Non-concentric casing tube phase-change solar heat-collector

A technology of solar heat collectors and bushings, applied in the field of solar energy utilization, can solve the problems of limiting the use environment and application fields of solar heat collectors, poor resistance to low temperature, and many interfaces are prone to water leakage, etc., to achieve simple and reliable structure, fast start-up Fast and selective absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] 1. Aluminum alloy-(acetone+ethanol) / R22 / R134 / R114 flat-plate solar water heater

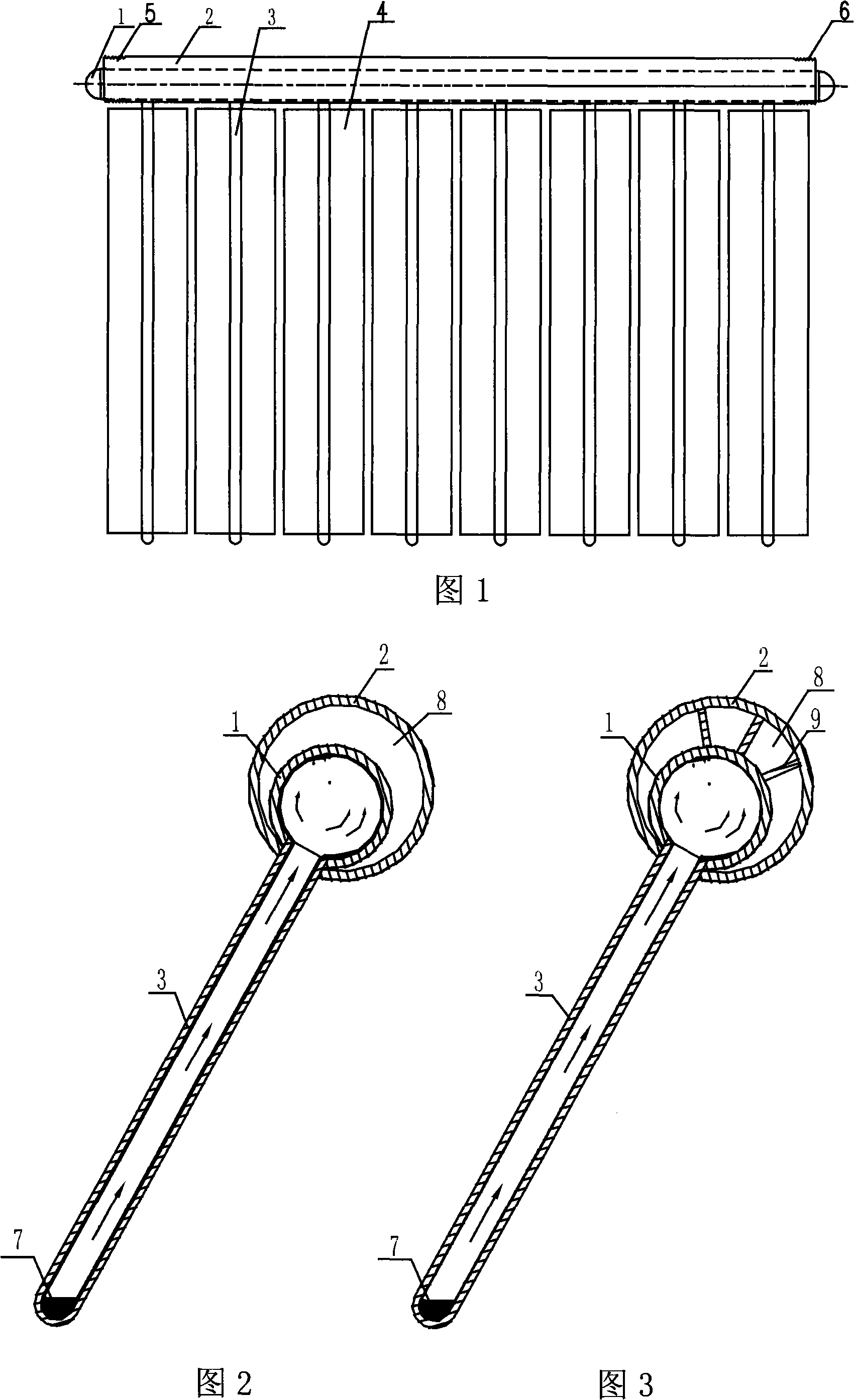

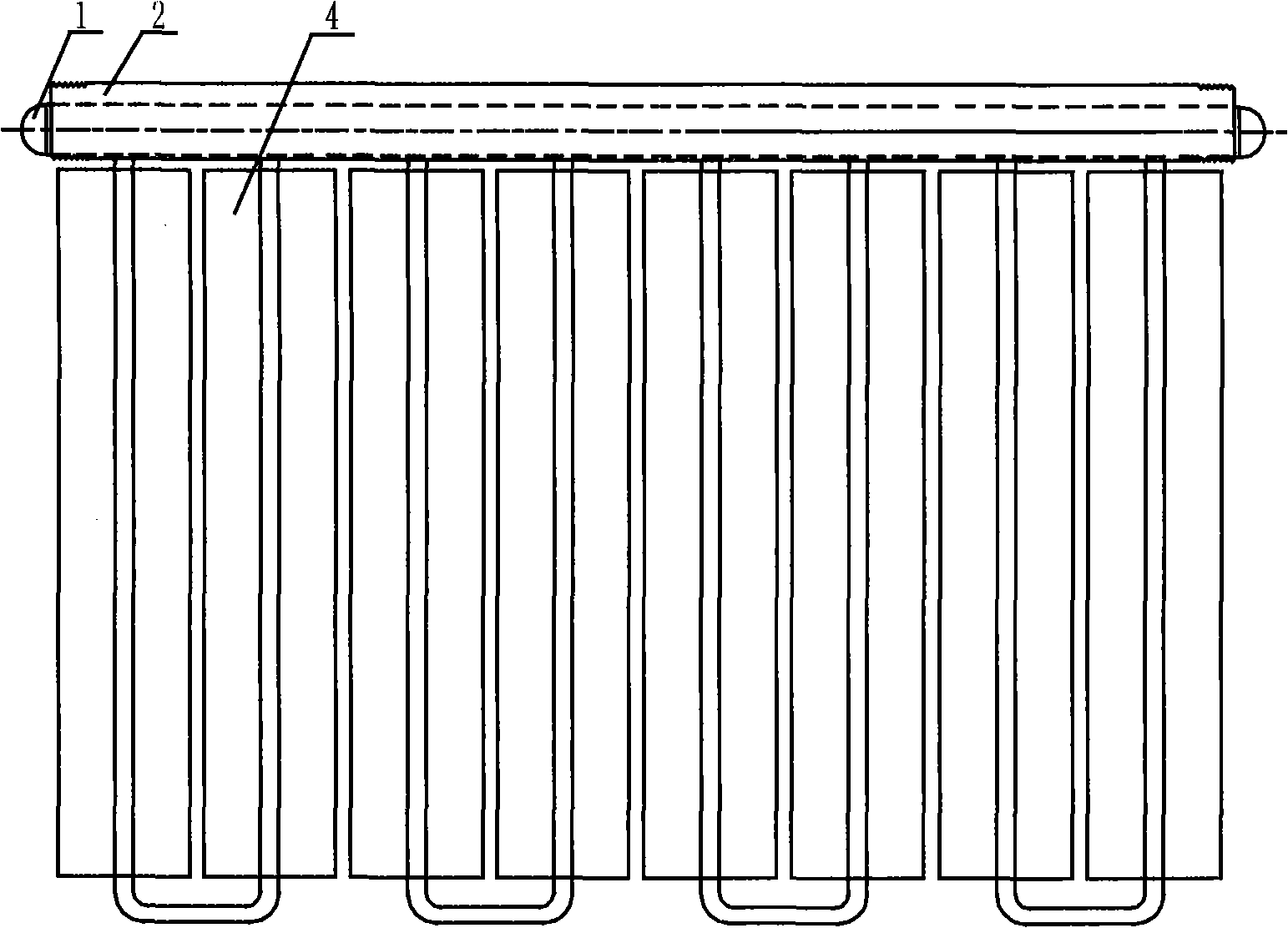

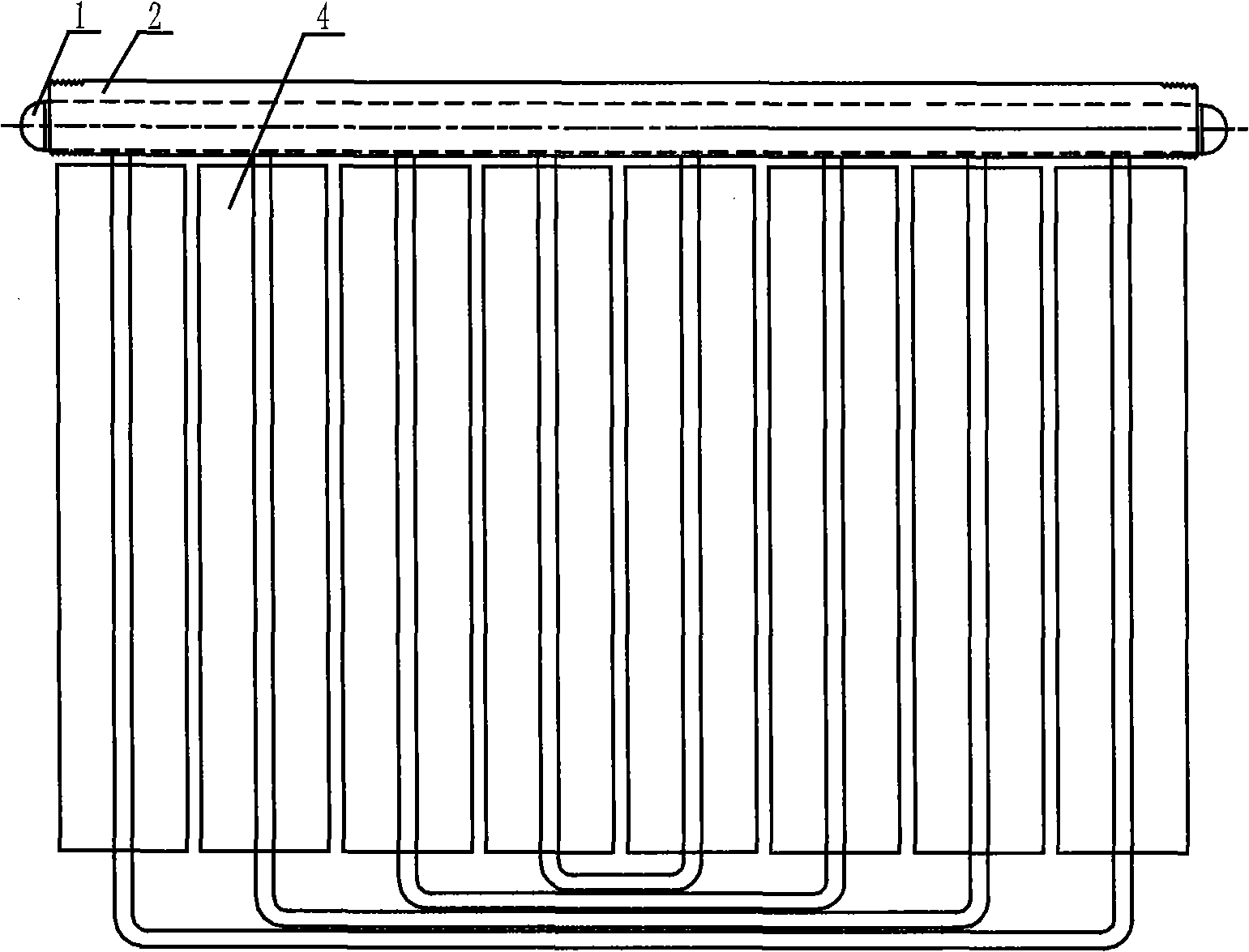

[0024] Structure: Heterocentric casing exchanger + U-shaped finned heat pipe collector welded;

[0025] Material: AL5051;

[0026] Working fluid: acetone / ethanol / R22 / R134 / R114

[0027] Operating temperature: -40℃~180℃.

[0028] 2. Copper-water / acetone / methanol / ethanol / R22 / R134 / R114 vacuum glass tube solar water heater

[0029] Structure: Heterocentric casing exchanger + straight tube finned heat pipe collector

[0030] Material: exchanger C1100, fin AL6061;

[0031] Working fluid: water / methanol

[0032] Operating temperature: -40℃~200℃.

[0033] 3. Steel-horizontal plate solar water heater

[0034] Structure: Heterocentric casing exchanger + straight tube type + finned heat pipe collector

[0035] Material: exchanger: steel, finned AL6061;

[0036] Working Fluid: Water / Degasser

[0037] Operating temperature: -40℃~200℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com