Loading and frequency conversion tuning cavity of large power ferrite

A frequency conversion tuning cavity and ferrite technology, which is applied in the direction of magnetic resonance accelerators, accelerators, electrical components, etc., can solve the problems of tuning capacitor burning and insulating medium heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

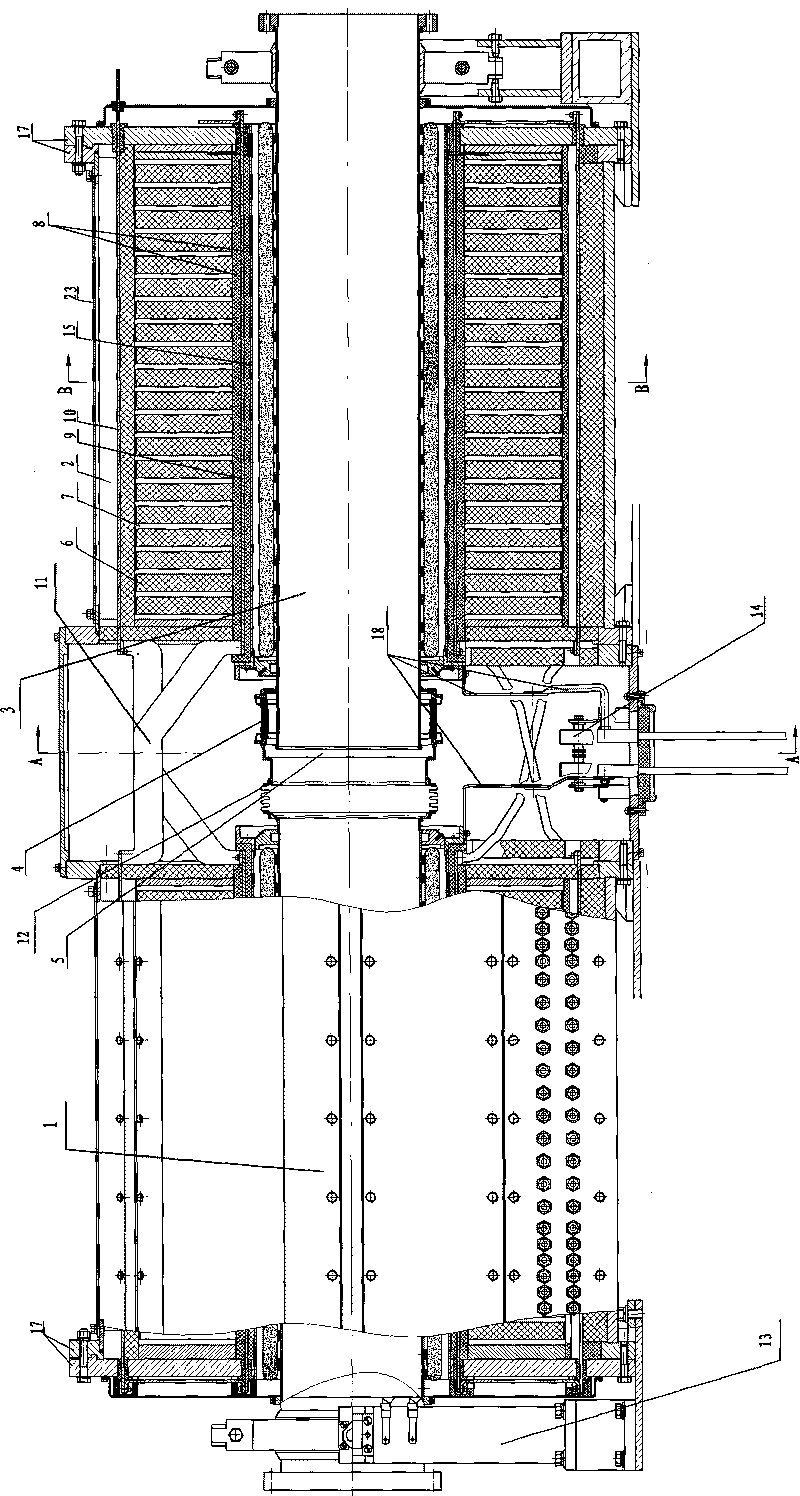

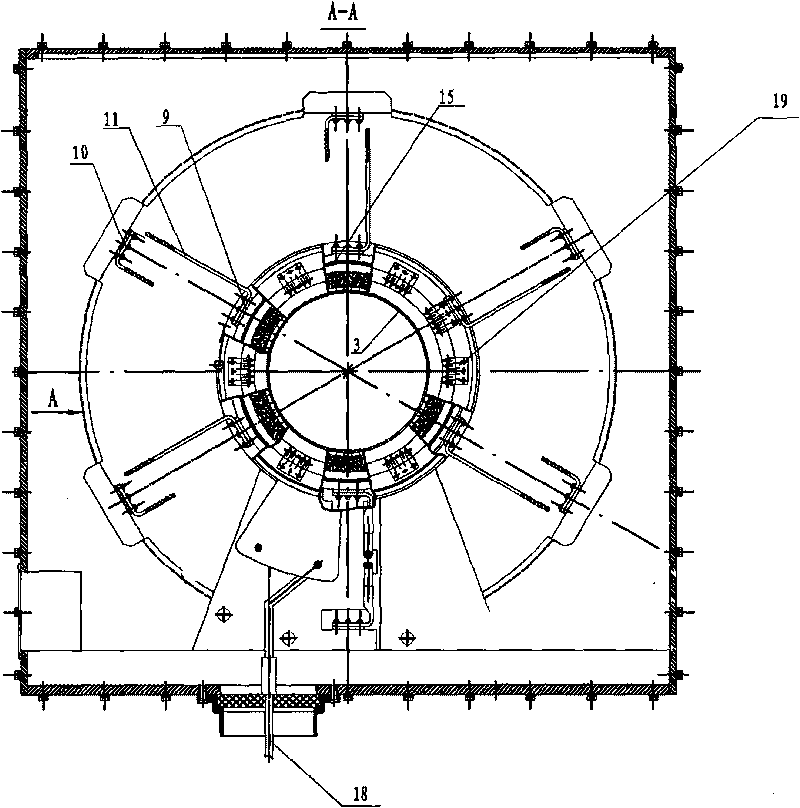

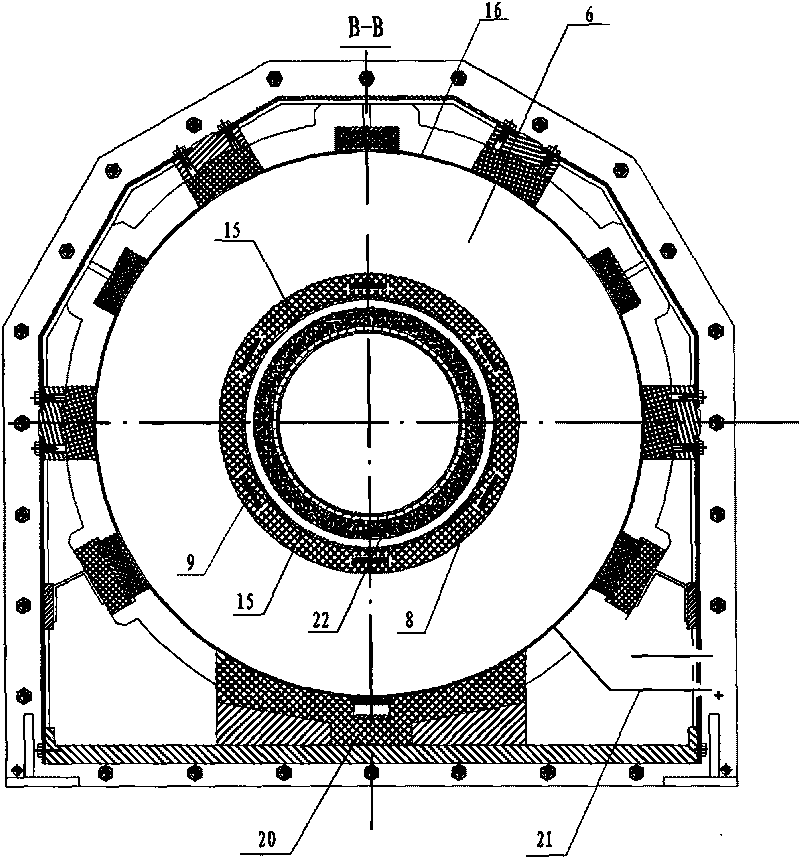

[0021] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

[0022] See figure 1 , 2 3. The high-power ferrite-loaded frequency conversion tuning cavity includes a left resonant cavity 1 and a right resonant cavity 2 coaxially placed opposite each other, and is characterized in that the inner conductor 15 and the outer conductor 15 of the right resonant cavity 2 Between the conductors 16 are filled ferrite magnetic rings 6 loaded with multiple cavities, and between the inner diameter of the ferrite magnetic rings 6 and the inner conductor 15 is filled with an insulating PTFE medium 8, and the insulating PTFE medium 8 is provided with The first bias coil conductor 9, the second bias coil conductor 10 is installed on the outside of the ferrite magnetic ring 6, the middle of the inner conductor 15 of the right resonant cavity 2 is a vacuum chamber 3, and the outside of the right resonant cavity 2 is equipped with a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com