Patents

Literature

36 results about "Standard ruler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A standard ruler is an astronomical object for which the actual physical size is known. By measuring its angular size in the sky, one can use simple trigonometry to determine its distance from Earth. In simple terms, this is because objects of a fixed size appear smaller the further away they are.

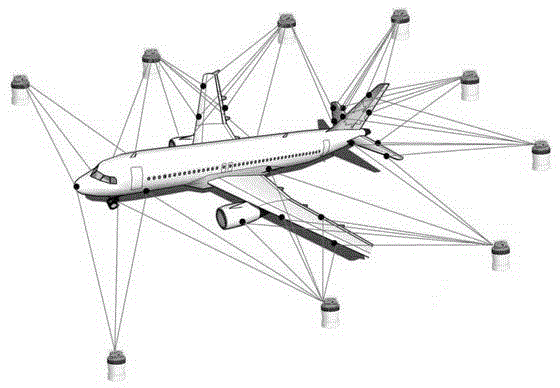

Full-airplane horizontal measurement method based on work space measurement location system

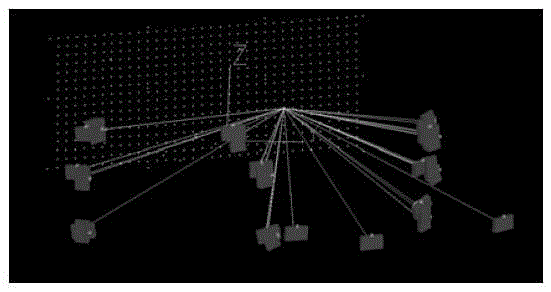

The invention provides a full-airplane horizontal measurement method based on a work space measurement location system. The method comprises first determining the number of measured work spaces and laser scanning base stations according to appearance dimensions and positions of measuring points; then using a standard ruler to calibrate external parameters of the measured work spaces formed by all the laser scanning base stations, and building a work space measurement location system coordinate system; then unifying the work space measurement location system coordinate system and an airplane coordinate system; using vector rods of the work space measurement location system to respectively perform contact measurement on each measuring point; and finally enabling measured coordinate values of each measuring point to be led into a data processor of the work space measurement location system, and comparing the actually-measured coordinate values with a theoretical value so as to judge whether airplane deformation is within an allowed range. The full-airplane horizontal measurement method solves the problems that a traditional airplane horizontal measurement method is poor in measurement precision, large in workload and low in measurement efficiency and is subjected to influences of operator's proficiency and the like.

Owner:吉林航空维修有限责任公司

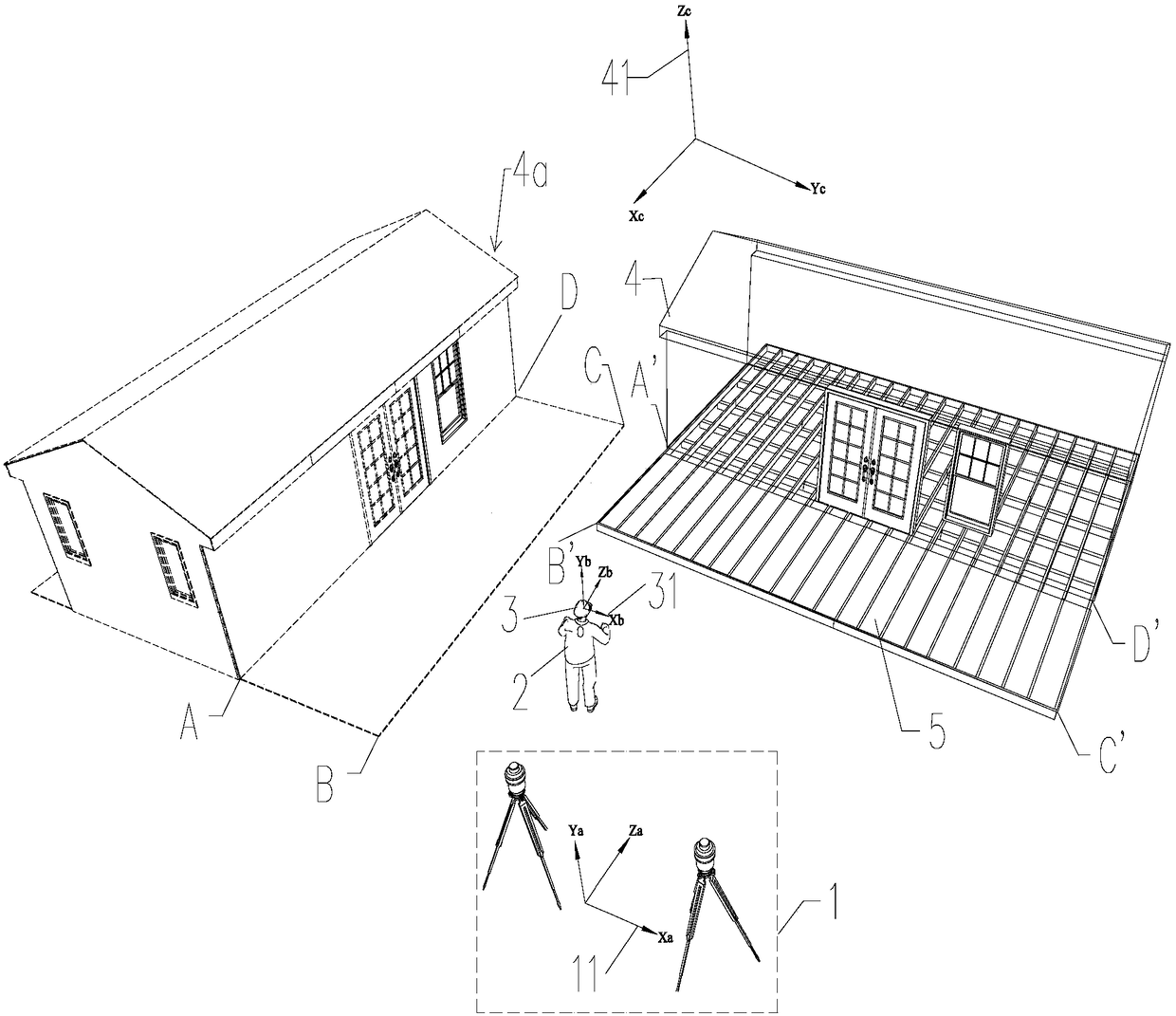

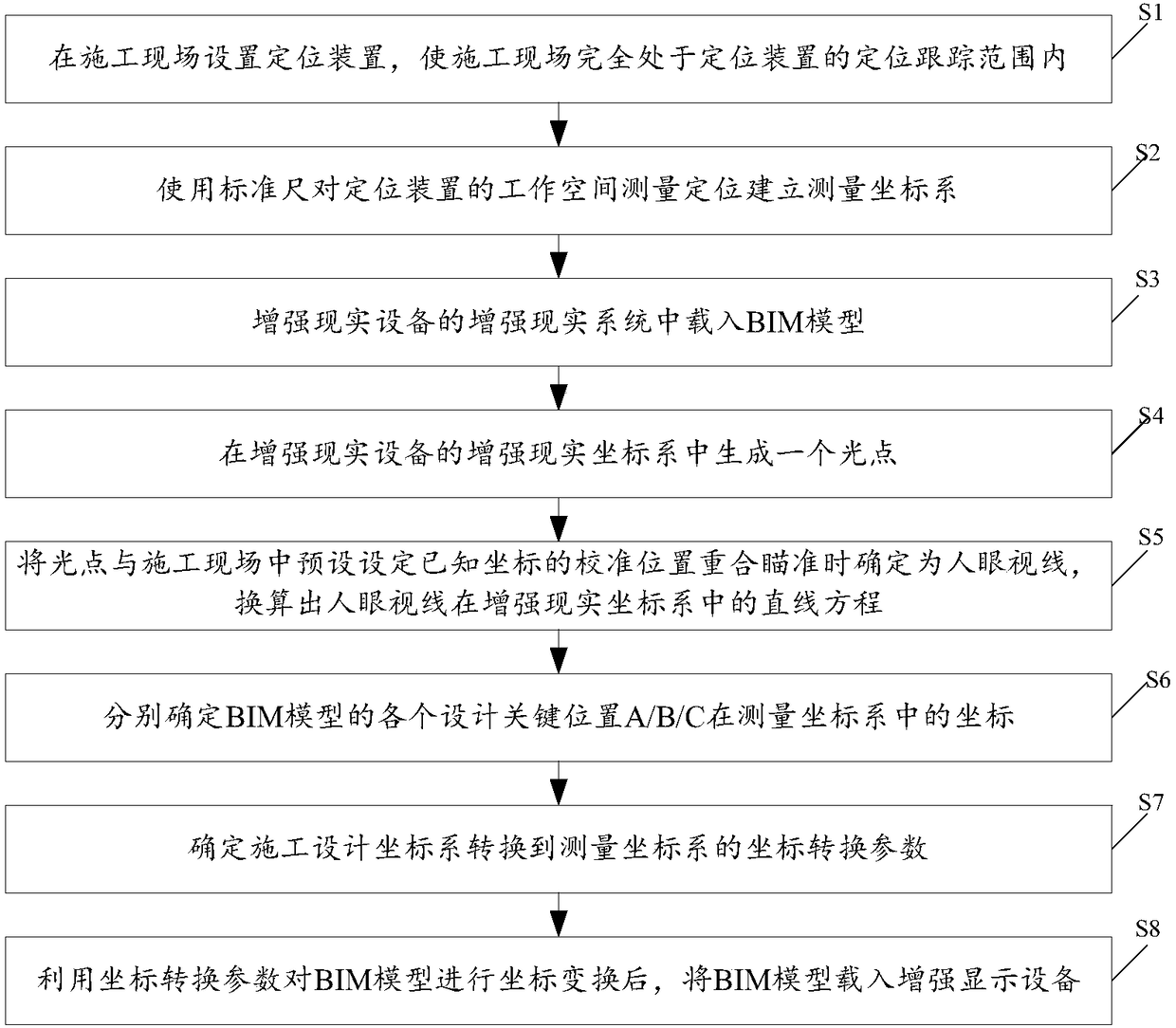

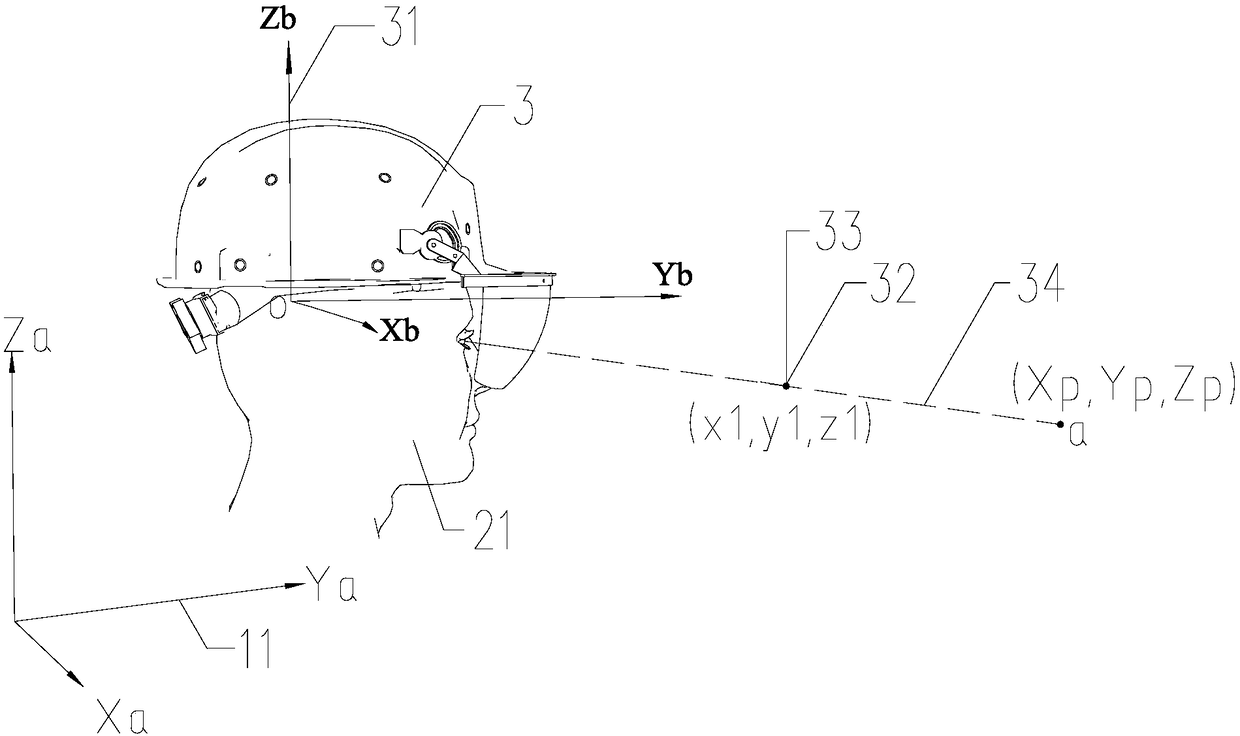

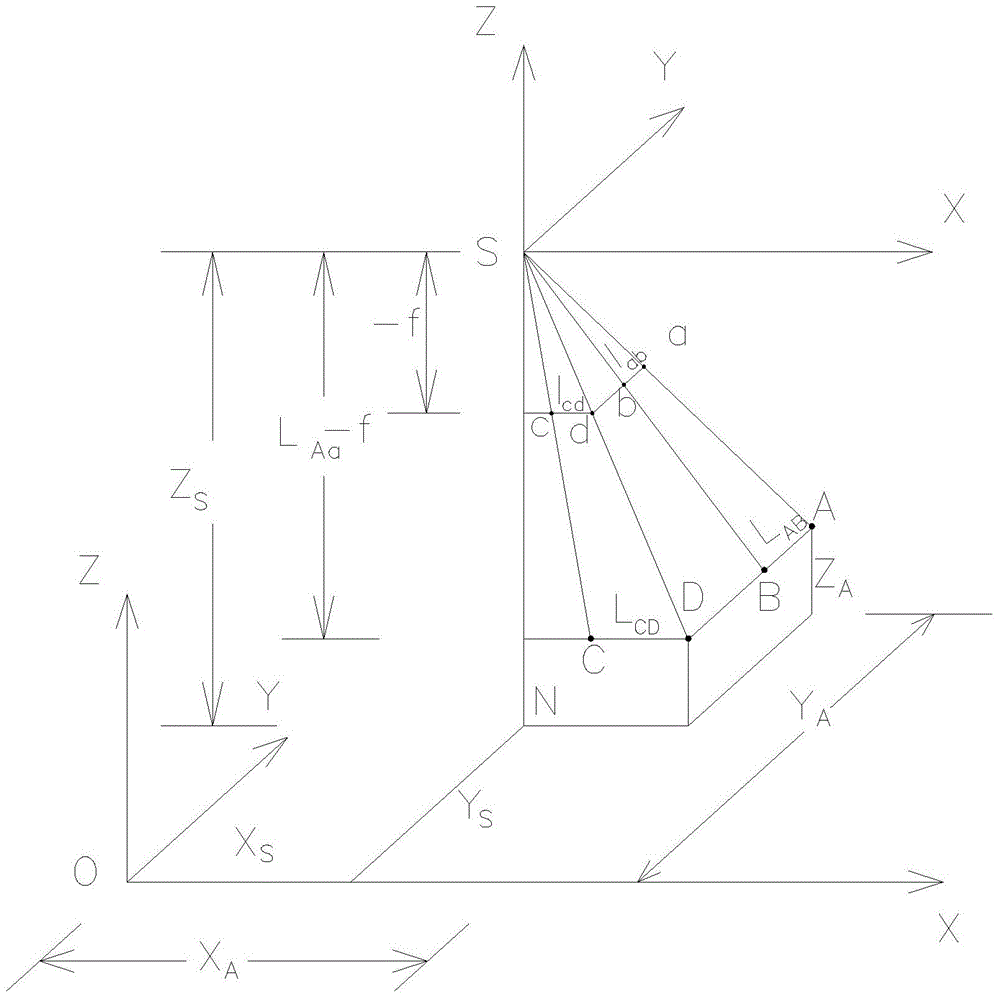

Augmented reality lofting system and implementation method based on BIM technology

ActiveCN108227929AEasy to superviseAvoid misunderstandingInput/output for user-computer interactionData processing applicationsTransformation parameterCritical position

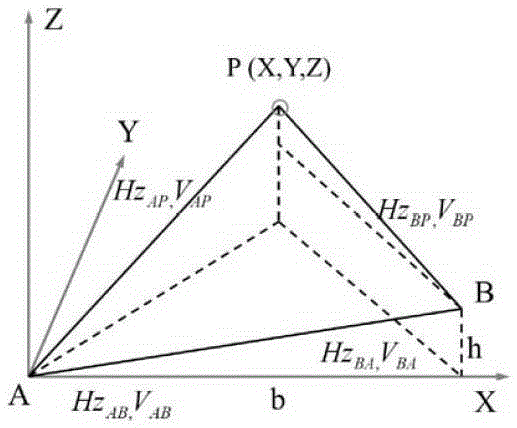

The invention discloses an augmented reality lofting system and method based on a BIM technology. The method comprises the steps that a construction site is located in a positioning and tracking rangeof a positioning device, and a standard ruler is used for measuring and positioning the working space of the positioning device and establishing a measurement coordinate system; coordinates of key design positions A / B / C in the measurement coordinate system are determined respectively; coordinate transformation parameters of a construction design coordinate system which is converted to the measurement coordinate system are determined; the coordinate conversion parameters are utilized to conduct coordinate transformation on a BIM model, then the BIM model after subjected to coordinate transformation is loaded into augmented reality equipment, and when a user wears the augmented reality equipment on the head to observe the construction site, the BIM model is displayed in the construction site and all the key design positions of the BIM model overlap with all key construction positions of the construction site one to one respectively. By means of the method, the mapping relationship of the construction site and the BIM model can be accurately determined so that a BIM three-dimensional design result of a design unit can be accurately superimposed on the construction site by using an augmented reality technology.

