Monolithic silicon-based transmitter

An emitter, silicon-based technology, used in phonon exciters, lasers, laser components, etc., can solve the problems of complex production, CMOS incompatibility, small process tolerance, etc., and achieve simple optical links and high integration. , The effect of large process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

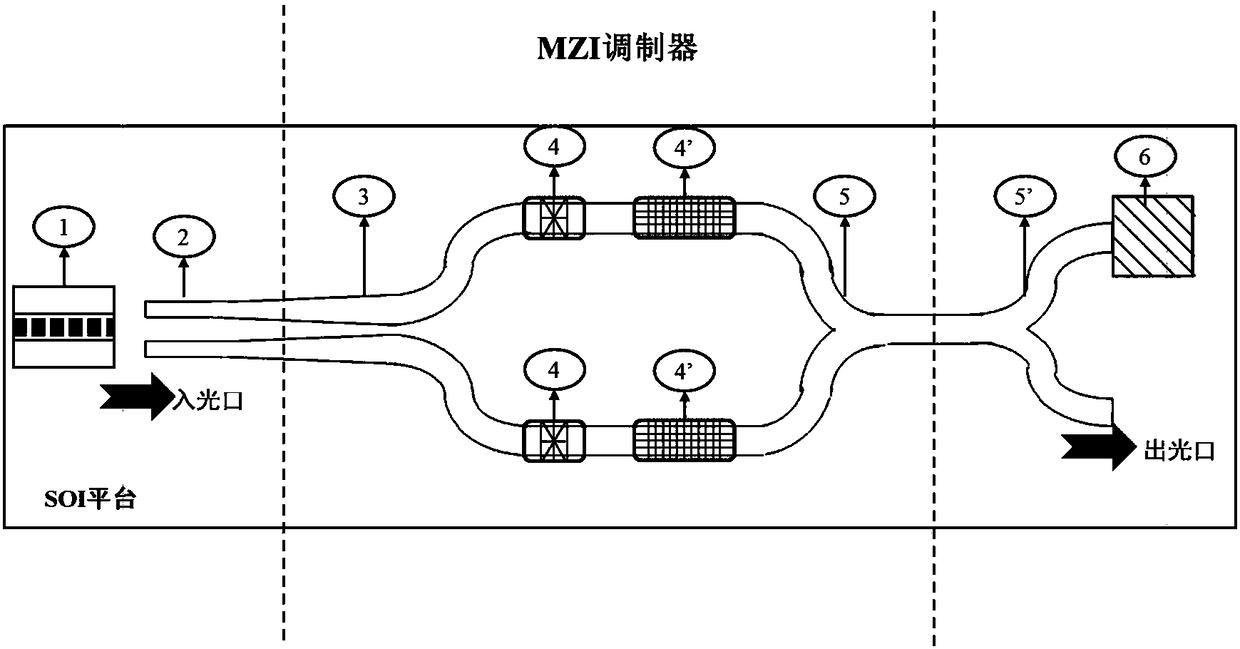

[0031] see figure 1 As shown, the embodiment of the present invention provides a monolithic silicon-based transmitter, which includes: a laser 1 integrated into a silicon-based platform, which is used as an on-chip light source to input continuous laser light; a tip mode formed on the end face of a silicon waveguide A spot matcher 2 is used to match the mode spot of the laser 1; a silicon waveguide biconical beam splitter 3 as the input end of the MZI (Mach-Zehnder interference) modulator is used to split the input optical power (its length design The phase of the waveguide supermode caused by the alignment process error of the laser 1 can be changed, and the light is divided into two paths of equal power and output to the two arms of the MZI modulator); two thermal electrodes 4 and / or are respectively formed on the two arms of the MZ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com