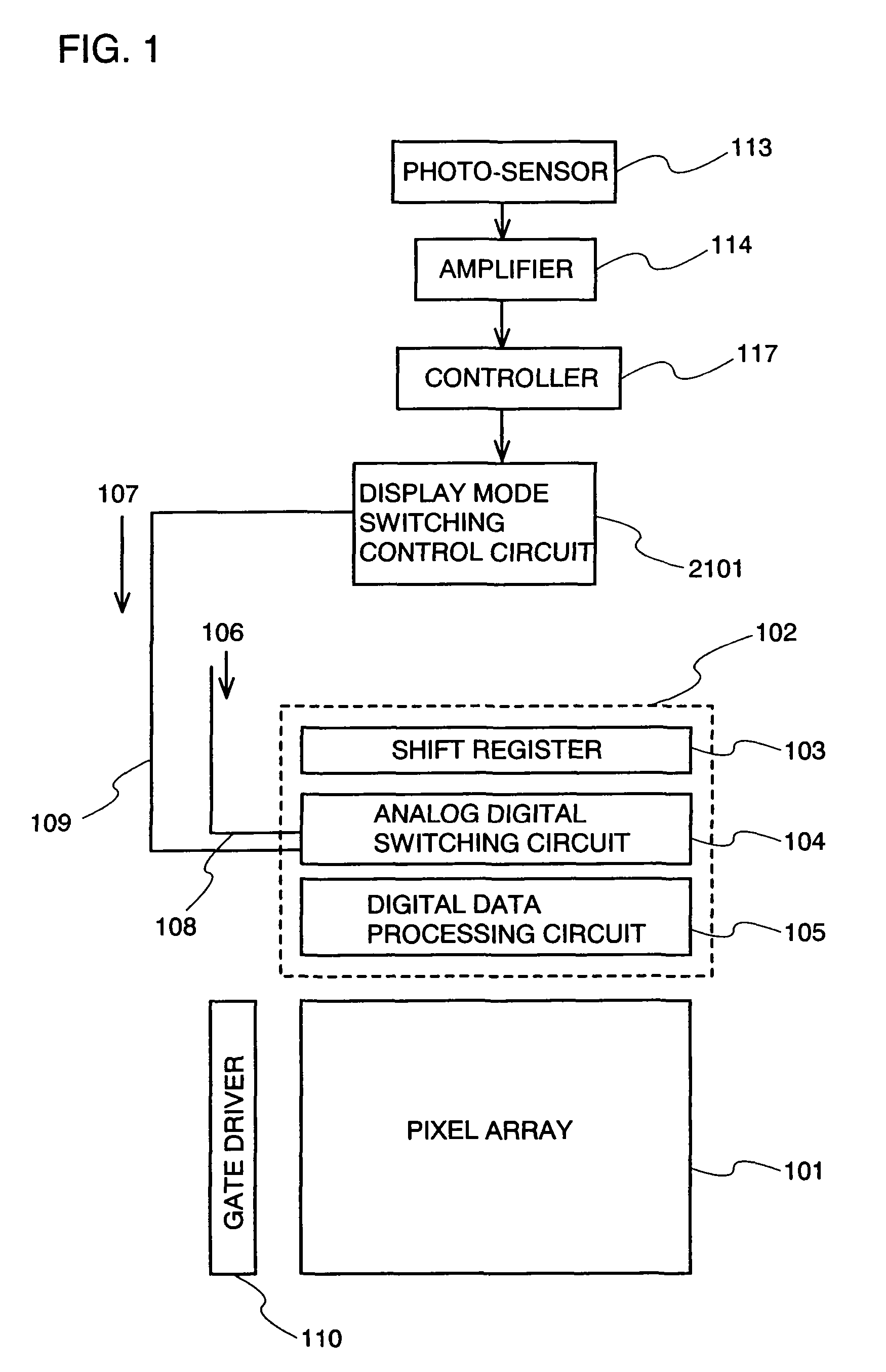

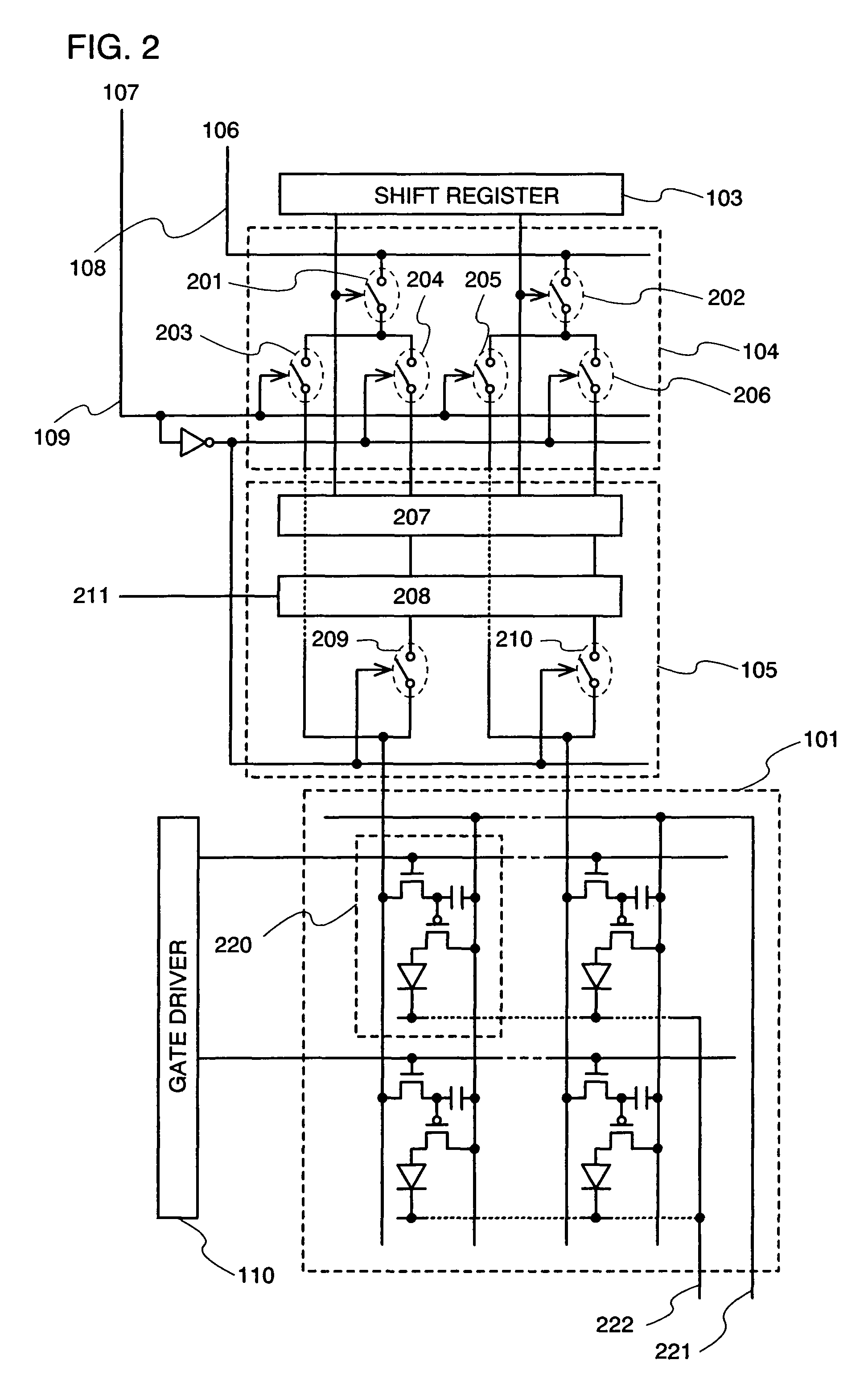

Display device and electronic device

InactiveUS20060273999A1Improve visibilityEnsure visibilityStatic indicating devicesElectroluminescent light sourcesVisibilityDisplay device

It is an object of the present invention to provide a display device in which images can be seen under a dark place to intense external light. In the display device, display is performed by changing the gray scale number depending on external light intensity, and display modes can be switched depending on contents displayed on the screen. An analog mode and a digital mode are switched depending on external light intensity. In an analog digital switching circuit, when a video signal is an analog value, a signal is outputted to a pixel array without any change and, when the video signal is a digital value, the signal is outputted to a circuit that performs a digital operation such as a latch circuit. Consequently, display gray scales of a pixel are changed appropriately. Accordingly, a clear image can be displayed. For example, it is possible to ensure visibility in a wide range of a dark place or under indoor florescent light to outdoor sun light.

Owner:SEMICON ENERGY LAB CO LTD

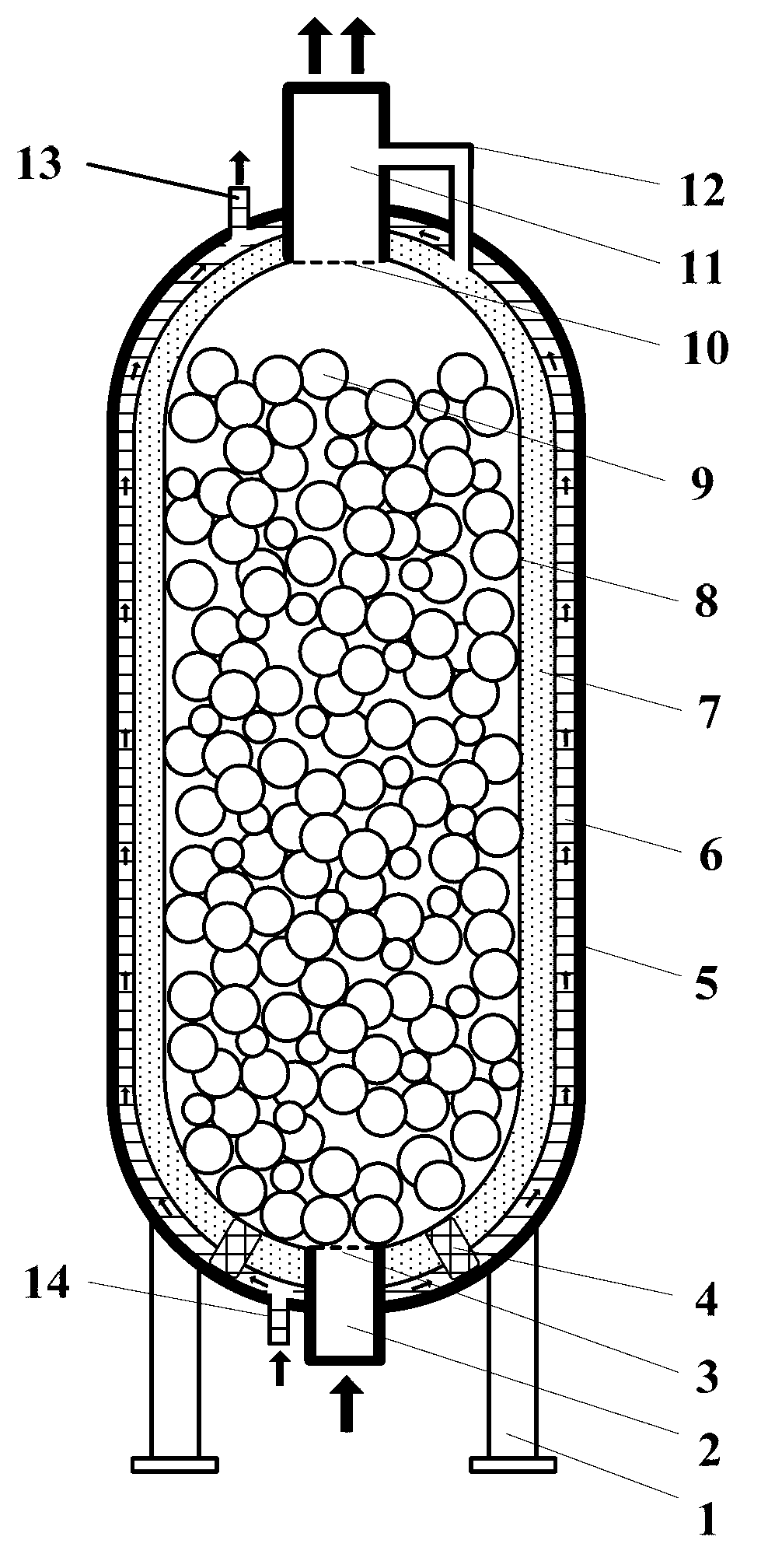

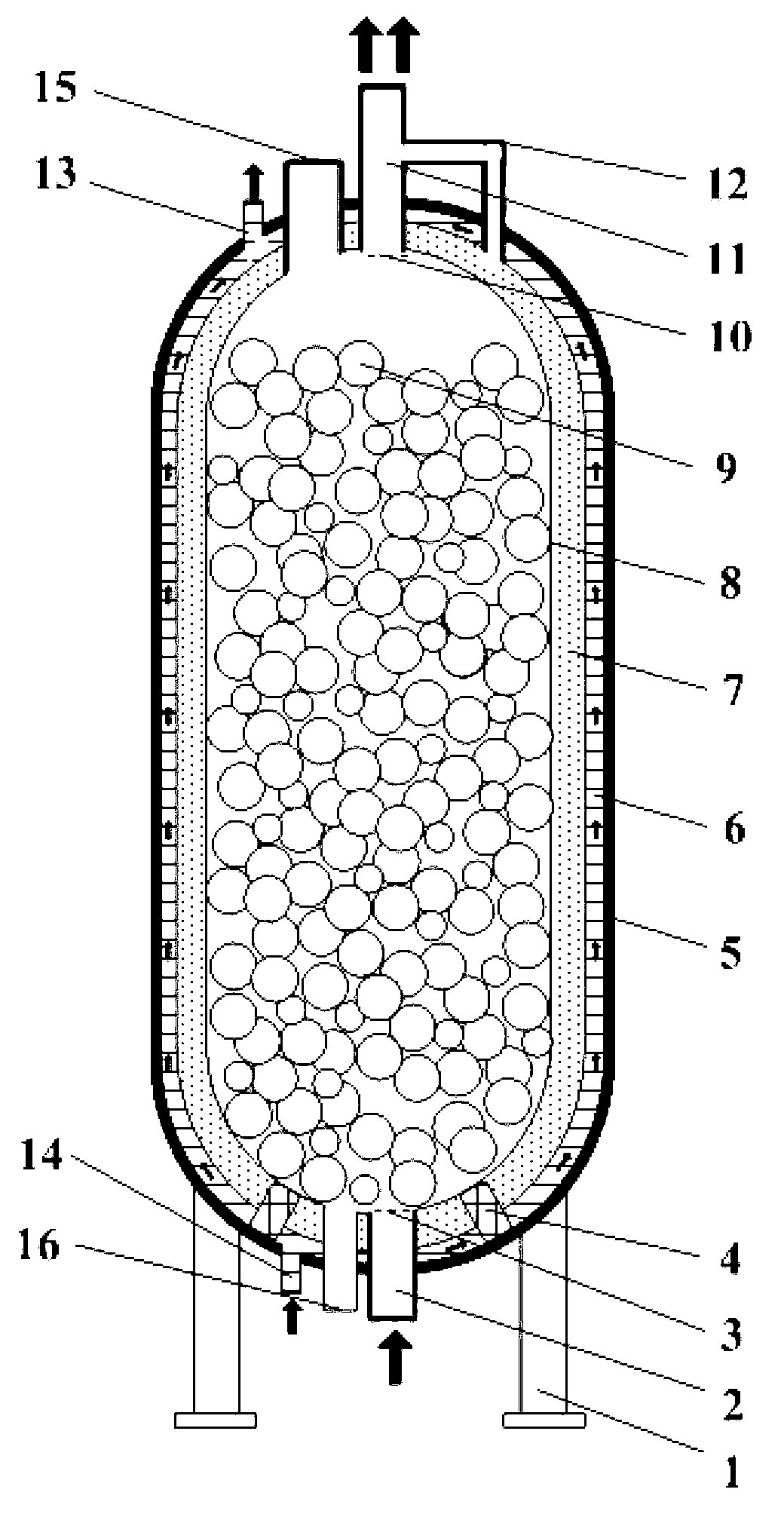

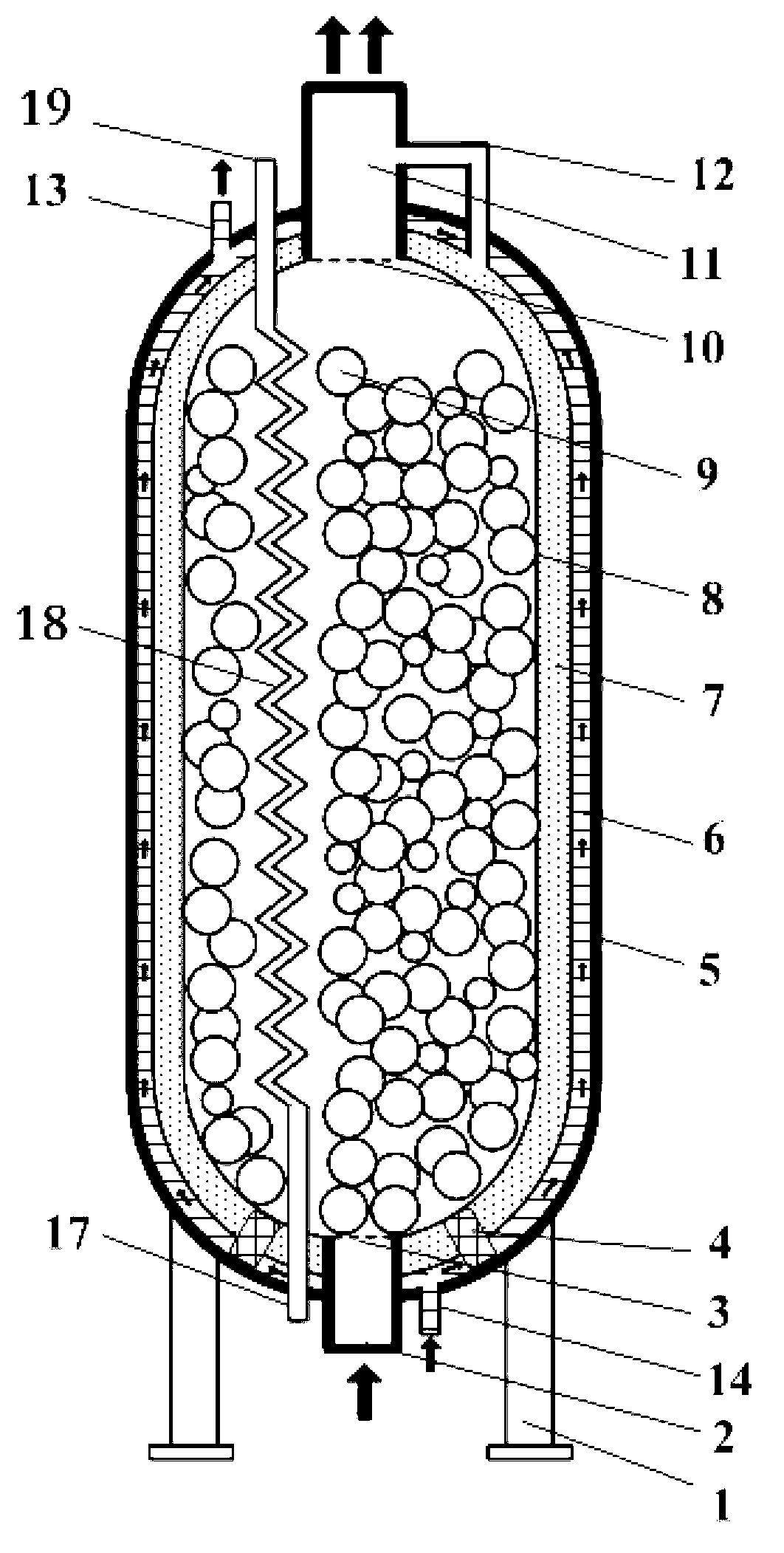

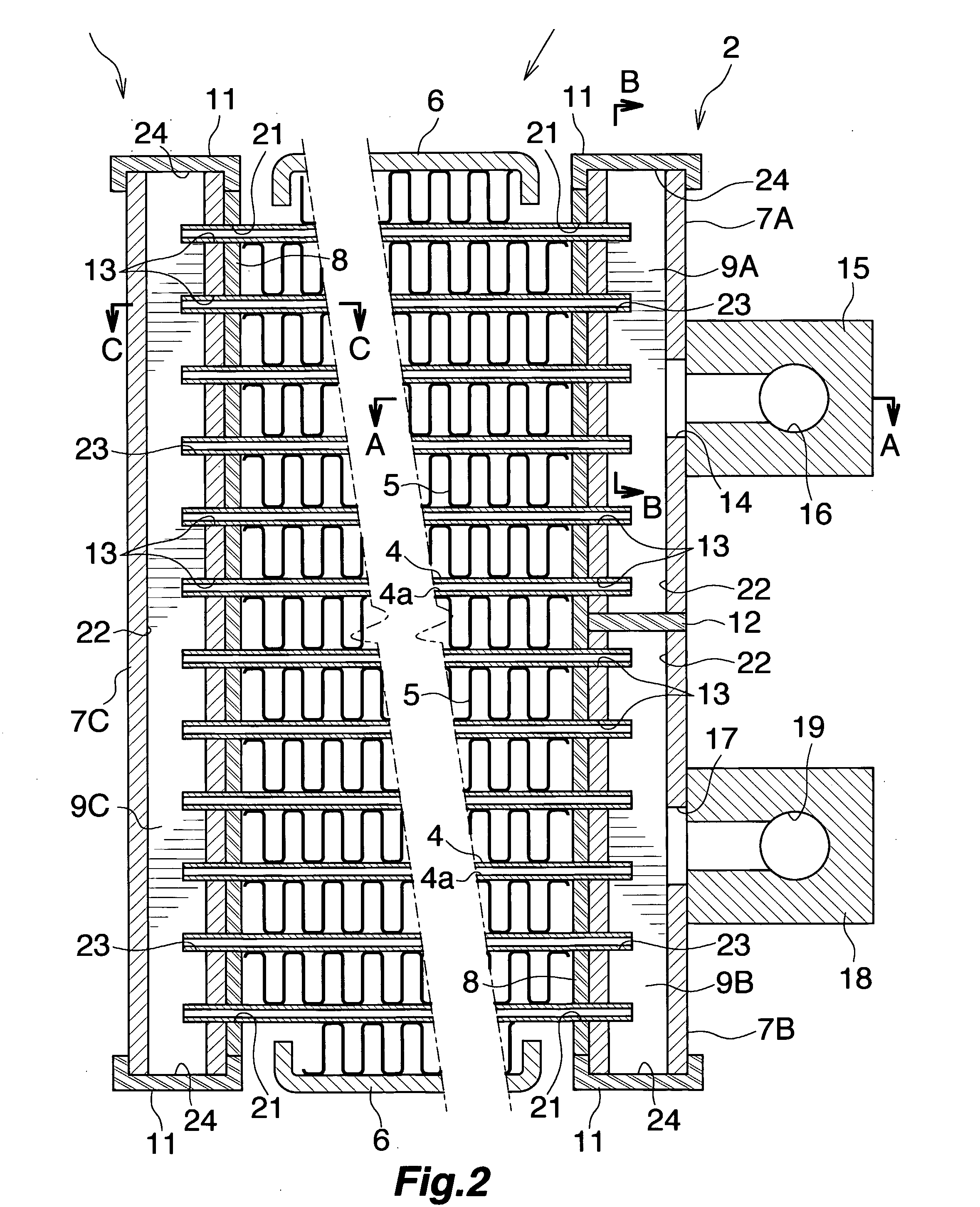

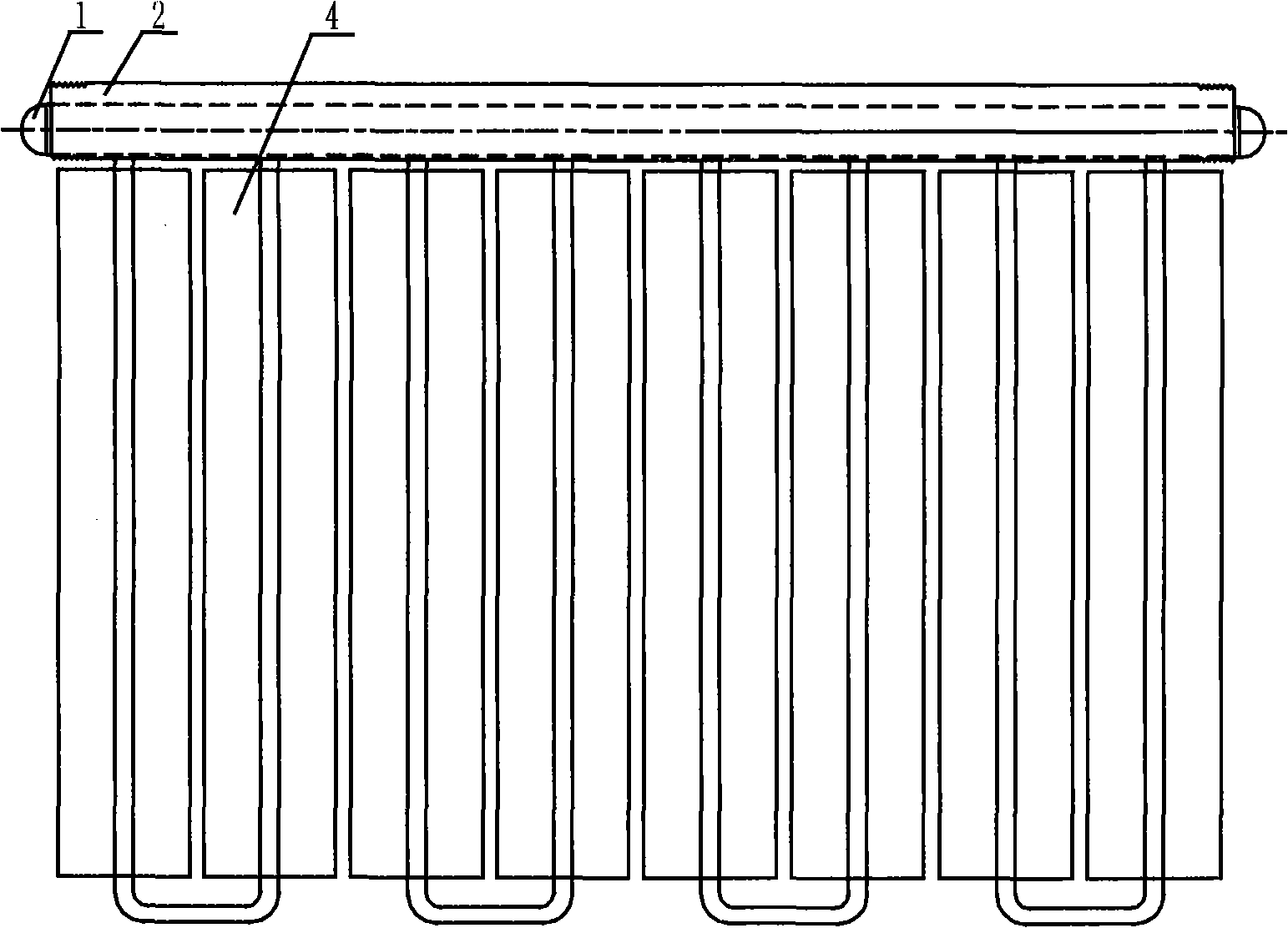

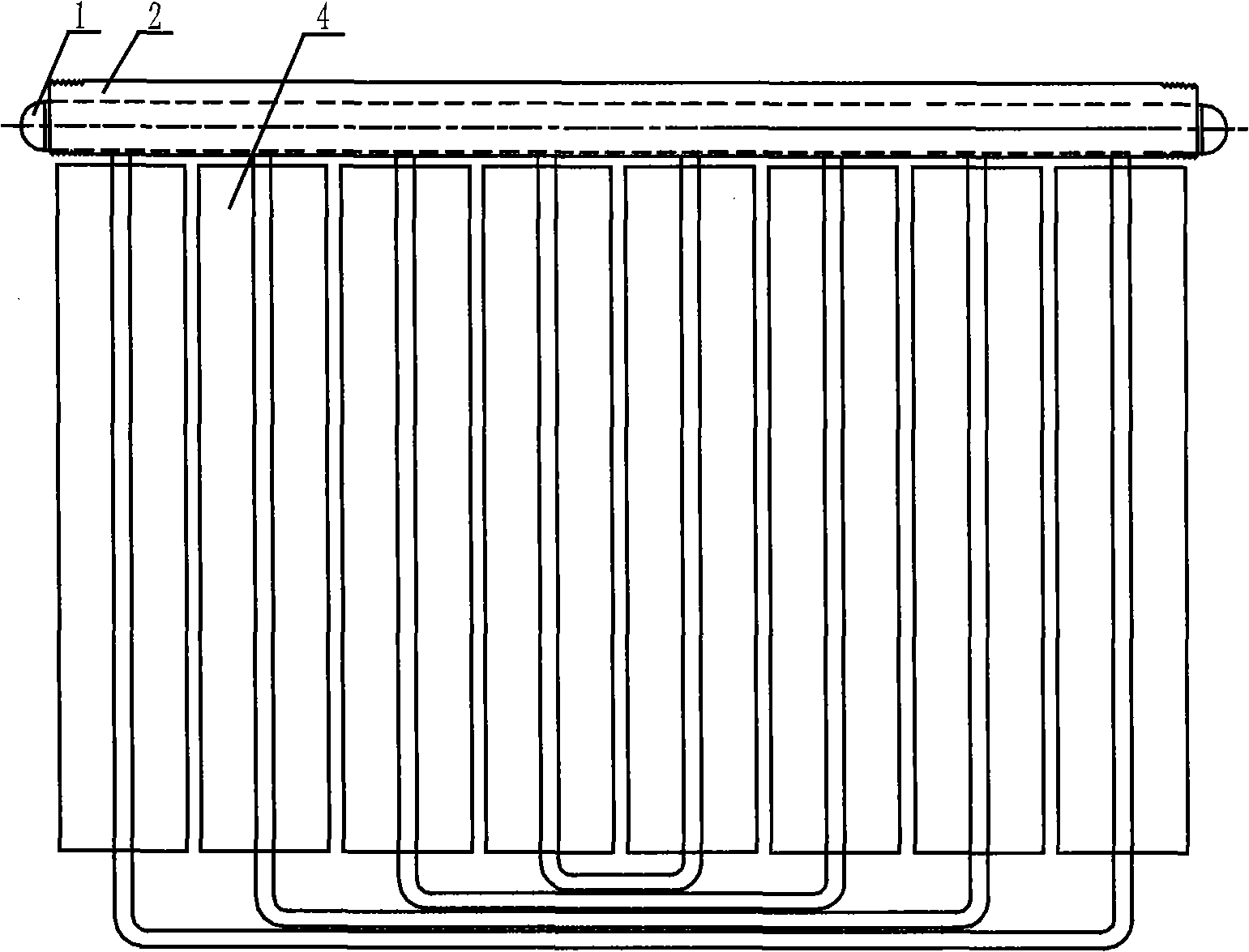

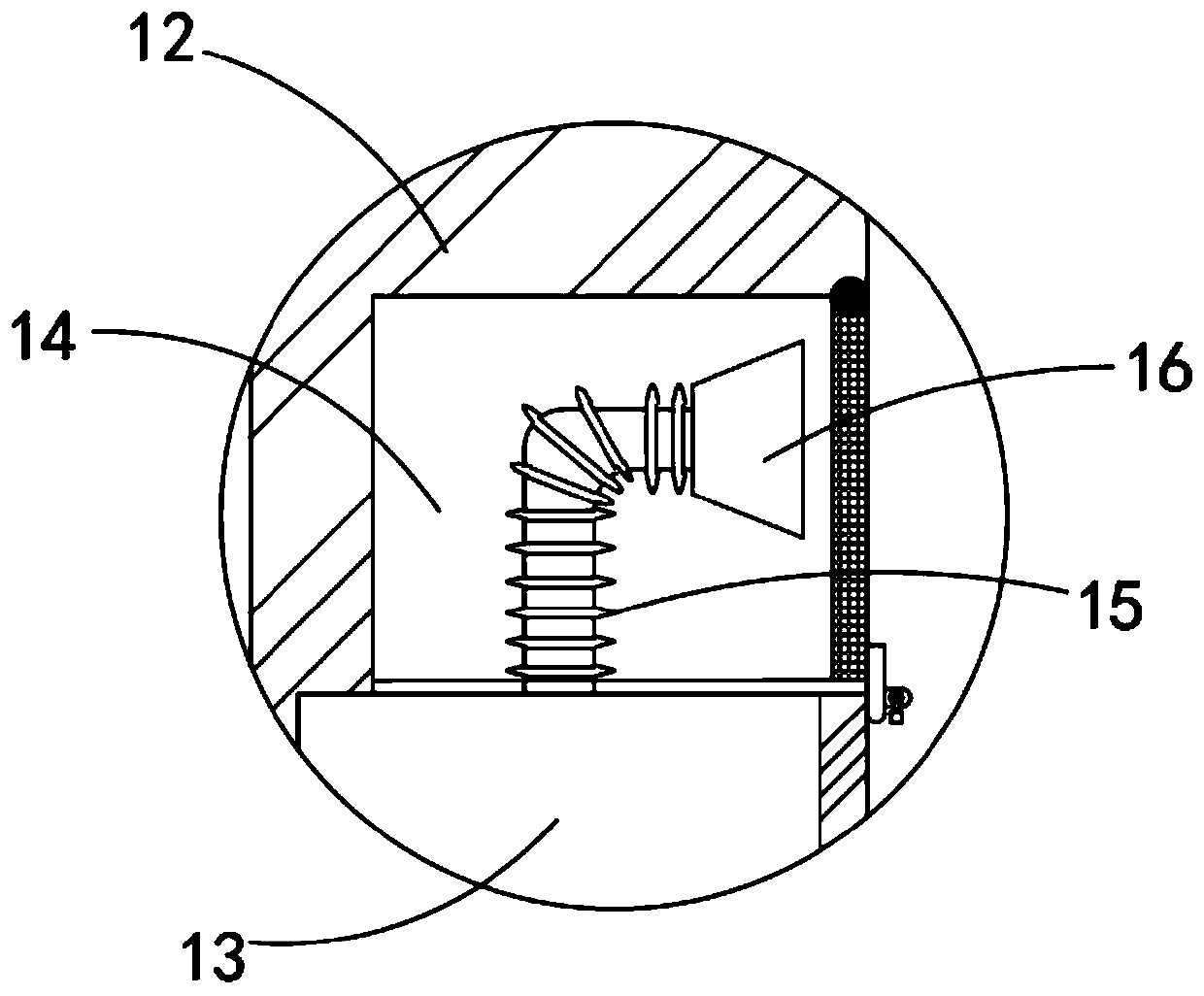

High-pressure heat-storing/or cold-storing device

ActiveCN103075906AUnder high pressureLow costDomestic cooling apparatusHeat storage plantsThermal energyLiquid layer