Owner:廖卫东 +2

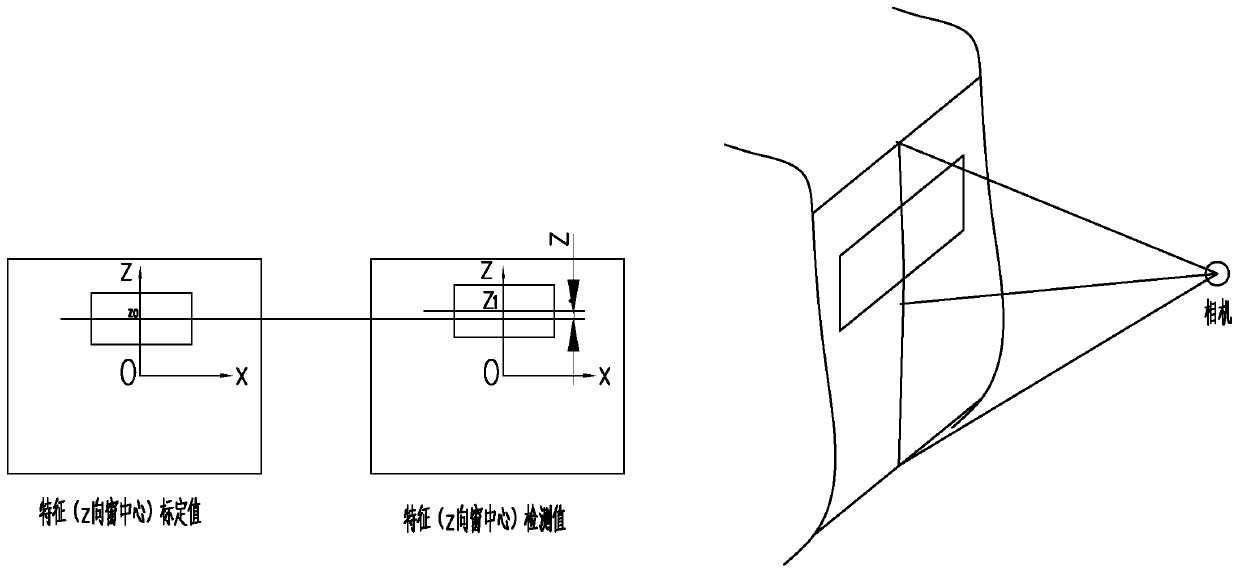

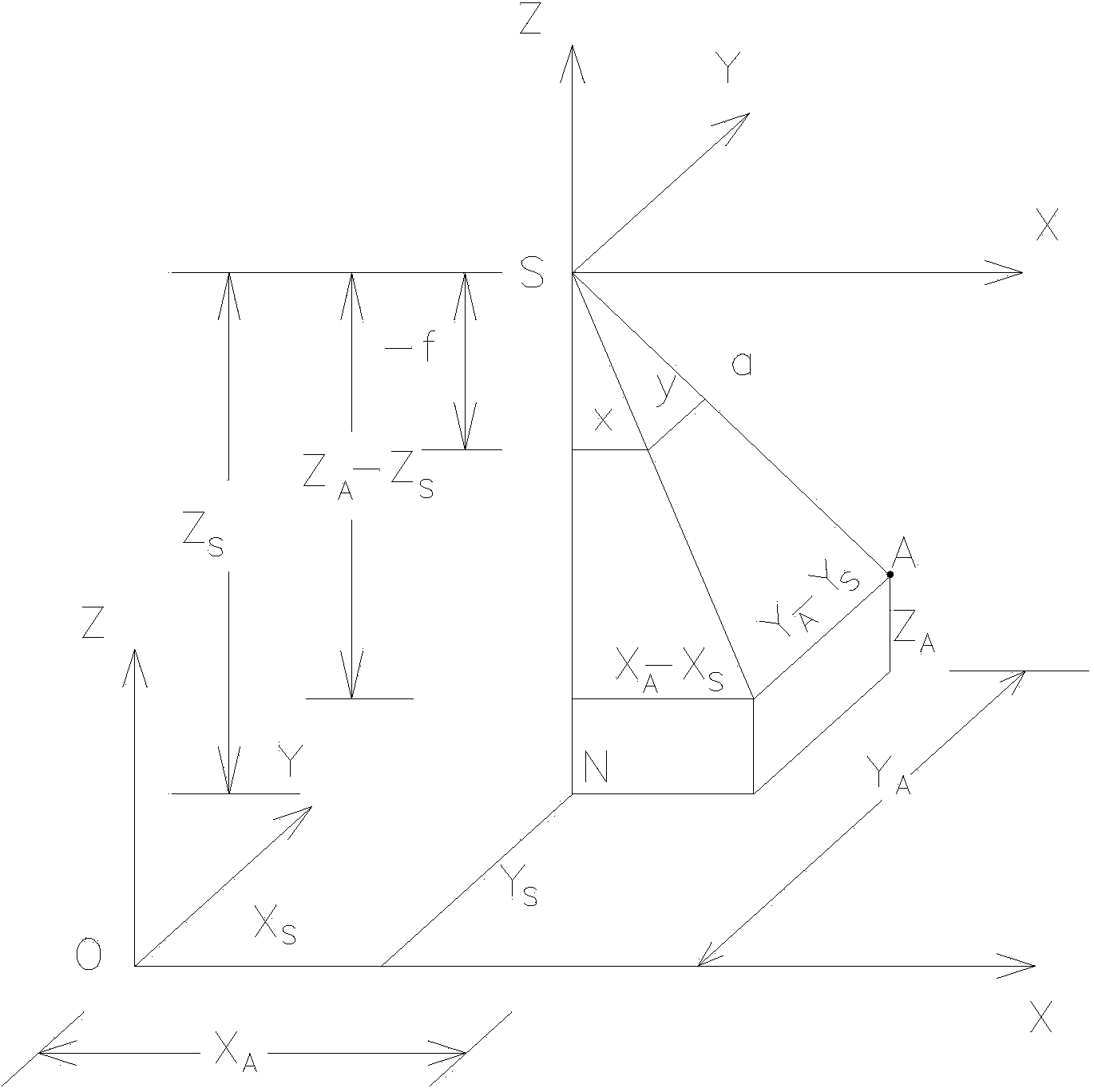

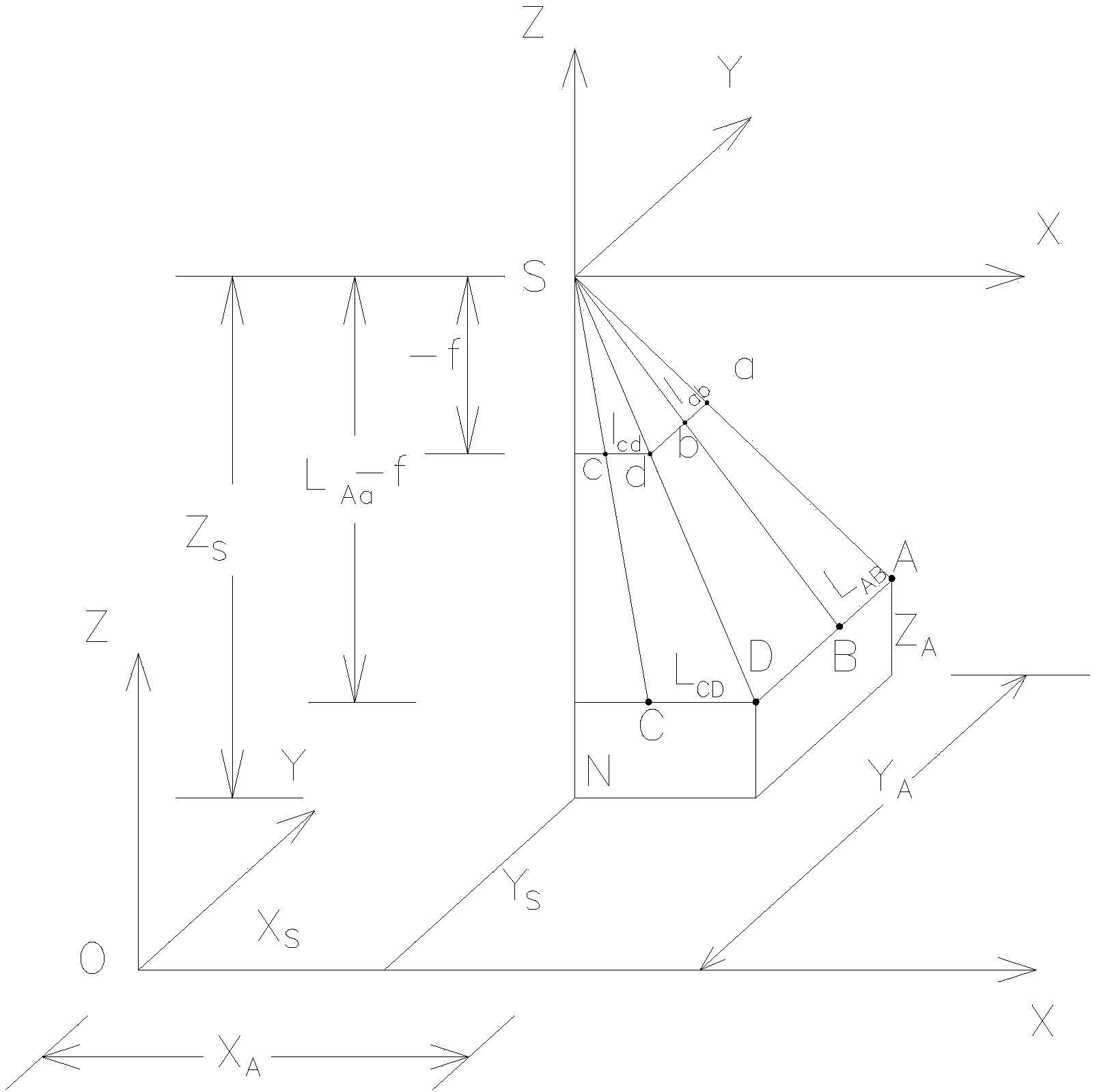

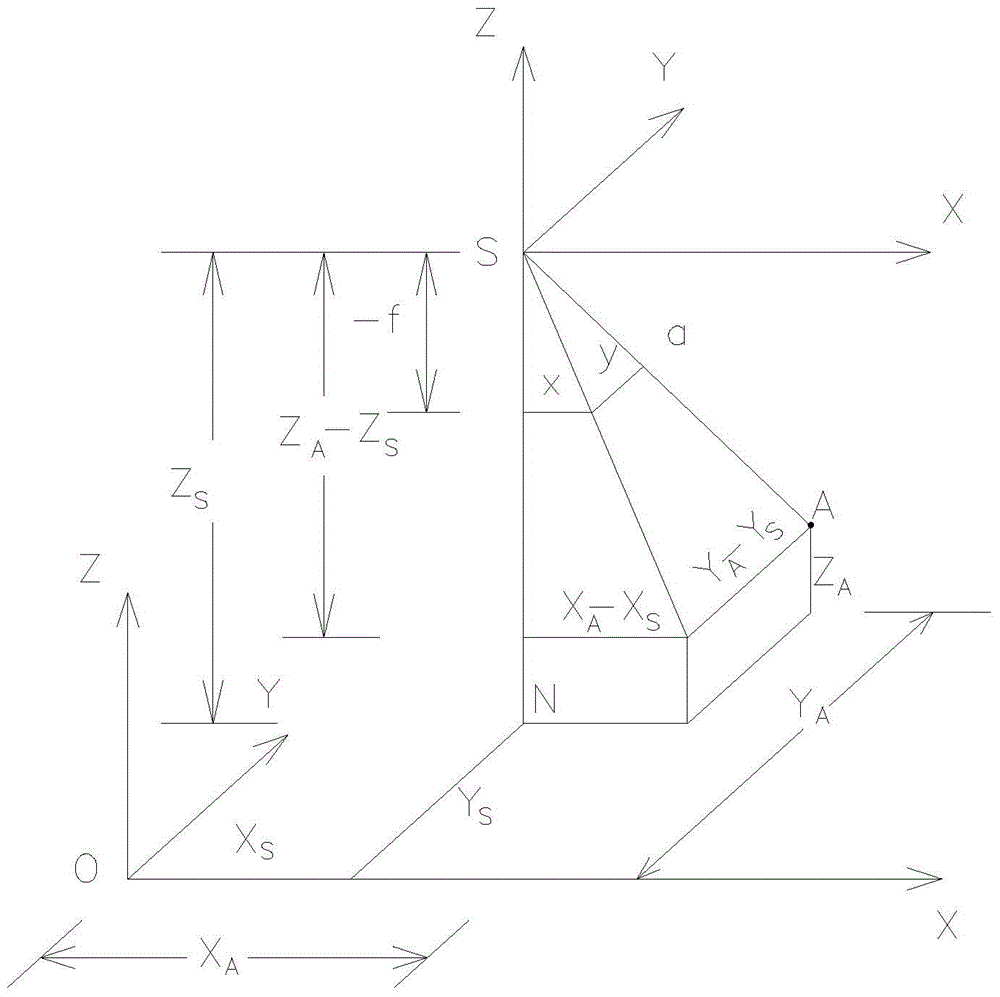

Digital camera projection center position precision calibration method based on photogrammetric technology

InactiveCN105424058AAchieve precise calibrationExcellent positioning accuracyMeasurement devicesCamera lensTheodolite

The invention relates to a digital camera projection center position precision calibration method based on a photogrammetric technology, and aims at effectively solving the problems of high precision and operability. The method comprises the steps that a return light reflection measurement mark, a control point mark, an encoding mark, a directional target and a standard ruler are laid to form a calibration field; an electronic theodolite and a to-be-inspected camera are arranged at the position 3 meters away from the calibration field, and the return light reflection measurement mark is stuck to a camera lens; the calibration field is photographed by the camera at the different horizontal positions to obtain multiple photos, the calibration field is photographed by the to-be-inspected camera at the different positions in front of the calibration field at different attitudes, and data of the control point mark are extracted from the photos to form calibration data; the coordinates of a central image point of the control point mark are corrected and resolved to obtain three projection center positions. According to the method, control point mark image center measurement, high-precision camera calibration and projection center precision measurement can be integrally achieved, and the calibration precision of the projection center positions is higher than 5 mm.

