Special molding machine for automobile seat angle adjustment assembly and its forming method

An angle adjustment, car seat technology, applied in vehicle parts, other manufacturing equipment/tools, feeding devices, etc., can solve the problems of low degree of automation, potential safety hazards, high welding quality requirements, and achieve construction site environmental hygiene, Avoid the effect of unstable fixation and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below through specific examples.

[0045] The front, back, left, right, up and down positions mentioned in the present invention are determined according to the feeding direction of the operator facing the linkage pipe 27 . The left side of the observer is the azimuth left, the downstream of the feed is the azimuth front, and the azimuth above the observer is the azimuth mentioned in the present invention.

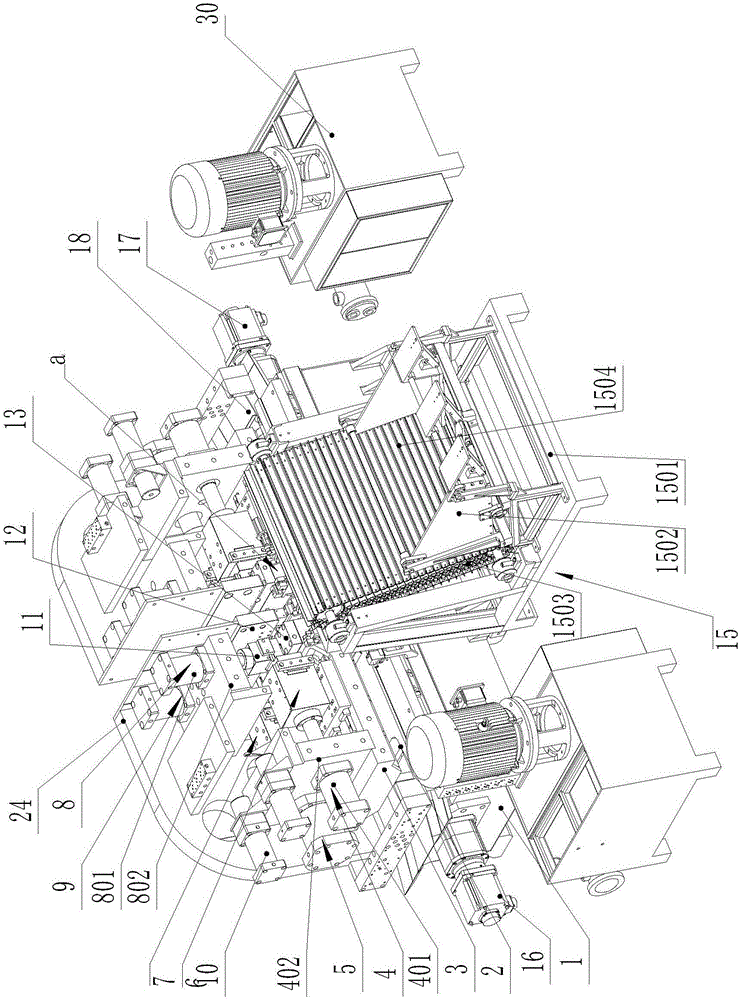

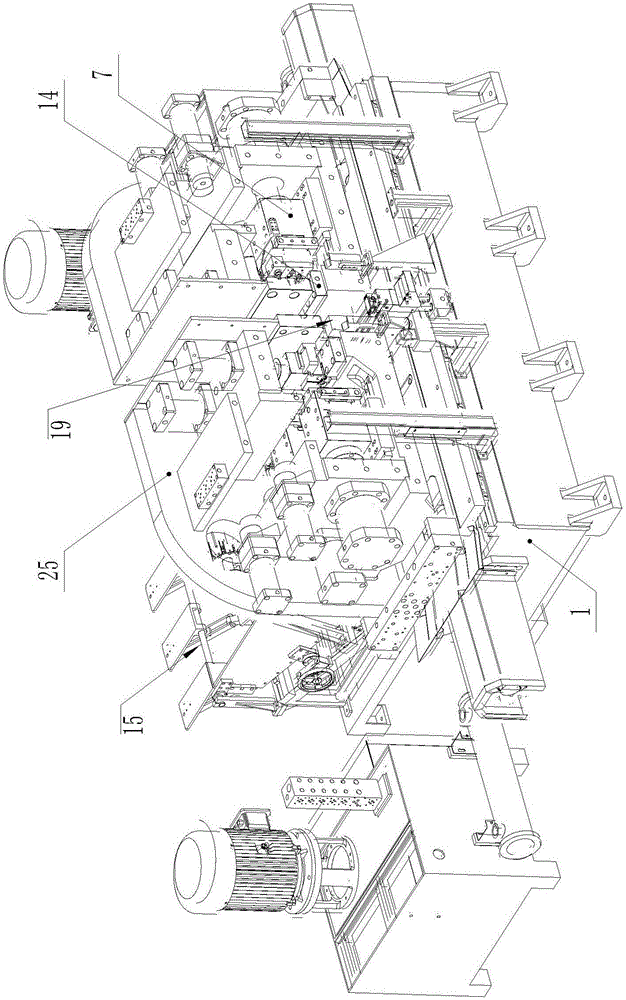

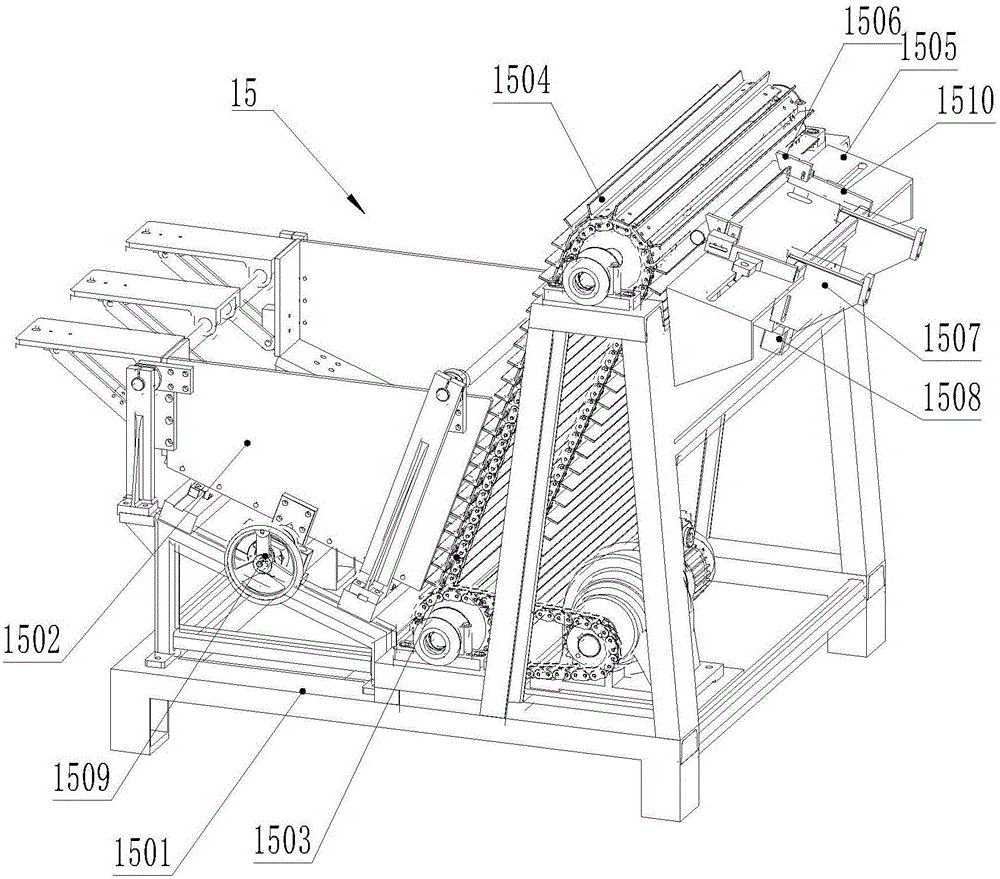

[0046] Such as Figure 1 to Figure 13 As shown, a special forming machine for an automobile seat angle adjustment assembly includes a frame 1 on which a primary forming device, an automatic assembly device and a linkage pipe station transfer device 19 are arranged, and the frame 1 is used as a whole Mounting base for molding machines.

[0047] Such as Figure 13 As shown, the adjustment assembly mentioned in the present invention includes a linkage pipe 27, the left end and the right end of the linkage pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com