The invention discloses a high-pressure heat-storing / or cold-storing device, which belongs to the field of high / low-temperature thermal energy storage. The high-pressure heat-storing / or cold-storing device is characterized in that an outer shell is used for bearing a high pressure; a cooling / heating liquid layer, a heat-preserving layer, a thin wall inner shell and an internal solid heat / cold storing medium are arranged in sequence from outside to inside; a solid material is taken as a heat / cold storing medium; and a high-pressure heat transfer medium flows through the surface of the heat / cold storing medium and undergoes heat exchange. The heat-storing / or cold-storing device disclosed by the invention has the advantages of high bearing pressure, low manufacturing cost, high efficiency, high thermal energy grade and the like, and is particularly suitable for heat-storing / or cold-storing occasions with large heat / cold storing and releasing temperature differences and frequent heat / cold storing and releasing.

Owner:葛洲坝中科储能技术有限公司

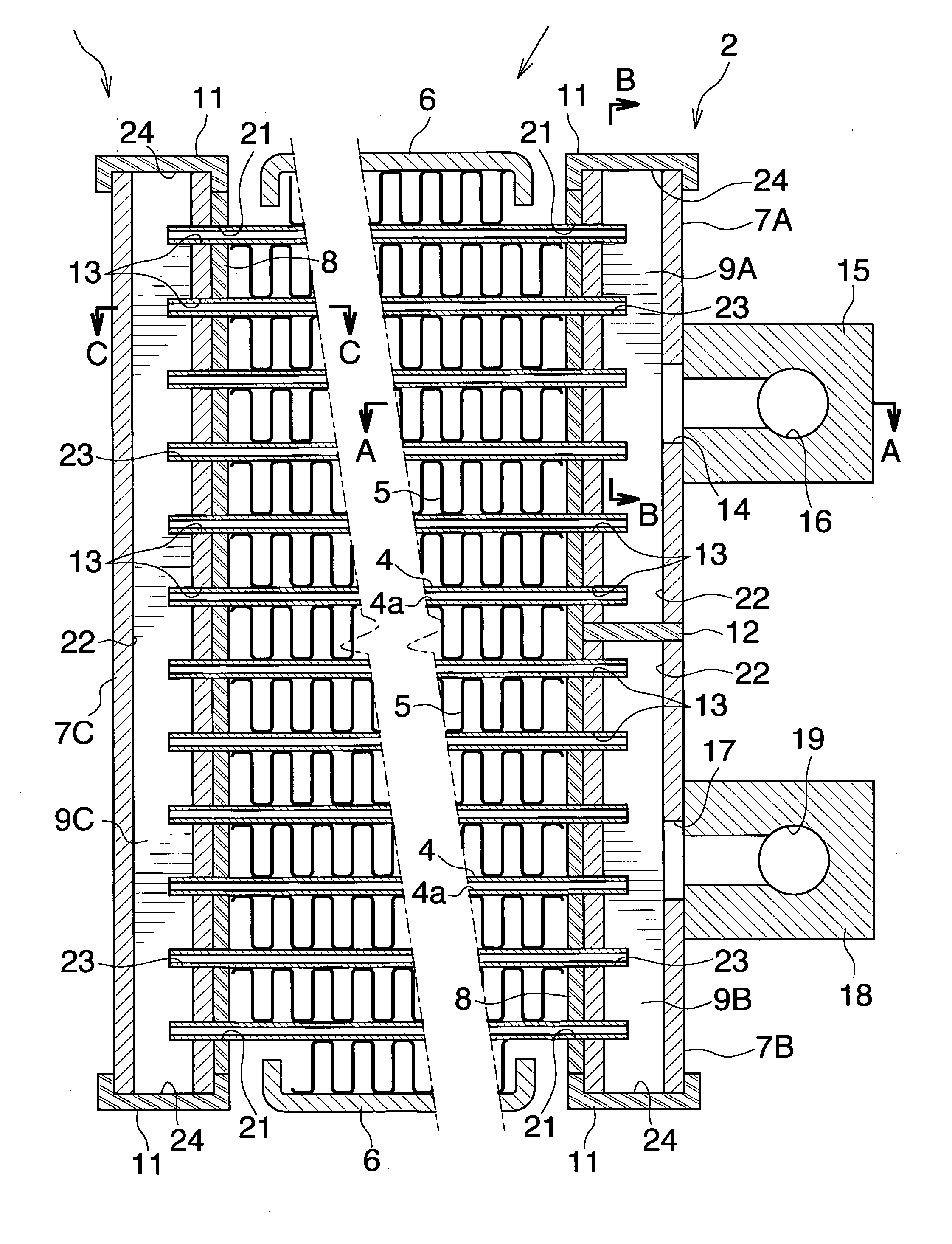

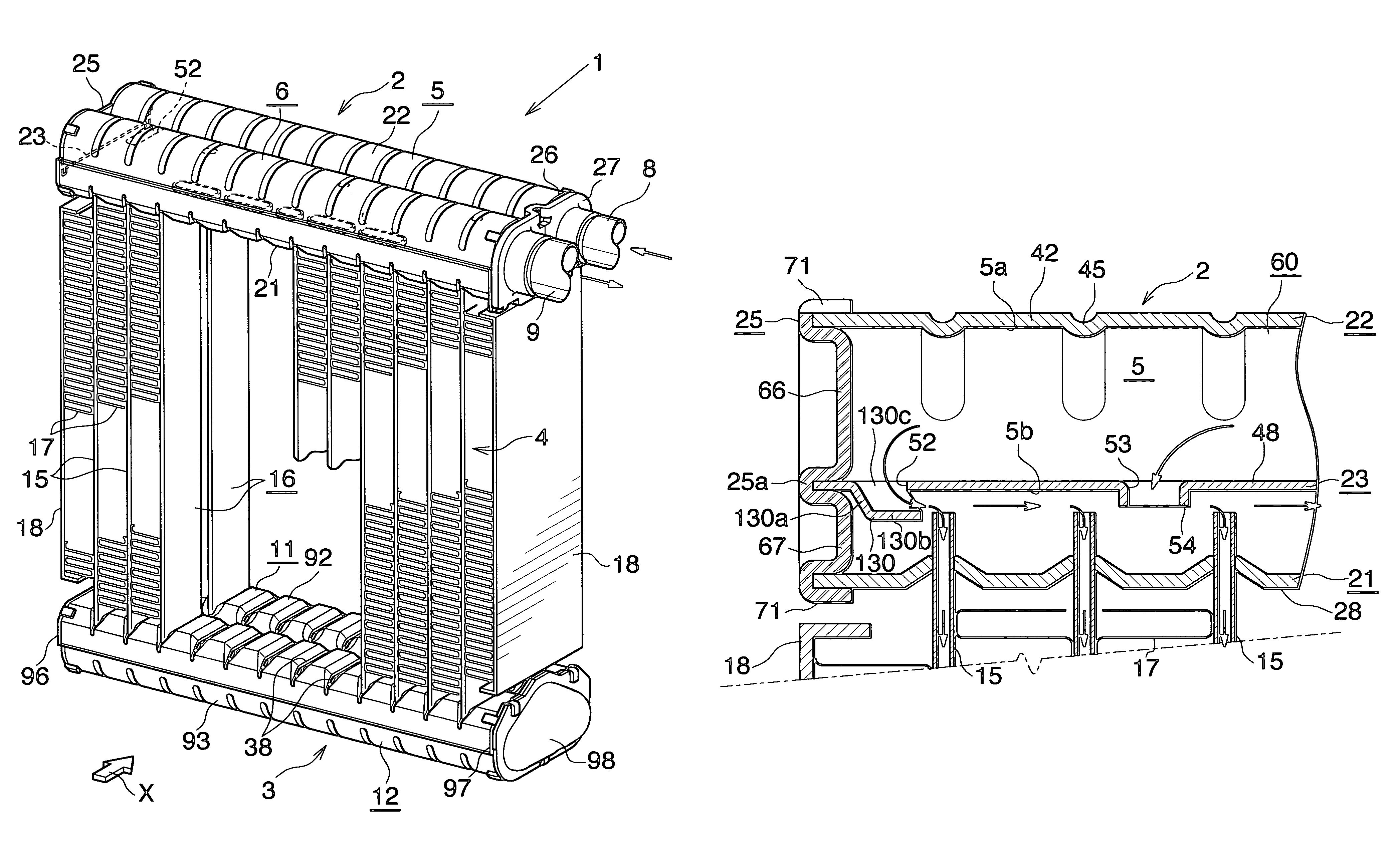

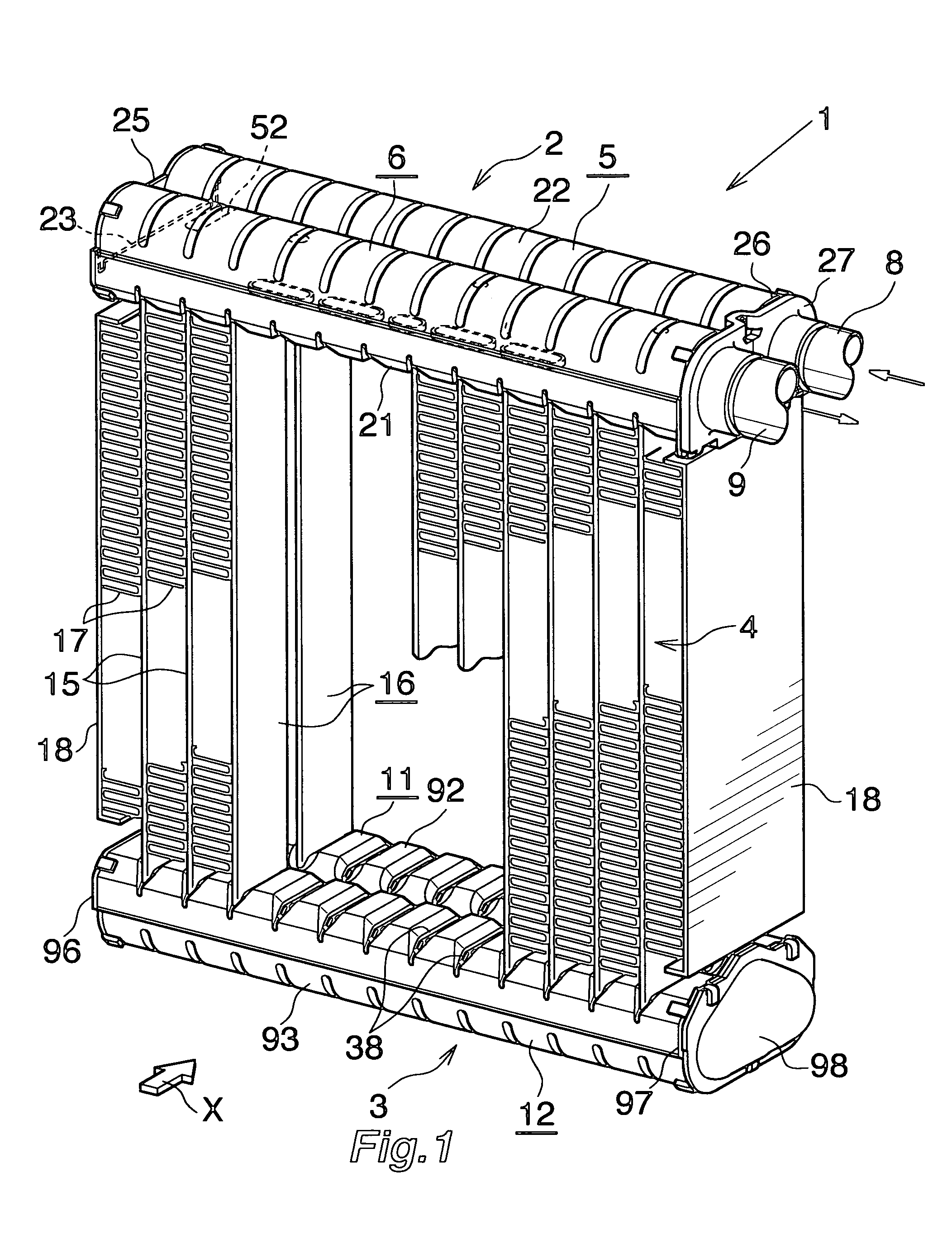

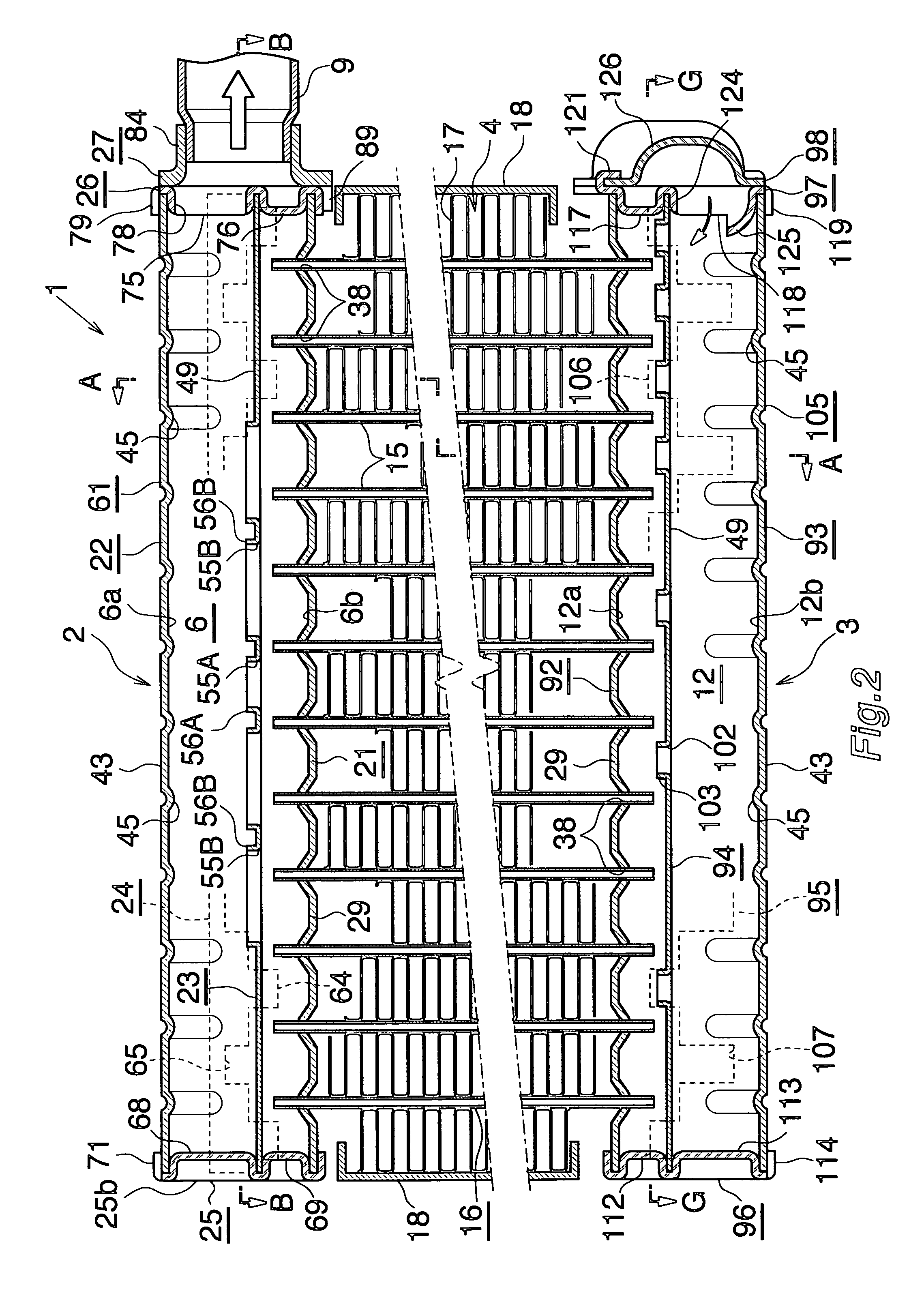

Heat Exchanger

InactiveUS20070204983A1Improve heat transfer effectUnder high pressureReinforcing meansCompression machines with non-reversible cycleGas coolerMechanical engineering

A heat-exchanger header tank of a gas cooler includes a tank formation member, a tube-connecting plate joined to the tank formation member outer surface, and a partition disposed within and joined to the tank formation member to divide the tank formation member interior into plural refrigerant channels extending in the longitudinal direction of the tank formation member and arranged in the front-rear direction. Tube insertion holes are formed in a wall of the tank formation member and in the tube-connecting plate at mutually aligned positions. Tube-end fit cutouts partially receiving corresponding end portions of heat exchange tubes are formed on the partition to align with corresponding tube insertion holes. The cross-sectional profile of the header tank can be appropriately selected for an installation space for the gas cooler, and the cross-sectional shape and area of a refrigerant channel can be readily changed.

Owner:SHOWA DENKO KK

Display device and electronic device

InactiveUS7636078B2Avoid instabilityTotal current dropElectroluminescent light sourcesSolid-state devicesVisibilityDisplay device

It is an object of the present invention to provide a display device in which images can be seen under a dark place to intense external light. In the display device, display is performed by changing the gray scale number depending on external light intensity, and display modes can be switched depending on contents displayed on the screen. An analog mode and a digital mode are switched depending on external light intensity. In an analog digital switching circuit, when a video signal is an analog value, a signal is outputted to a pixel array without any change and, when the video signal is a digital value, the signal is outputted to a circuit that performs a digital operation such as a latch circuit. Consequently, display gray scales of a pixel are changed appropriately. Accordingly, a clear image can be displayed. For example, it is possible to ensure visibility in a wide range of a dark place or under indoor florescent light to outdoor sun light.

Owner:SEMICON ENERGY LAB CO LTD

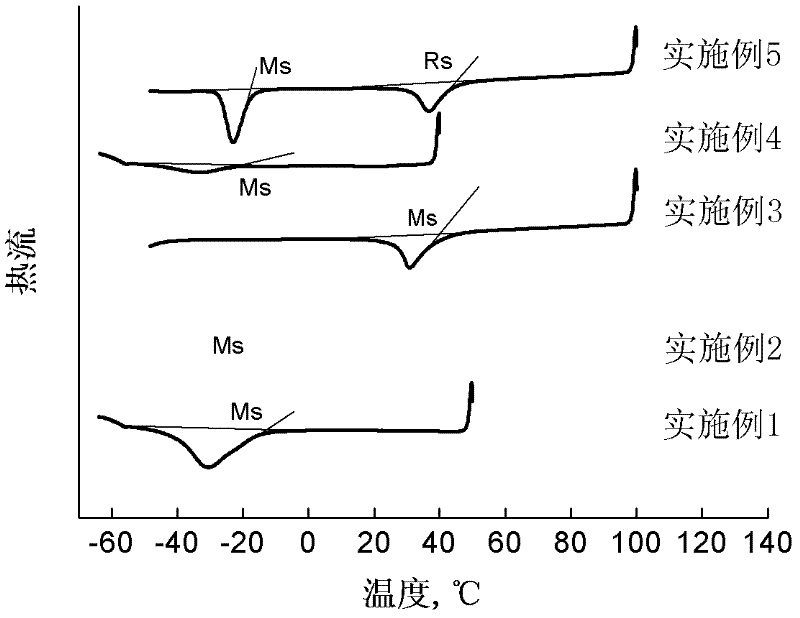

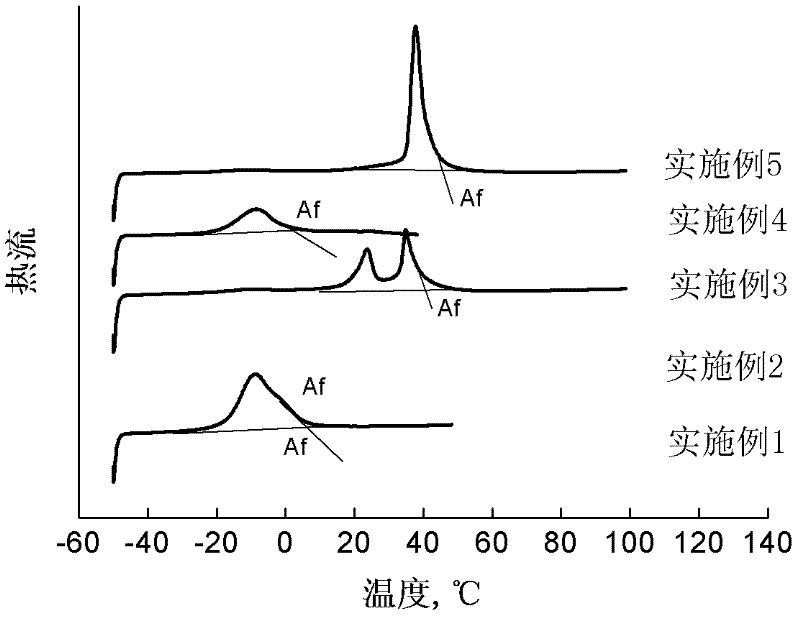

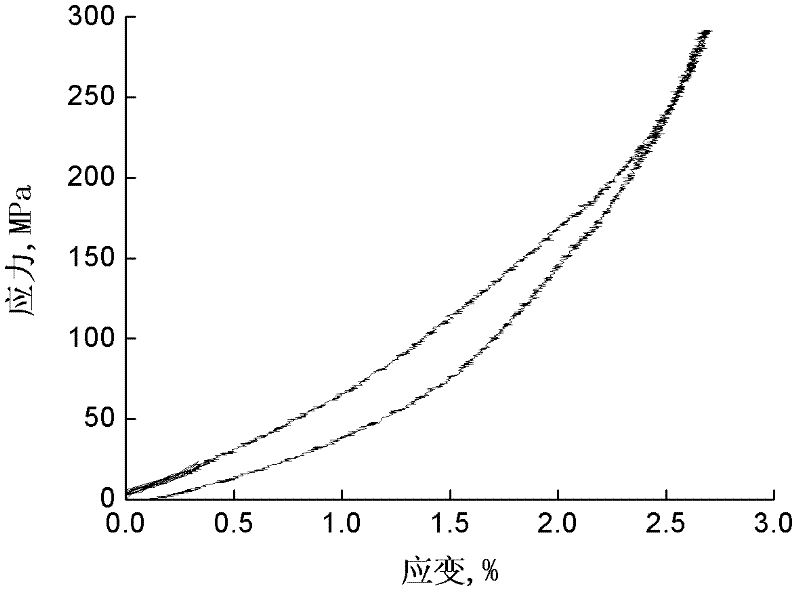

Shape memory alloy sealing gasket and production technology thereof

InactiveCN102409197AUnder high pressureGuaranteed anti-agingFlanged jointsNiti alloyShape-memory alloy

The invention discloses a shape memory alloy sealing gasket. The sealing gasket is characterized in that the material comprises the following components in parts by weight: 53.25-58.42 parts of Ni, 41.63-45.82 parts of Ti, 0.1-0.2 part of Al, 0.01-0.03 part of Cu and 0.015-0.12 part of V. The shape memory alloy sealing gasket utilizes the superelasticity and shake-suction performance of the NiTi alloy and has the advantages of good compression elasticity, corrosion resistance, fatigue resistance, high pressure resistance and good safe reliability.