Owner:THE PLA INFORMATION ENG UNIV

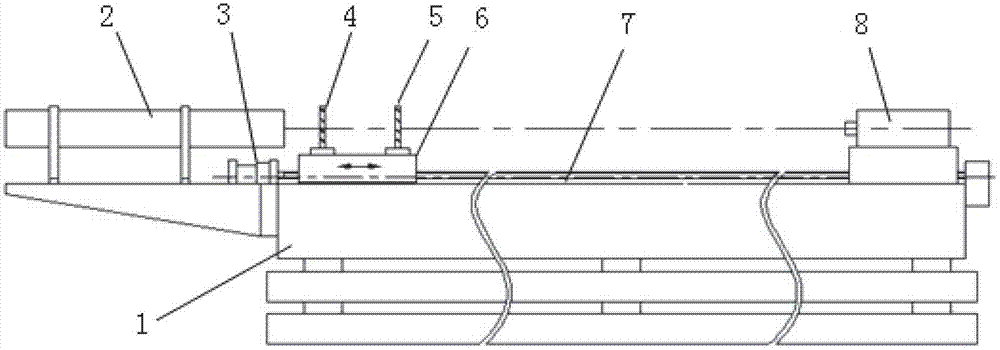

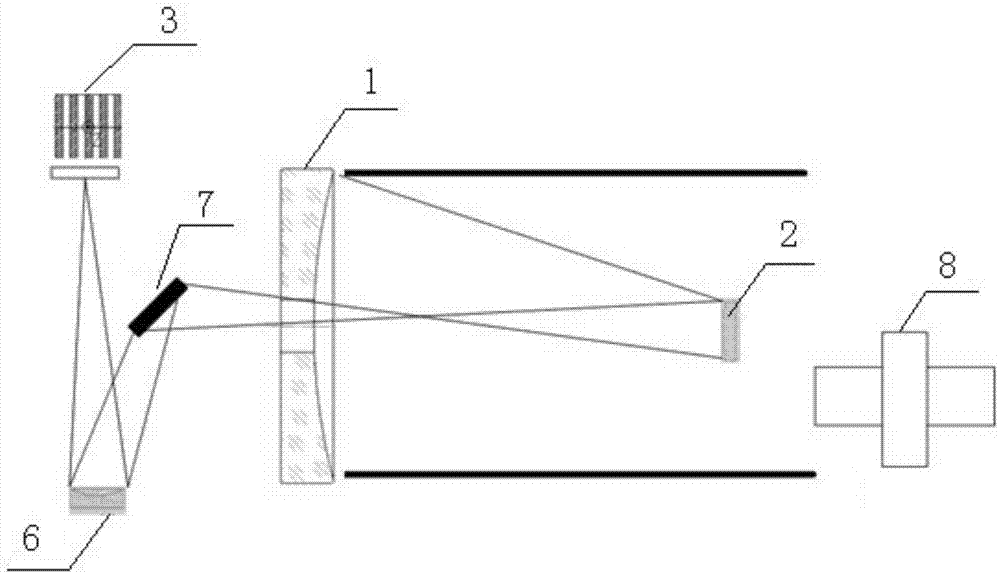

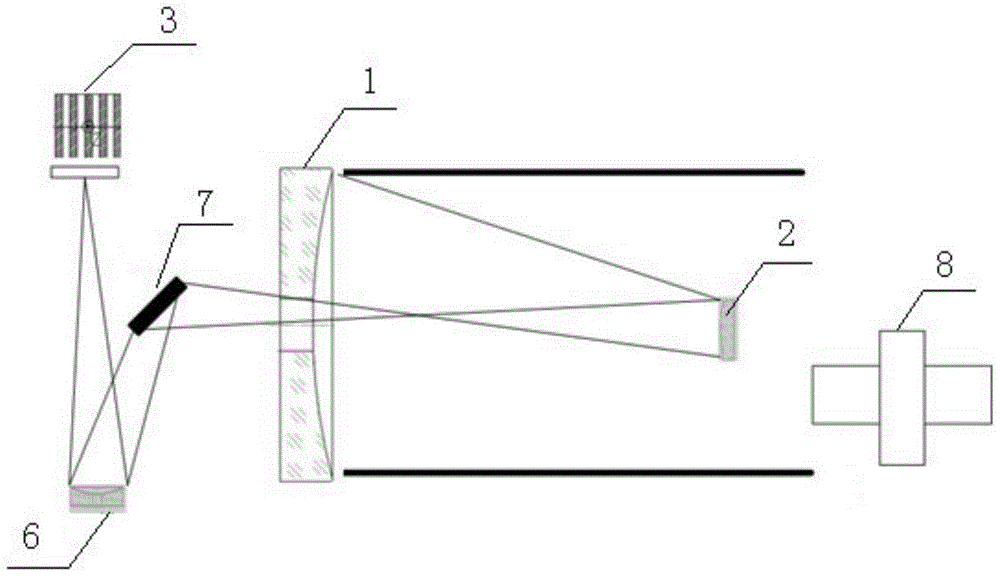

Non-contact automatic detection device for absolute grating ruler overall measuring accuracy

The invention discloses a non-contact automatic detection device for absolute grating ruler overall measuring accuracy, and belongs to the field of grating detection. The device comprises a working platform, a collimator, a screw rod, a first reflector, a second reflector, a sliding platform, a grating ruler and a laser interferometer, wherein the collimator is fixed on one side of the working platform, a standard ruler in the grating ruler is disposed on the working platform and parallel to a guide rail of the working platform, a reading head of the grating ruler is disposed in the sliding platform, the screw rod is fixed on the working platform below the collimator, the sliding platform is disposed on the guide rail of the working platform, the screw rod controls the sliding platform to move on the guide rail, the first reflector and the second reflector are fixed on the sliding platform, and the laser interferometer is fixed on the other side of the working platform. By non-contact detection, the device is used for detecting overall measuring accuracy of the grating ruler after processed and mounted, a qualified grating ruler is selected for online real-time detection to guarantee accuracy requirements needed by the grating ruler.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

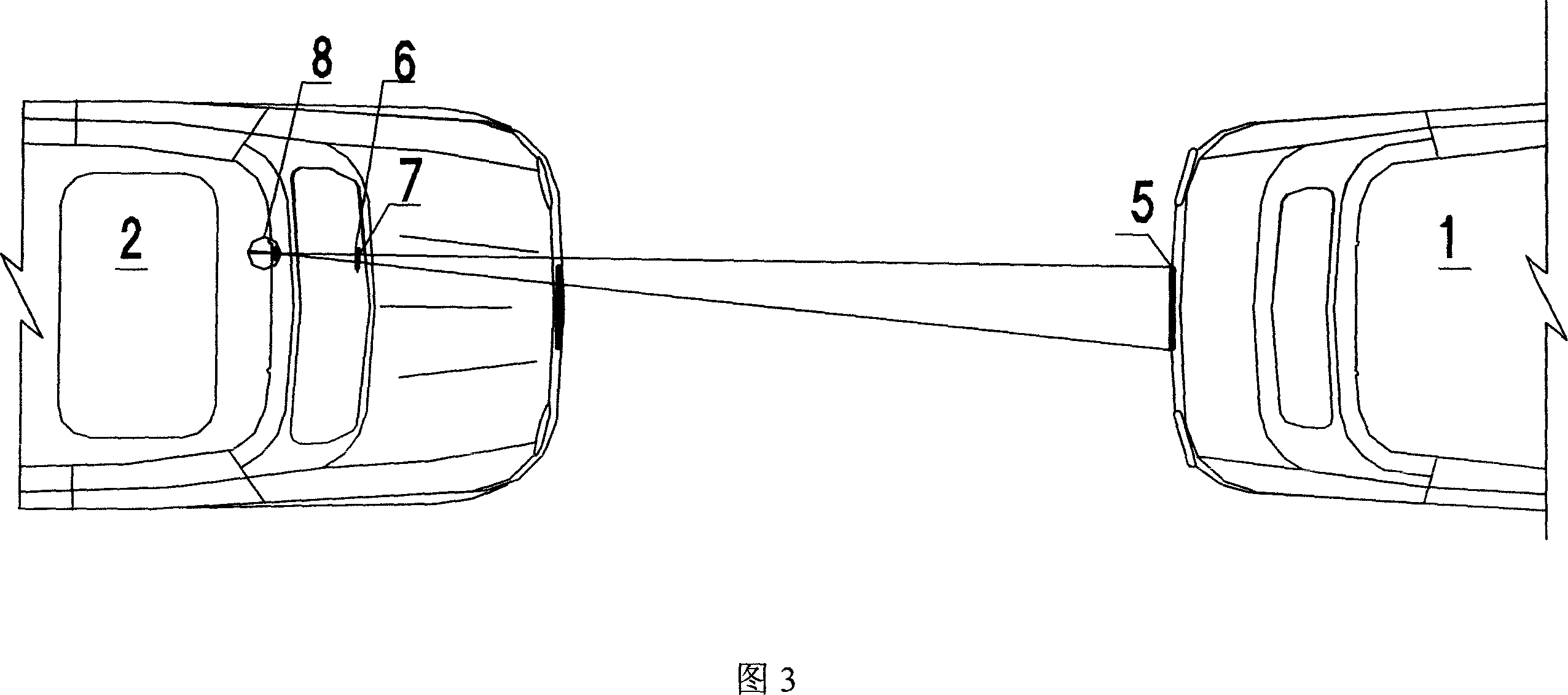

Method for measuring distance between cars and telemeter

InactiveCN1963389AAccurate rangingSimple structureOptical rangefindersPedestrian/occupant safety arrangementVisual perceptionTelemeter

This invention relates to one method and device to measure car distance, which is based on human visual principle image to collect different distance at different time point and uses standard object length of car to be tested at front wind block glass of car or transparent label on meter bench as standard ruler to judge distance between car and driving car; the meter ruler is to measure different car distance and the car to be tested at transparent label object length.

Owner:杨楠

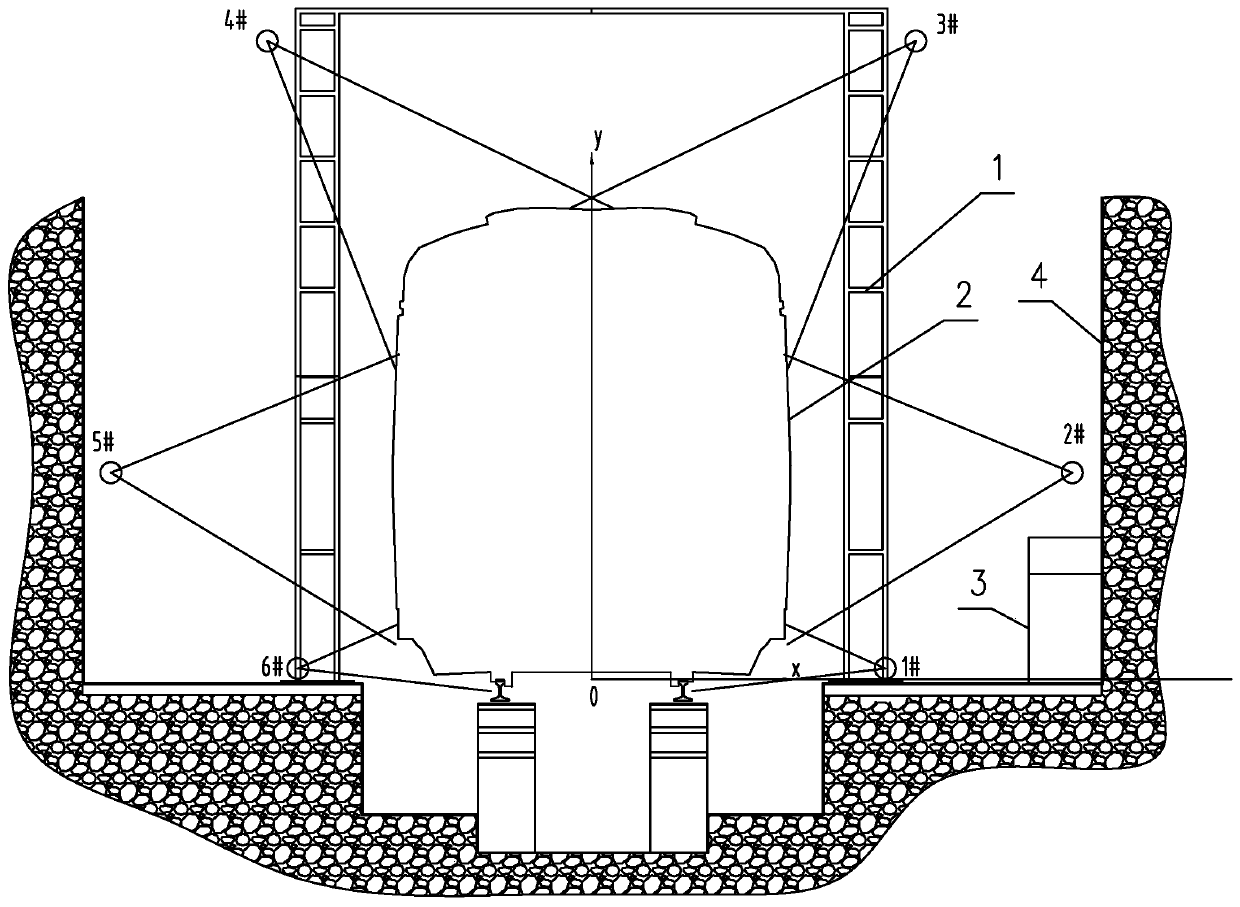

Vehicle profile measurement method based on vector image measurement

The invention discloses a vehicle profile measurement method based on vector image measurement. The method comprises a step of installing line scan cameras at left and right sides of upper and middleparts of left and right top angle lines and left and right bottom angle lines of a vehicle profile line near a track in a detection area to form left and right linear arrays of an upper part, a middlepart and a lower part, a step of establishing a space vector measurement coordinate system with a train traveling direction as an X axis position direction and setting an X direction standard rule inan X axis, a step of setting the linear arrays in a way that one of the upper right linear array and left linear array is in front and the other one is behind the one, one of the middle right lineararray and left linear array is in front and the other one is behind the one, and the coordinates of two linear arrays in front or back in the X direction are the same and two parallel measurement sections are formed, wherein the X direction distance of the two parallel measurement sections is a nominal value of a standard ruler, and a lower measurement section formed by the lower left and right linear arrays is located in the middle of the two parallel measurement sections. According to the invention, the moving speed of the train can be accurately through the standard ruler to track the sampling line frequencies of the line scan cameras, the undistorted sampling with a high speed can be achieved, and the accurate measurement is achieved.

