Full-series large-capacity automatic ball installing and digital control staged fracturing ball injector

A digitally controlled, staged fracturing technology for fluid production, wellbore/well components, earthmoving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with accompanying drawing:

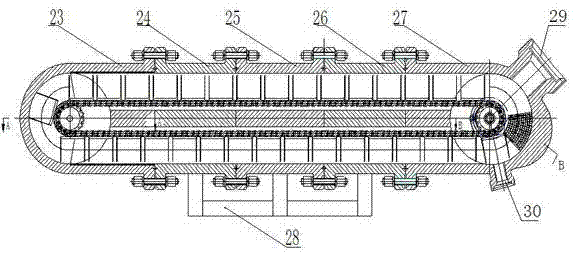

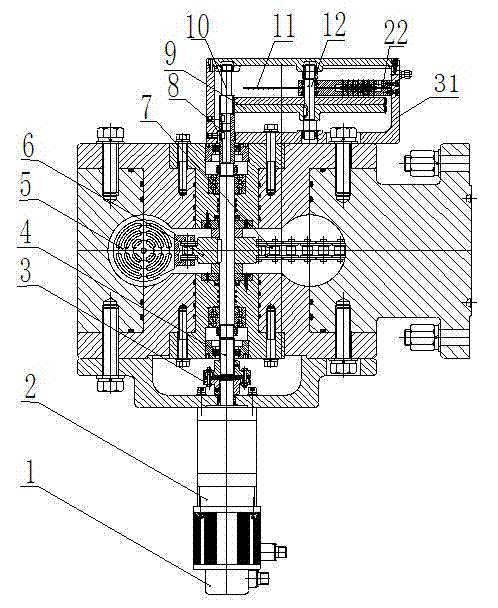

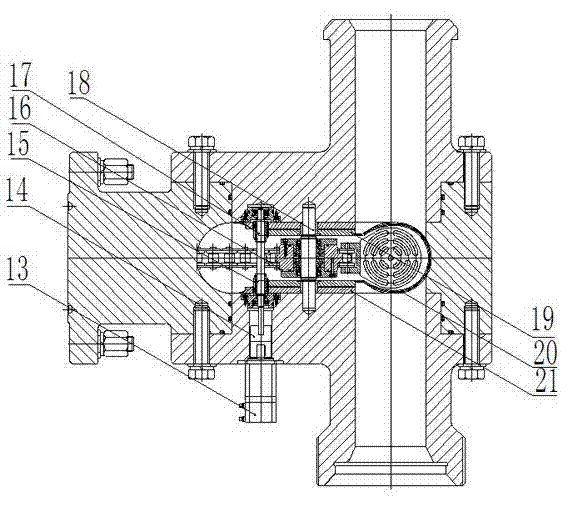

[0069] Such as figure 1 , 2As shown in , 3, a full series of large-capacity automatic ball loading digital control segmental fracturing pitcher, including bracket 28, AC digital servo motor I1, reducer 2, elastic coupling I3, driving sprocket 6, chain 7 , ball chamber 5, ball feeder driving end 23, ball feeder body I24, ball feeder body II25, ball feeder body III26, ball feeder discharge end 27, elastic coupling II8, anti-backlash gear set 9, photoelectric receiving and sending assembly 22, AC digital servo motor Ⅱ13, elastic coupling Ⅲ 14, active spur gear 15, external meshing passive spur gear 19, internal meshing passive spur gear 21, explosion-proof electrical control box, programmable controller, touch screen and position detection sensor , characterized in that: the pitcher body includes a pitcher drive end 23, a pitcher body I24, a pitcher body II25, a pitcher body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com