Owner:NANJING UNIV OF TECH

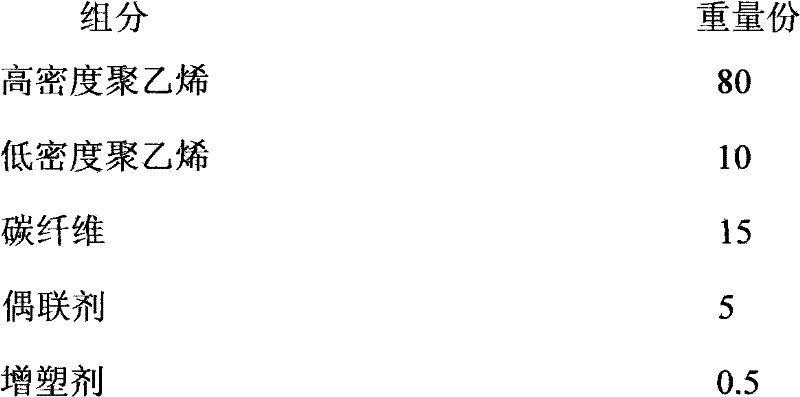

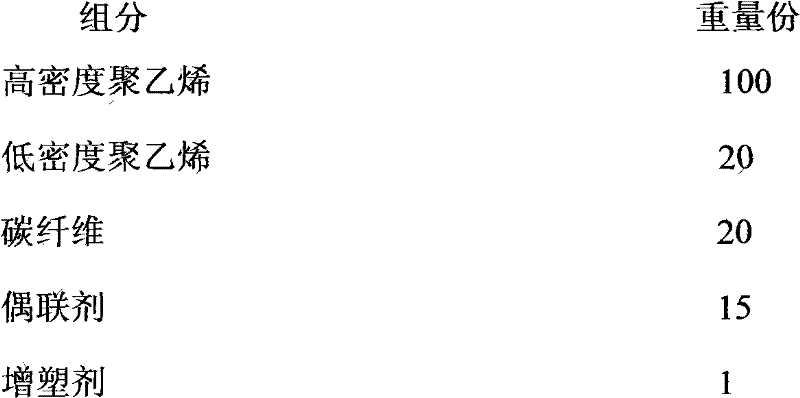

Carbon-fiber-reinforced polyethylene composite material

Owner:SHANGHAI BANGZHONG NEW MATERIAL

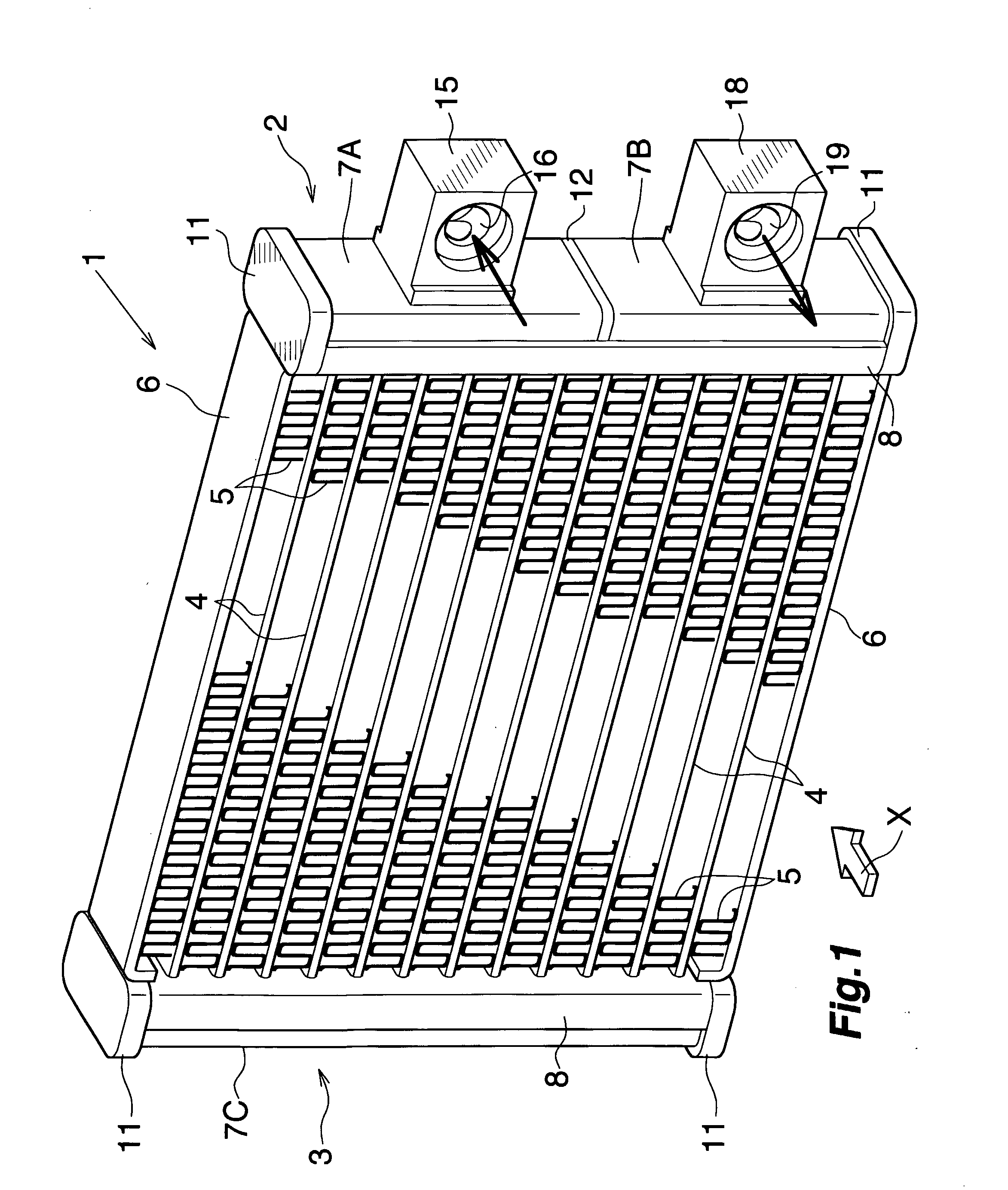

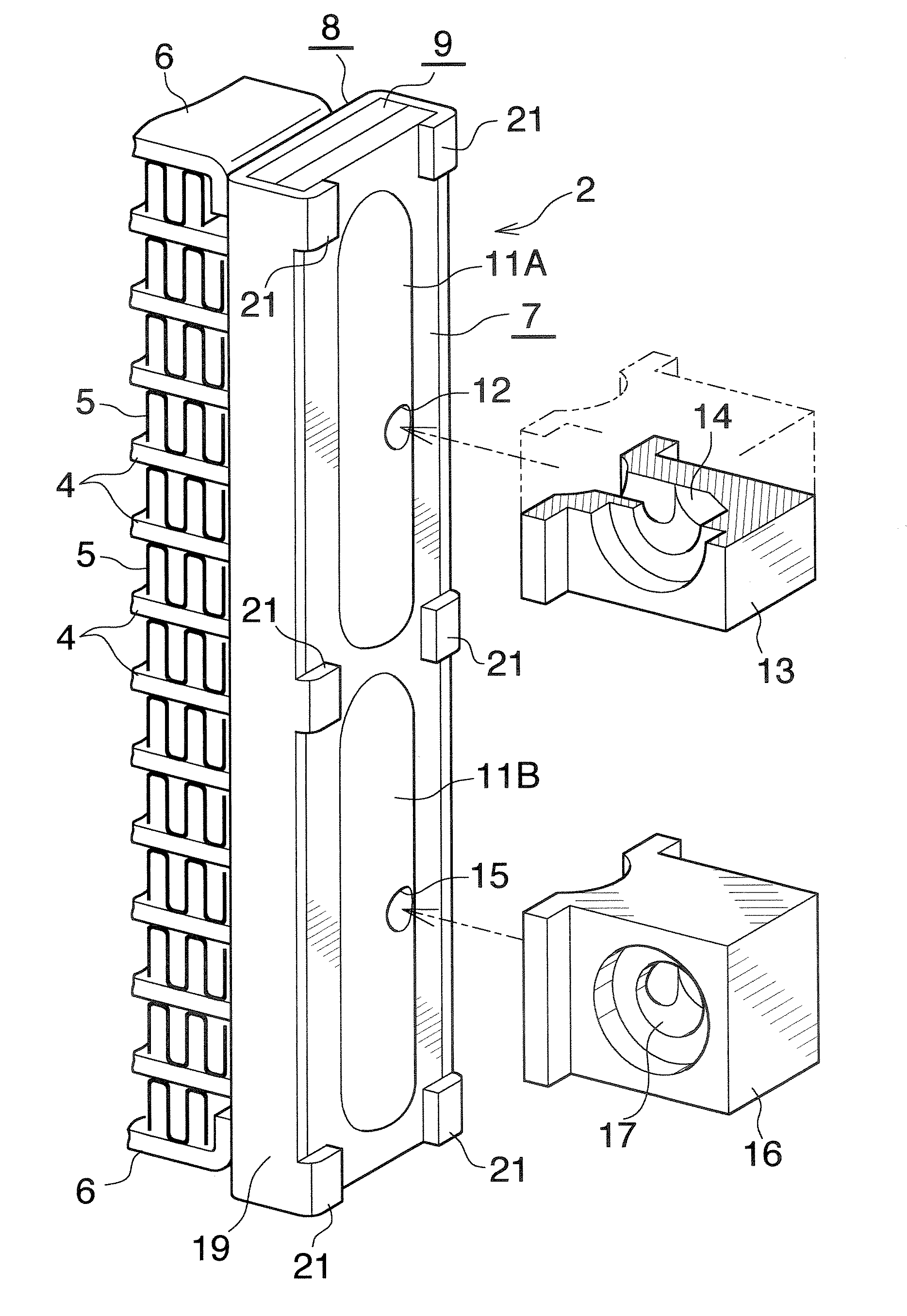

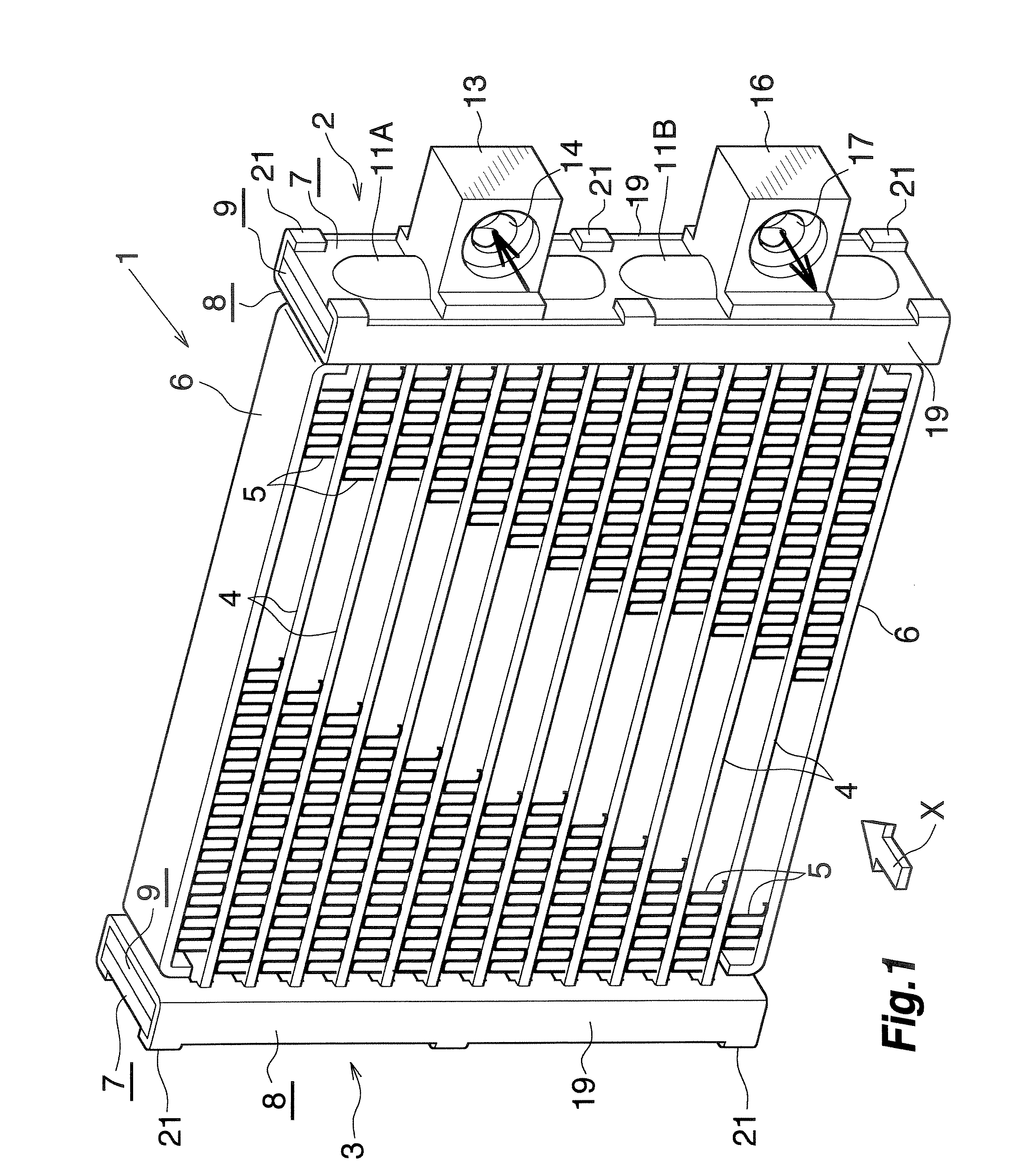

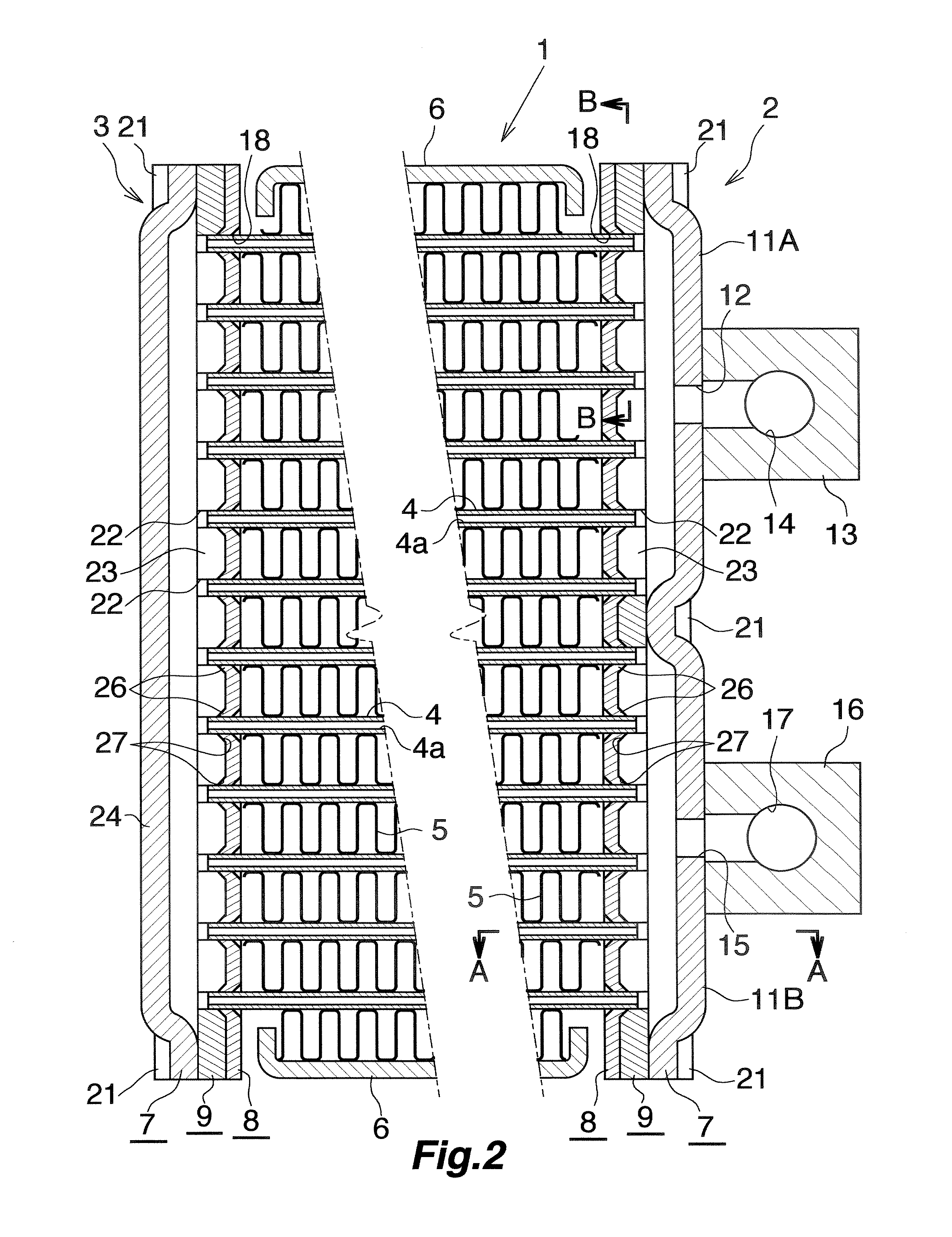

Heat exchanger

InactiveUS20080017364A1Well formedEasy to insertEvaporators/condensersStationary conduit assembliesEngineeringMechanical engineering

A heat exchanger includes two header tanks and a plurality of heat exchange tubes. The header tanks each include an outside plate, an inside plate, and an intermediate plate. The outside plate has an outwardly bulging portion(s). The inside plate has a plurality of tube insertion holes. The intermediate plate has communication holes for allowing communication of the tube insertion holes with the outwardly bulging portion of the header tank. A pair of inclined portions inclined in a fanning-out fashion toward the inside plate are formed at inside-plate-side edge portions of opposite wall surfaces of each communication hole which extend in the hole-length direction. Projecting portions of the inside plate are formed by bending, toward the intermediate plate, portions of the inside plate located at opposite edges of each tube insertion hole which extend in the hole-length direction. The projecting portions are closely brazed to the corresponding inclined portions.

