Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

A water-based polyurethane and composition technology, which is applied in the directions of abrasion-resistant fibers, textiles and papermaking, and fiber processing. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

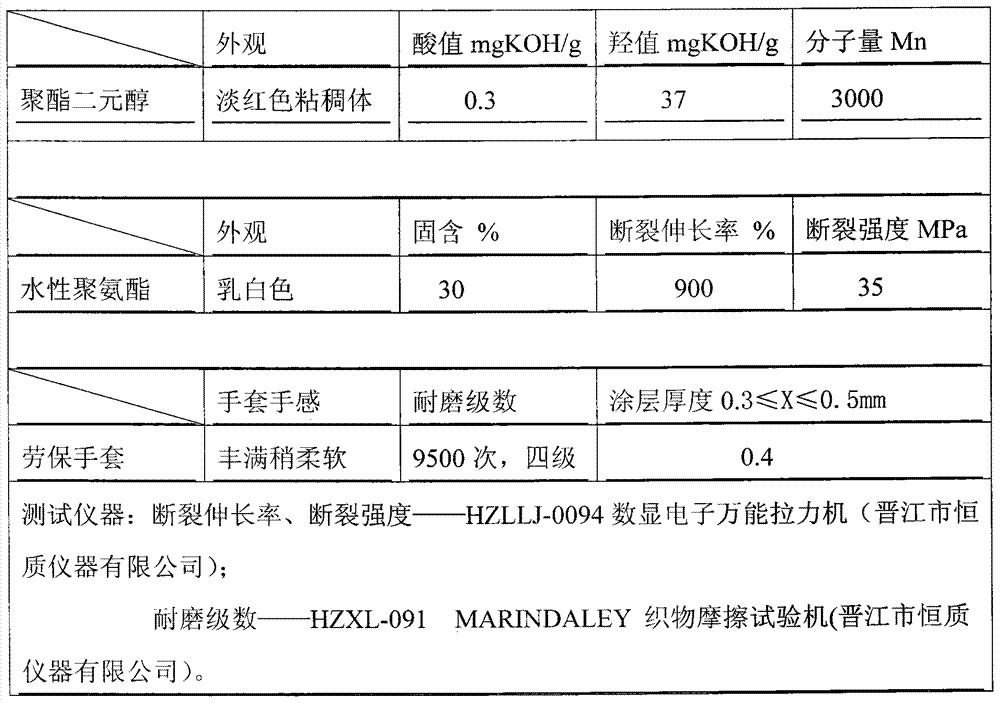

Embodiment 1

[0042] A kind of super-elastic wear-resistant water-based polyurethane resin, composition and preparation method applied to knitted glove coating:

[0043] (1) Preparation of polyester diol: under the protection of inert gas, put 500kg of succinic acid, 300kg of glutaric acid, 423kg of ethylene glycol and 0.2kg of antioxidant into the reaction kettle and add it to 150~170℃ for reaction 1~2h, with the evaporation of water, then heat up to 190~210°C, when the measured acid value is lower than 30mgKOH / g, add 0.8kg of catalyst, start vacuuming in stages, and gradually increase the vacuum degree. After reaching -0.09MPa, keep warm for 6-8 hours during this process, the acid value drops to 0.4mgKOH / g and the measured hydroxyl value is 37-38mgKOH / g (Mn=3000), stop the reaction, cool down and discharge the material, and obtain poly Ester diol is light red viscous colloid.

[0044] (2) Preparation of super-elastic and wear-resistant water-based polyurethane resin: in kg by weight, und...

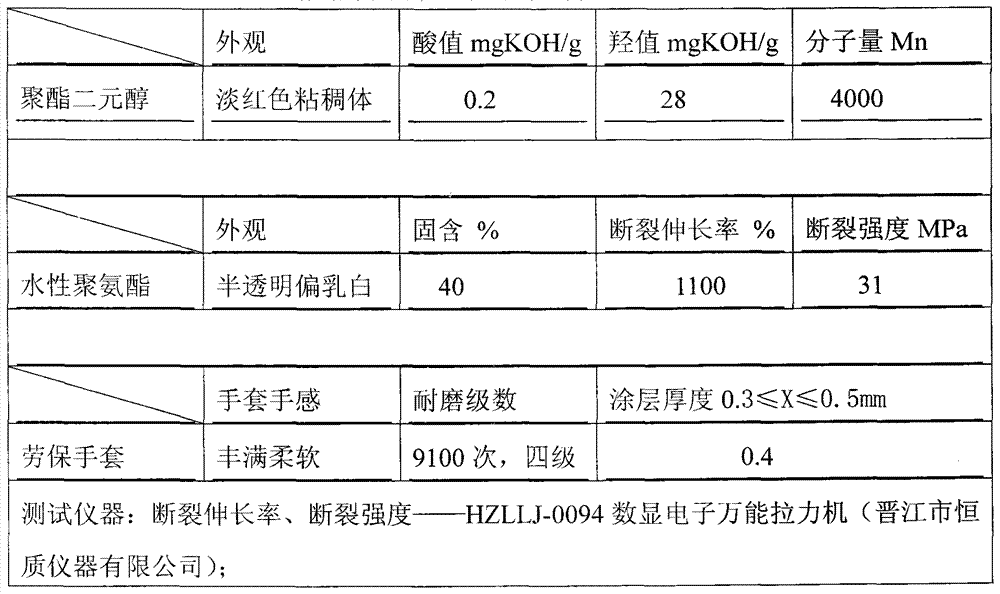

Embodiment 2

[0049] A kind of super-elastic wear-resistant water-based polyurethane resin, composition and preparation method applied to knitted glove coating:

[0050] (1) Preparation of polyester diol: under the protection of inert gas, 647kg adipic acid, 200kg1, 4-butanediol, 300kg1, 6-hexanediol and 0.2kg antioxidant are dropped into the reaction kettle to add, and the liter React at 150-170°C for 1-2 hours, then heat up to 190-210°C as the water evaporates, and when the measured acid value is lower than 30mgKOH / g, add 0.8kg of catalyst, start vacuuming in stages, and gradually increase the vacuum degree , generally requires the vacuum degree to reach -0.09MPa. During this process, keep warm for 6-8 hours, after the acid value drops below 0.4mgKOH / g and the measured hydroxyl value is 28.5-29mgKOH / g (Mn=4000), stop the reaction and cool down Discharging, the polyester diol obtained at normal temperature is light red viscous colloid.

[0051] (2) Preparation of super-elastic and wear-re...

Embodiment 3

[0057] A kind of super-elastic wear-resistant water-based polyurethane resin, composition and preparation method applied to knitted glove coating:

[0058] (1) Preparation of polyester diol: under the protection of inert gas, put metered 300kg adipic acid, 300kg succinic acid, 268.7kg1, 3-propanediol, 1391,6-hexanediol and 0.2kg antioxidant into the reactor Add it in, raise it to 150-170°C and react for 1-2 hours, then heat up to 190-210°C as the water evaporates, and when the measured acid value is lower than 30mgKOH / g, add 0.8kg of catalyst and start vacuuming in stages. Gradually increase the vacuum degree, and generally require the vacuum degree to reach -0.09MPa. During this process, keep warm for 6-8 hours, after the acid value drops below 0.4mgKOH / g and the measured hydroxyl value is 22-23mgKOH / g (Mn=5000) , stop the reaction and cool down to discharge, and obtain the polyester diol as light red viscous colloid at normal temperature.

[0059] (2) Preparation of super-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com