High-pressure hose for air compressor

A high-pressure hose and air compressor technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve problems such as short service life and industrial accidents, and achieve the effects of high pressure, good oil resistance, and excellent pulse performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

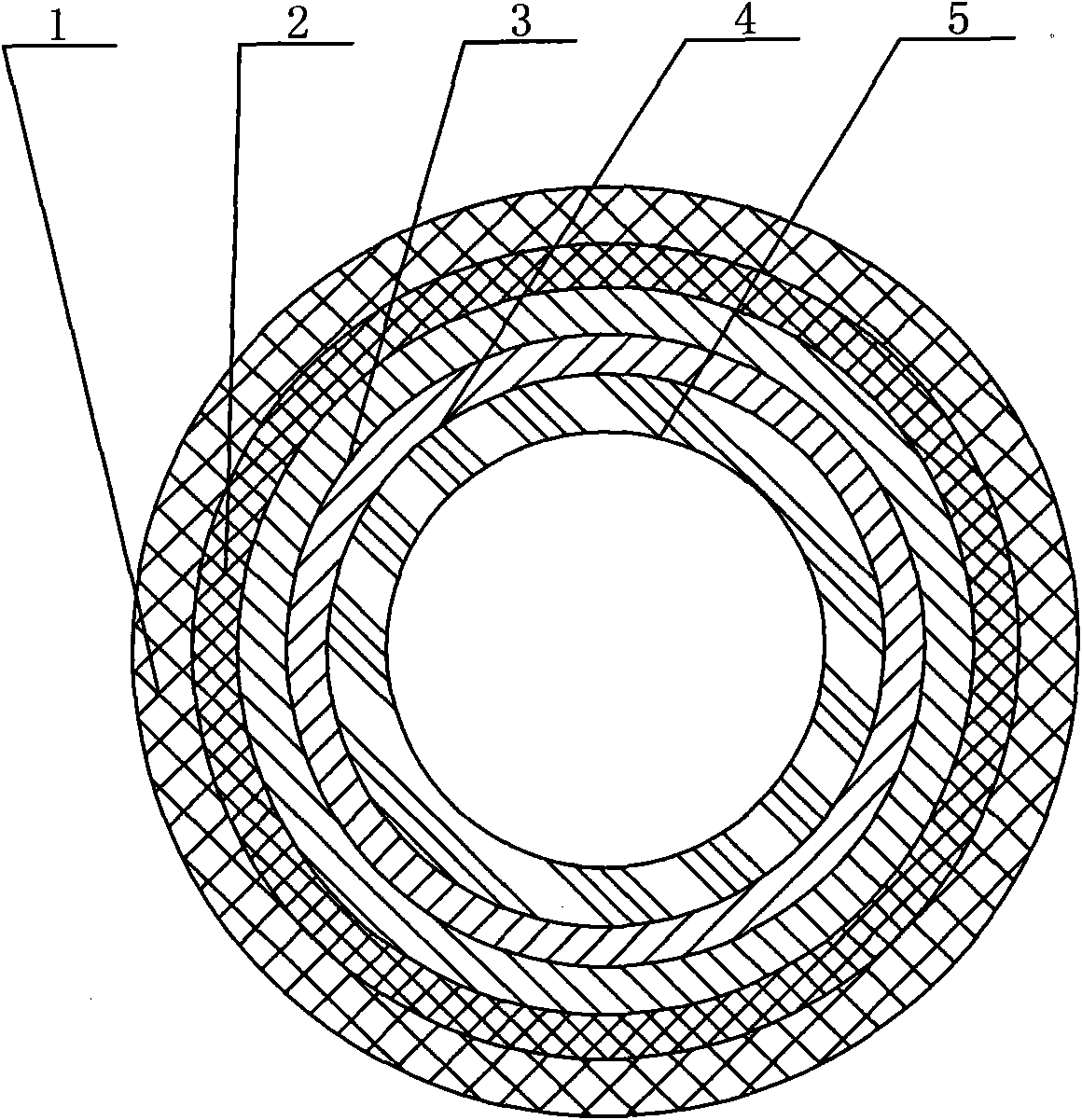

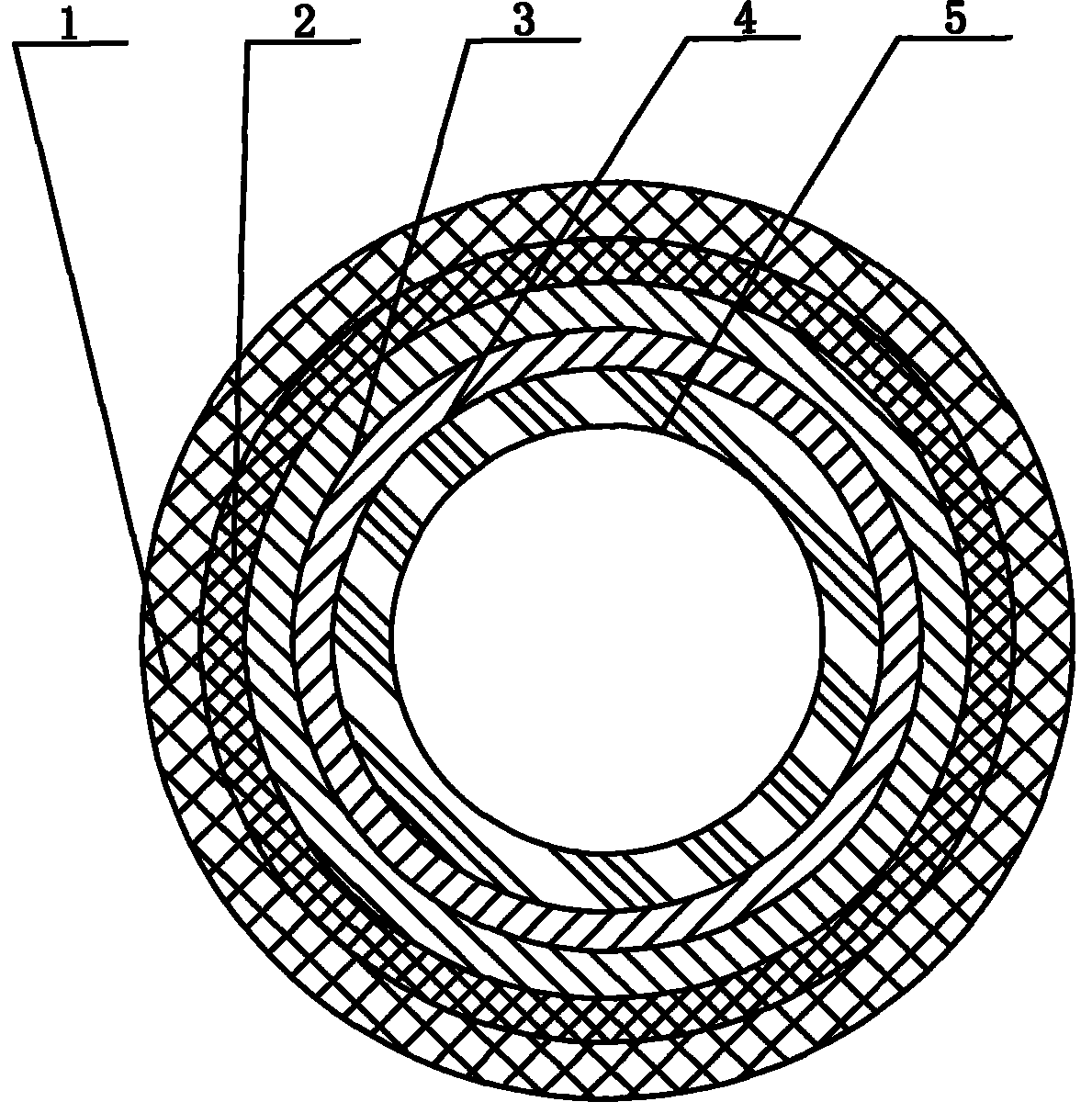

[0008] see figure 1 , the specific embodiment adopts the following technical scheme: it comprises PVC soft rubber layer 1, polyester polyester thread layer 2, steel wire braided layer 3, fluororubber silicone rubber layer 4 and fluororubber layer 5; fluororubber layer 5 is wrapped There is fluororubber silicone rubber layer 4, fluororubber silicone rubber layer 4 is wrapped with steel wire braid layer 3, steel wire braid layer 3 is glued with polyester thread layer 2, polyester thread layer 2 is glued with PVC soft glue Layer 1.

[0009] An adhesive is arranged between the fluororubber silicone rubber layer 4 and the fluororubber layer 5 .

[0010] This specific embodiment has good oil resistance, heat resistance and aging resistance, high pressure resistance, excellent pulse performance, and is suitable for use in many equipments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com