Owner:SHOWA DENKO KK

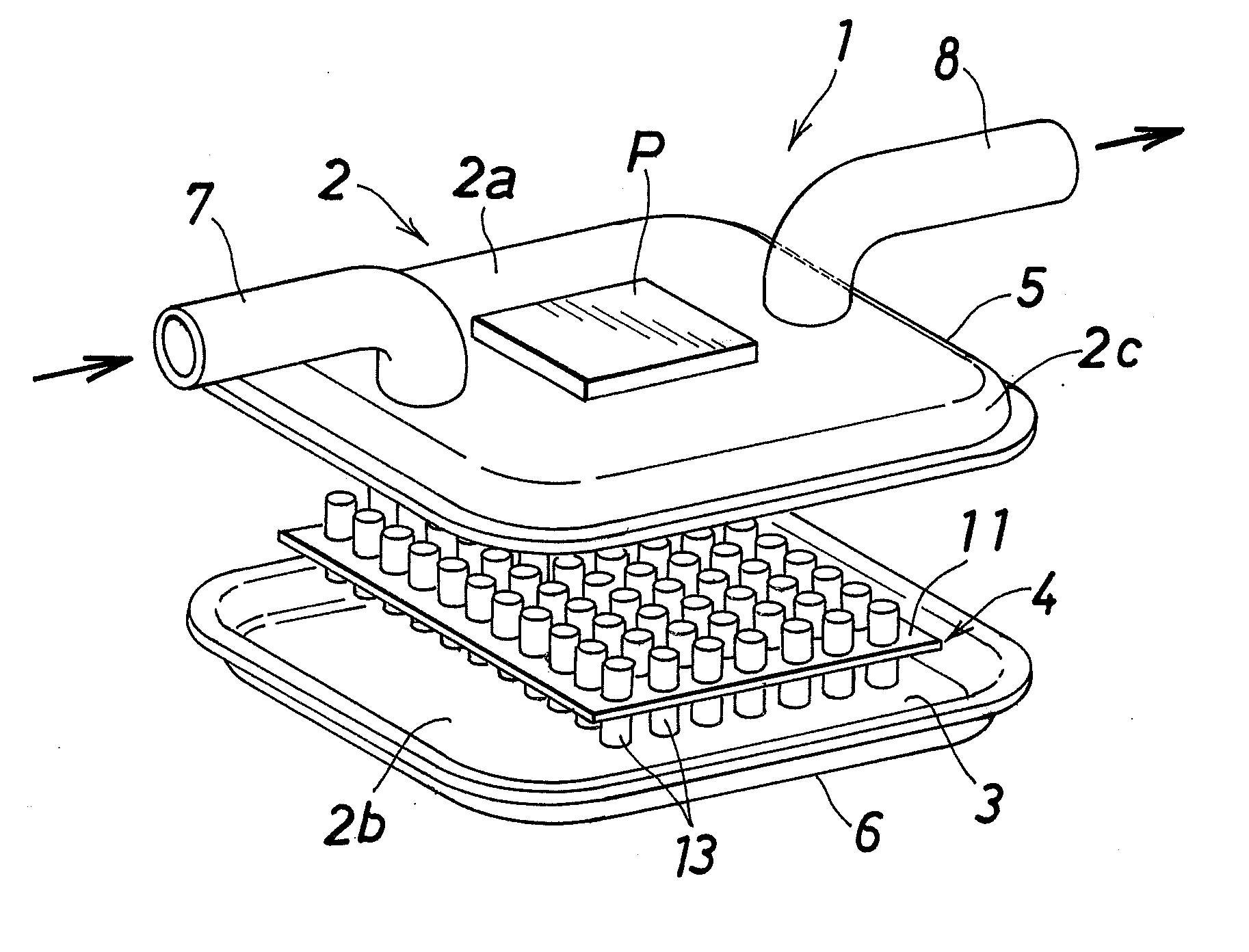

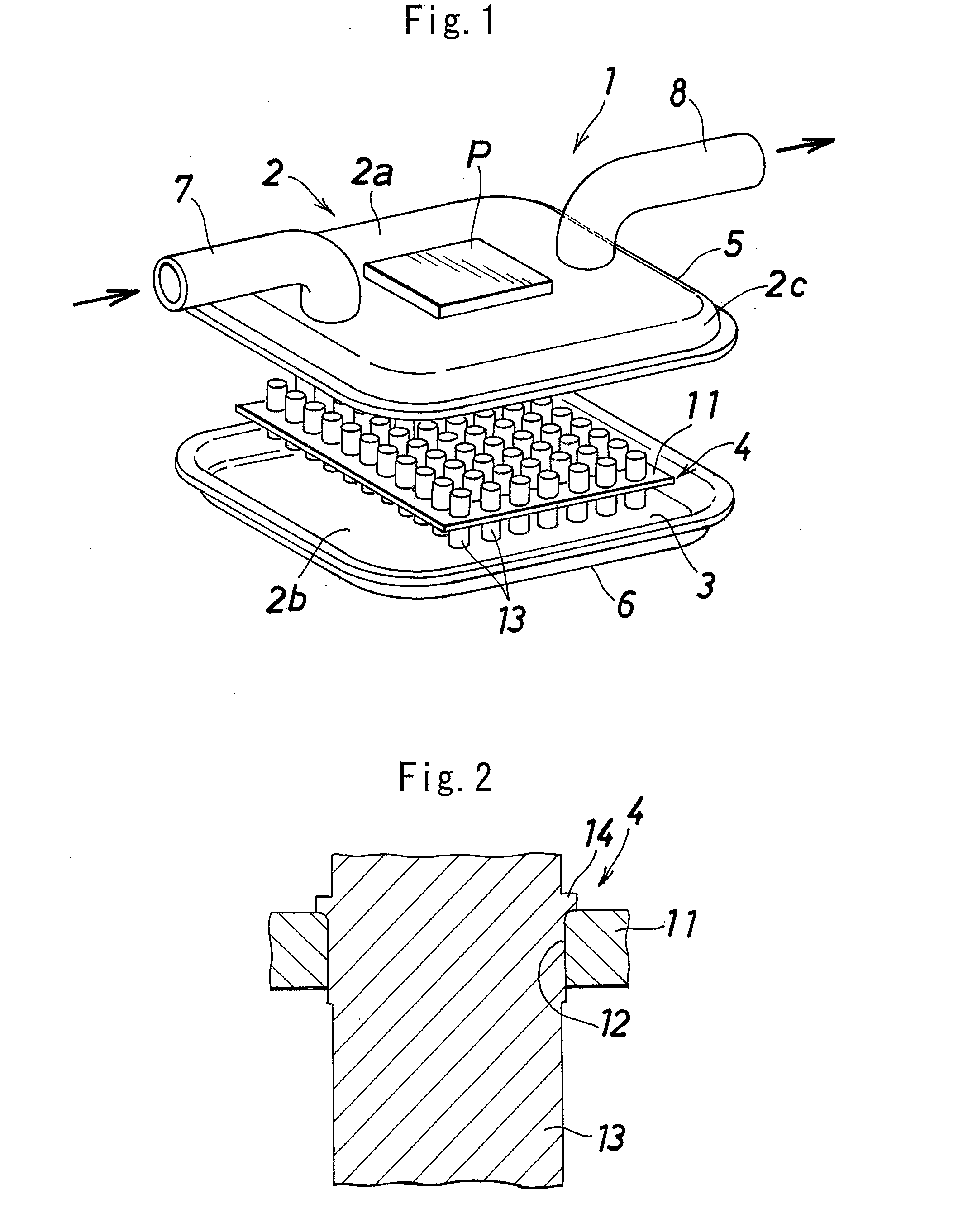

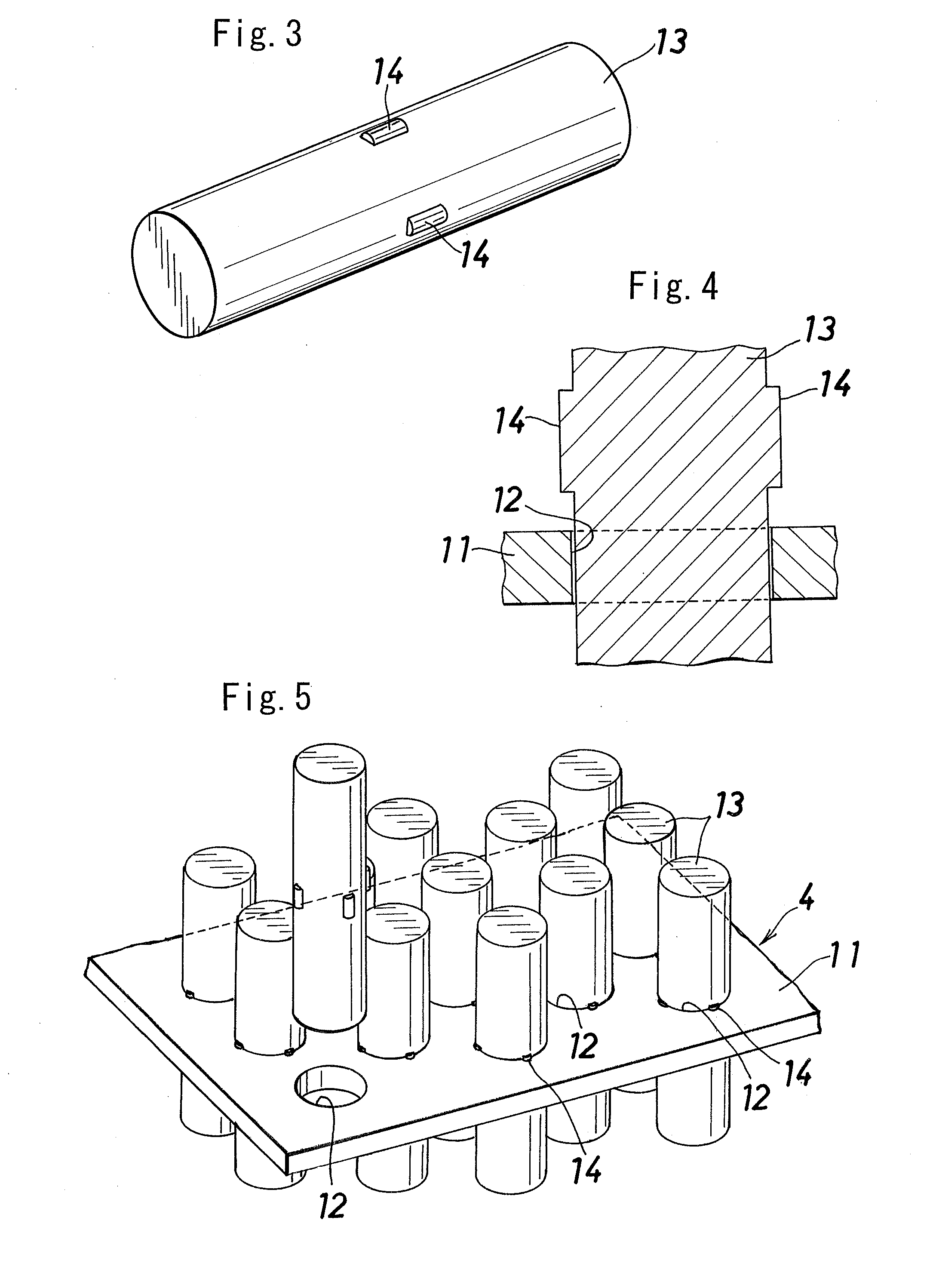

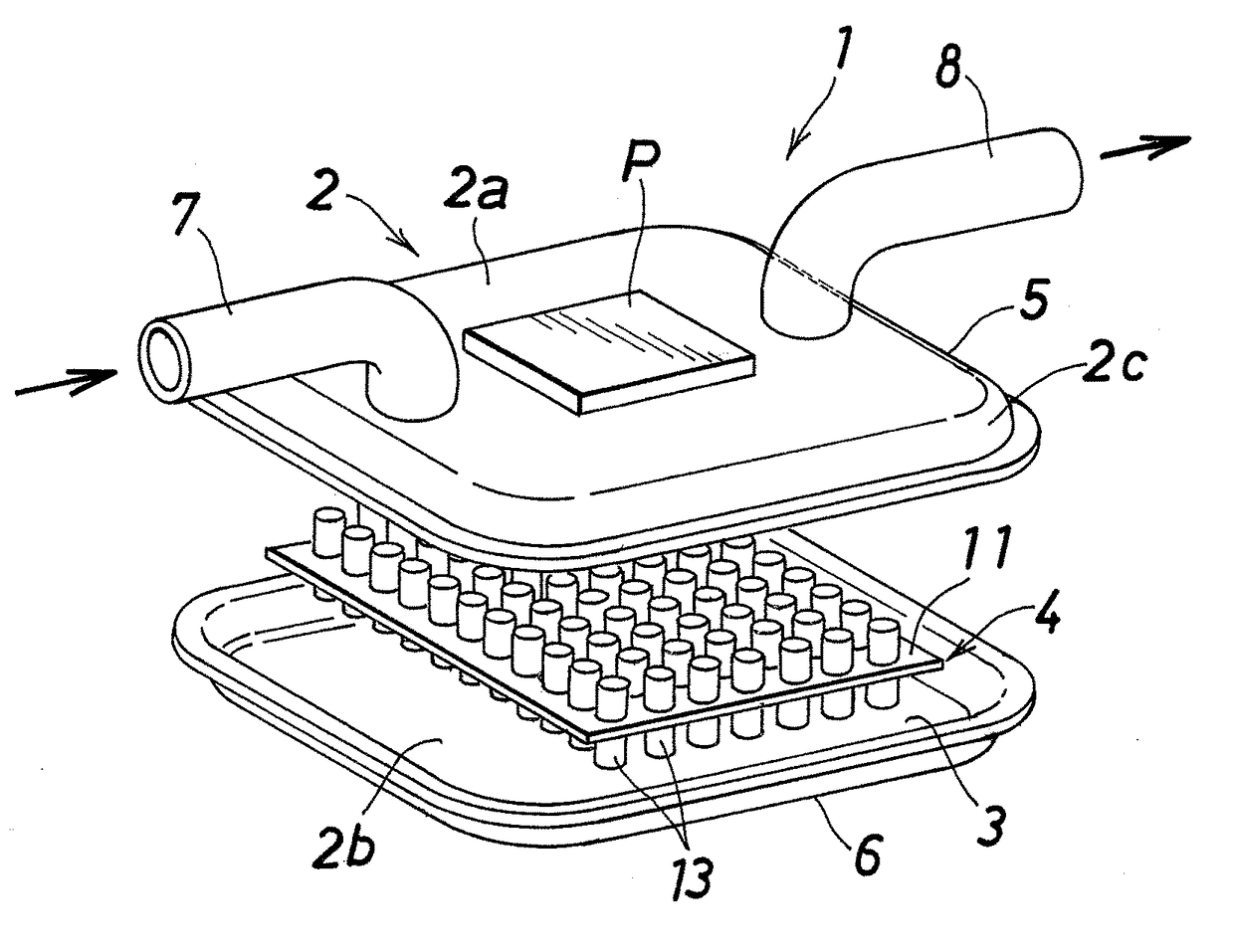

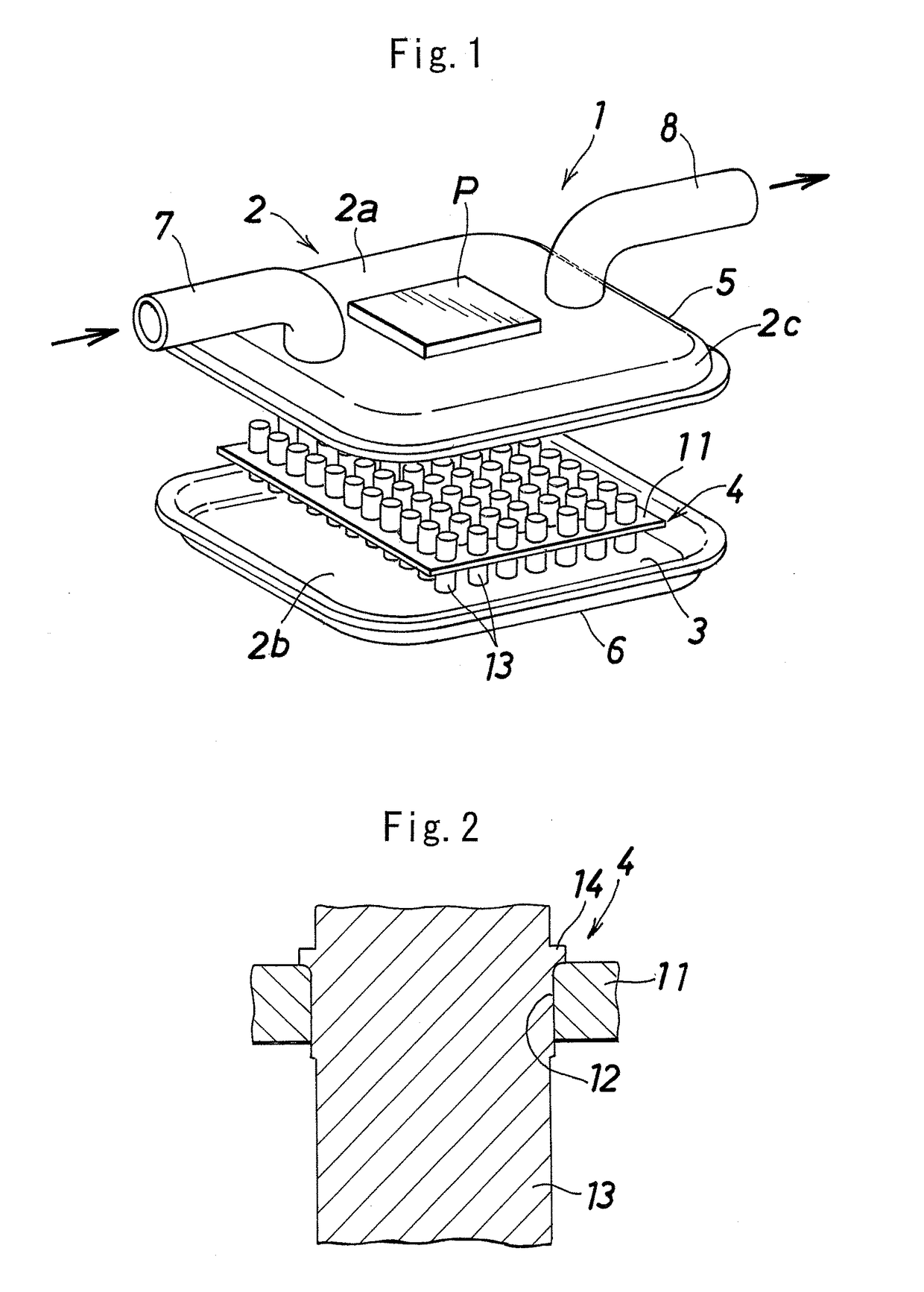

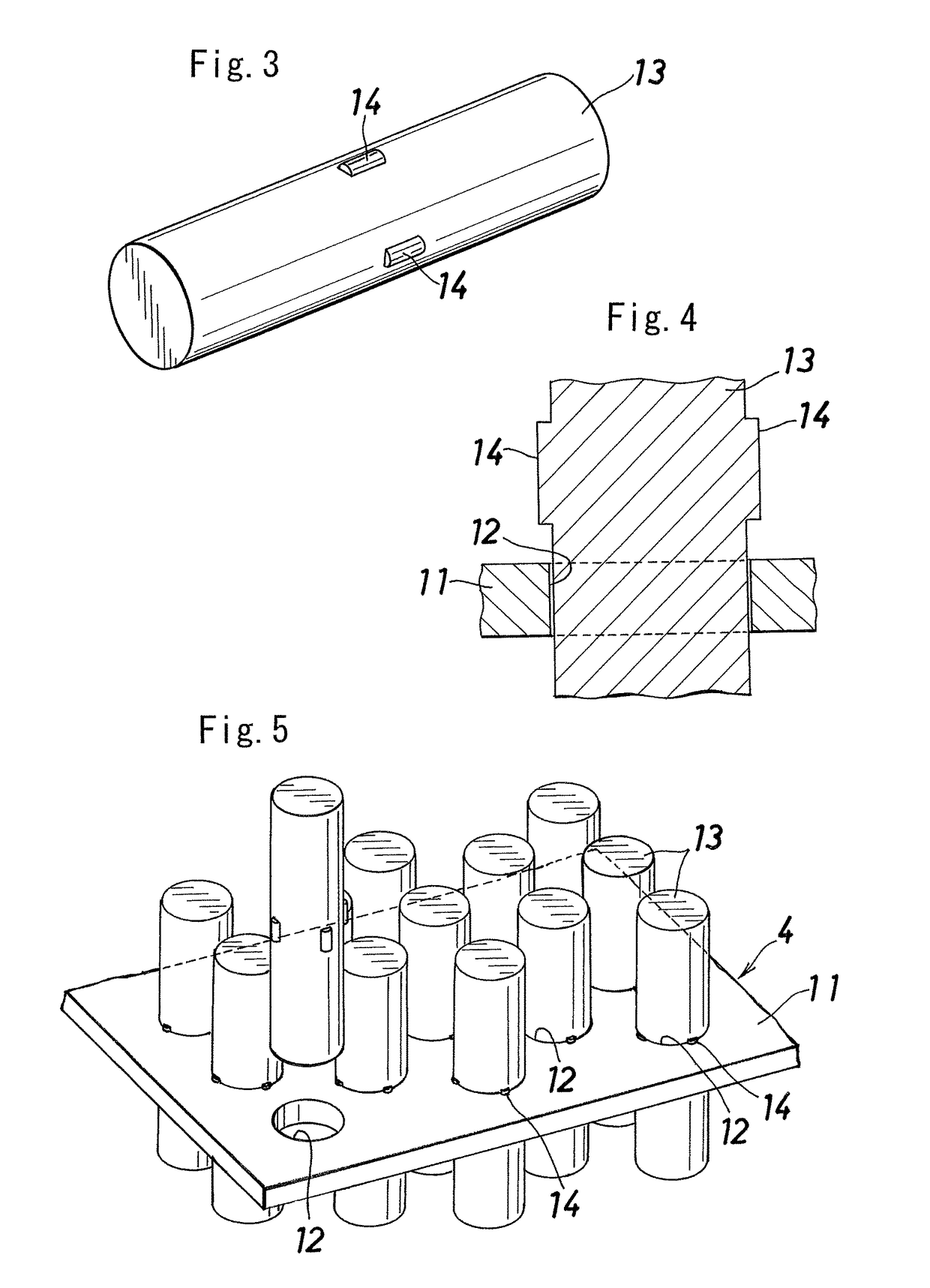

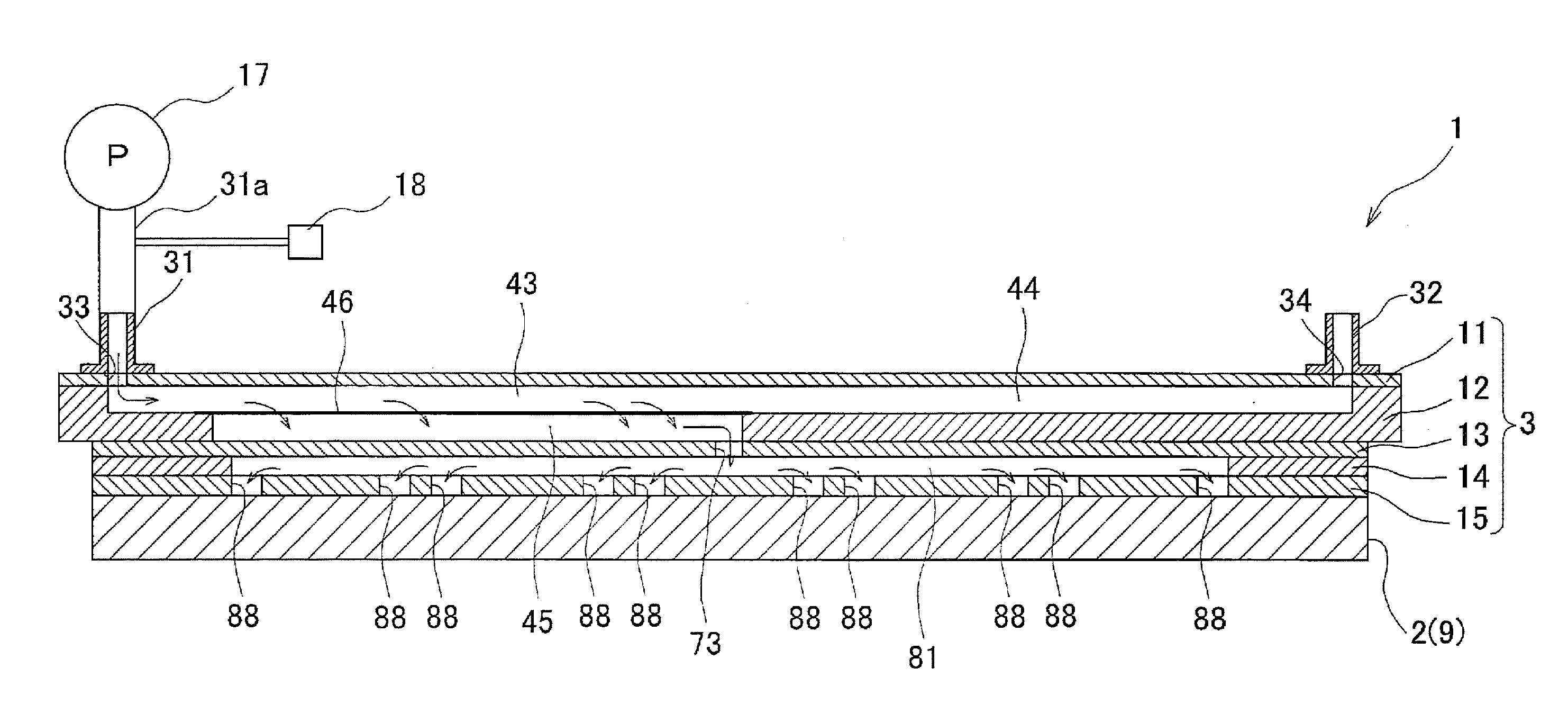

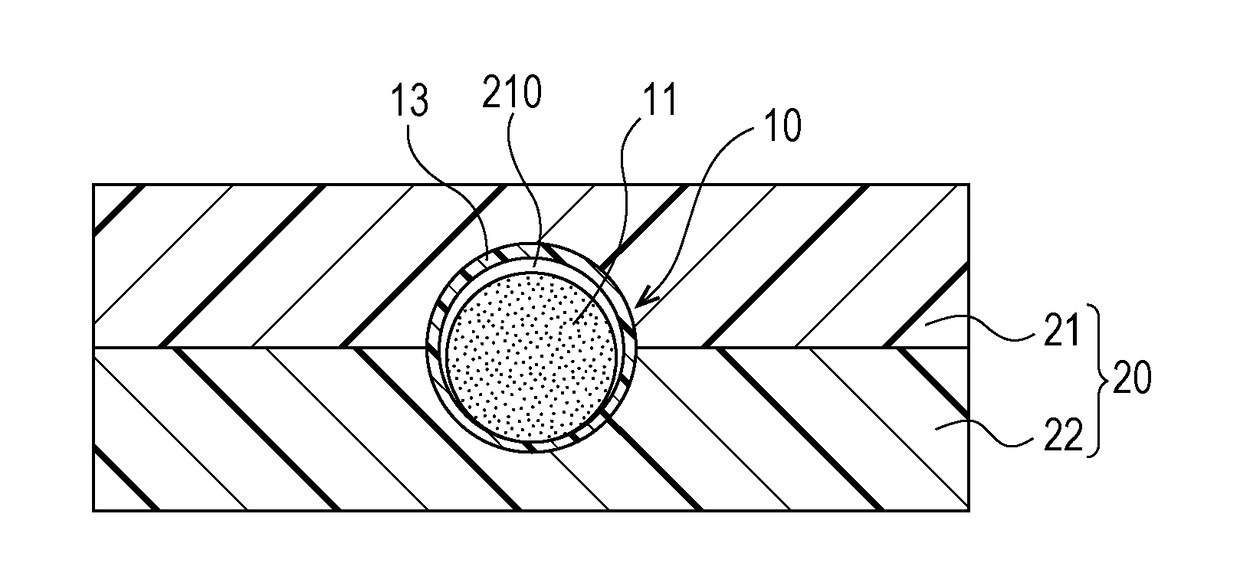

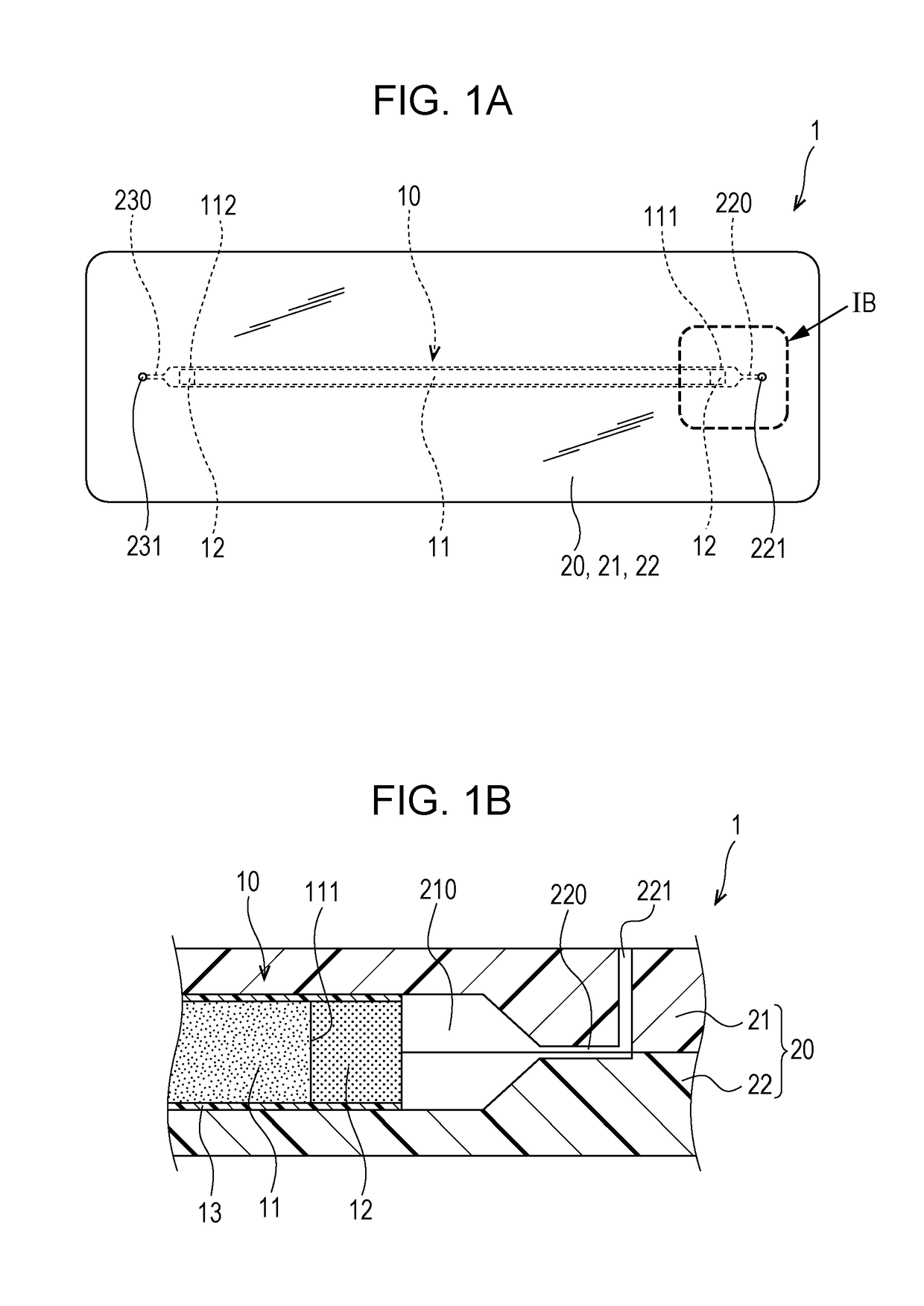

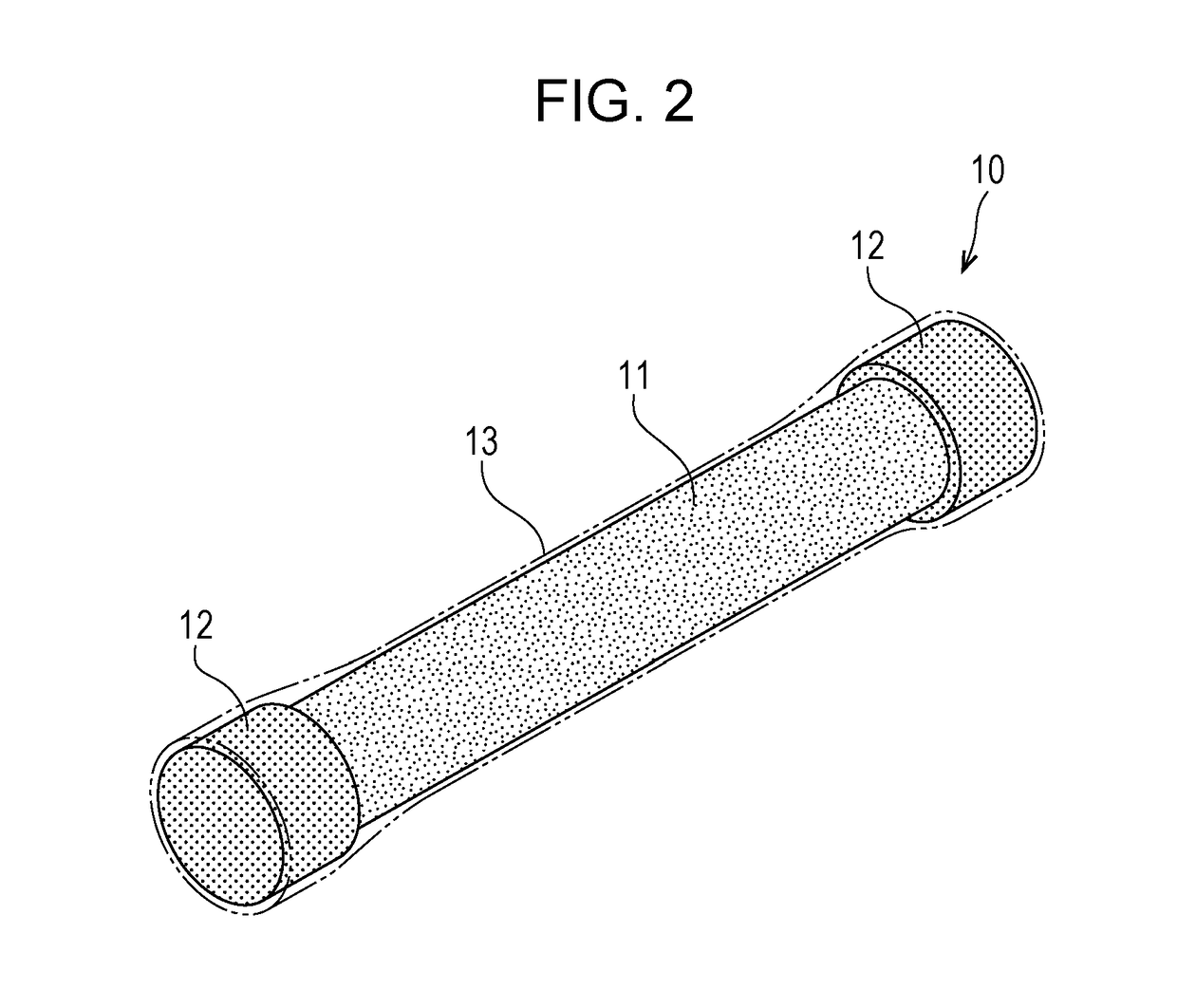

Liquid-cooled-type cooling device and manufacturing method for same

ActiveUS20130284404A1Improve cooling effectUnder high pressureSemiconductor/solid-state device detailsMetal-working apparatusCooling fluidCoolant channel

A liquid-cooled-type cooling device includes a casing having a top wall, a bottom wall, and a cooling-liquid passage, and a radiating member disposed in the cooling-liquid passage. The radiating member has a substrate and a plurality of pin-shaped fins. Longitudinally intermediate portions of the pin-shaped fins are brazed to the substrate. The substrate has a plurality of fin insertion holes, and the pin-shaped fins are inserted into the fin insertion holes of the substrate. A plurality of convex portions are integrally formed on the longitudinally intermediate portion of each pin-shaped fin. The substrate and the pin-shaped fins are provisionally fixed together by plastically deforming the convex portions such that they are crushed. In this state, the substrate and the pin-shaped fins are brazed together. The upper and lower end portions of the pin-shaped fins are brazed to the top wall and bottom wall, respectively, of the casing.

