Method for preparing dendriticnano-silver quickly and conveniently

A nano-silver and dendritic technology, which is applied in the field of quick and easy preparation of dendritic nano-silver, can solve the problems of limited synthesis scale at the laboratory level, restrictions on dendritic nano-silver, and harsh synthesis conditions, so as to achieve convenient and rapid preparation and avoid Low requirements for preparation and purification process and preparation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

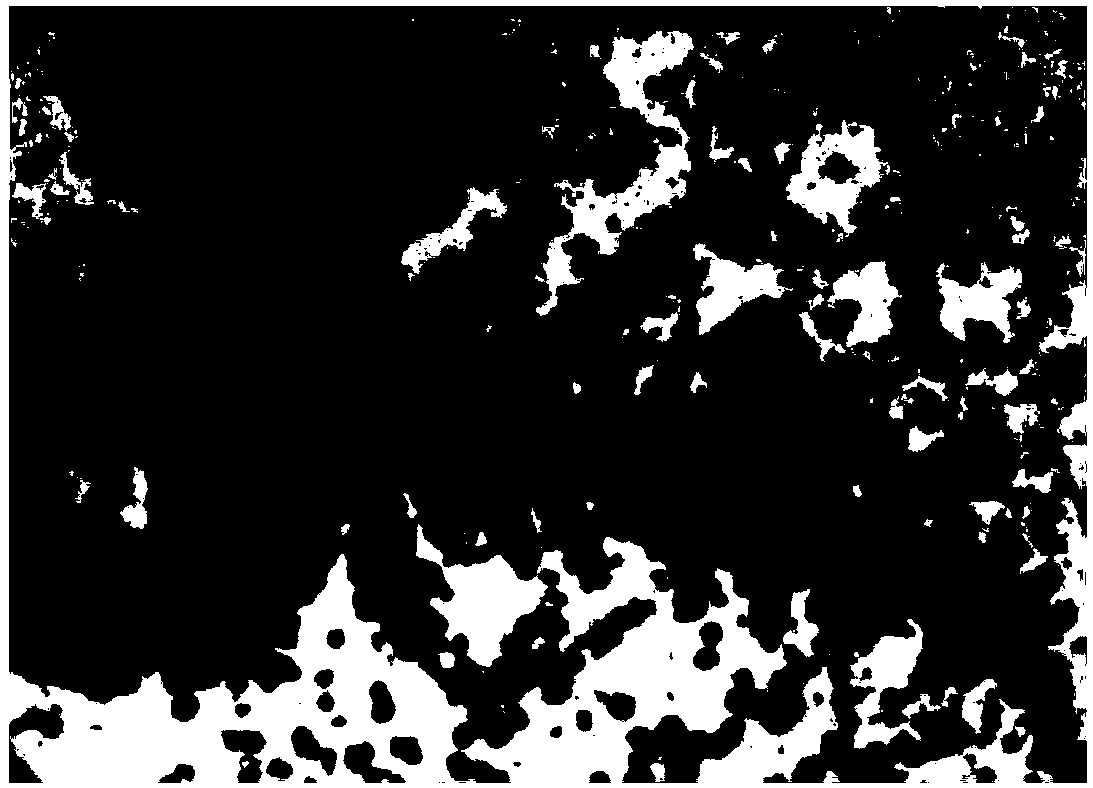

Image

Examples

Embodiment 1

[0023] Add 1g of silver nitrate, 4g of polyvinylpyrrolidone with a molecular weight of 3500, 3mg of sodium chloride and 100g of ethylene glycol into a 200mL two-necked flask, stir and heat at 90°C for 1 hour, and then react at 130°C for 3 hours. After the reaction is stopped, the reaction liquid is naturally cooled, settled with acetone, diluted three times with 1% by weight polyvinylpyrrolidone aqueous solution, and finally prepared into a dispersion liquid with ethylene glycol for use.

Embodiment 2

[0025] Add 10g of silver nitrate, 30g of polyvinylpyrrolidone with a molecular weight of 8000, 20mg of sodium chloride and 1000g of ethylene glycol into a 2L two-necked flask, stir and heat at 80°C for 1.5 hours, and then react at 120°C for 2.5 hours. After the reaction is stopped, the reaction liquid is naturally cooled, settled with acetone, diluted three times with 1% by weight polyvinylpyrrolidone aqueous solution, and finally prepared into a dispersion liquid with ethylene glycol for use.

Embodiment 3

[0027] Add 4g of silver nitrate, 7.2g of polyvinylpyrrolidone with a molecular weight of 40,000, 10mg of sodium chloride and 400g of ethylene glycol into a 1L two-necked flask, stir and heat at 100°C for 0.5 hours, and then react at 150°C for 2 hours , after stopping the reaction, after the reaction liquid is naturally cooled, it is settled with acetone, then diluted three times with 1% by weight polyvinylpyrrolidone aqueous solution, and finally prepared into a dispersion liquid with ethylene glycol for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com