Owner:GUANGZHOU AUTO TRANSPORT MEASURE & CONTROL TECH

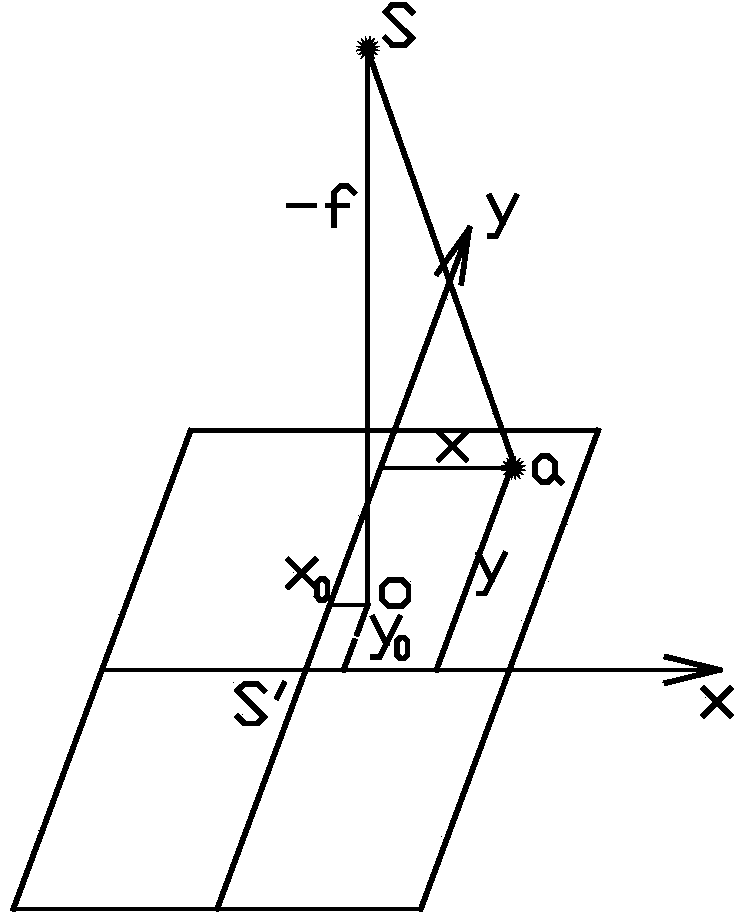

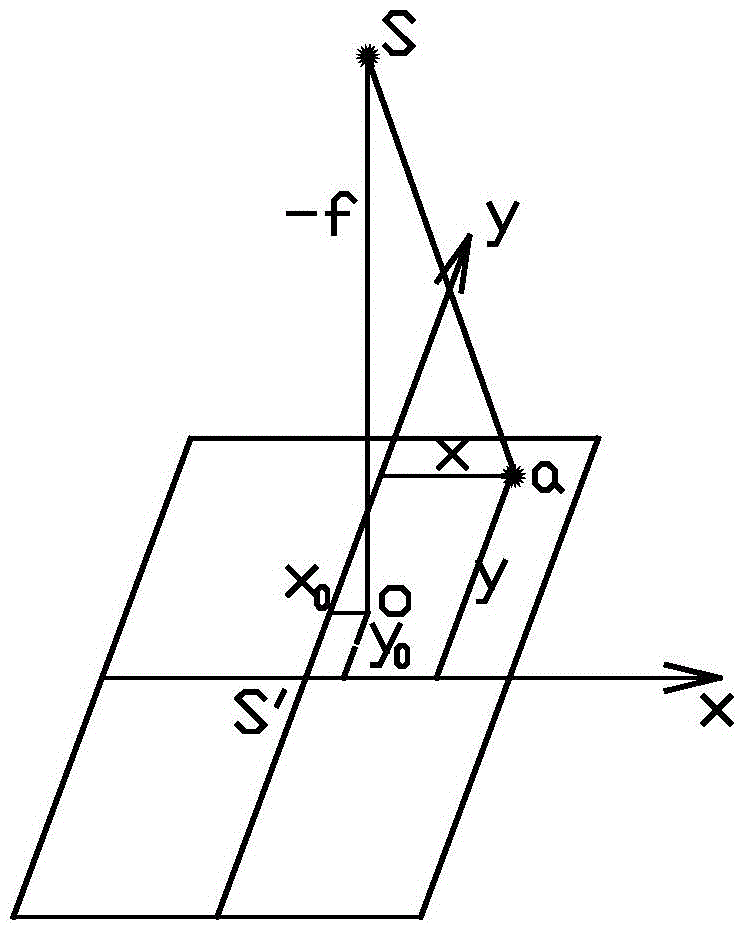

Surveying and mapping method for ancient architecture by matching digital camera with measuring tool

The invention discloses a surveying and mapping method for an ancient architecture by matching a digital camera with a measuring tool. The digital camera and the measuring tool are taken as tools to measure vertical-face dimension of an architecture in a single-image mode under a condition that elements of interior orientation are not known and elements of exterior orientation are known or measurable; the surveying and mapping method specifically comprises the following steps: measuring a vertical distance between a photographing point and an external vertical face of the architecture by using the measuring tool; fixing horizontal and vertical standard rulers on the external vertical face of the architecture; keeping the digital camera in a horizontal state for photographing to obtain photos of a to-be-measured area, obtaining image space dimensions of the standard rulers by virtue of the photos; determining a scale value of the image space dimensions and an object space dimension in the horizontal direction and the vertical direction by utilizing proportional relation of similar triangles according to the image space dimension of the standard rulers; respectively obtaining the dimension of each part of the external vertical face of the architecture in the horizontal direction and the vertical direction according to the scale value of the image space dimensions and an object space dimension in the horizontal direction and the vertical direction. The method disclosed by the invention can simply and quickly measure the vertical face dimension of the architecture, and improves surveying and mapping precision and the working efficiency.

Owner:徐州市勘察测绘研究院有限公司

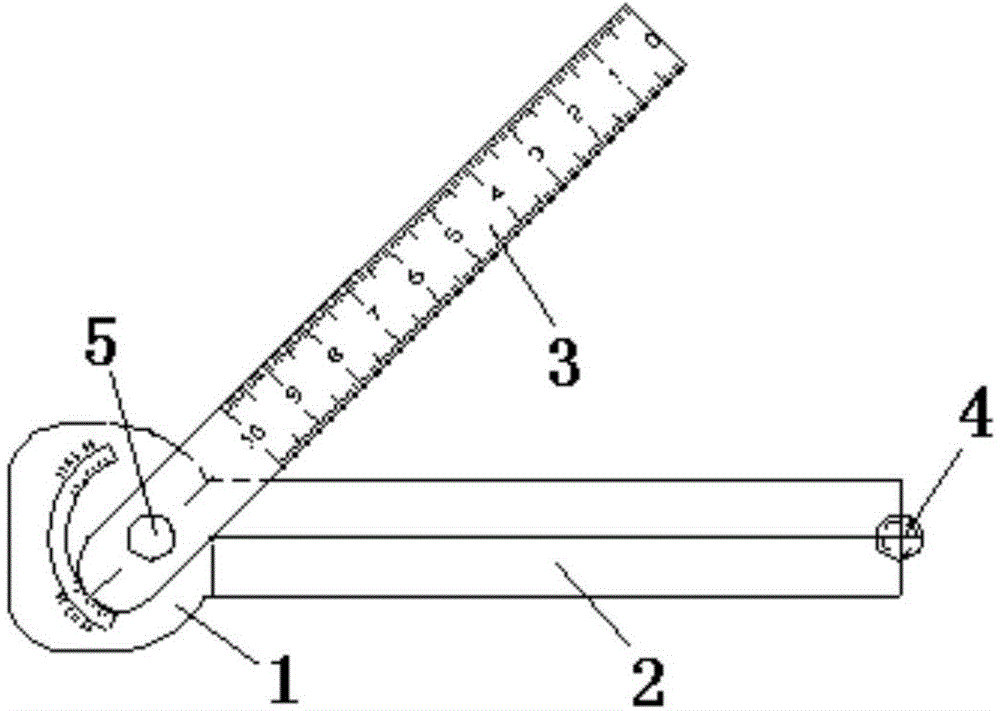

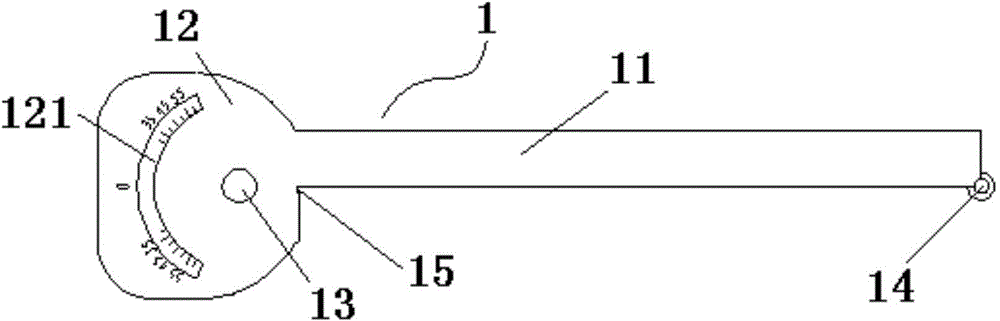

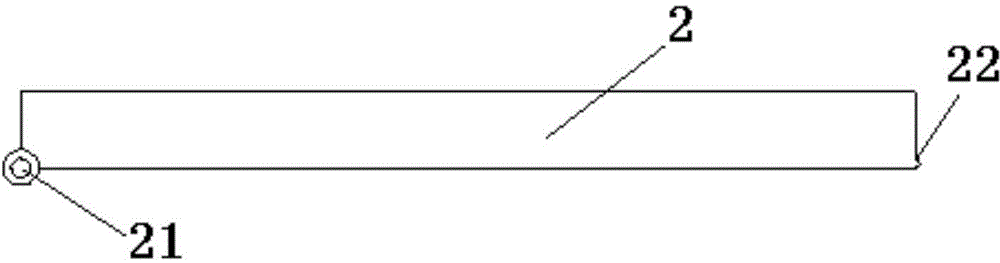

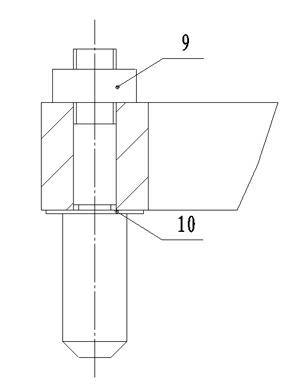

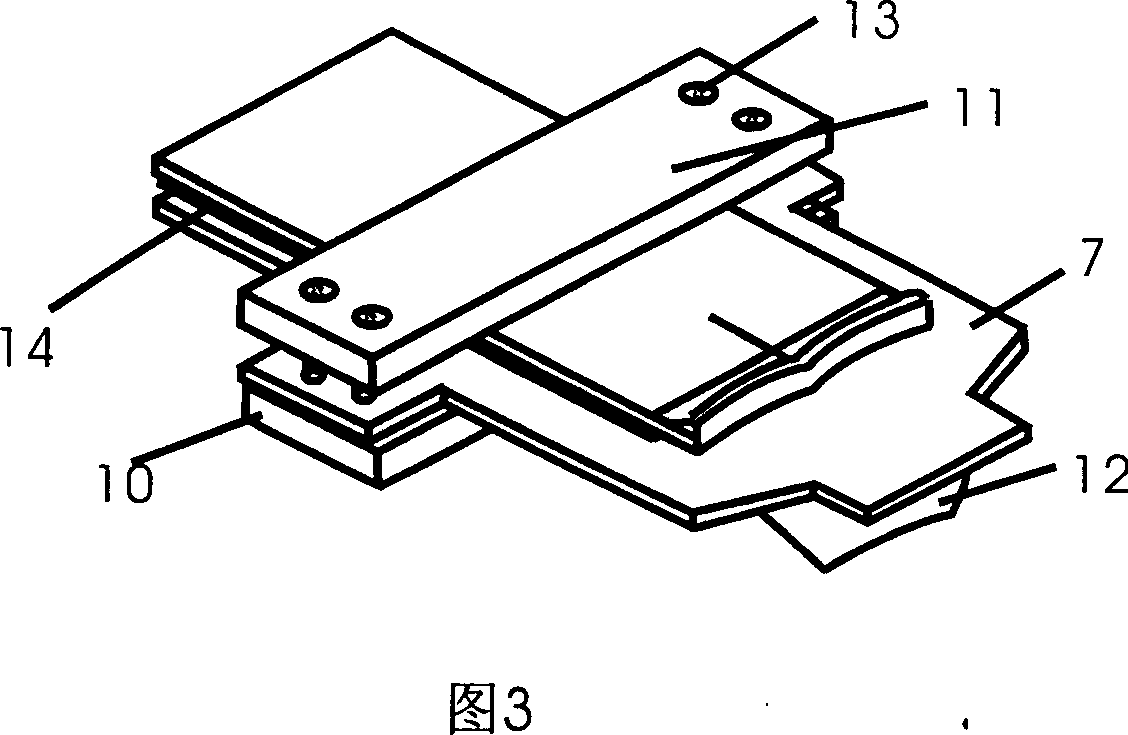

Integrated magnetic particle indication measuring tool and measuring method

InactiveCN104976933AAvoid destructionReduce mistakesAngles/taper measurementsMeasuring rulerStandard ruler

The invention relates to an integrated magnetic particle indication measuring tool and measuring method. The integrated magnetic particle indication measuring tool is characterized by comprising a standard ruler, an auxiliary ruler and a measuring ruler. The standard ruler comprises a straight ruler. One end of the straight ruler is internally provided with an angle measuring plate. The bottom part of the other end of the straight ruler is provided with a fist circular hole. The angle measuring plate is provided with an arc-shaped scale bar. The center of the arc-shaped scale bar is arranged on the axis of the straight ruler. The position of the arc core of the arc-shaped scale bar on the angle measuring plate is provided with a first through hole. The auxiliary ruler has a straight ruler structure. The bottom part of one end of the auxiliary ruler is provided with a second circular hole. The auxiliary ruler is rotatably connected with the standard ruler via a flexible rivet penetrating through the first circular hole and the second circular hole. The measuring ruler has a straight ruler structure. One end of the measuring ruler is provided with a second through hole. The measuring ruler is rotatably connected with the standard ruler via another flexible rivet penetrating through the first through hole and the second through hole The angle measuring plate is arranged on the standard ruler, and one measuring ruler is rotatably connected on the angle measuring plate so that measurement of defect magnetic particle indication direction and length can be performed simultaneously, and determination error and divergence can be reduced.

Owner:CRRC BEIJING ERQI VEHICLE CO LTD

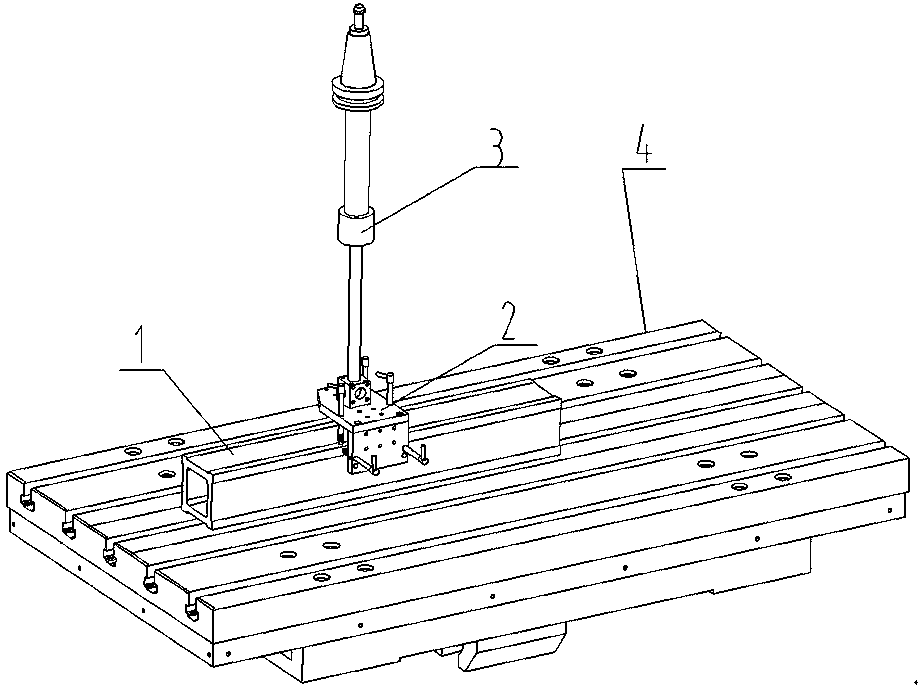

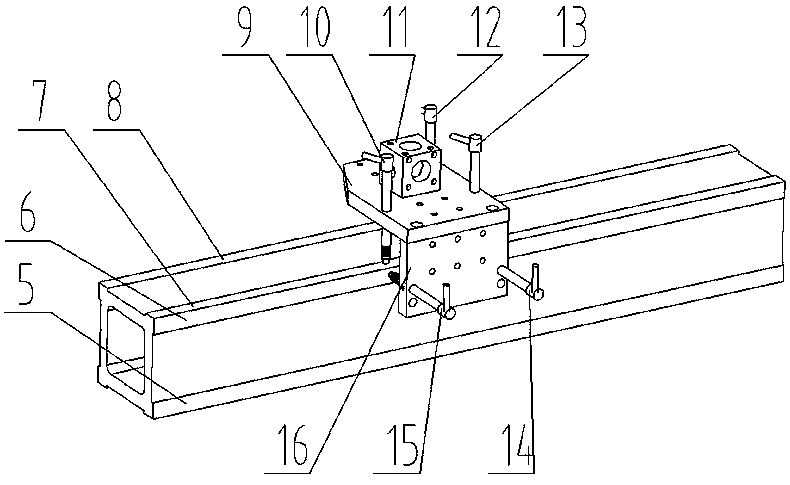

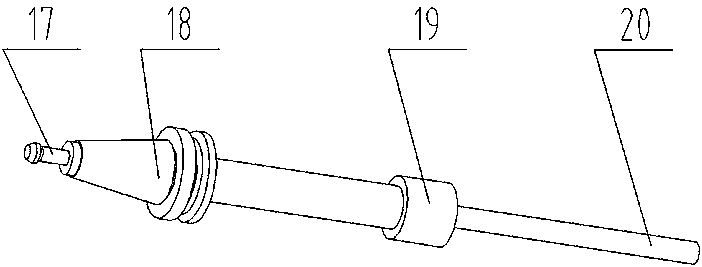

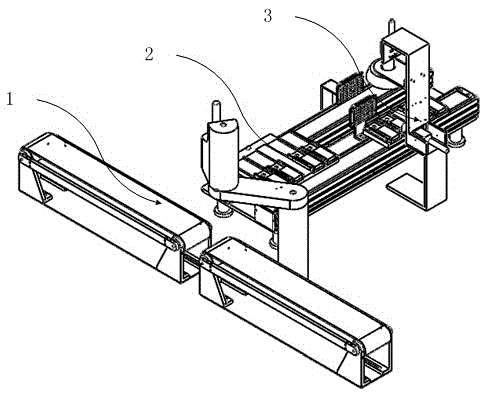

Full-degree-of-freedom precision detecting device of machine tool linear movement running state