Owner:RESONAC CORP

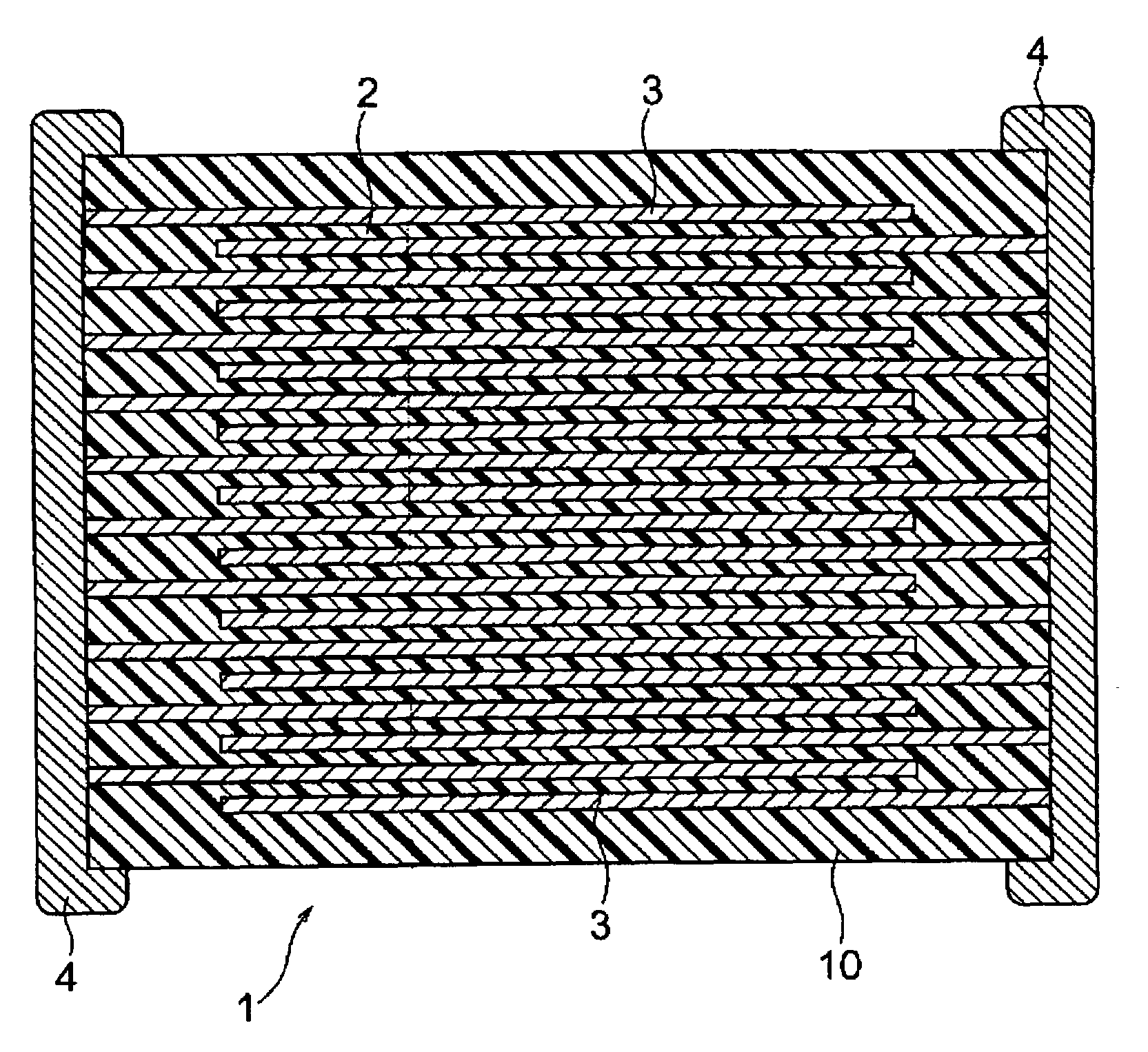

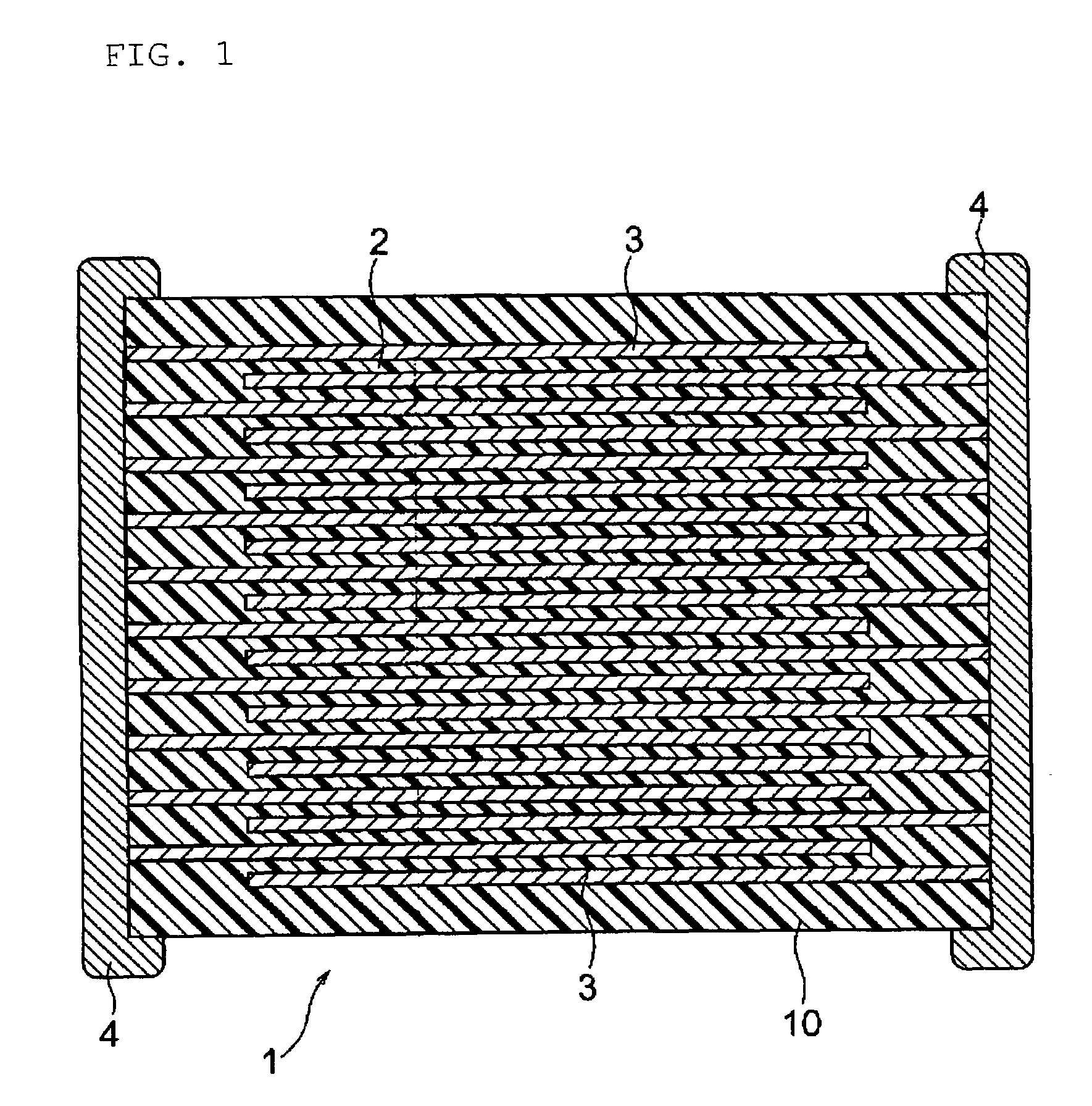

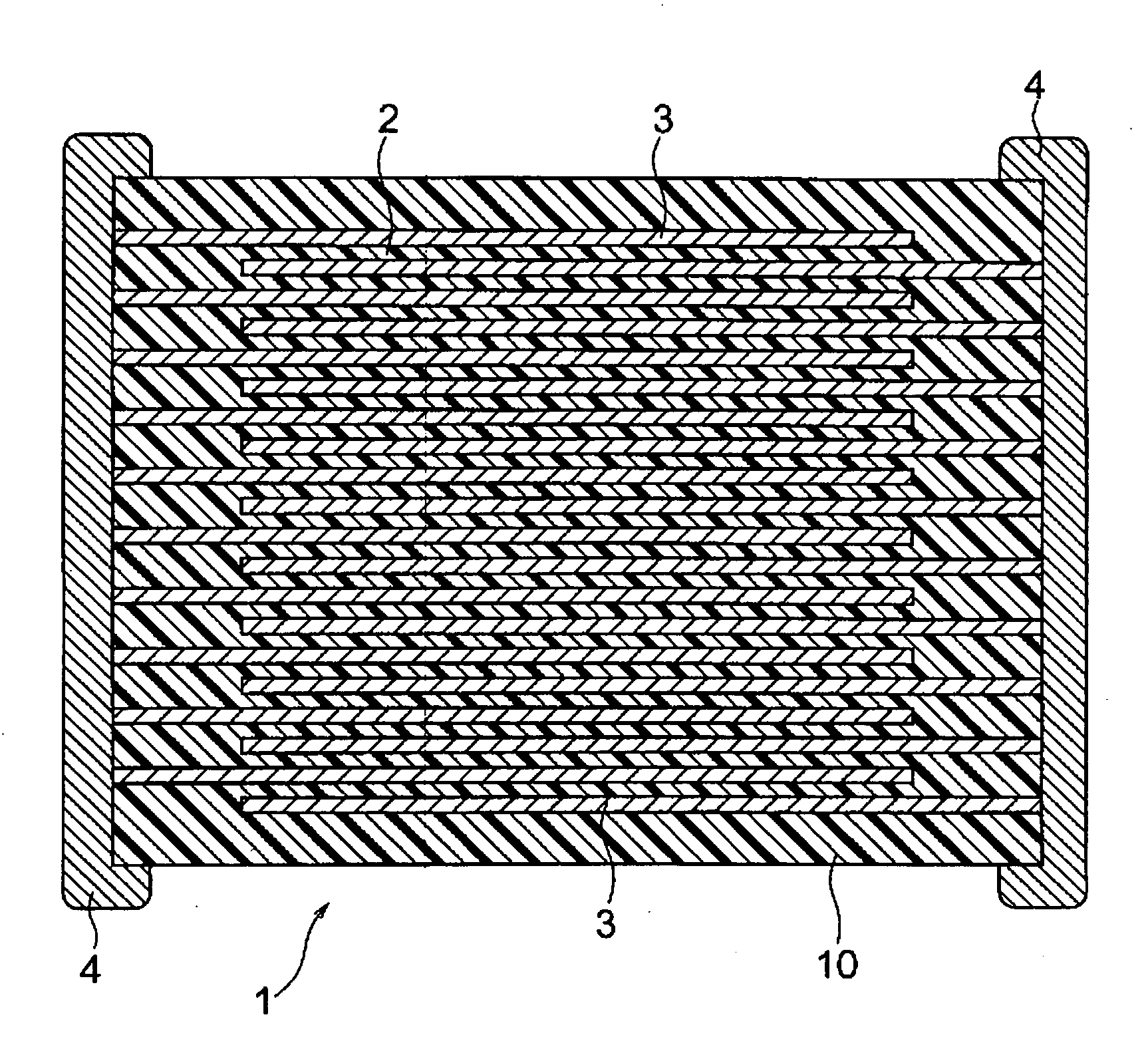

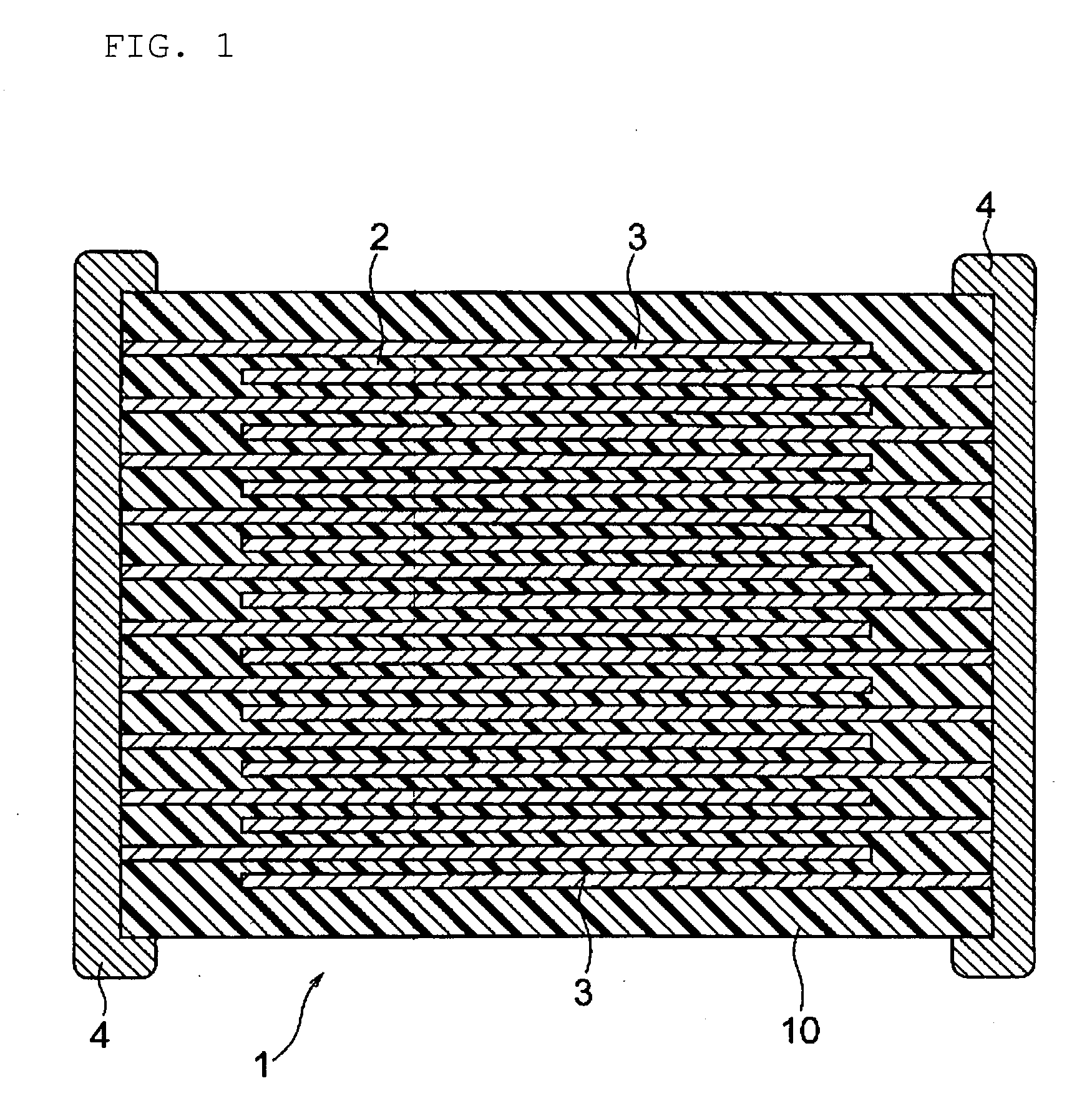

Dielectric ceramic composition and electronic device

ActiveUS7580242B2Extended service lifeReducing atmosphereFixed capacitor dielectricStacked capacitorsMaterials scienceOxide

Owner:TDK CORPARATION

Heat exchanger

InactiveUS8235099B2Uniform temperatureImprove uniformityReinforcing meansEvaporators/condensersEngineeringHeat exchanger

A heat exchanger used as an evaporator includes a refrigerant inlet header section having a refrigerant inlet at a right end portion, and a plurality of heat exchange tubes connected to the refrigerant inlet header section. The interior of the refrigerant inlet header section is divided by a partition plate into an upper space into which refrigerant flows via the refrigerant inlet and a lower space into which the heat exchange tubes project. A communication opening is formed in the partition plate on the left side of a heat exchange tube at the left end so as to establish communication between the upper and lower spaces. A guide portion is formed at a left edge portion of the communication opening such that the guide portion projects from a lower surface of the partition member into the lower space so as to guide the refrigerant toward the right end side.

Owner:KEIHIN THERMAL TECH CORP

Dielectric ceramic composition and electronic device

ActiveUS20080297979A1Improve withstand pressure (breakdown voltage)Good specific permittivityFixed capacitor dielectricStacked capacitorsMaterials scienceOxide

A dielectric ceramic composition comprising BamTiO2+m (note that “m” satisfies 0.99≦m≦1.01) and BanZrO2+n (note that “n” satisfies 0.99≦n≦1.01), an oxide of Mg, an oxide of R (note that R is at least one selected from Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu), an oxide of at least one element selected from Mn, Cr, Co and Fe, and an oxide of at least one element selected from Si, Li, Al, Ge and B. With respect to 100 moles of said BamTiO2+m, 35 to 65 moles of BanZrO2+n, 4 to 12 moles of an oxide of Mg, 4 to 15 moles of an oxide of R, 0.5 to 3 moles of an oxide of Mn, Cr, Co and Fe, and 3 to 9 moles of an oxide of Si, Li, Al, Ge and B are included therein.

Owner:TDK CORPARATION

Flame-retardant carbon-fiber-reinforced polyethylene composite material

The invention discloses a flame-retardant carbon-fiber-reinforced polyethylene composite material which comprises the following components in parts by weight: 80-100 parts of high-density polyethylene, 10-20 parts of low density polyethylene, 15-20 parts of carbon fiber, 5-15 parts of coupling agent, 0.5-1 part of plasticizer, 0.1-0.5 part of dispersing agent and 10-15 parts of flame retardant. The composite material has the advantages of high strength, high bearing pressure and poor thermal deformation in the high-density polyethylene, and also has the advantages of favorable impact resistance and favorable toughness in the low-density polyethylene. The composite material has the characteristics of flame retardancy and high strength.

Owner:王寿高

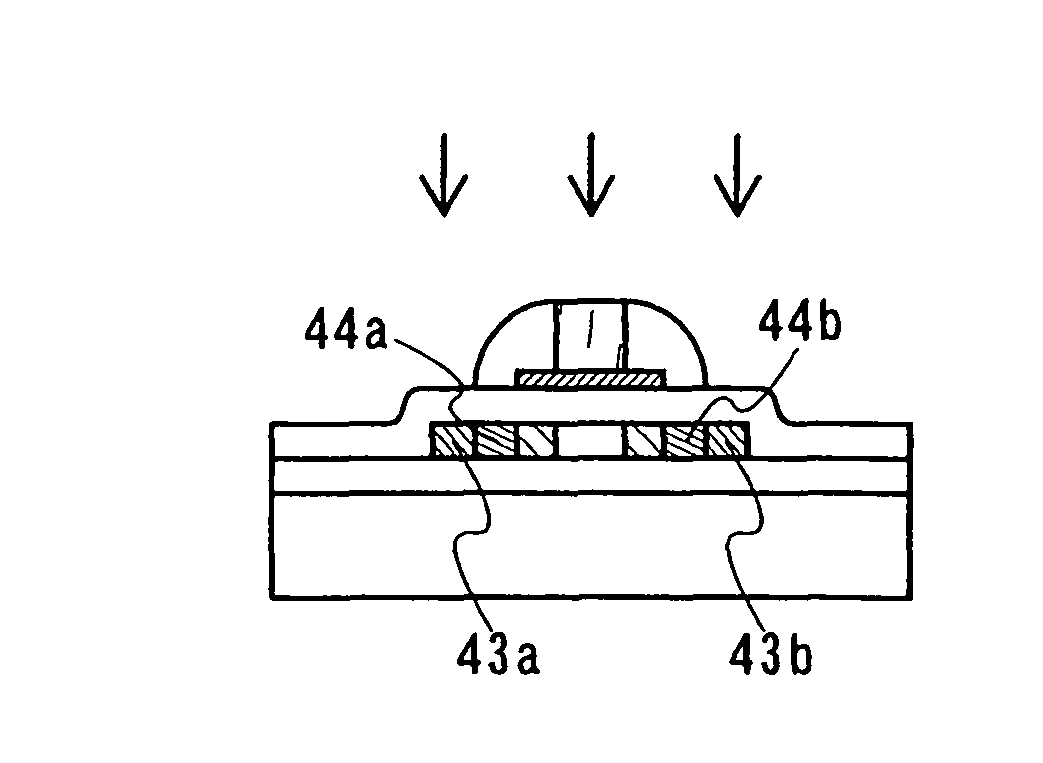

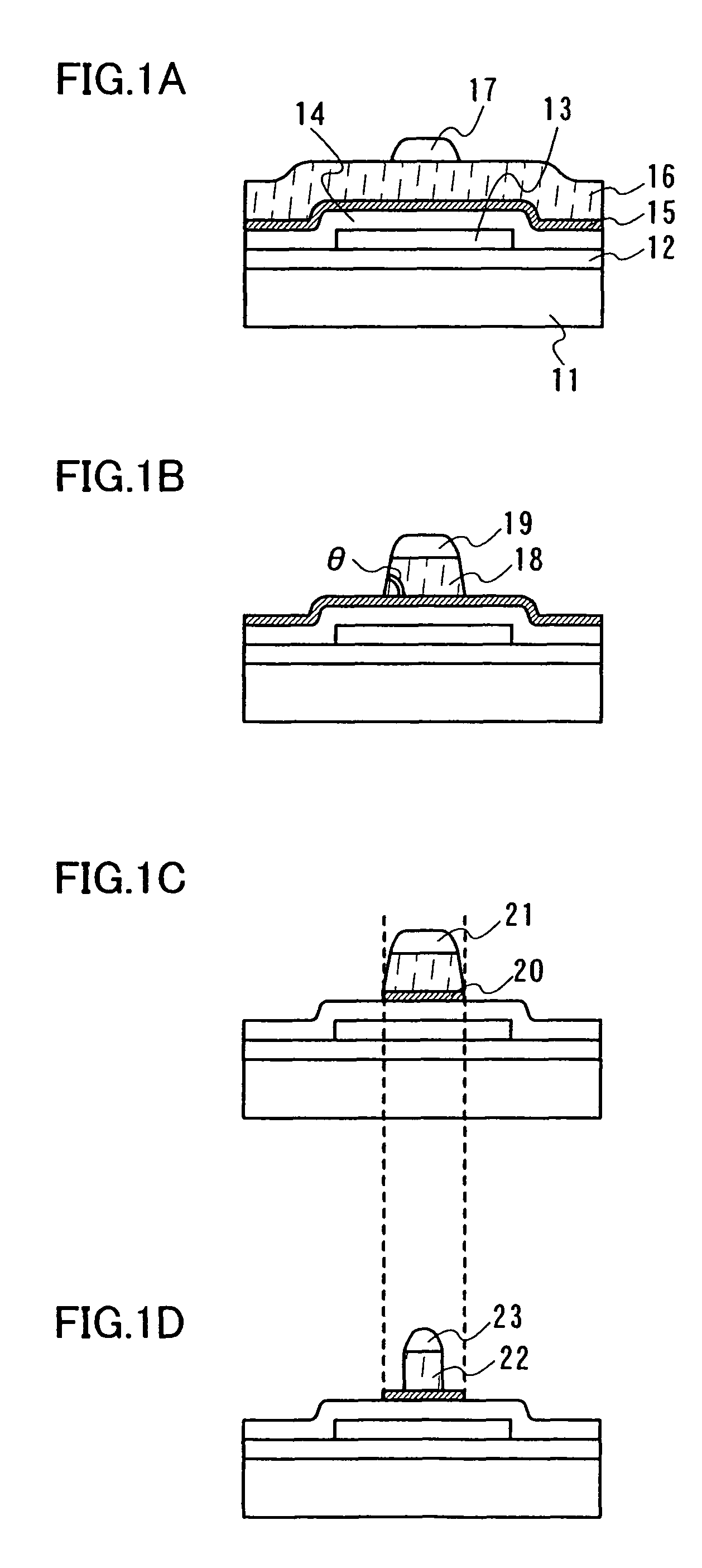

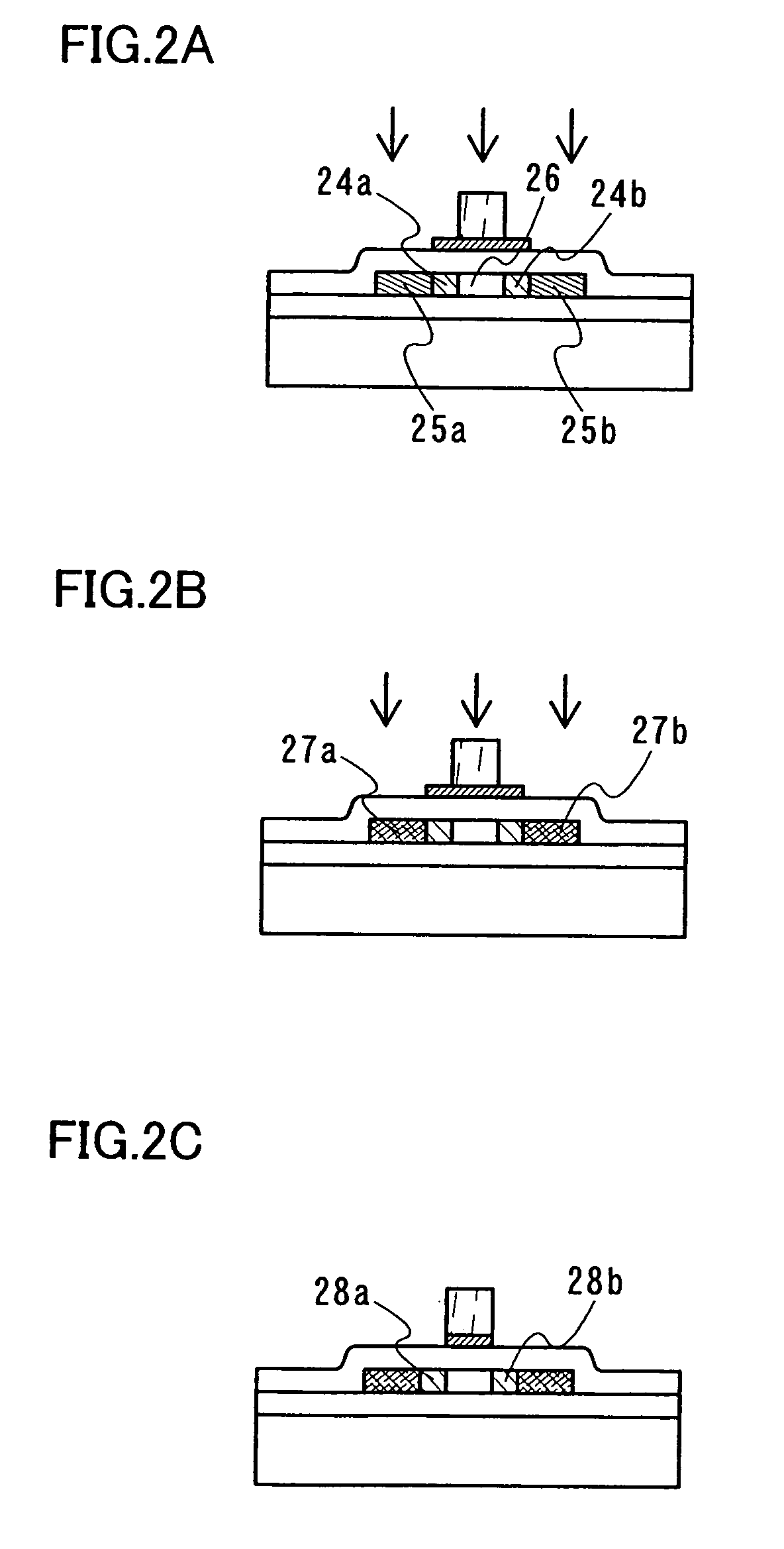

Method for manufacturing semiconductor device including hat-shaped gate electrode

InactiveUS8008140B2Preferable operating characteristicReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingResistSemiconductor

It is an object of the present invention to manufacture a TFT having a small-sized LDD region in a process with a few processing step and to manufacture TFTs each having a structure depending on each circuit separately. According to the present invention, a gate electrode is a multilayer, and a hat-shaped gate electrode is formed by having the longer gate length of a lower-layer gate electrode than that of an upper-layer gate electrode. At this time, only the upper-layer gate electrode is etched by using a resist recess width to form the hat-shaped gate electrode. Accordingly, an LDD region can be formed also in a fine TFT; thus, TFTs having a structure depending on each circuit can be manufactured separately.

Owner:SEMICON ENERGY LAB CO LTD

Polygonal thin-oil rubber sealed gas holder

ActiveCN101749535AReduce welding workloadEasy to makeVariable capacity gas holdersRubber ringMechanical engineering technology

The invention relates to a gas holder sealing device, in particular to a polygonal thin-oil rubber sealed gas holder, namely a POR gas holder, and belongs to the technical field of mechanical engineering. In the POR gas holder, a self-supporting sealing system is arranged on a piston; derrick type corner slider sealing systems are arranged on two sides of the corner of an upright post; and the sealing systems mainly consist of more than three groups of sealing rubber rings and canvas. The polygonal thin-oil rubber sealed gas holder has obvious effect, can greatly enhance the sealing effect and loading capacity and integrates the advantages of a MAN-type gas holder and a novel gas holder, so the gas holder can be used for the reconstruction of the MAN-type gas holder and can be popularized in the gas cabinets.

Owner:CISDI ENG CO LTD

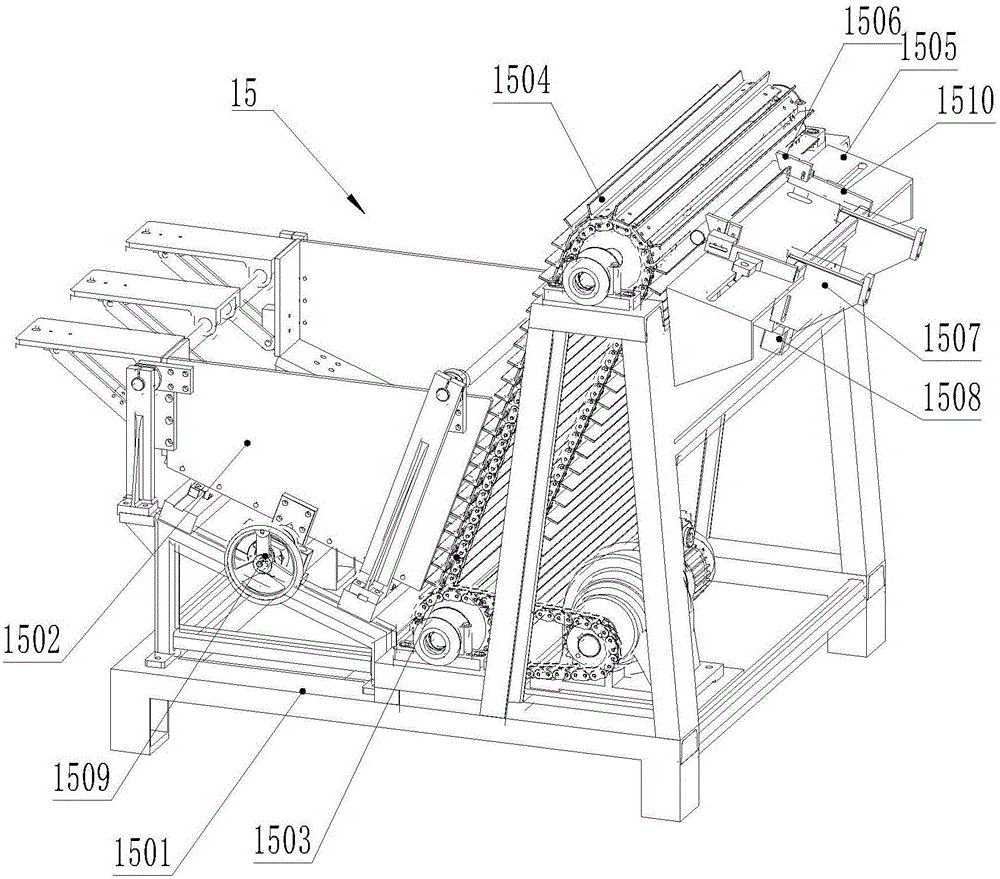

Production process for high-strength corrugated board

InactiveCN106379032AHigh strengthHigh bonding strengthNon-macromolecular adhesive additivesStarch adhesivesPaperboardHigh intensity

The invention specifically relates to a production process for a high-strength corrugated board, belonging to the field of processing of paperboards. The production process comprises the following steps: preparing glue, allowing a corrugated medium to pass through a fixed guide roller and a swinging guide roller, gluing the corrugated medium with a glue spreader so as to obtain a first corrugated layer and bonding the first corrugated layer with a first surface paper layer so as to obtain a first single-side single-arch corrugated board; allowing the corrugated medium to pass through the fixed guide roller and the swinging guide roller, gluing the corrugated medium with the glue spreader so as to obtain a second corrugated layer and bonding the second corrugated layer with a second surface paper layer so as to obtain a second single-side single-arch corrugated board; allowing the corrugated medium to pass through the fixed guide roller and the swinging guide roller, gluing the corrugated medium with the glue spreader so as to obtain a third corrugated layer and bonding the third corrugated layer with a third surface paper layer and a fourth surface paper layer so as to obtain a third double-side single-arch corrugated board; and bonding the first single-side single-arch corrugated board, the second single-side single-arch corrugated board and the third double-side single-arch corrugated board and then carrying out heating and curing on the bonded corrugated boards in a vacuum curing channel. The production process improves product quality and reduces energy consumption and environmental pollution.

Owner:KUNSHAN MINGPENG PAPER IND

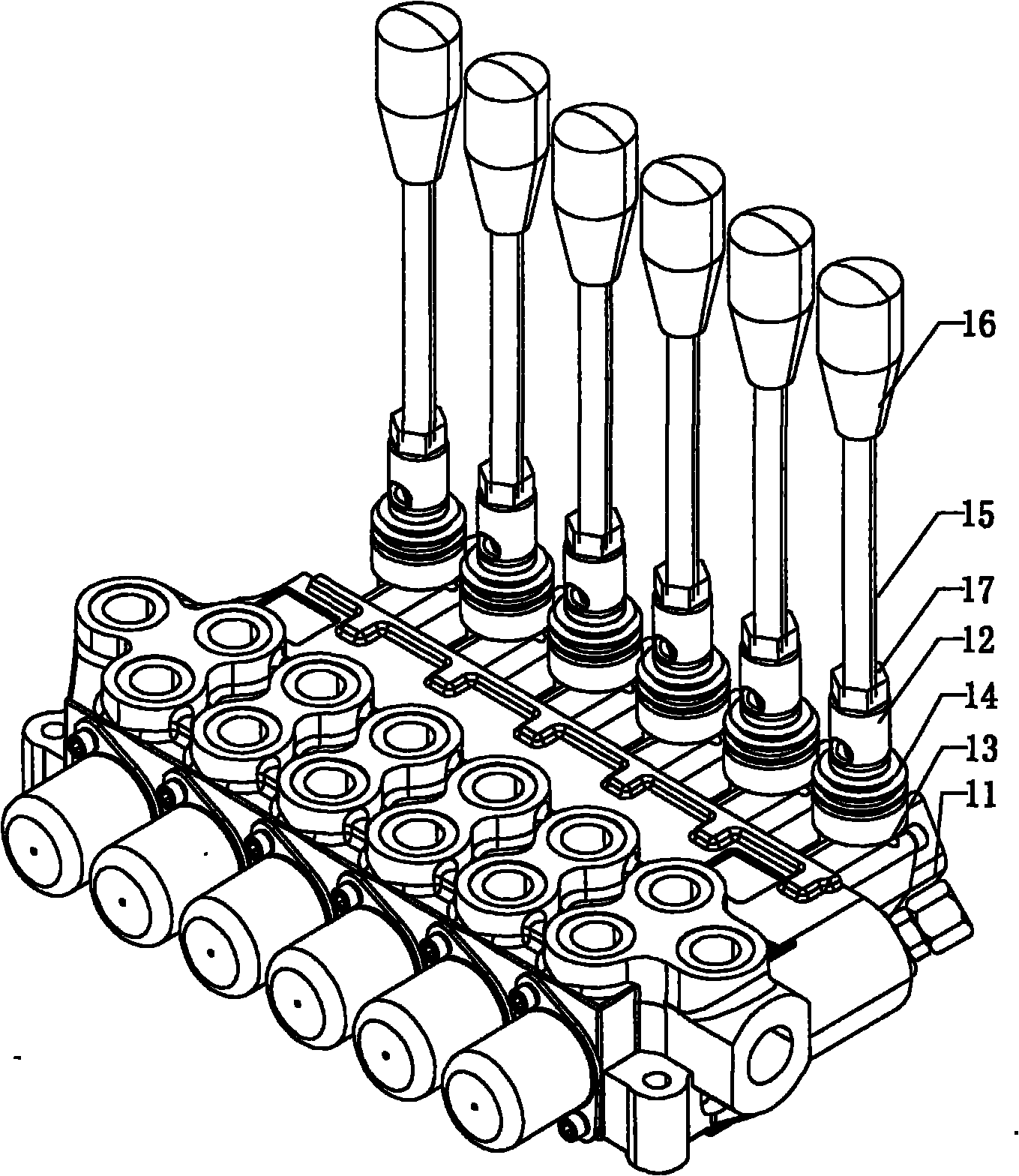

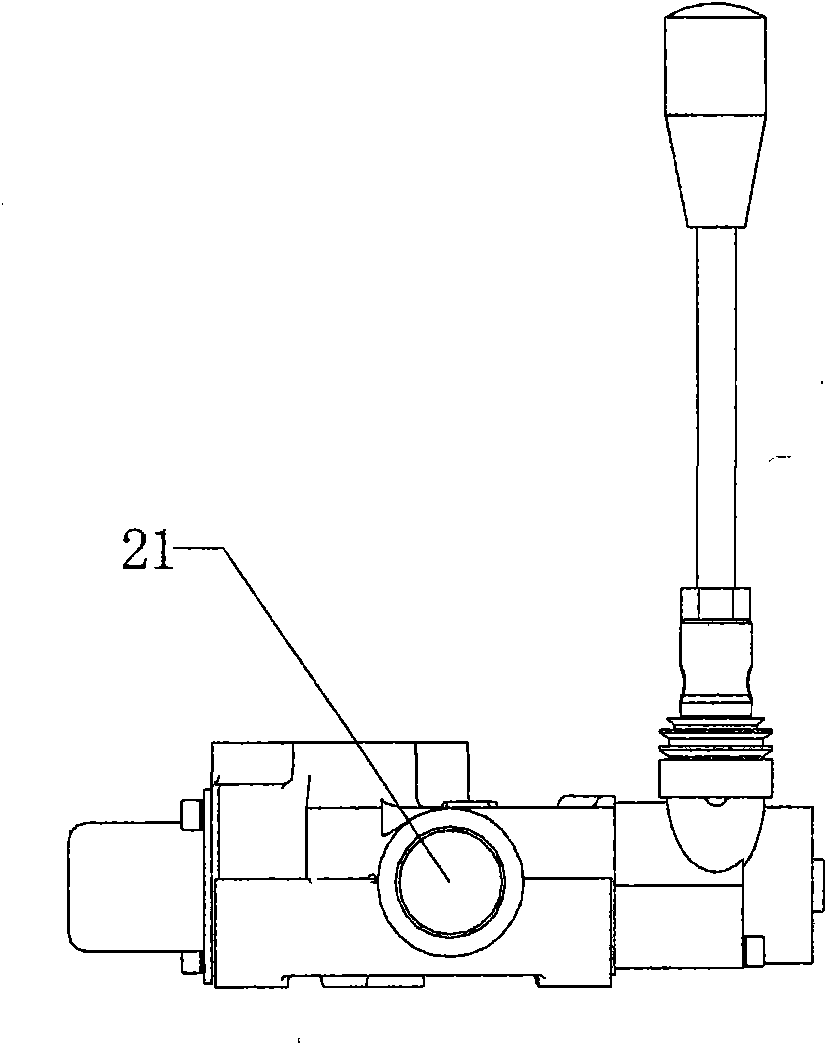

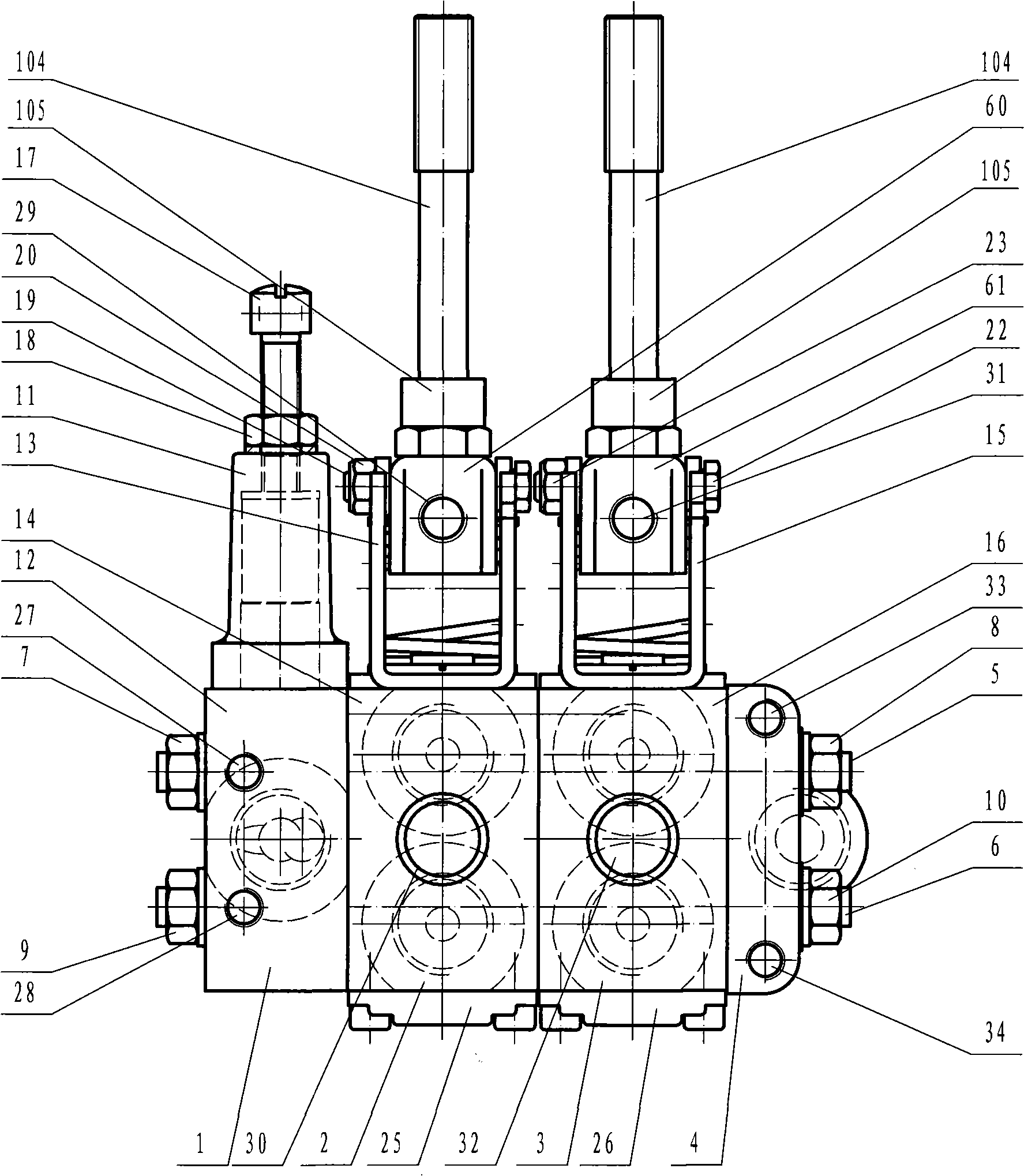

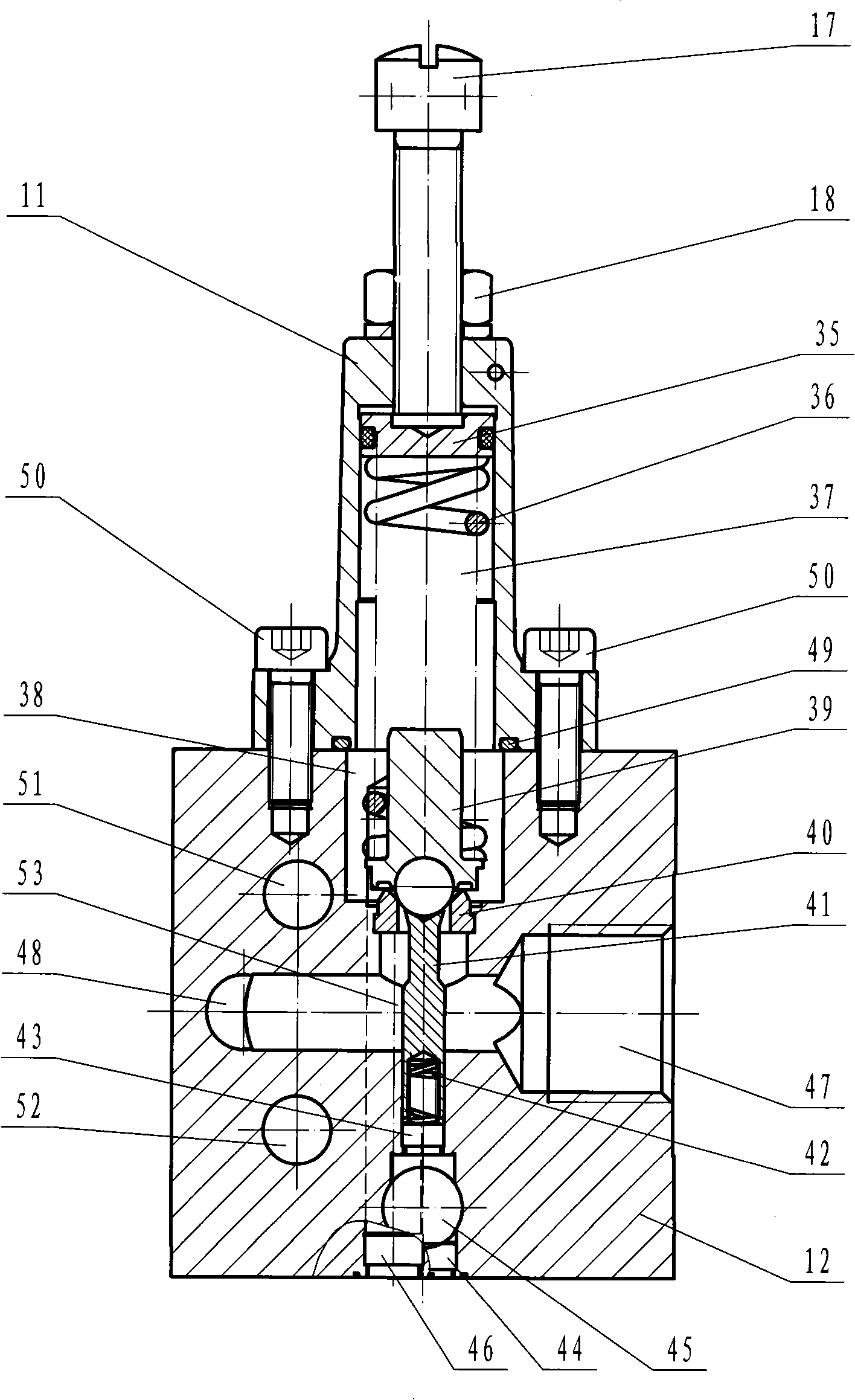

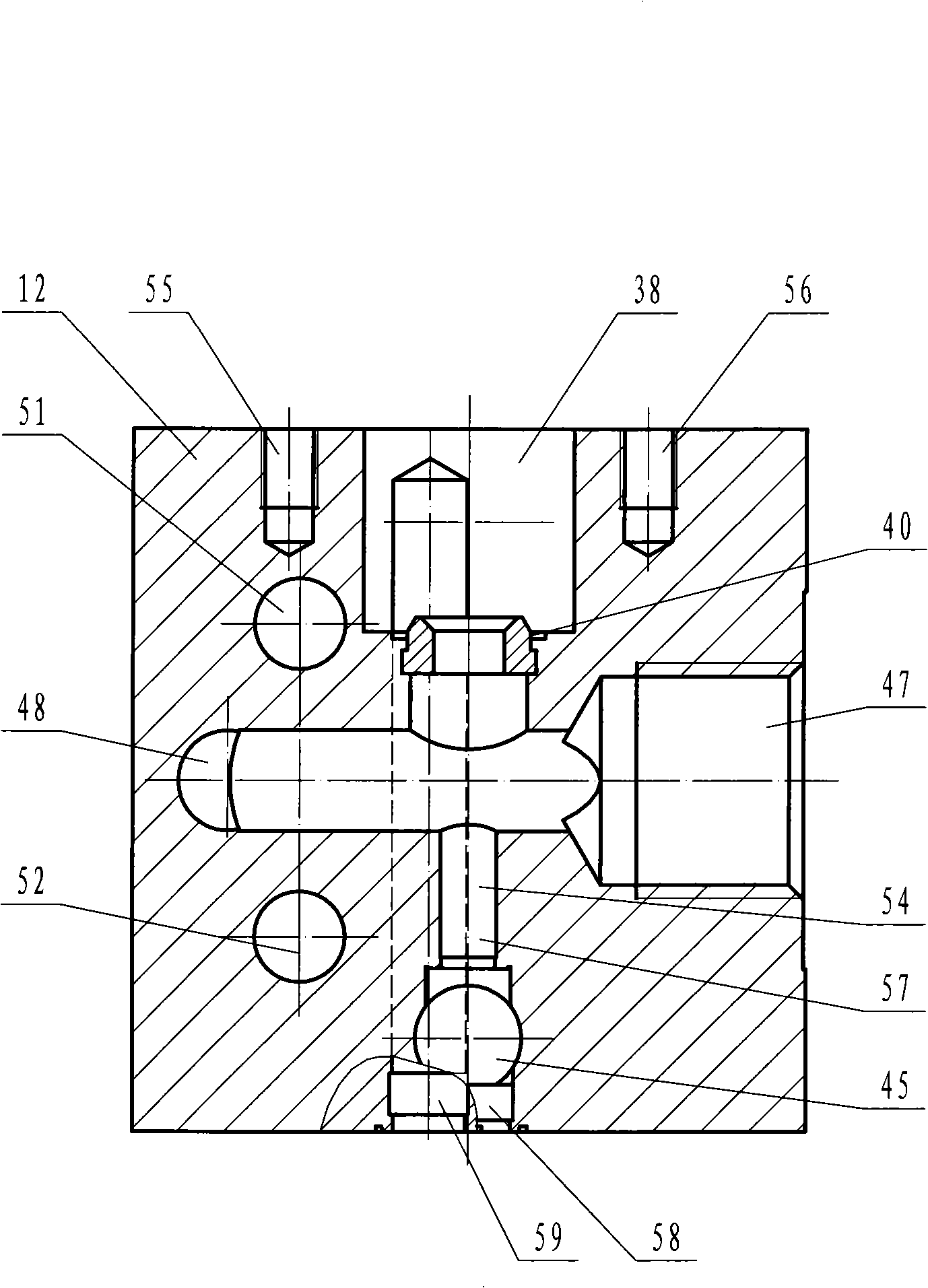

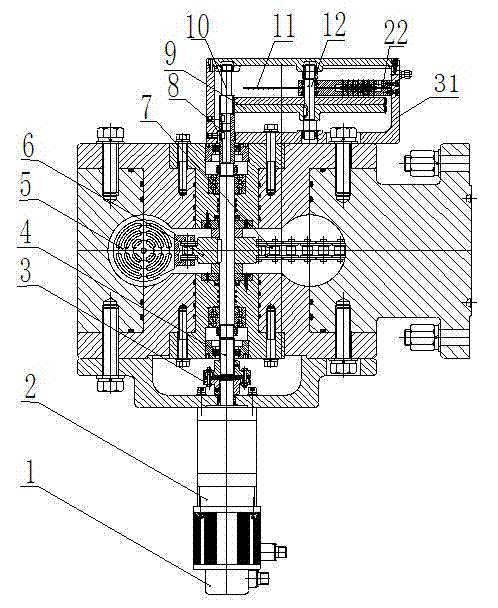

Integral multi-way reversing valve

InactiveCN101846107ANo effect on pressure lossNo impact lossOperating means/releasing devices for valvesServomotor componentsInlet valveEngineering

The invention relates to an integral multi-way reversing valve, which comprises an operating handle, a valve body, an end cover and a front cover, wherein the upper end of an operating rod is connected with the handle, while the lower end is connected with a pin shaft through screw threads; the upper part of the pin shaft is provided with a clamp nut, and the lower part of the pin shaft is connected with the end cover through pins; a valve rod is arranged inside the valve body, a plug hole is formed outside the valve body, and two ends of the valve body are connected with the end cover and a front cover thread respectively; and a spring, a stroke gasket and a retainer ring are arranged in the end cover. The integral multi-way reversing valve has the following advantages that: an oil inlet valve body, a reversing valve body and an oil return valve body are integrated by adopting an integral casting process, and small mass, simple appearance and smooth transition of the cavity of the valve enable a complex flow passage not to affect the pressure loss of liquid so as to well control the loss of oil pressure, shorten the time of hydraulic oil flowing through the valve body and ensure the purity of the hydraulic oil; castings have good compactness and high bearing pressure; and the problem of leakage between sheets of a sheet valve does not exit.

Owner:WUHAN LAZY CAT TECH

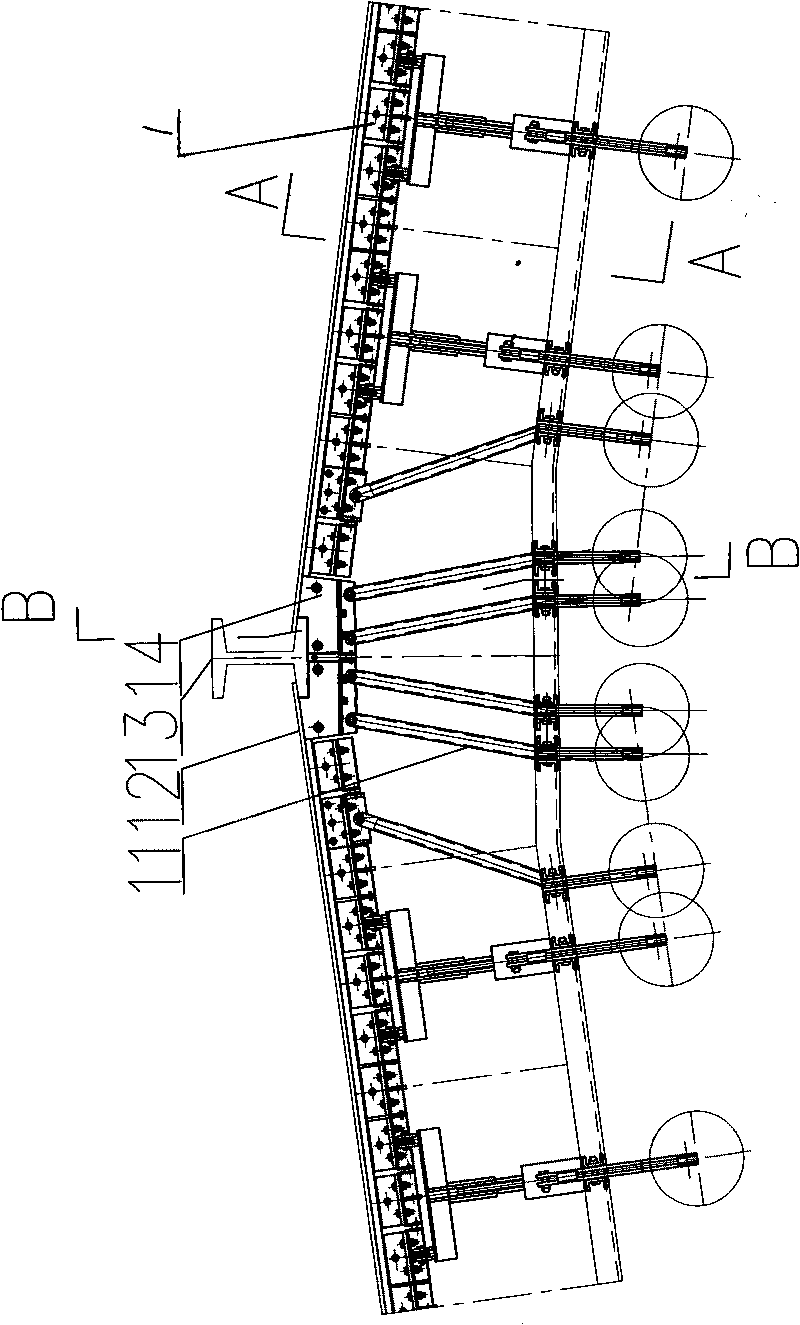

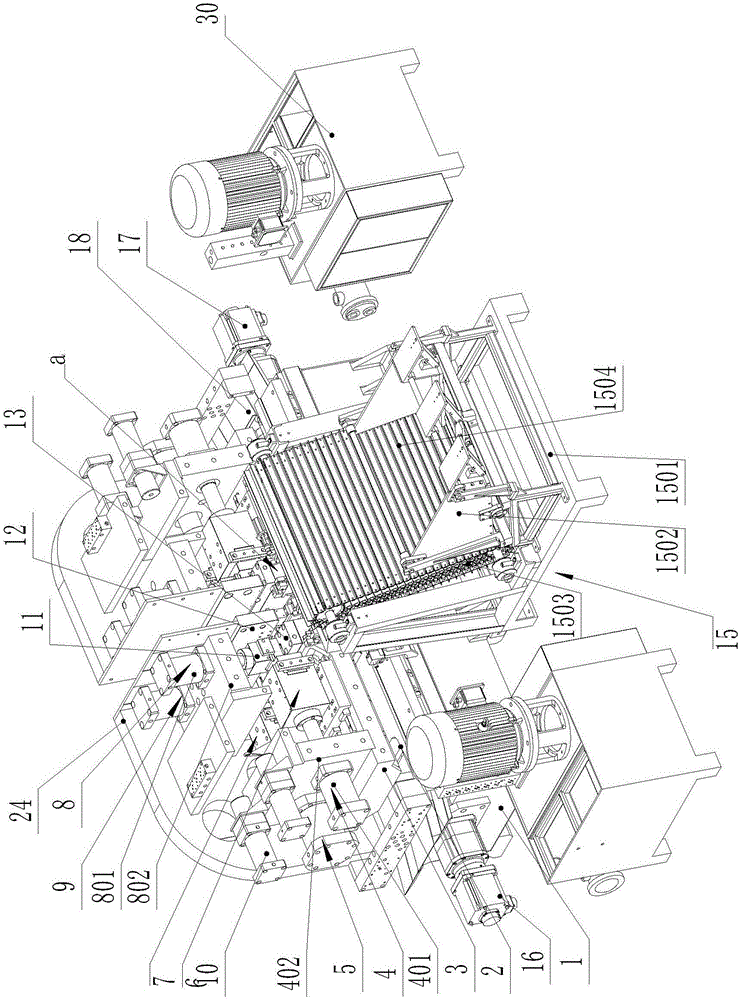

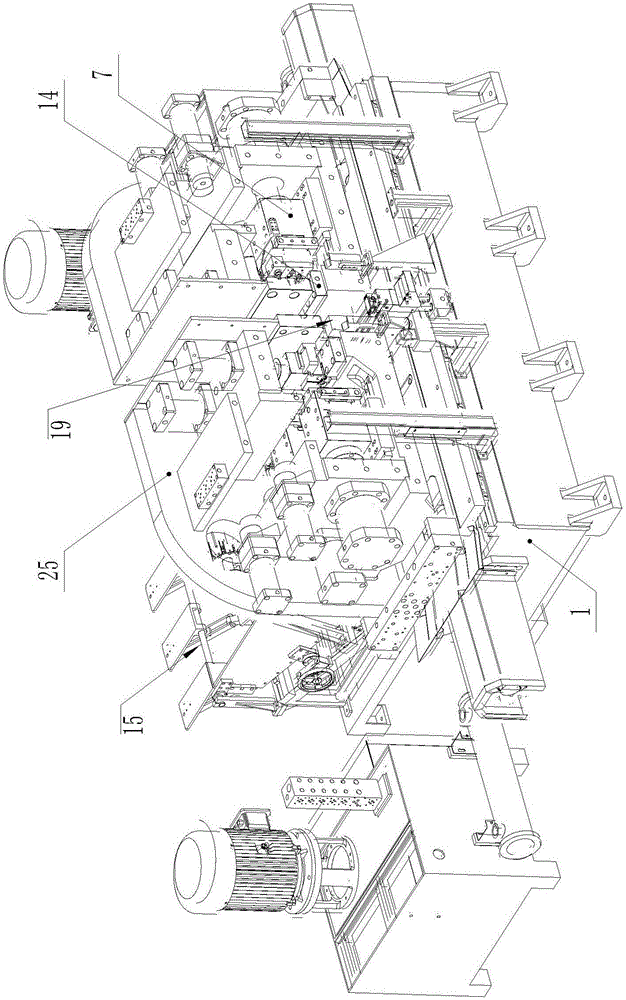

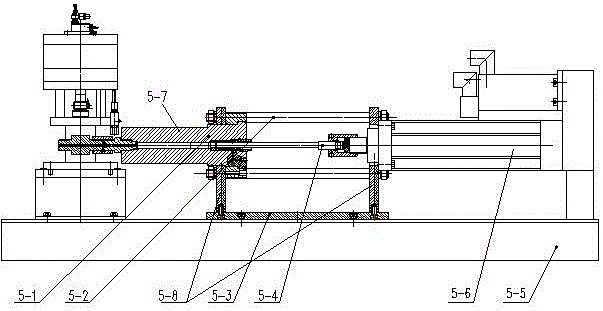

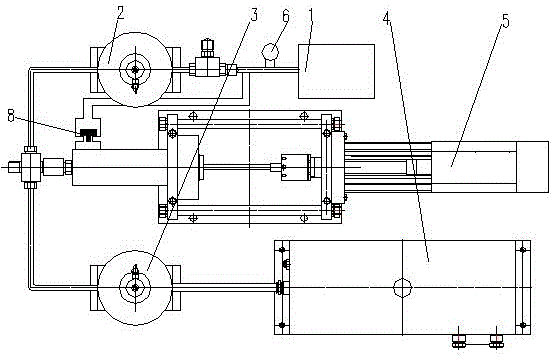

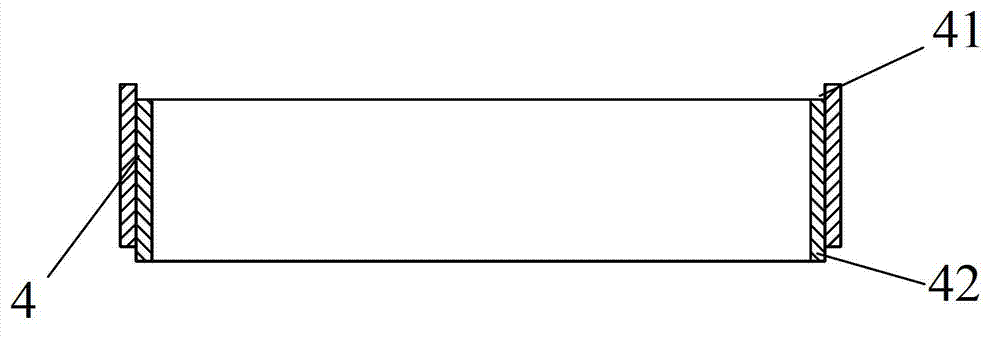

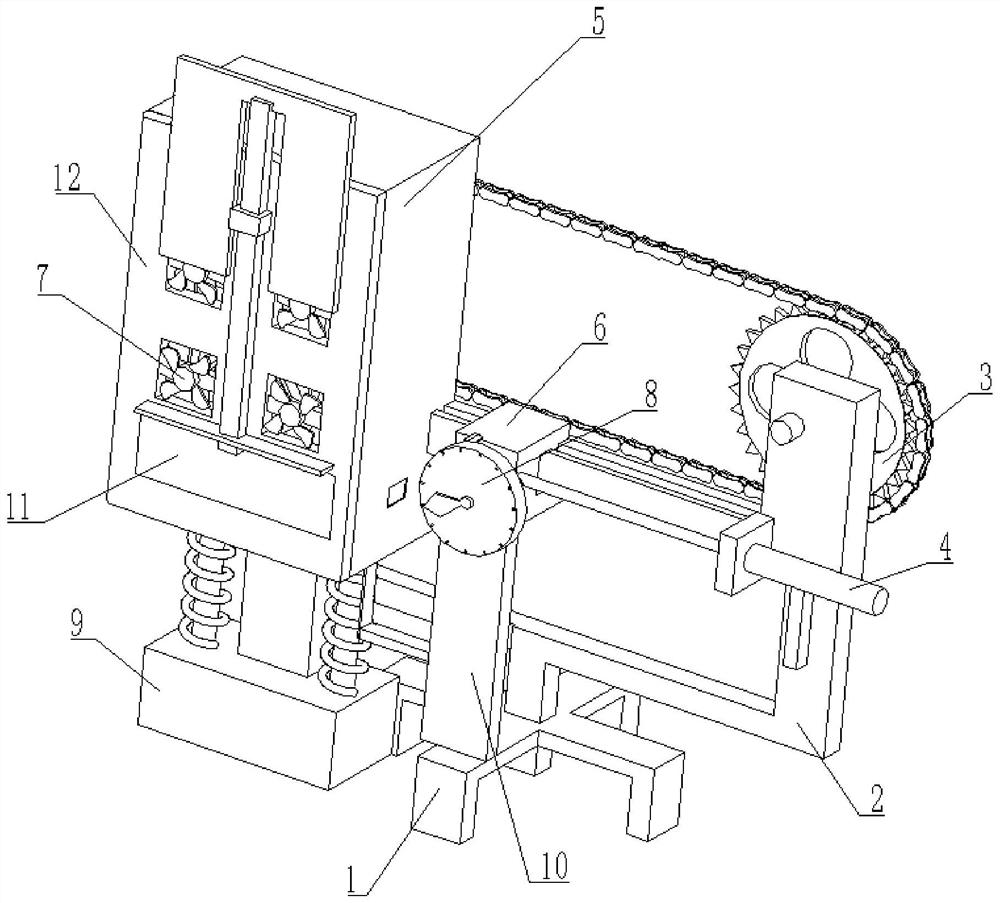

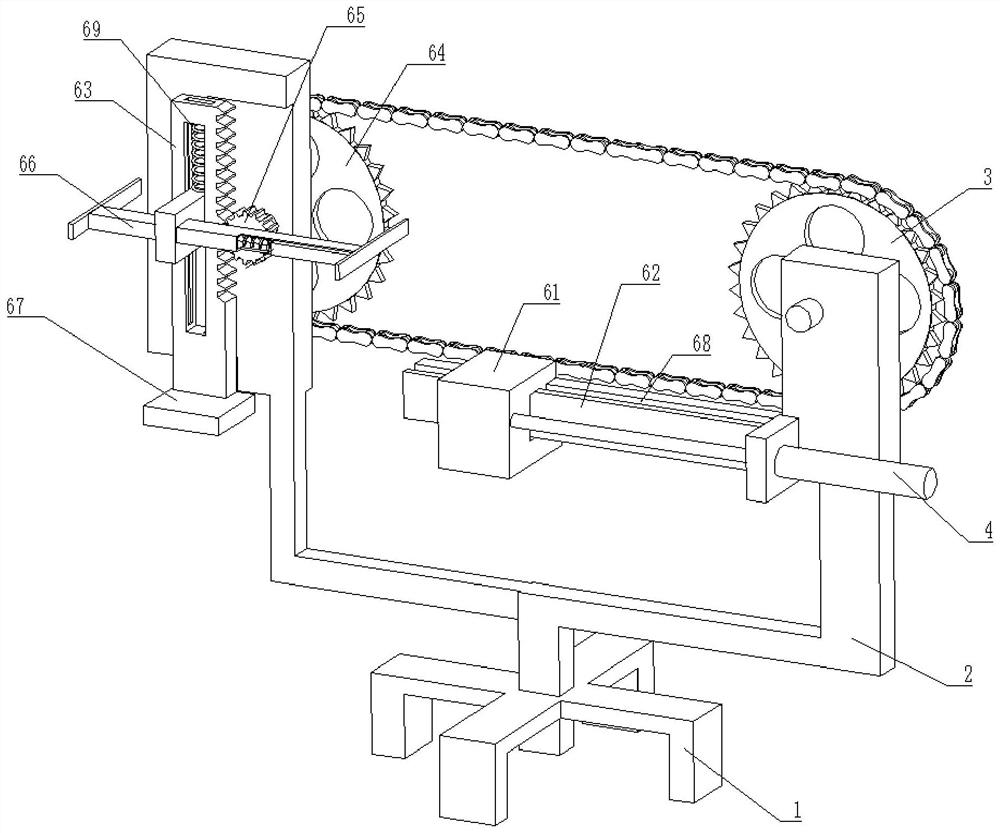

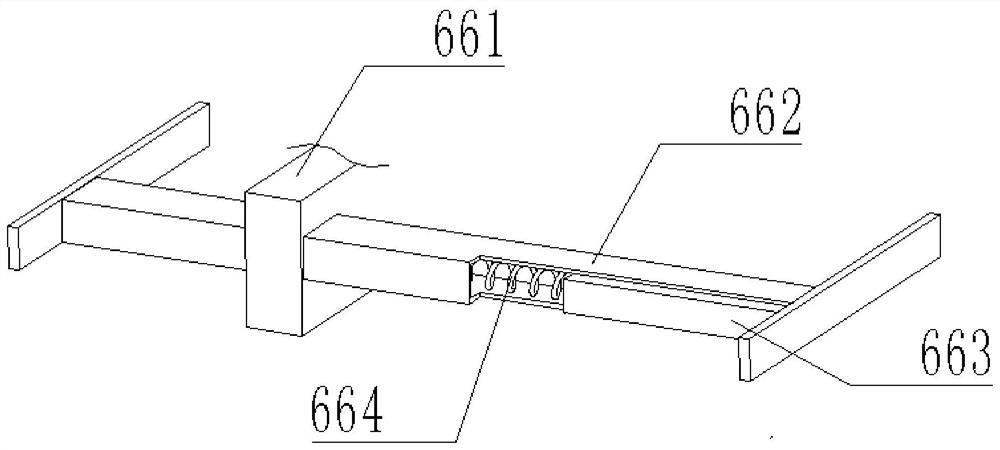

Special molding machine for automobile seat angle adjustment assembly and its forming method

ActiveCN106734653AHigh degree of automationEasy to operateMetal-working feeding devicesOther manufacturing equipments/toolsMoulding deviceEngineering

The invention discloses a special molding machine for automobile seat angle adjustment assembly, comprising a frame. The frame is provided with a primary forming device, an automatic assembling device and an linkage pipe station transfer device. An automatic feeding device is arranged at the upstream of the primary forming device. A discharge station is arranged at the downstream of the automatic assembling device, the linkage pipe is provided with a left inner convex ring and a right inner convex ring through the primary molding device. A left connecting plate and a right connecting plate are assembled on the automatic assembling device in a sleeving mode and a left outer convex ring and a right outer convex ring are formed on the automatic assembling device. The special molding machine does not need the welding operation, so that the left connecting plate and the right connecting plate are fixed in the left and right ends of the linkage pipe in a way similar to the riveting way, the firmness is higher, the degree of automation is high, and heat deformation of the linkage pipe is avoided. The invention also discloses a method for forming the regulating component, the forming method has the same effect as the molding machine.