ActiveCN108153234ATime-consuming to solve the measurementSolve problems such as complicated measurement processProgramme controlComputer controlLinear motionAngular degrees

The invention discloses a full-degree-of-freedom precision detecting device of a machine tool linear movement running state. The device comprises a standard ruler, a measuring unit and an installing unit, and the device can measure the linear bias and the angle bias of the linear motion shaft state at the same time; the reference ruler provides measurement standard for the full-degree-of-freedom precision measurement in a linear movement running state; the measuring unit can measure the linear bias and the angle bias of the linear movement running state; the installing unit can tightly connectthe measuring unit with the machine tool. The full-degree-of-freedom precision detecting device of a machine tool linear movement running state solves the problems of many time wastes of measurementand complex measurement processes caused by multi-plane separate measurement of linear bias and separate measurement of angle bias, and other problems; the full-degree-of-freedom precision detecting device has the advantages of being high in measuring efficiency, simple in structure, and convenient to install, and the like.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

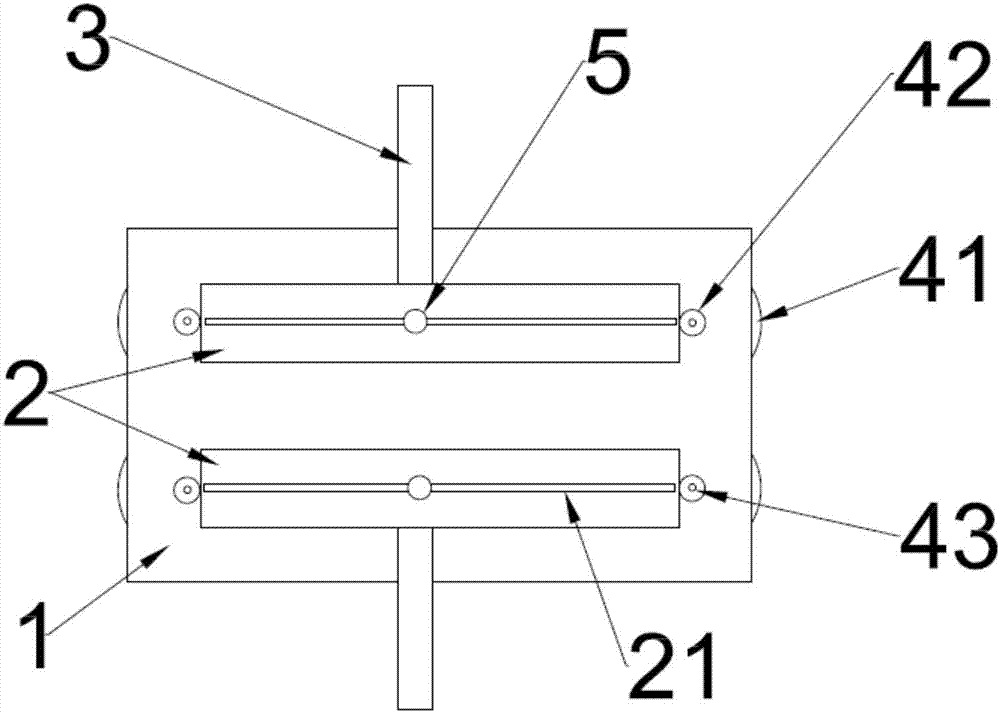

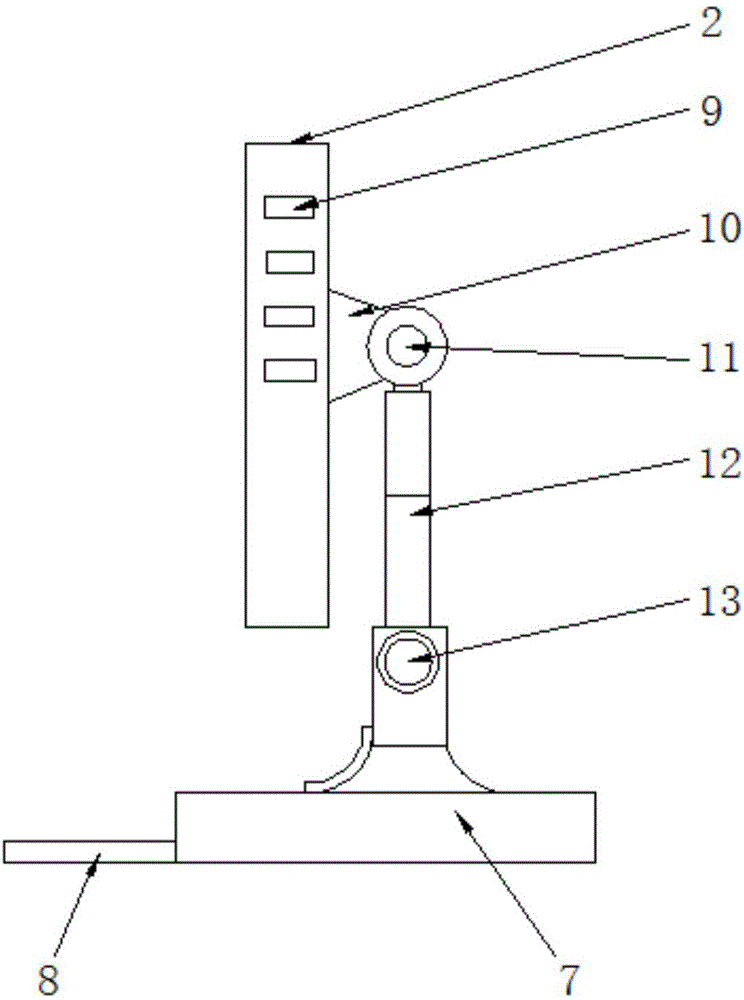

Distance measuring device

The invention discloses a distance measuring device. The device includes a standard ruler base, a lifting platform, standard rulers and a transmission mechanism; one side of the standard ruler base is provided with an installation space, the lifting platform is provided with sliding grooves in the length direction, the wall surface of one side of each sliding groove is provided with a straight-line-shaped guide groove, and two end faces, in the length direction, of the lifting platform are provided with gear grooves, the standard rulers are arranged in the sliding grooves and can move to any positions in the sliding grooves along the sliding grooves, the transmission mechanism includes regulating discs, shafts, bearings and gears, the bearings are arranged on the standard ruler base, the shafts pass through the bearings, one end of each shaft is fixedly connected with the corresponding gear, and the other end of each shaft is fixedly connected with the corresponding regulating disc; the lifting platform can move back and forth under the drive of the transmission mechanism. The device has the advantages that the standard rulers can slide at will in the sliding grooves, when the standard rulers slide to the positions of points needing measurement, a fastening piece is used for fixing the standard rulers to the lifting platform, the regulating disc is rotated so as to move the lifting platform up and down until the two standard rulers are abutted to the thighbone and the shin bone, and the distance between any two corresponding points can be measured.

Owner:苏州奥特科然医疗科技有限公司

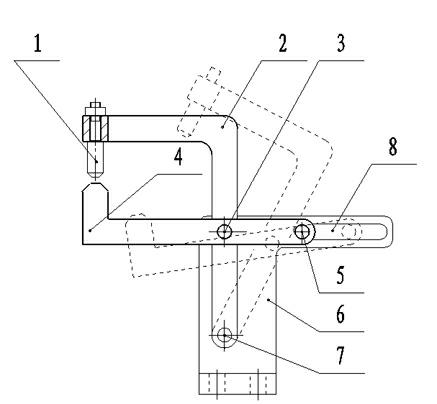

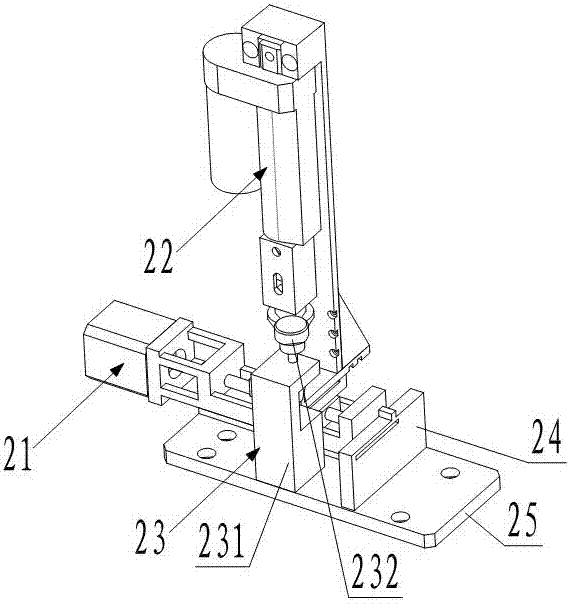

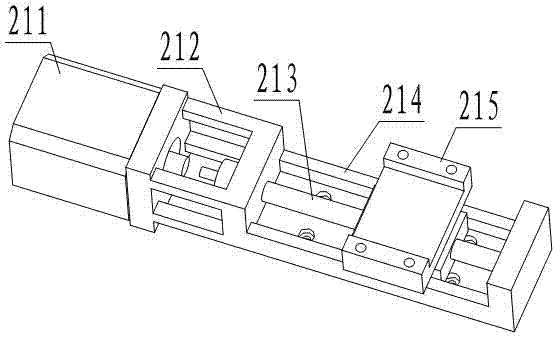

Mechanism for detecting forming accuracy of hot stamped part

The invention discloses a mechanism for detecting the forming accuracy of a hot stamped part. The tensile strength of the hot stamped part is high, so that the high forming accuracy contributes to subsequent welding. When the position accuracy of certain key points on the hot stamped part is detected, the steps of positioning, clamping and measuring are needed; during measurement, the size deviation of a workpiece is detected by a plug gauge so as to judge whether the forming accuracy of the point meets the requirement or not; and when measurement points are more, the method is low in efficiency. The invention discloses a quick detection device suitable for detecting a certain measurement point on the stamped part. Two measurement jaws are used as standard rulers in the device, and the opening-closing state of a loop is measured so as to judge whether a formed part is qualified or not.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

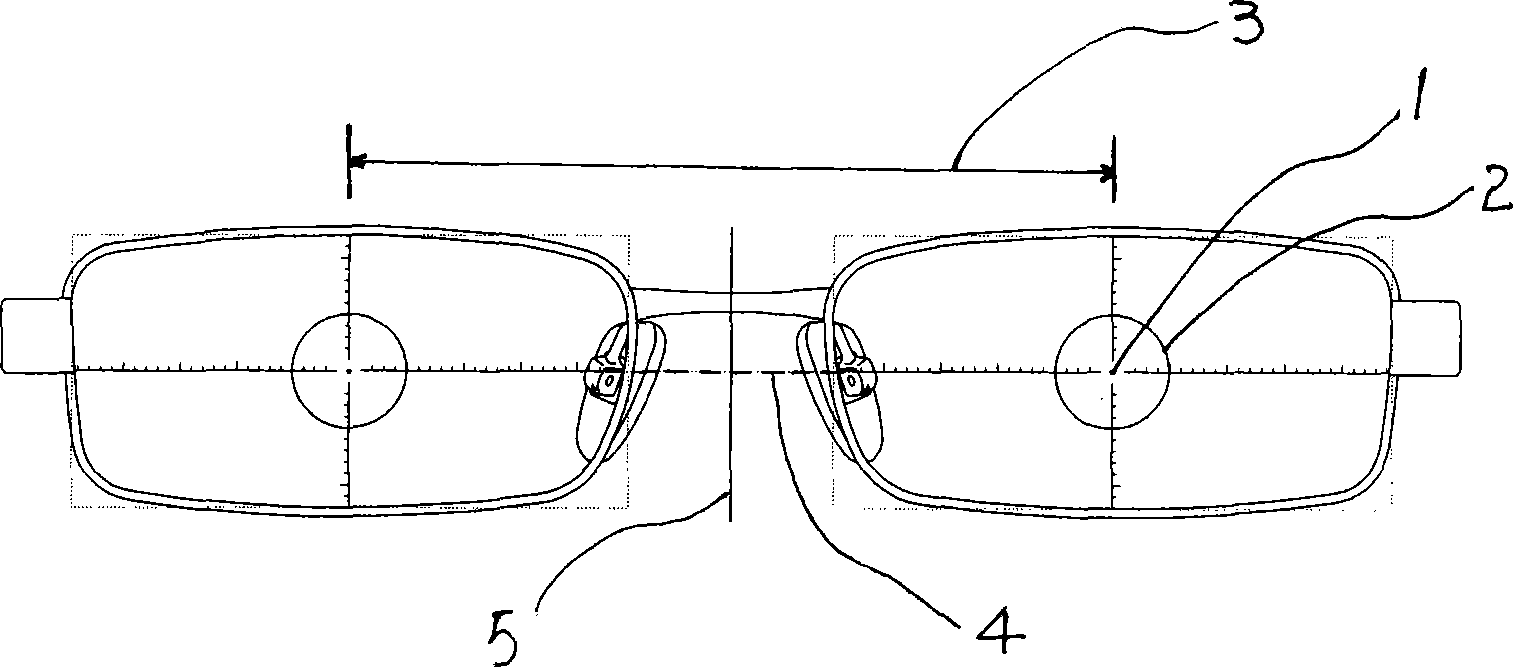

Computer network spectacles matching system

InactiveCN101441752AImprove accuracyOptional operation is convenient2D-image generationEye diagnosticsMethod selectionDisplay device

The invention relates to a glasses prescription system of a computer network. The glasses prescription system comprises a data processing center which is suitable for a user to enter through a public communication network and is selectively reflected on a display device of a user terminal and an uploading platform connected with the data processing center; the data processing center comprises a glasses frame database, a standard ruler, a portrait picture processing center and a matching selection system; a terminal user uploads portrait data; after a benchmark point is determined on a portrait of the display device, a portrait picture is processed through the portrait picture processing center to meet the specification standardized by the standard ruler and is displayed on the display device of the user terminal; and the terminal user selects a glasses frame through the matching selection system and tries in the glasses frame. The glasses prescription system overcomes the disadvantages that the prior glasses prescription method has small selection range and wastes more time; through the design, a merchant can carry out glasses prescription according to the portrait picture and accurate relevant data provided by a client; and the glasses prescription system has the advantages of convenient operation of selection and prescription and high accuracy of glasses prescription.

Owner:陈艳阳

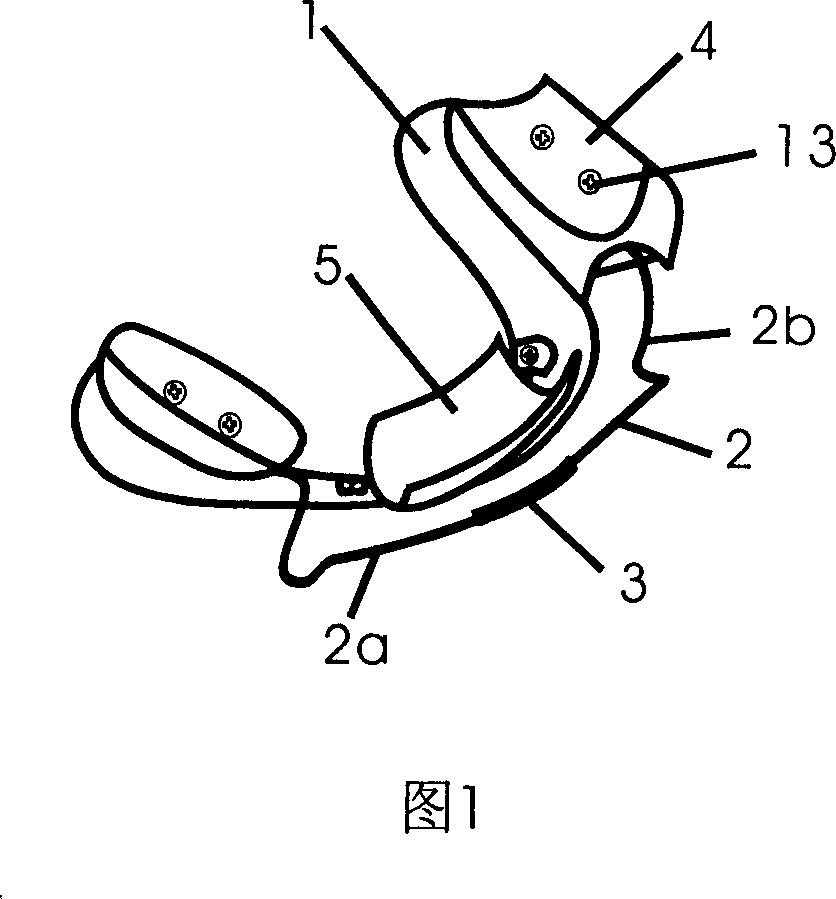

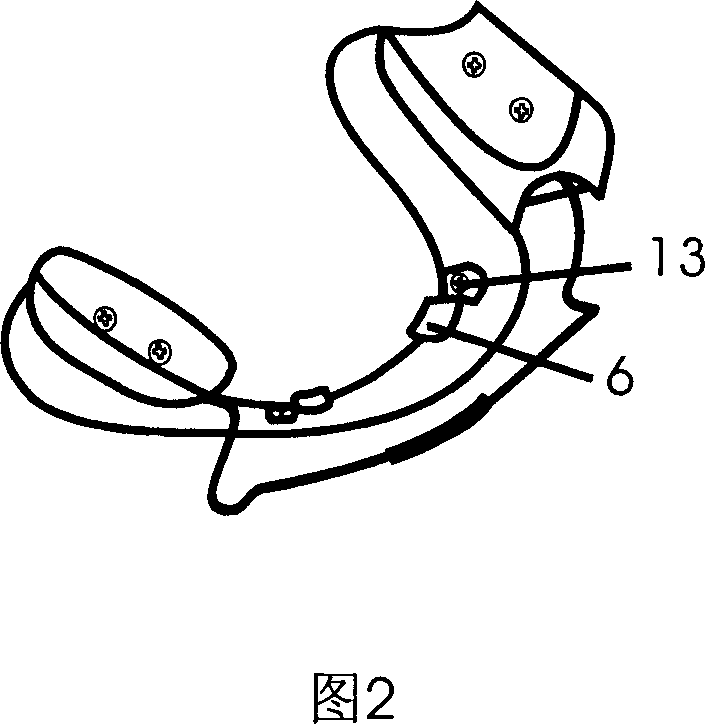

Oral cavity function orthopetical device and its mounting process

The invention relates to a mouse corrector, which comprises corrector and positioning ruler. Wherein, the corrector comprises base support, band ring, left and right pads, upper protective pad and positioning ruler support; the band ring is at the front of base support whose two ends are fixed on the base support; the band ring is formed by two half rings to be connected by muffle to extend; the left and right pads are mounted at left and right of base support, with adjustable left and right positions, to form clamping with the front protective pad; the positioning ruler support is fixed between left and right pads at the back of base support; the positioning ruler comprises connecting bridge, lower cross standard ruler, upper cross ruler, lower compressing bar, upper compressing bar; the connecting bridge is between lower cross standard ruler and upper cross ruler, to be fixed with lower and upper compressing bars; the front of connecting bridge has insert plate inserted into the positioning ruler support; the lower cross standard ruler has cross scale line; the upper cross ruler has cross line without scale; the connecting bridge, lower cross standard ruler and upper cross ruler are made from transparent materials.

Owner:卢崇伟

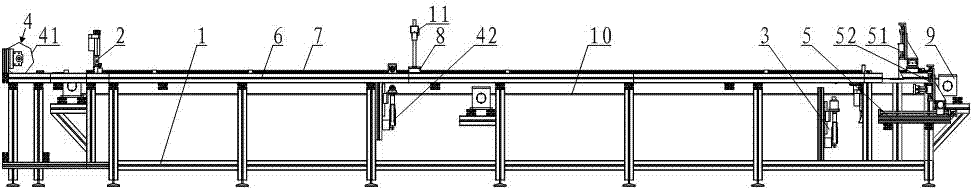

Steel tape automatic verification system

The invention discloses an automatic verification system for a steel tape, comprising a horizontal horizontal support, a zero alignment device, a tension loading and unloading device and a camera, wherein the zero alignment device, the tension loading and unloading device and the camera are all arranged on the horizontal horizontal support superior. The zero alignment device includes a precision displacement table, a clamping mechanism for the tested scale and a clamping mechanism for the standard scale. The tension loading and unloading device includes the clamping mechanism of the checked ruler and the loading mechanism that drives the clamping mechanism of the checked ruler to move rightward to apply the rated tension force to the checked ruler. The invention also discloses a verification method of the automatic verification system for the steel tape measure. When the verification system of the present invention is applied, it is convenient to realize loading and unloading of steel tape tension force and zero alignment during the verification process, can reduce labor intensity, and can improve work efficiency and measurement accuracy.

Owner:成都市计量检定测试院

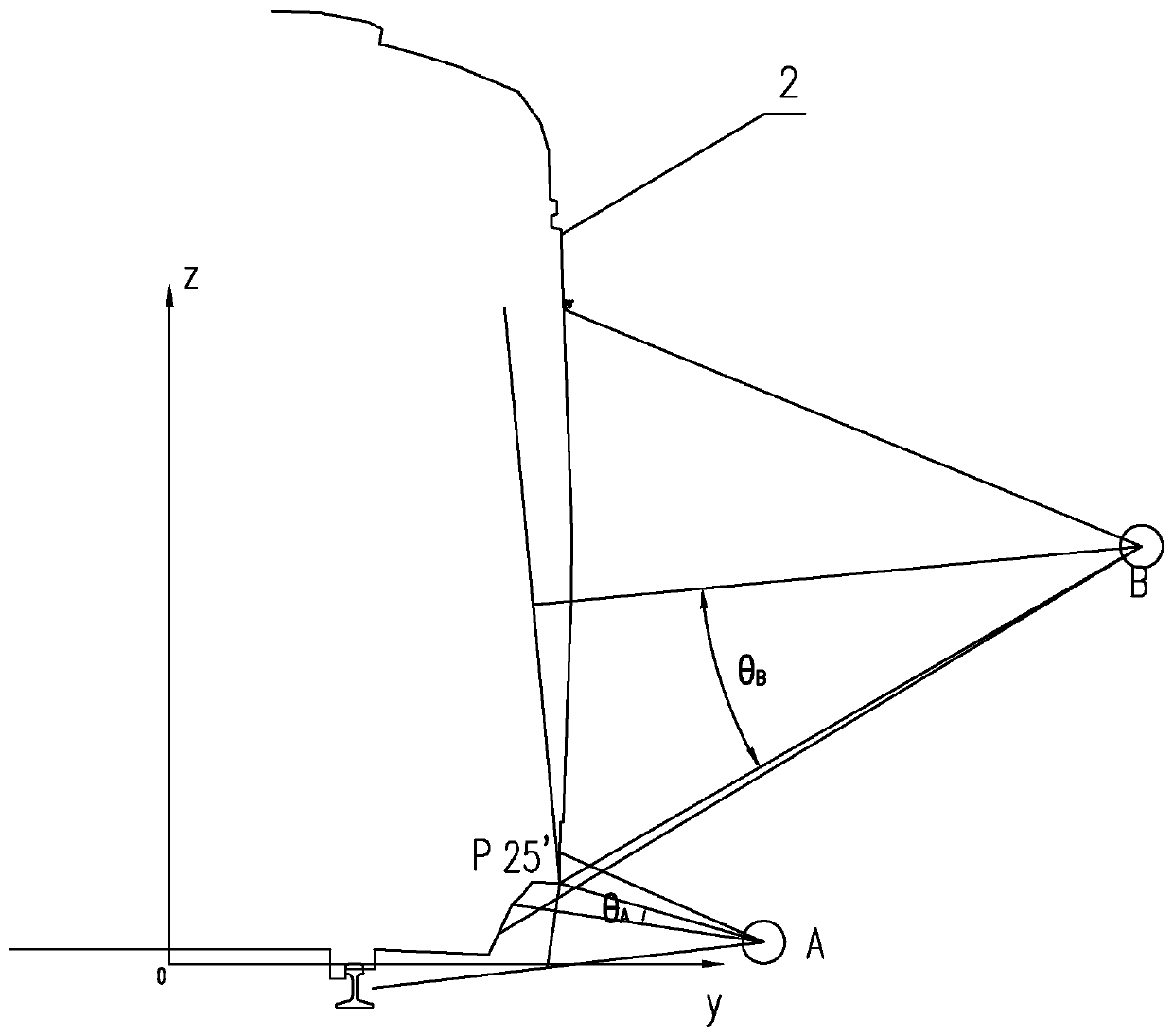

Deformation compensating method of forging die

ActiveCN108044012AImprove manufacturing precisionForging/hammering/pressing machinesUsing optical meansEngineeringStandard ruler

The invention relates to a deformation compensating method of a forging die. The deformation compensating method of the forging die comprises the steps of setting at least two observation identification points on a side face of a die, setting a camera at a preset distance far away from the die, enabling the observation identification points to be located in a shooting range of the camera, and setting a standard ruler within the shooting range of the camera; compounding the die without a load, and using the camera for shooting the observation identification points to obtain initial photos; compounding the die with pressure, maintaining pressure for a preset time, and using the camera for shooting the observation identification points to obtain deformed photos; and entering the initial photos and the deformed photos into a computer, identifying, measuring and calculating a change value of a distance between each two adjacent observation identification points through the computer by comparing with the standard ruler, further obtaining the deformation of the die, and compensating and adding the deformation of the die into extrusion stroke parameters of a forging machine, so that the manufacturing accuracy of a die forging piece can be improved.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND +1

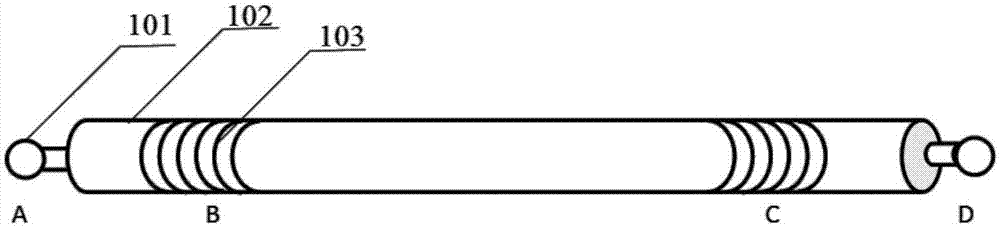

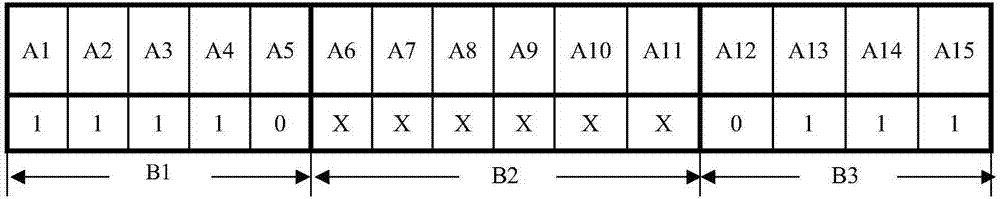

All-angle imaging standard ruler

ActiveCN107131889AImplement reflectionRealization of full-angle imagingUsing optical meansBarcodeAngular degrees

The invention discloses an all-angle imaging standard ruler which comprises a body, standard length endpoints and a standard ruler identification encoding. The standard length endpoints are spherical mark points coated with self-reflective materials, arranged at the front end and the tail end of the body and fixedly connected with the body, the standard ruler identification encoding is provided with a one-dimensional bar code, and the one-dimensional bar code is longitudinally lengthened and winds the body of the standard ruler in a 360-degree manner. According to the all-angle imaging standard ruler, all-angle reflection of incident light is achieved by the aid of spherical self-reflective mark points, the encoding is provided with the one-dimensional bar code, and the one-dimensional bar code is longitudinally lengthened and winds the body of the standard ruler in a 360-degree manner, so that all-angle imaging and bar encoding identification are achieved. According to the all-angle imaging standard ruler, all-angle imaging of the standard ruler is achieved in measurement space.