Owner:张家港和顺机械制造有限公司

Liquid-cooled-type cooling device and manufacturing method for same

ActiveUS9845999B2Reduce the numberImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesCooling fluidCoolant channel

A liquid-cooled-type cooling device includes a casing having a top wall, a bottom wall, and a cooling-liquid passage, and a radiating member disposed in the cooling-liquid passage. The radiating member has a substrate and a plurality of pin-shaped fins. Longitudinally intermediate portions of the pin-shaped fins are brazed to the substrate. The substrate has a plurality of fin insertion holes, and the pin-shaped fins are inserted into the fin insertion holes of the substrate. A plurality of convex portions are integrally formed on the longitudinally intermediate portion of each pin-shaped fin. The substrate and the pin-shaped fins are provisionally fixed together by plastically deforming the convex portions such that they are crushed. In this state, the substrate and the pin-shaped fins are brazed together. The upper and lower end portions of the pin-shaped fins are brazed to the top wall and bottom wall, respectively, of the casing.

Owner:RESONAC CORPORATION

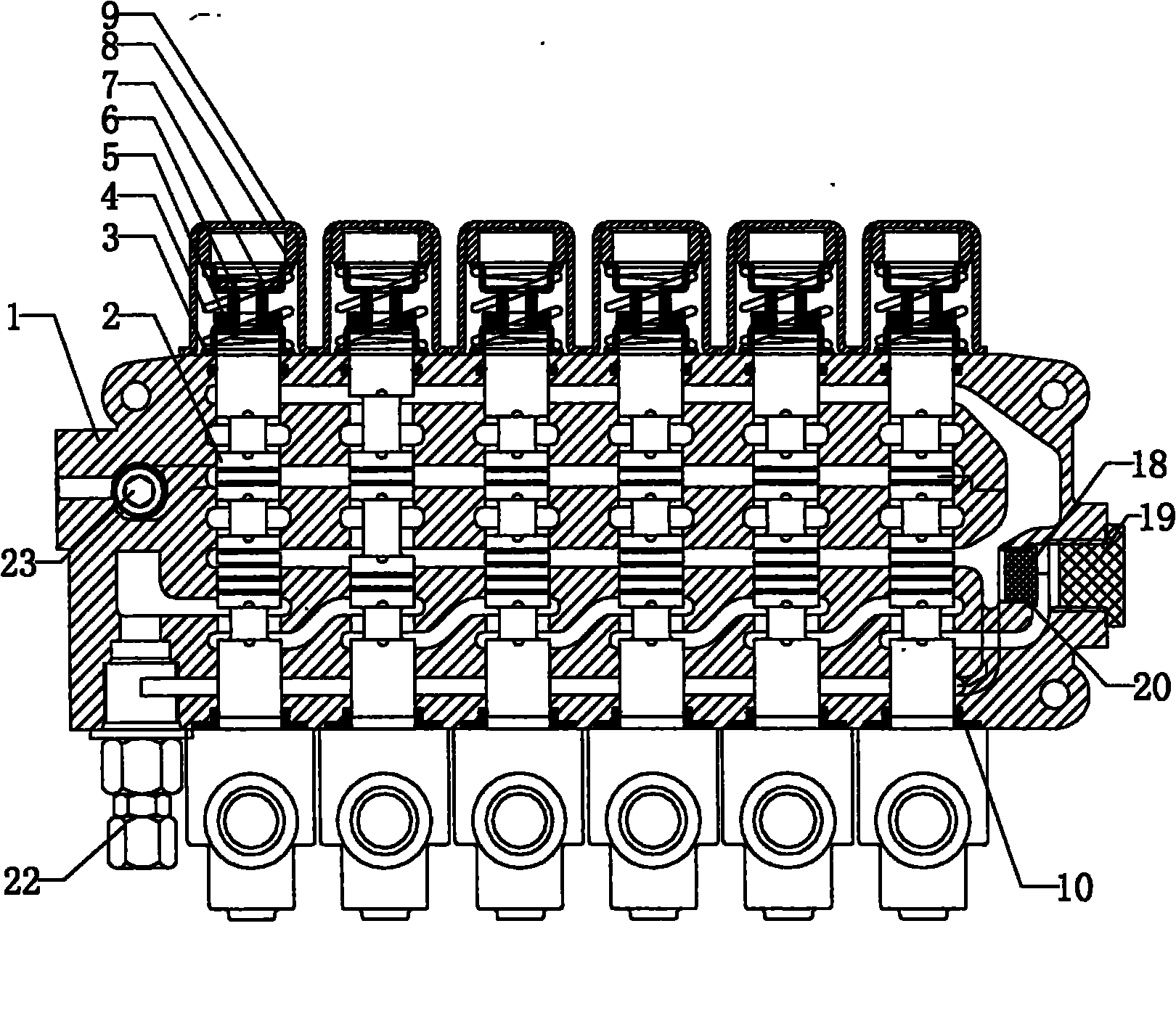

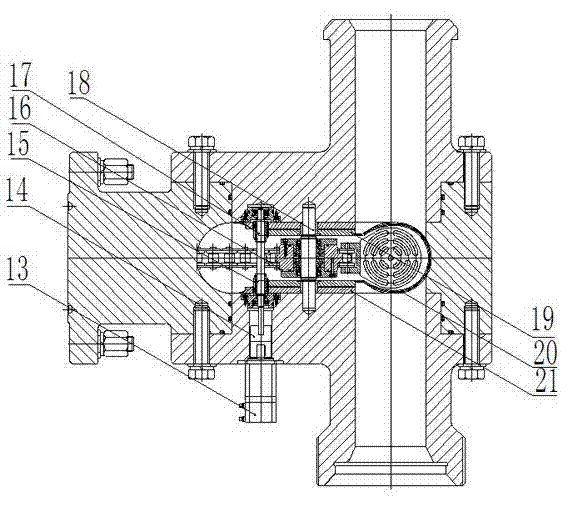

Multi-way reversing valve of hydraulic device

InactiveCN101328912AHigh strengthReduce intensityServomotor componentsValve housingsInlet valveHigh intensity

The invention relates to a multichannel reversing valve of a hydraulic device. The main structure of the multichannel reversing valve consists of a liquid inlet valve, a reversing valve, a throttle reversing valve and a liquid return valve; the liquid inlet valve uses a piston mode to control the oil hydraulic pressure; the common reversing valve and the throttle reversing valve are adopted to carry out dual control for reversing; the reversing valve is assembled by adopting an upper valve body and a lower valve body to form an integrated reversing valve chamber; the revering valve mainly uses a piston rod, a valve core, a one way valve, a liquid feed port, a dual liquid outlet to carry out liquid in and out in turns, thereby completing a reversing function; the throttle reversing valve is provided with a throttle port inside to effectively control a hydraulic oil amount; the reversing valve chamber has large path, high bearing pressure and small thickness; the valve chamber adopts a punch forming technology, the valve body has high intensity, high service time, material saving, rapid reversing speed which can be increased by 100 percent than the prior art, high efficiency and good universality; the device has a compact structure, reasonable design and a small size and is safe, stable, sensitive, rapid and reliable and is a very perfect universal multichannel reversing valve of the hydraulic device and quite suitable for underground operation in a coal mine under harsh environments.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

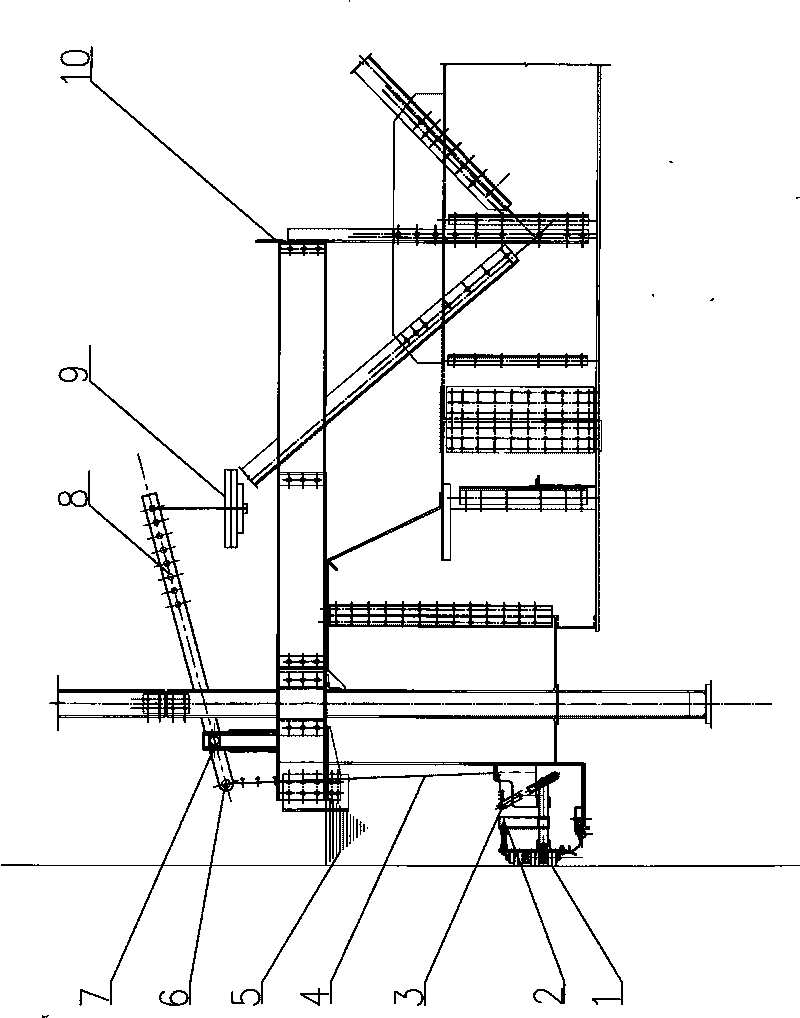

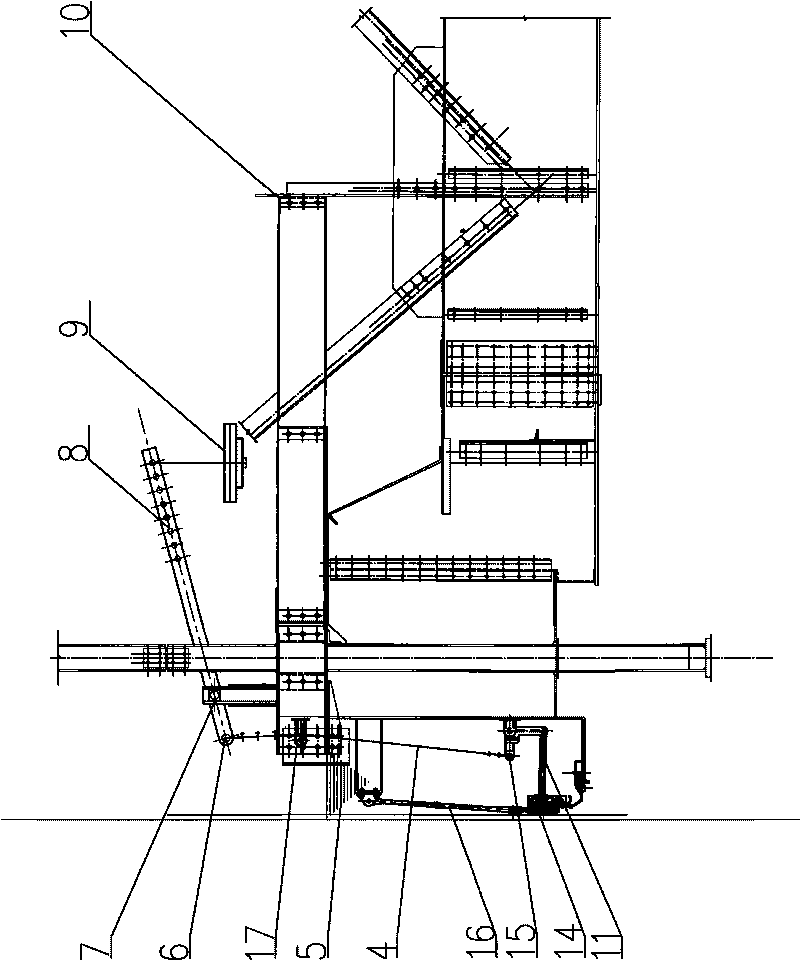

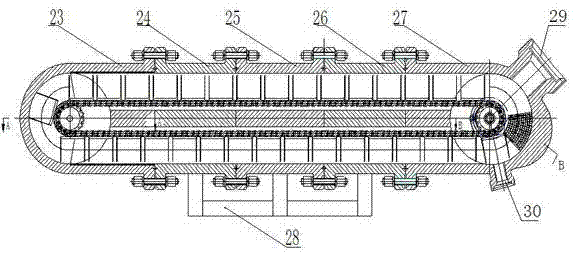

Full-series large-capacity automatic ball installing and digital control staged fracturing ball injector

The invention discloses a full-series large-capacity automatic ball installing and digital control staged fracturing ball injector. The full-series large-capacity automatic ball installing and digital control staged fracturing ball injector comprises a ball injector body, an alternating-current digital servo motor, a ball room, a ball injector driving end and a ball injector discharging end. A chain is driven to rotate by the alternating-current digital servo motor to drive the ball room on the chain to rotate, and ordered or unordered ball injection is achieved through a programmable logic controller and a position sensor. The full-series large-capacity automatic ball installing and digital control staged fracturing ball injector can be widely applied to oil-and-gas well acid fracturing operation and can be particularly and widely applied to staged and layered fracturing operation of unconventional gas horizontal well. The number of installed balls is large, and 33 balls of any stage difference can be installed from any positions in the ball room in an ordered or unordered mode automatically or manually and can be put from any positions in an ordered or unordered mode automatically or manually. The inner wall of the ball injector is processed through corrosion prevention and acid and alkali prevention technologies, chrome is plated with the surfaces of all parts making contact with fracturing fluid, V-type sealing and O-type sealing are adopted in sealing portions, and sealing under high-pressure operation is greatly guaranteed.

Owner:兰州城临石油钻采设备有限公司

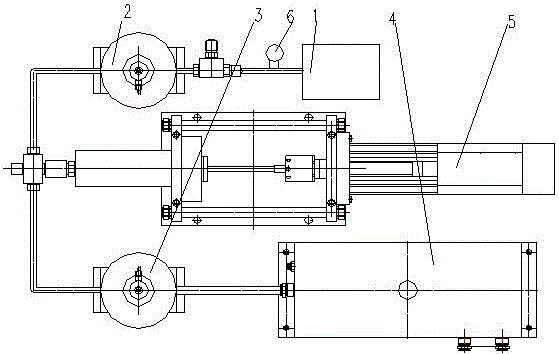

Ultrahigh pressure testing system and control method thereof

ActiveCN106094913AUnder high pressurePrecise position controlMaterial strength using tensile/compressive forcesFluid pressure control using electric meansPressure riseAutomatic control

The invention discloses an ultrahigh pressure testing system and a control method thereof. The ultrahigh pressure testing system comprises a liquid box, a first control valve and a servo supercharger. The liquid box is connected with the first control valve and the servo supercharger in sequence. The servo supercharger is connected with a pressure testing device. A second control valve is connected between the servo supercharger and the pressure testing device. A first pressure detection module is arranged between the first control valve and the second control valve. A second pressure detection module is arranged between the pressure testing device and the second control valve or in the pressure testing device. The technical purpose of the invention is to provide the ultrahigh pressure testing system which uses the servo supercharger as a power source to ensure high precision and high pressure of medium pressurization and intelligently control the pressure rising / reducing rate, and provide the control method of the ultrahigh pressure testing system to realize automatic control in the pressure testing process.

Owner:四川杰特机器有限公司

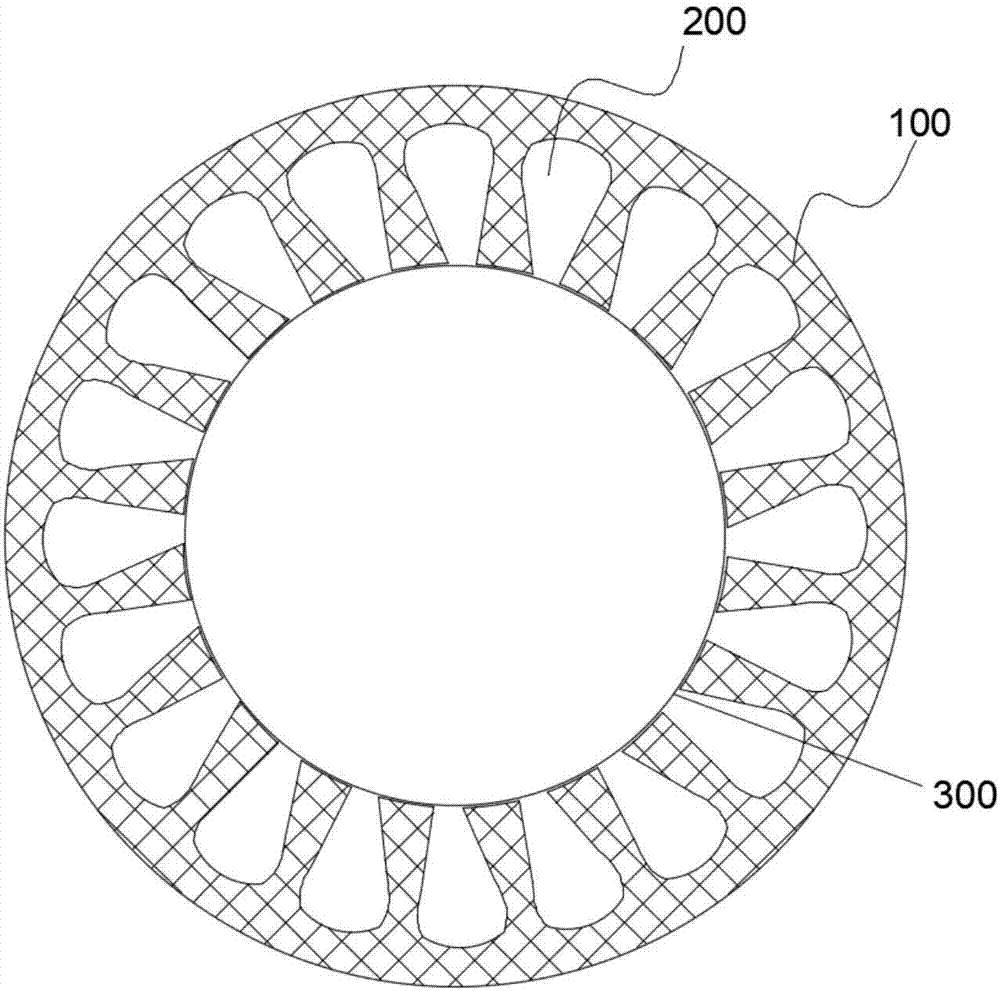

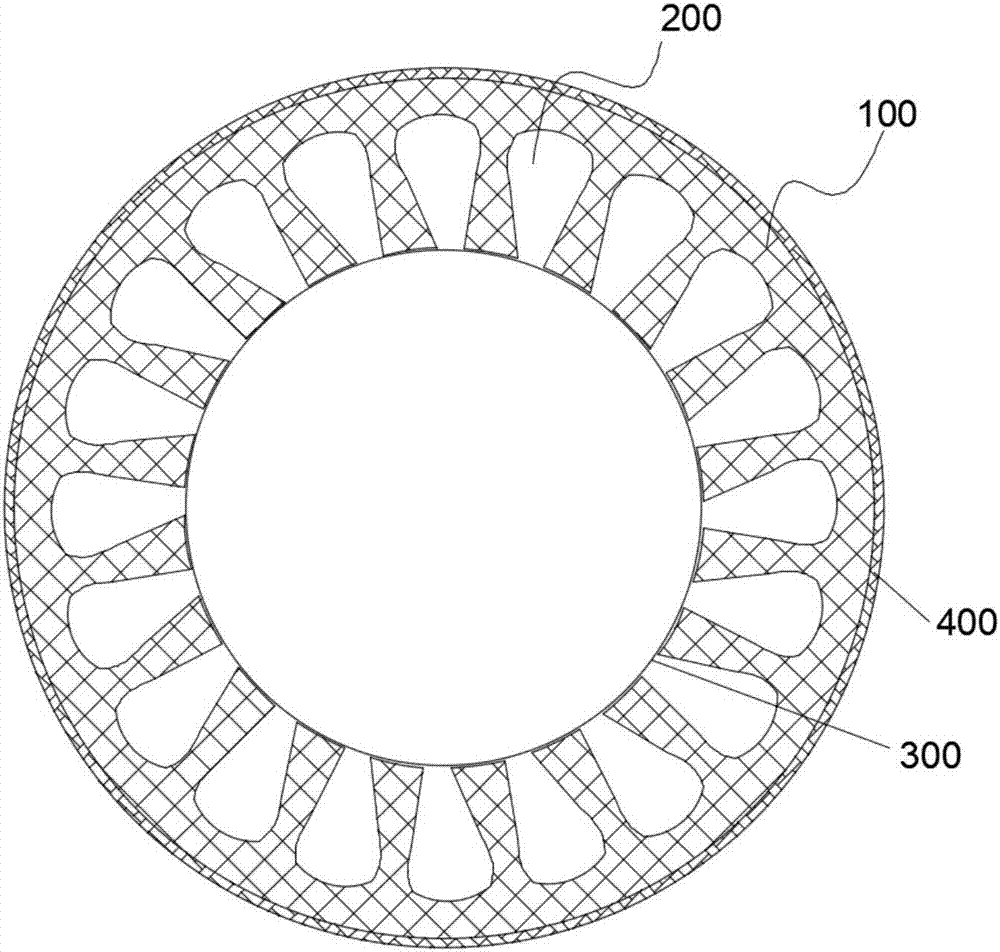

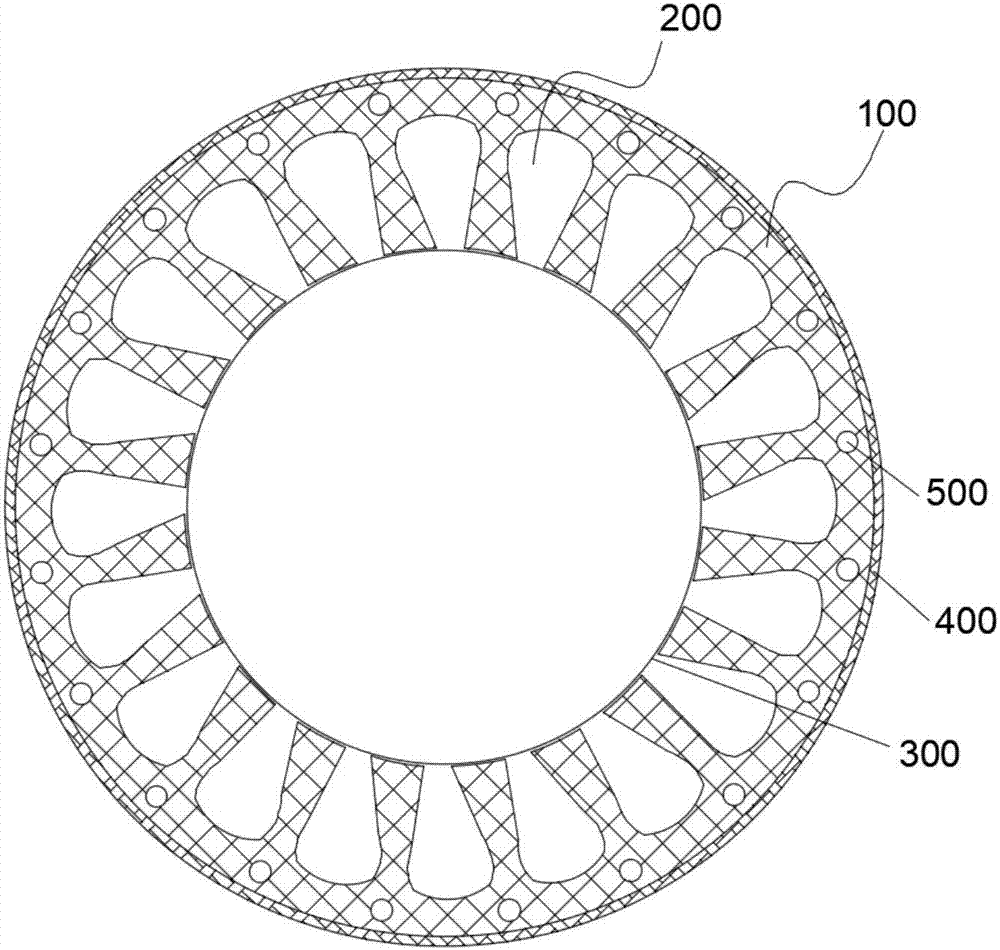

Tire and bicycle

InactiveCN108001126AImprove riding experiencePrevent decouplingNon-inflatable tyresEngineeringMechanical engineering

The invention relates to the technical field of vehicle tires and relates to a tire and a bicycle. The tire comprises a solid tire body and multiple cavity grooves formed in the solid tire body. Openings of the cavity grooves face the center of the solid tire body. A sealing edge used for sealing the cavity grooves is arranged at the opening ends of the cavity grooves and connected with the cavitygrooves to form a sealing gas barrel. After the solid tire body is arranged on a rim, the sealing edge can be tightly attached to a steel ring rim face, the solid tire body is pressed and can compactthe sealing edge, the sealing edge is connected with the cavity grooves to form the sealing gas barrel, large pressure intensity and elastic supporting can be formed through gas sealed in the sealinggas barrel in the rolling process of the solid tire body, a steel ring is firmly fixed and prevented from being separated, the borne pressure is greatly increased, a secondary shock absorption effectis greatly improved, meanwhile, the dead weight and use materials are reduced, and the riding experience of a user is improved. Compared with the prior art, the bicycle has the above beneficial effects.

Owner:天津市宝永啟臣橡胶科技有限公司

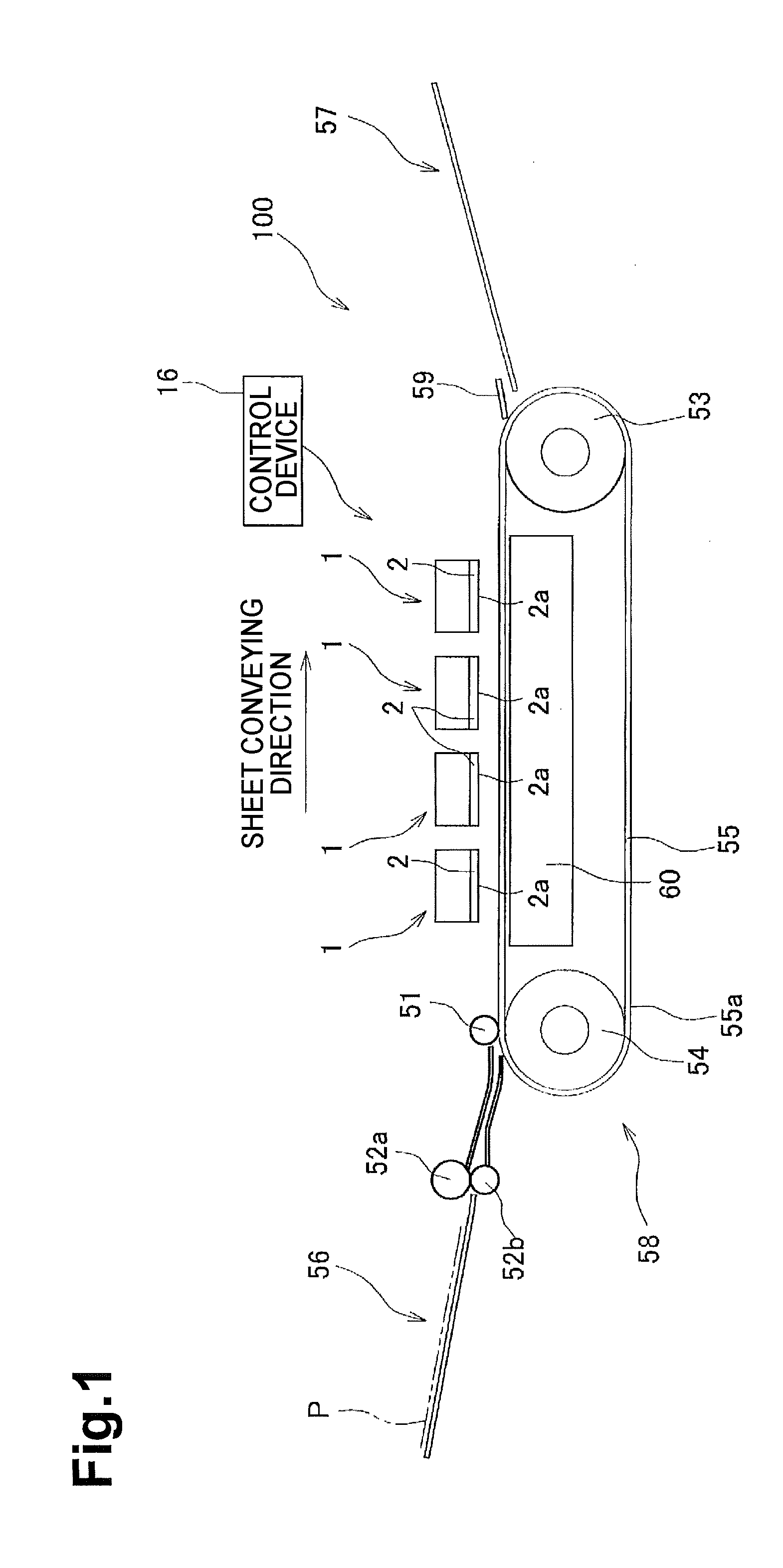

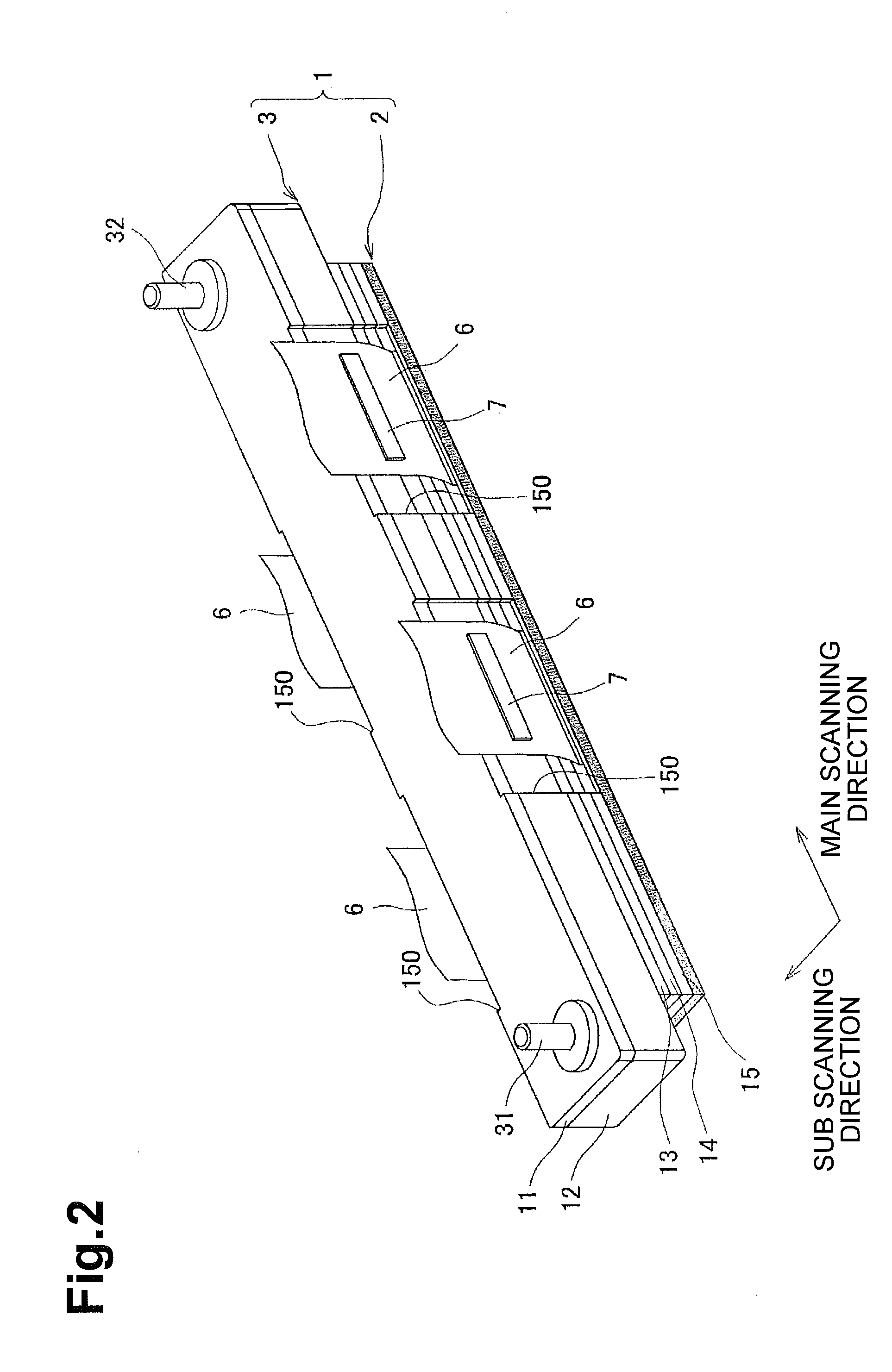

Recording apparatus and inkjet printer

ActiveUS20090219344A1Efficient removalReduce fluid consumptionOther printing apparatusInk printerEngineering

A recording apparatus may comprise a channel unit comprising a pressure chamber configured to store a liquid, and nozzles. The recording apparatus may comprise a reservoir unit connected to the channel unit and comprising a supply port, a drain port, a supply channel communicating with the channel unit, and a drainage channel branching off from the supply channel and communicating with the outside via the drain port. The recording apparatus may comprise a plurality of actuators configured to apply pressure to the liquid in the pressure chamber. The recording apparatus may comprise a meniscus vibrator configured to drive the actuators to vibrate meniscus produced in the nozzles without causing liquid droplets to be ejected therefrom when the liquid supplied from the supply port is being drained from the drain port after traveling through the supply channel and the drainage channel.

Owner:BROTHER KOGYO KK

Cold rolling and rough rolling lubricating agent for copper and copper alloy sheet strip

The invention relates to a cold rolling and rough rolling lubricating agent for a copper and copper alloy sheet strip. 32# oil for a total-loss system is used as base oil and is matched with various composite additives including an anti-wear agent, an oiliness agent, an anti-oxidant and anti-corrosive additive, a metal deactivator, an anti-foaming agent, a dispersing agent and the like. The lubricating agent has the characteristics of relatively high viscosity, thick and firm oil film, high allowable pressure, good cooling performance and flowability and strong pollution, emulsion and foam resistance so as to be suitable for being used under the working conditions of hard rolled pieces and high rolling pressure.

Owner:GUANGXI UNIV

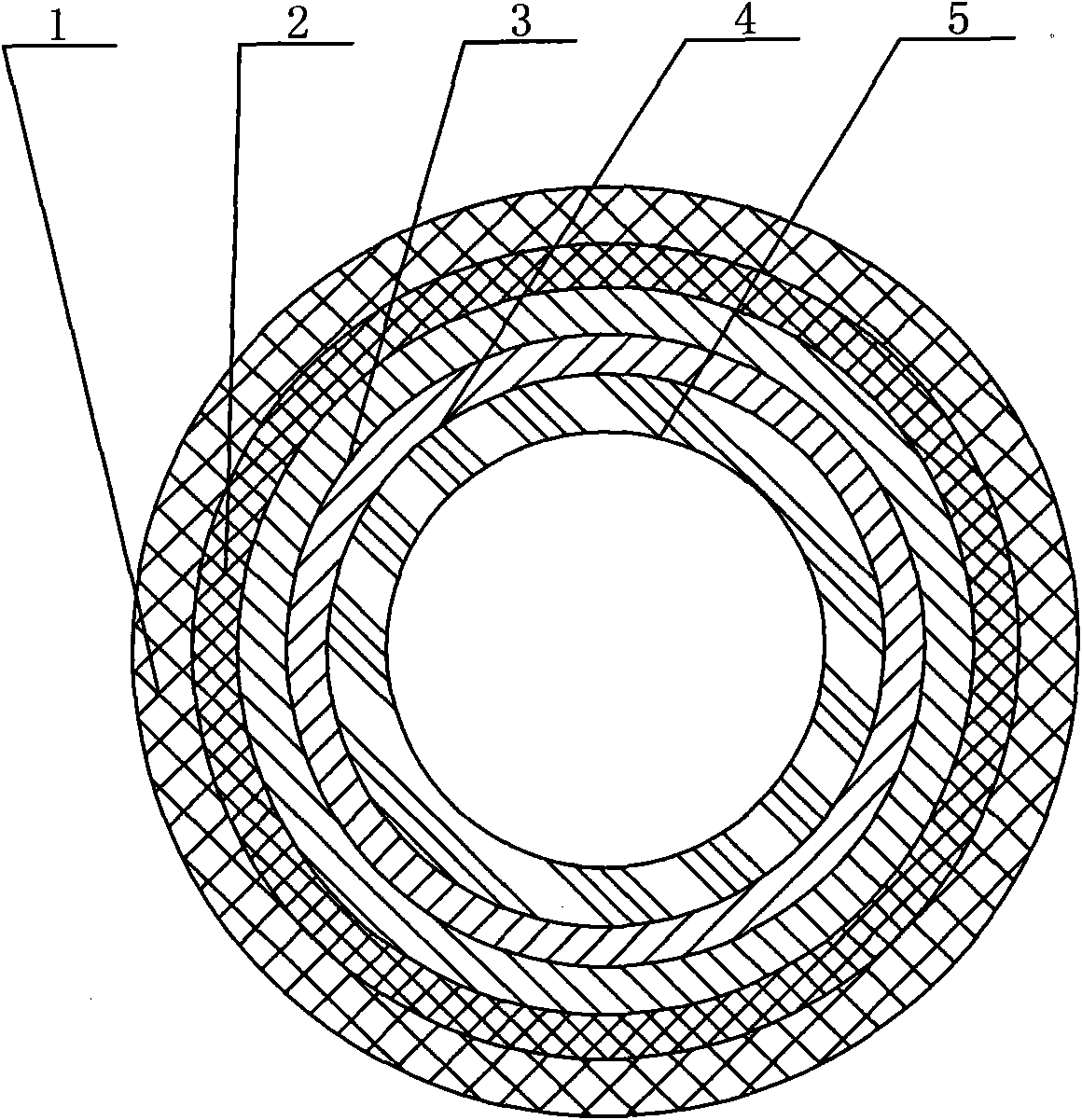

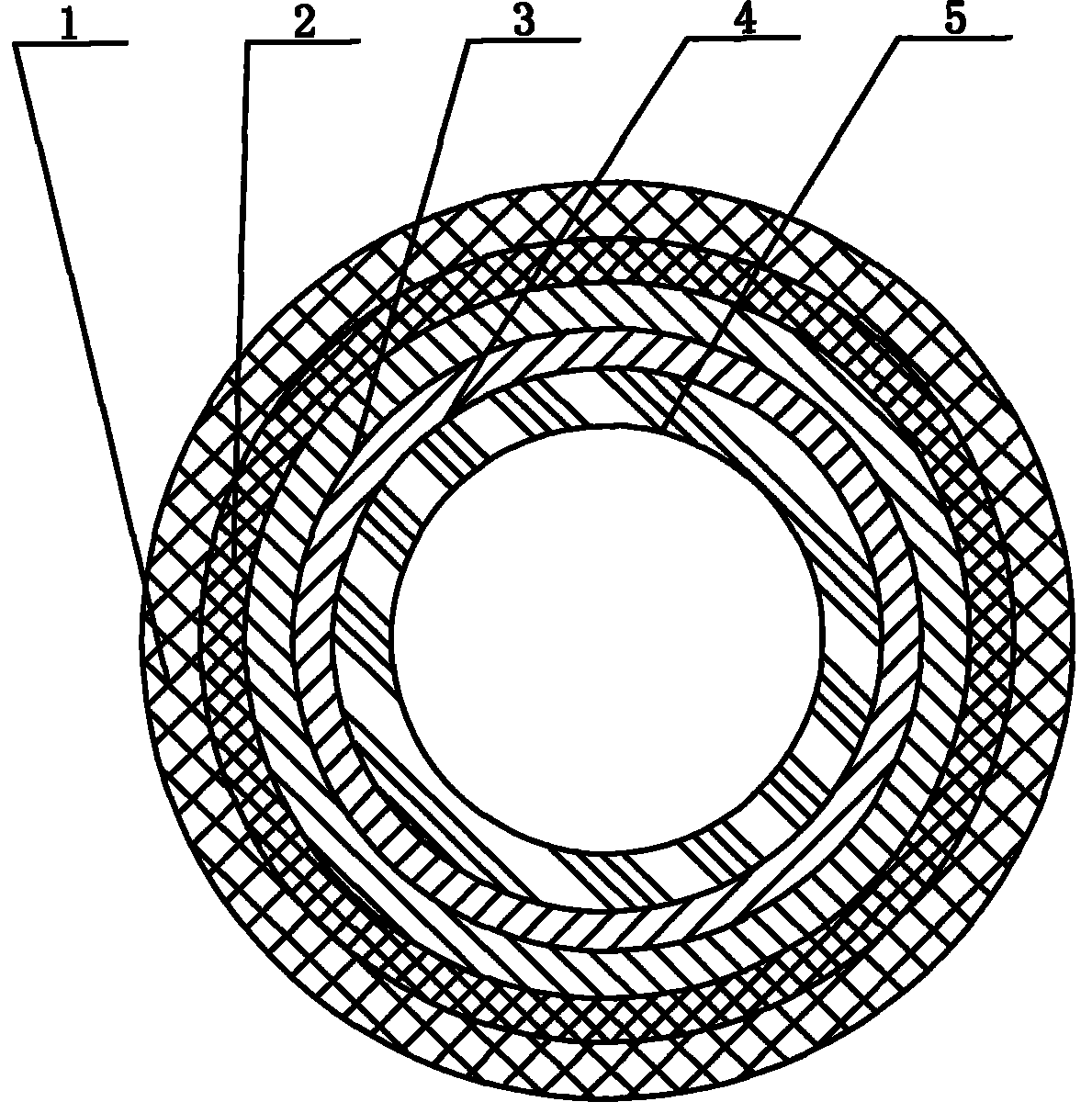

High-pressure hose for air compressor

The invention belongs to the field of industrial pipes and in particular relates to a high-pressure hose for an air compressor. The high-pressure hose comprises a PVC (Poly Vinyl Chloride) flexible glue layer (1), a polyester thread layer (2), a steel wire braid layer (3), a fluorine rubber and silicone rubber layer (4) and a fluorine rubber layer (5); wherein the fluorine rubber and silicone rubber layer (4) is wrapped outside the fluorine rubber layer (5), the steel wire braid layer (3) is wrapped outside the fluorine rubber and silicone rubber layer (4), the polyester thread layer (2) is pasted outside the steel wire braid layer (3), and the PVC flexible glue layer (1) is pasted outside the polyester thread layer (2). The high-pressure hose has favorable resistance to oil, heat and ageing, high pressure bearing capability and favorable pulse property, and is suitable to massive equipment to use.

Owner:NANTONG SANCHUANG MACHINE MFG

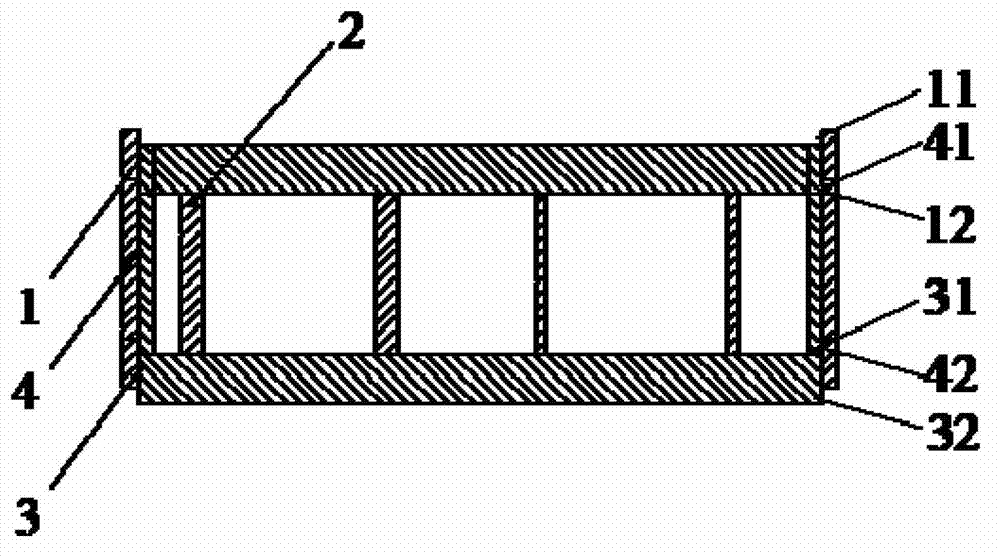

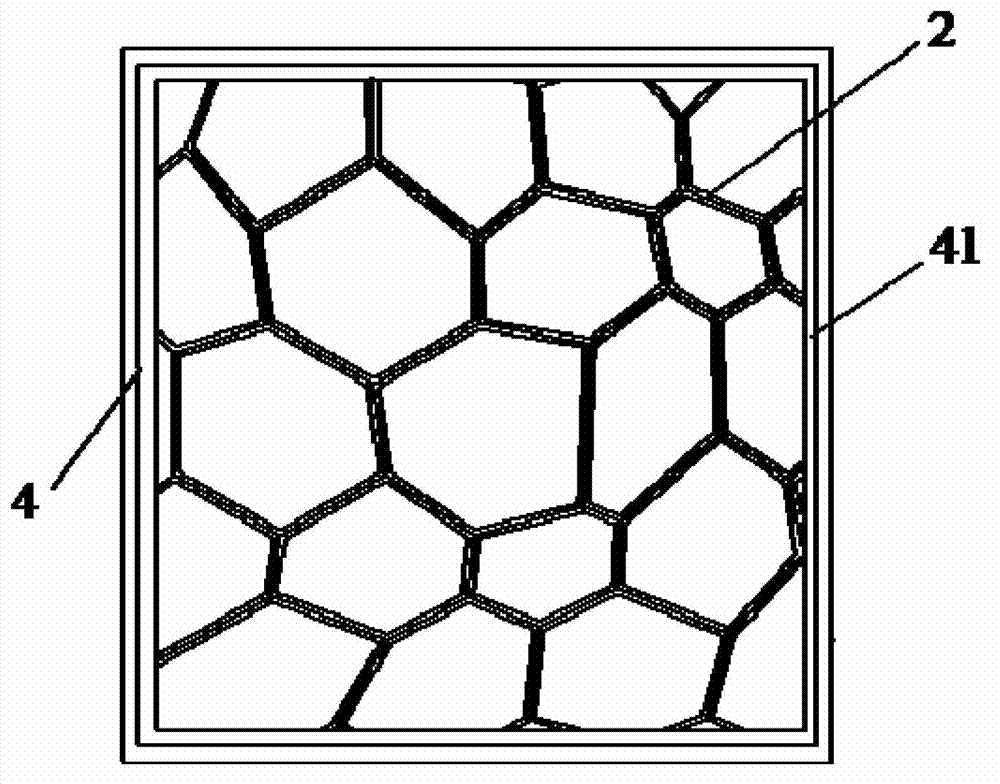

Lined packing box and packing method

InactiveCN103043280AImprove space utilization efficiencyUnder high pressureRigid containersHoneycombEngineering

The invention discloses a lined packing box. The lined packing box comprises a honeycomb type liner, at least one cavity communicating the top with the bottom is arranged in the honeycomb liner, a cover plate is arranged above the honeycomb liner, and a bottom plate is arranged below the honeycomb liner. Surrounding plates are arranged on the outer periphery of the honeycomb liner. Cover plate protrusion blocks are arranged at the lower end of the cover plate, surrounding plate grooves corresponding to the cover plate protrusion blocks are arranged at the upper ends of the surrounding plates, bottom plate grooves are arranged at the upper end of the bottom plate, and surrounding plate protrusion blocks corresponding to the bottom plate grooves are arranged at the lower ends of the surrounding plates. Cover plate grooves corresponding to the cover plate protrusion blocks are arranged at the upper end of the cover plate, and bottom plate protrusion blocks corresponding to the bottom plate grooves are arranged at the lower end of the bottom plate.

Owner:江苏时代天勤彩色包装有限公司

Automatic electrical equipment detection device

PendingCN112461677AReduce tensionReducer thrustMaterial strength using tensile/compressive forcesStructural/machines measurementEngineeringSprocket

The invention relates to the technical field of electrical detection and discloses an automatic electrical equipment detection device. The device comprises a base, wherein the upper surface of the base is fixedly connected with a support plate and a connecting frame, the front part of the connecting frame is connected with an electric push rod through a bolt, and the output end of the electric push rod is provided with a force reducing mechanism; the rear portion of the connecting frame is rotationally connected with a driving chain wheel through a shaft rod, the front portion of the supporting plate is provided with a display mechanism, the surface of the base is fixedly connected with a fixing plate, the surface of the connecting frame is fixedly connected with a test box, and the test box is internally provided with a test mechanism. According to the automatic electrical equipment detection device, the pinion is driven to rotate through transmission of the chain wheel, so that whenthe whole electric push rod or similar push assembly is pressurized, the tension or push force is effectively reduced, and the downward pressure is increased, so the whole equipment is used more smoothly, and the service life of the equipment is prolonged.

Owner:王利杰

Flow passage unit

ActiveUS20180100836A1Short timeHigh analysisComponent separationOther chemical processesEngineeringStationary phase

A flow passage unit has a column for used in a liquid chromatograph and a support body that supports the column. The column has: a porous stationary phase; a porous pressure adjusting part disposed at least at the flow-in end of the stationary phase, a liquid entering the flow-in end, the pressure adjusting part being harder than the stationary phase; and a covering part that covers the stationary phase and pressure adjusting part. The support body has a first plate and a second plate that are mutually joined, the support body forming a column holding part and a liquid flow passage, the column holding part holding the column between the first plate and the second plate, the liquid flow passage communicating with the column holding part. Pressure applied from the first plate and second plate to the pressure adjusting part is higher than pressure applied to the stationary phase.

Owner:ALPS ALPINE CO LTD

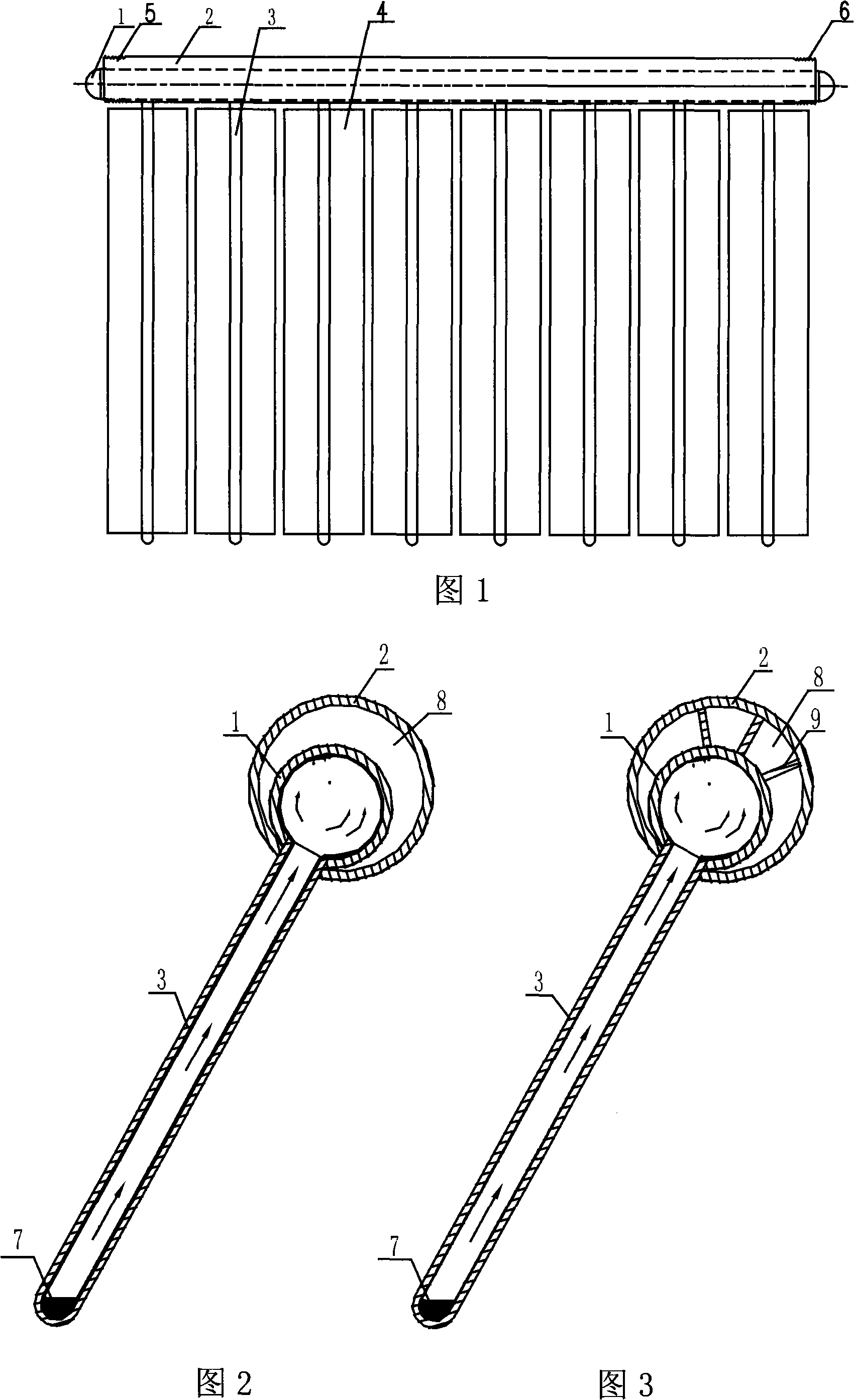

Non-concentric casing tube phase-change solar heat-collector

InactiveCN101290171ALow costThe overall structure is simple and reliableSolar heating energySolar heat devicesWorking fluidSolar water

The present invention relates to a non-concentrical cannula phase-transition solar heat collector. The solar heat collector is characterized in that the solar heat collector comprises a set of cannula structure fixed by two internally tangent circular pipes with different diameters; two ends of an internal cannula are sealed by welding; metal heat pipes penetrate the pipe wall of an external cannula and are welded at intervals on the internal cannula axially; each metal heat pipe and the internal cannula form a through structure which is isolated from the outside; a water inlet and a water outlet are formed on the outer cannula; and a heating media working fluid is arranged in the communicated structure formed by the metal heat pipe and the internal cannula. The solar heat collector has the advantages that the collector is simple and reliable in structure, light in weight, high in pressure bearing capacity, high in selective absorbability, low in material cost and long in service life. With the special structural design, the product not only has good low temperature performance, but also has excellent antifreeze performance. The collector is resistant to a low temperature of 40 DEG.C below zero. Additionally, the product integrates heat absorption, transmission and heat discharge, and is exceedingly high in integral heat efficiency, fast in start speed, good in reliability, and low in application cost. The collector can be used for externally-hung domestic solar water heaters, and can be further used for hot water engineering, solar energy-assisted air-conditioners and solar energy heating and heat-collecting devices, etc. The solar heat collector is a breakthrough for solar energy recycling devices.

Owner:内蒙古普汇设备有限公司

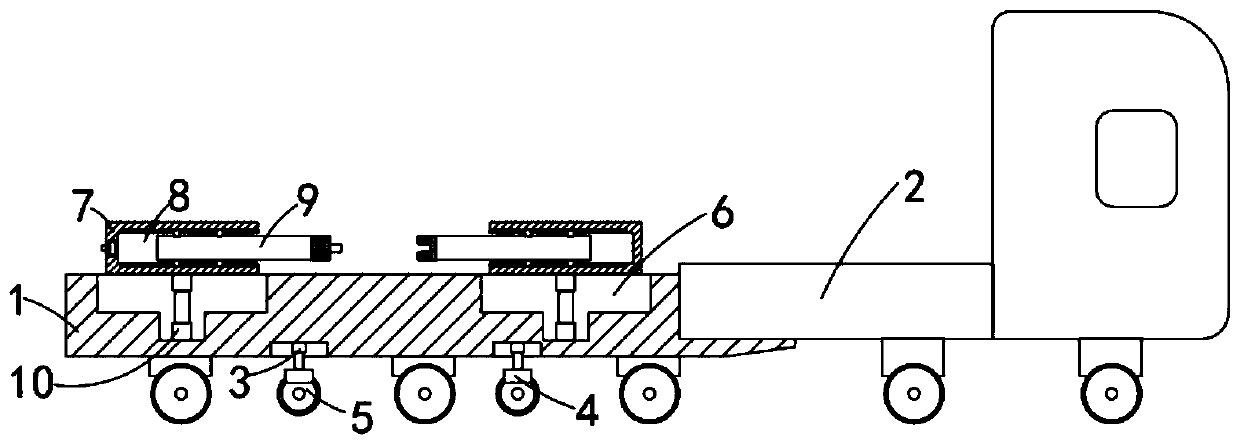

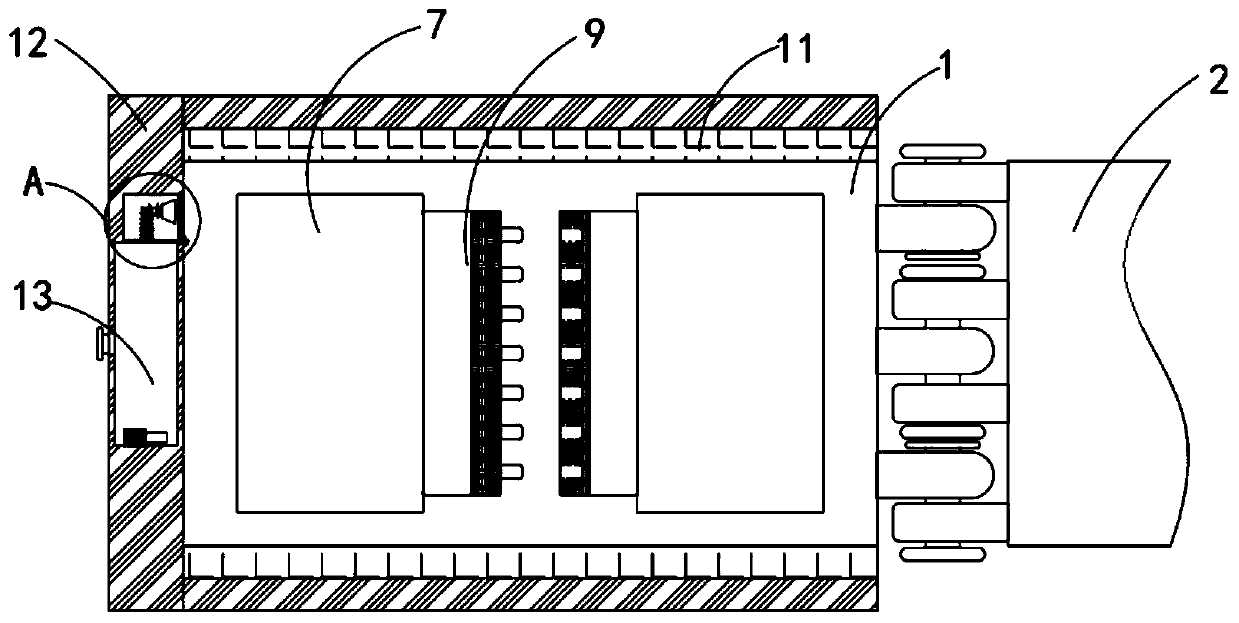

Semitrailer with high bearing pressure and high supporting strength

InactiveCN110194225ASolve the problem of insufficient support strength due to limited pressureImprove work efficiencyTractor-trailer combinationsVehicle cleaningEngineeringUltimate tensile strength

The invention belongs to the field of semitrailers, and particularly relates to a semitrailer with the high bearing pressure and the high supporting strength. The following scheme is proposed for solving the problems that the low bearing pressure and the low high supporting strength of existing semitrailers, the semitrailer with the high bearing pressure and the high supporting strength includes afirst carriage seat, a second carriage seat and a carriage arranged on the upper part of the first carriage seat, the first carriage seat and the second carriage seat are fixedly connected through aplurality of sets of locking bolts, the lower side wall of the second carriage seat is fixedly provided with a plurality of sets of first telescopic rods which are uniformly distributed, the lower endof each first telescopic rod is fixedly connected with a corresponding spare wheel support, a spare wheel is arranged in a support of each spare wheel, and the upper side wall of the first carriage seat is further provided with longitudinal rectangular grooves in the symmetrical positions. According to the semitrailer with the high bearing pressure and the high supporting strength, the supportingstrength is high, the bearing pressure is high, the transportation efficiency is improved, the semitrailer can be cleaned at any time and anywhere, and meanwhile, the potential safety hazards for transportation personnel are also lowered.

Owner:沛县迅驰专用车辆制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com