Owner:BEIJING INFORMATION SCI & TECH UNIV

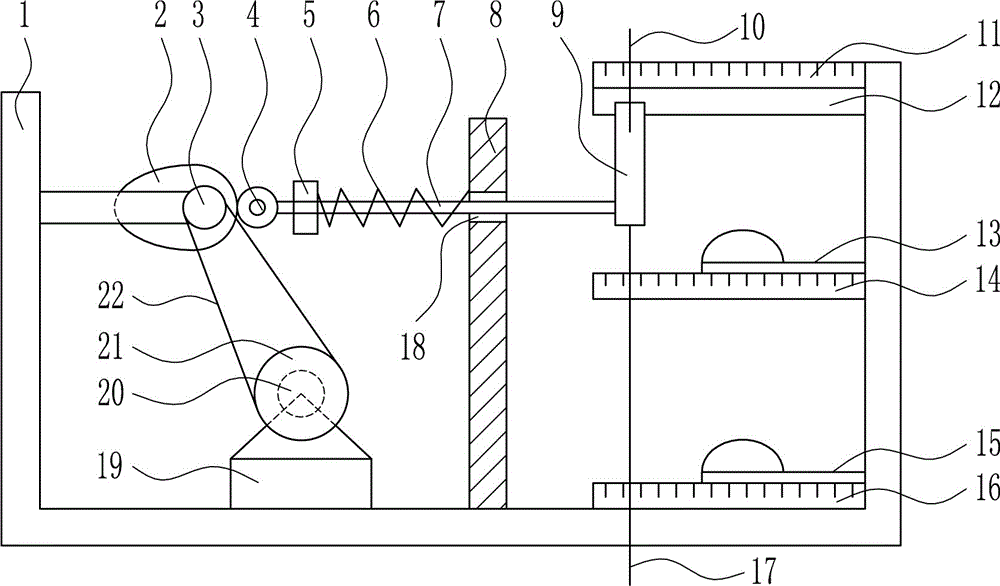

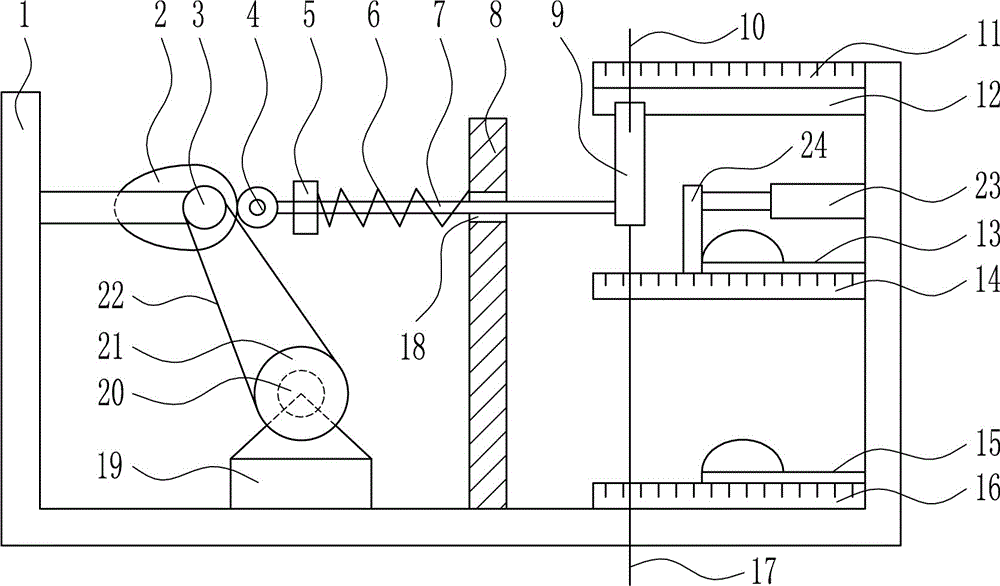

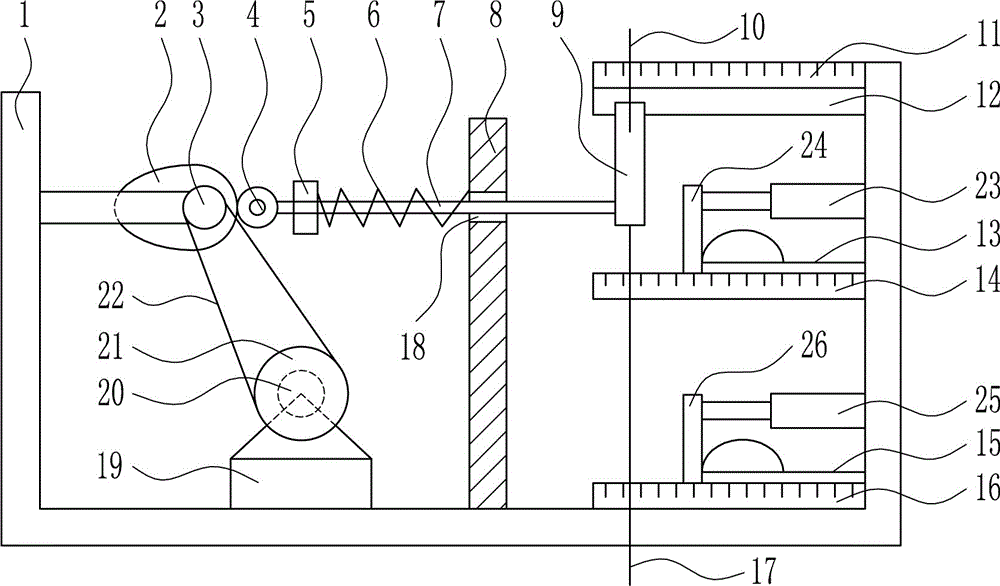

Reliable shoe size detection device

InactiveCN106108253AEasy to observe and readAccurate size detection resultsFoot measurement devicesEngineeringCam

The invention relates to a size detection device, in particular to a reliable shoe size detection device and aims to achieve the technical purpose of providing the reliable shoe size detection device with detection results being precise. To achieve the technical purpose, the reliable shoe size detection device is provided and comprises a support, a cam, a small belt pulley, a contact wheel, a fixing block, a spring, a lifting rod, a guiding plate, a sliding block, a standard rod, a standard ruler, a sliding rail, a first ruler, a second ruler, a measuring rod, a connection base, a motor, a large belt pulley and a flat belt. The guiding plate and the connection base are arranged on the inner bottom of the support, the guiding plate is located on the right of the connection base, a guiding hole is formed in the guiding plate, and a motor is arranged on the connection base. The size detection device achieves the effects that the detection results are precise, the detection time is short, and detection operation is easy.

Owner:刘小波

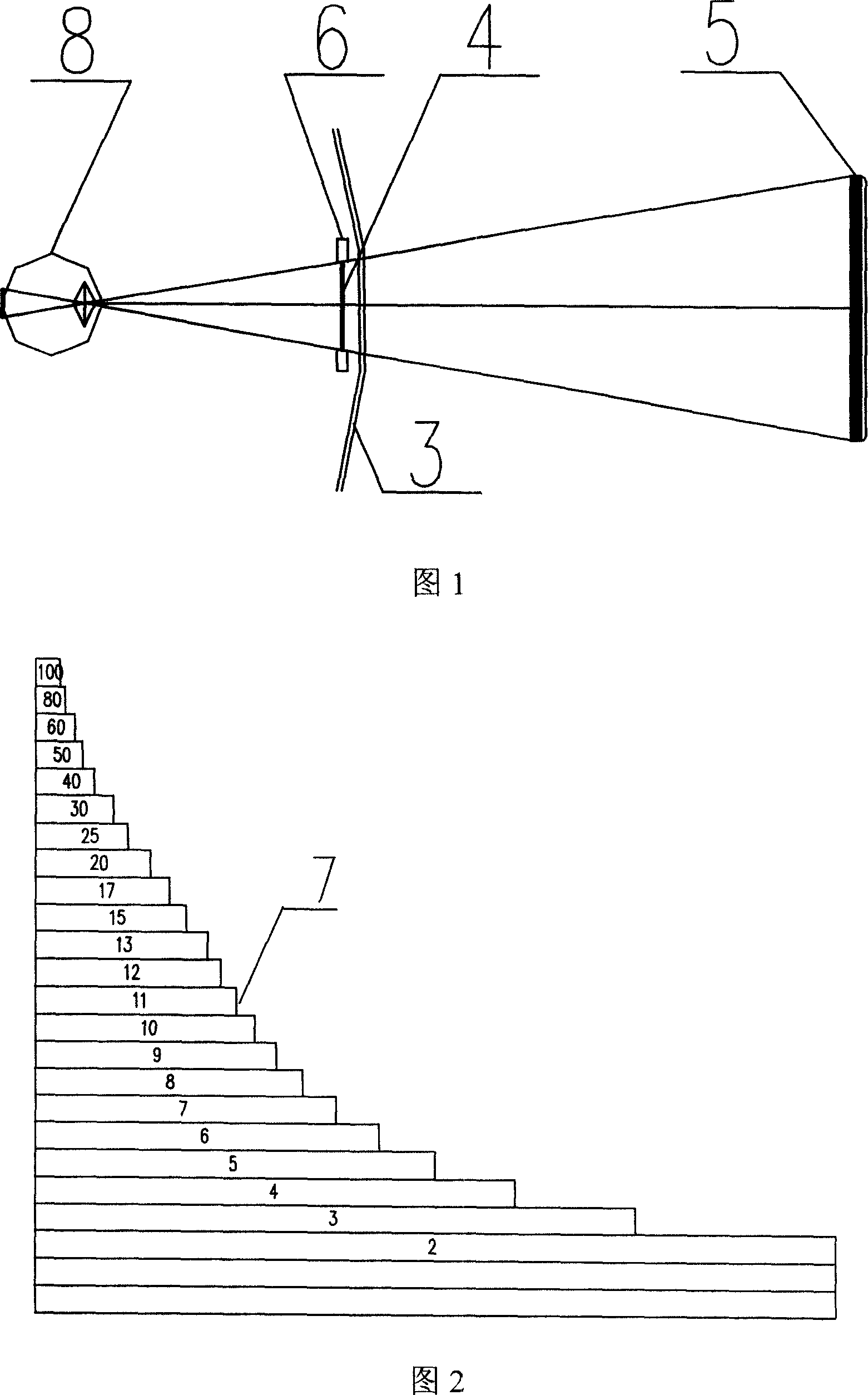

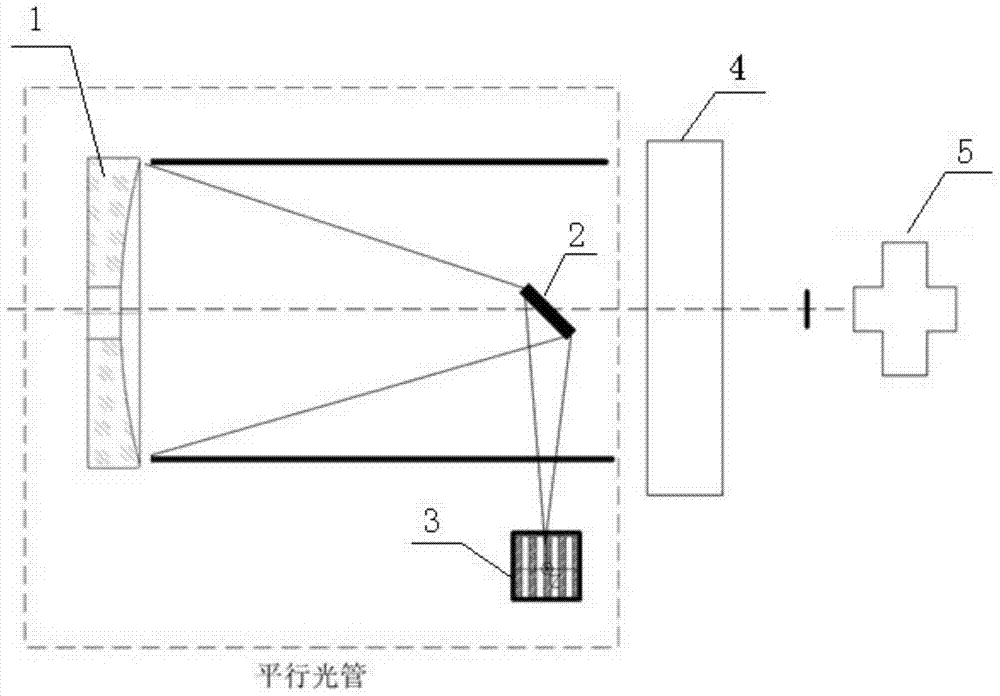

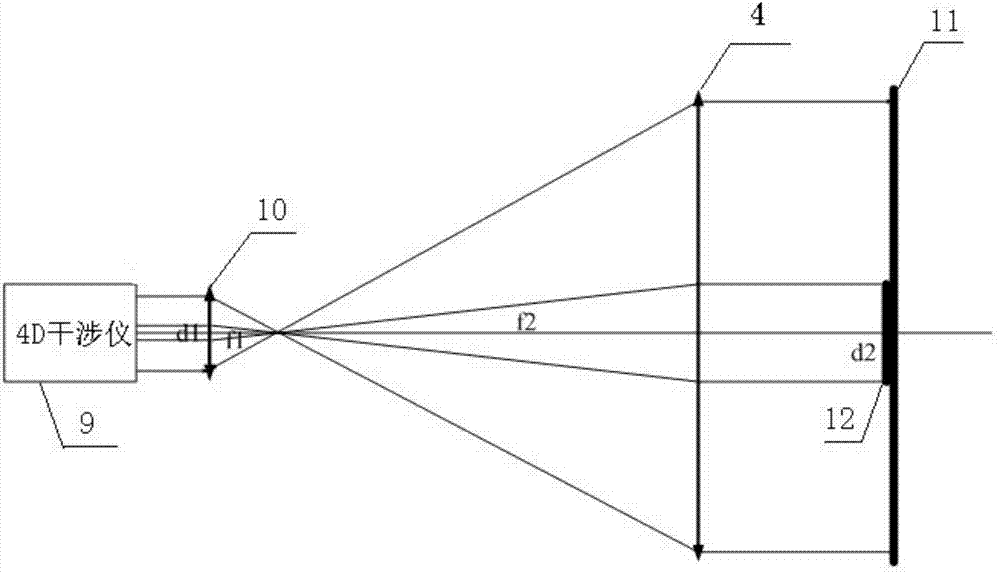

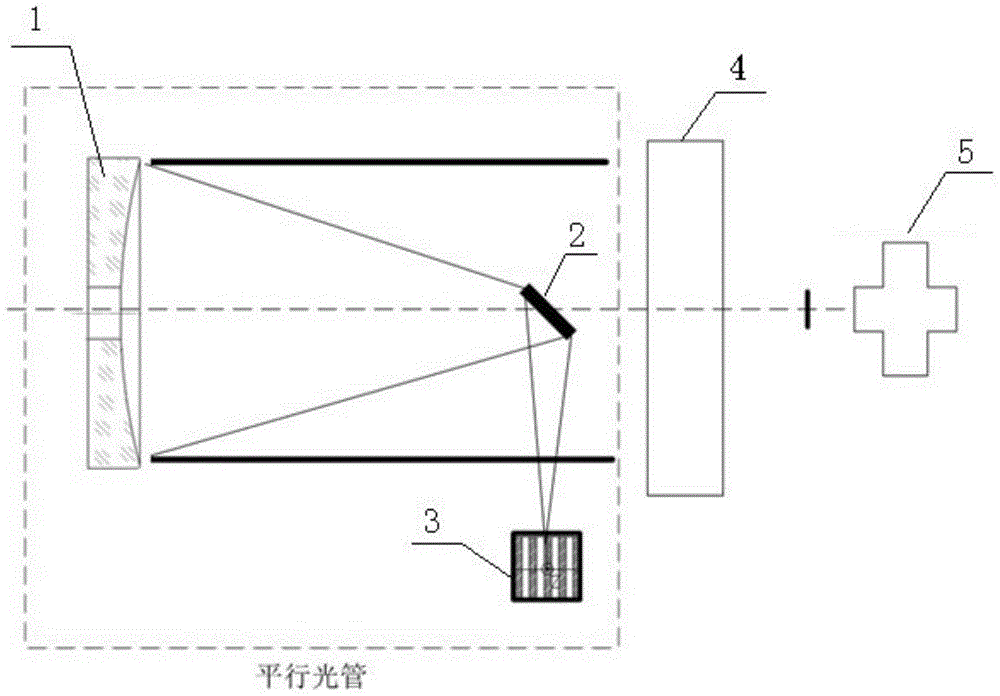

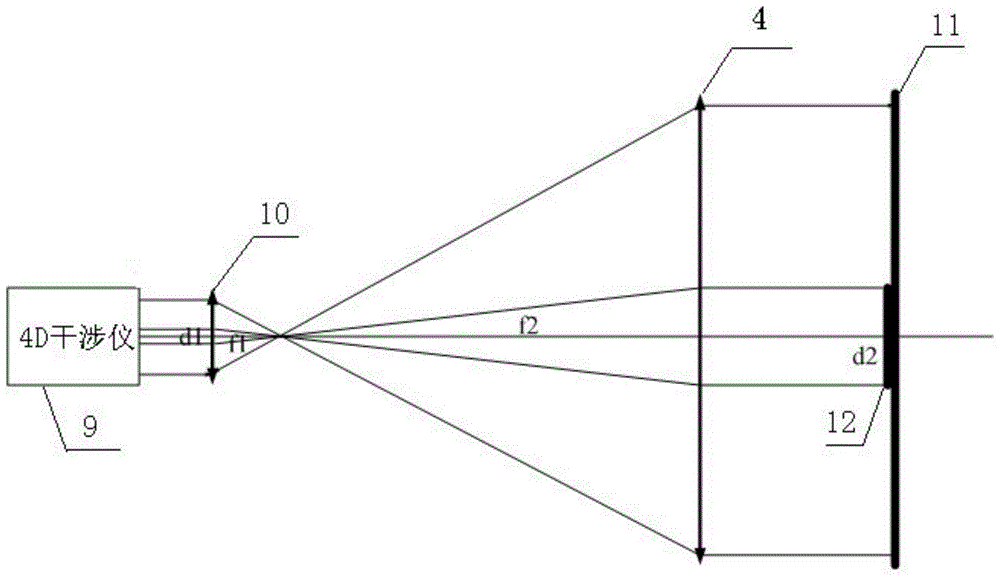

Method for precisely measuring focal distance of superlong-focal-distance space camera

ActiveCN104515671AWide focal length coverageShorten the timeTesting optical propertiesFour quadrantsPlane mirror

The invention discloses a method for precisely measuring focal distance of a superlong-focal-distance space camera, relates to the technical field of optical measuring methods and solves the problem that an existing method for measuring the focal distance of a long-focal-distance space camera is low in measuring accuracy, high in expense needed by supporting equipment and the like. The method includes adopting a spherometer to measure curvature of a spherical standard lens of an interferometer, adopting a mirror surface locator to measure lens thickness of the standard lens, and calculating focal distance of the spherical standard lens of the interferometer according to the curvature radius and the lens thickness which are acquired; adopting the mirror surface locator to measure length of a standard ruler, and placing the standard ruler after length measuring on a two-dimensional adjusting platform; placing the measured camera, a plane mirror and the standard ruler in front of the interferometer, performing coarse adjusting, and performing precise adjusting on the plane mirror; enabling an interferogram of the measured camera to image on a detector of the interferometer; adopting a four-quadrant analysis method to calculate an image on the detector, and acquiring length of an image of the standard ruler; acquiring the focal distance of the measured camera according to the focal distance of the dry standard lens, the length of the standard ruler and the length of the image of the standard ruler.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

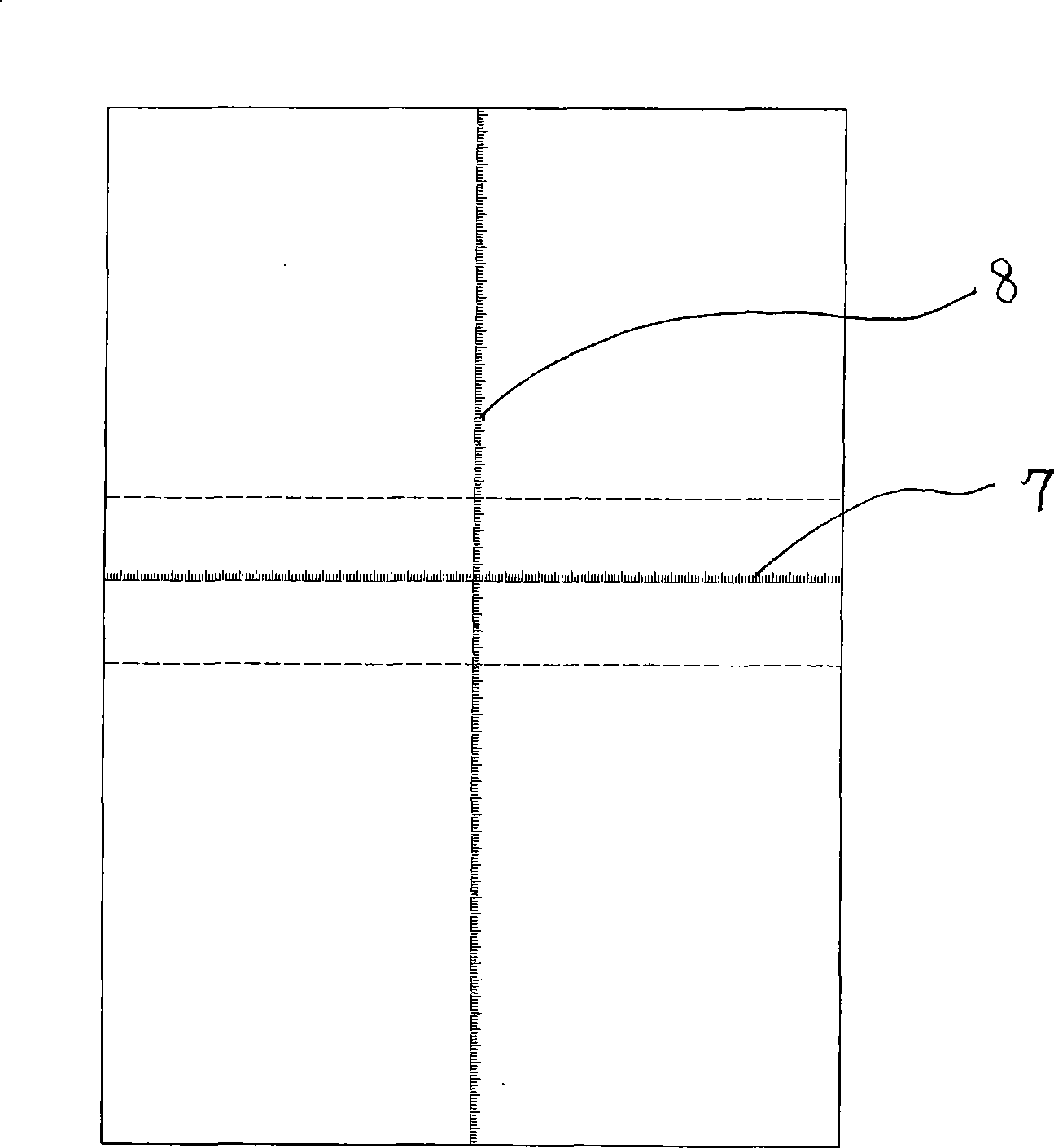

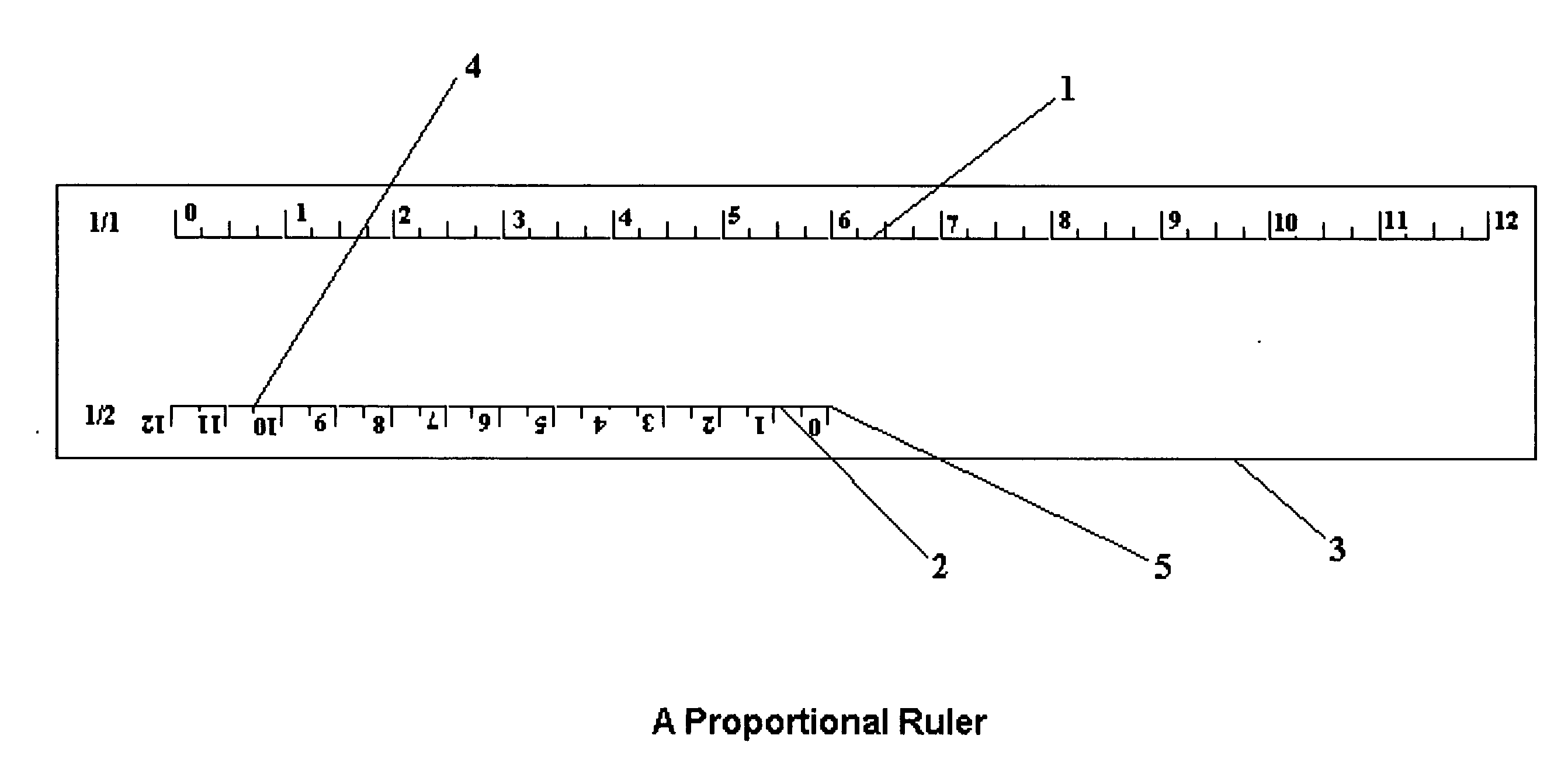

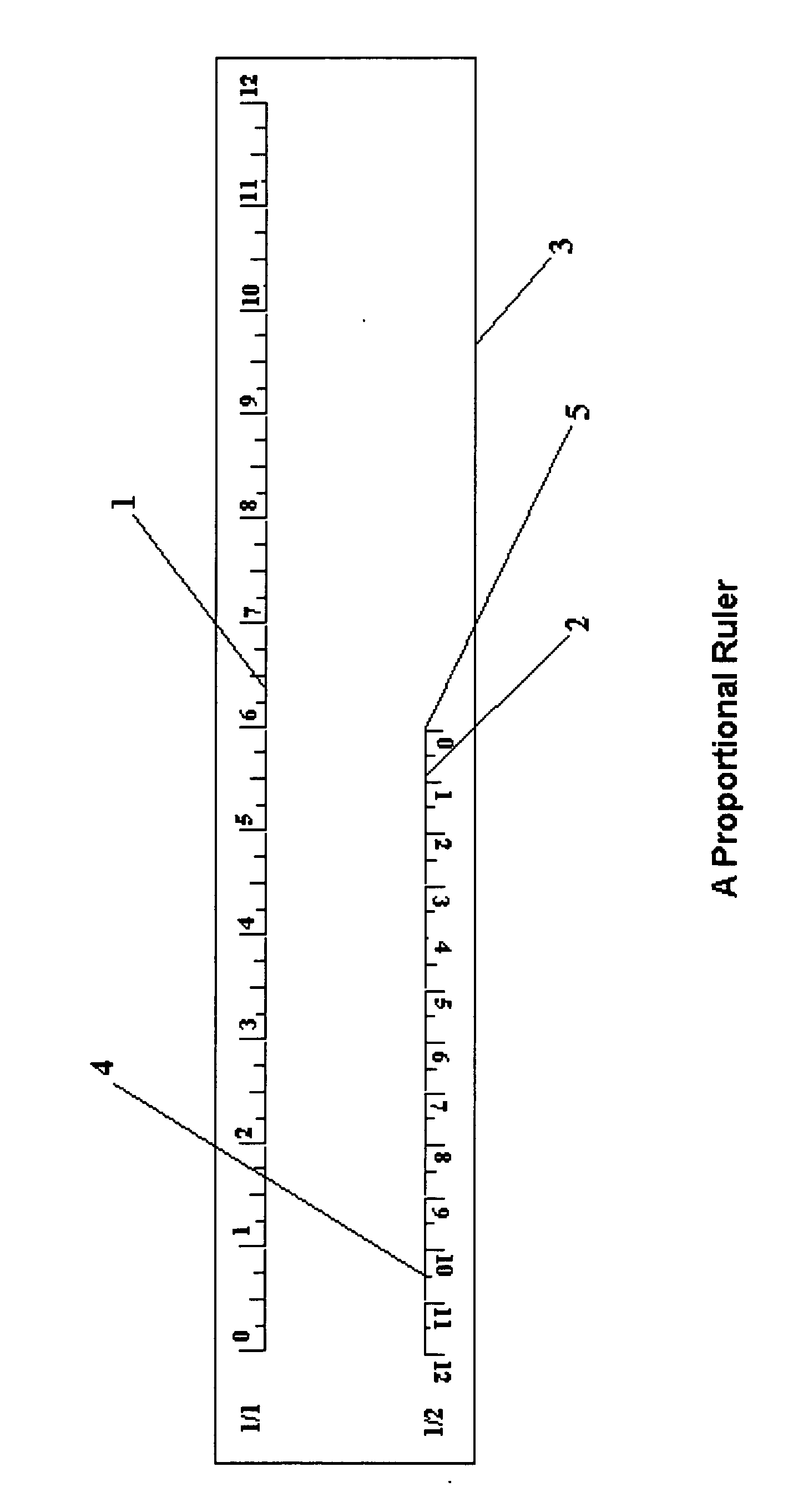

Proportional ruler

InactiveUS20080022541A1Reduce the necessary timeReduce the possibilityOptical rangefindersStraightedgesComputer scienceStandard ruler

A proportional ruler for dividing a length into equal parts or converting a given length into a proportional length comprises a standard ruler scale and proportional scales with specific proportional coefficients. While a standard ruler scale gives a reading of actual length of an object, proportional scales will give a length equal to the actual length over the proportional coefficient. If a proportional coefficient is a whole number, the scale can be used as a divider to divide a length into the whole number of equal parts.

Owner:LU GUIXIAN +1

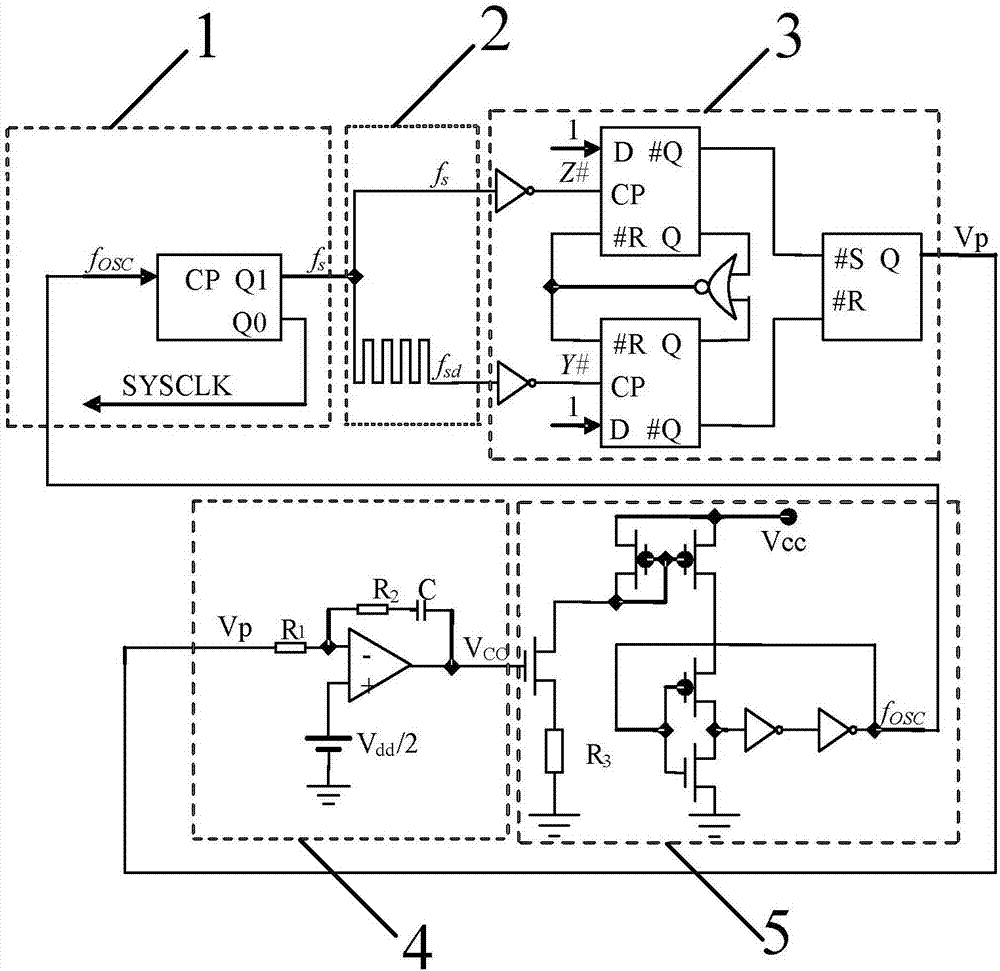

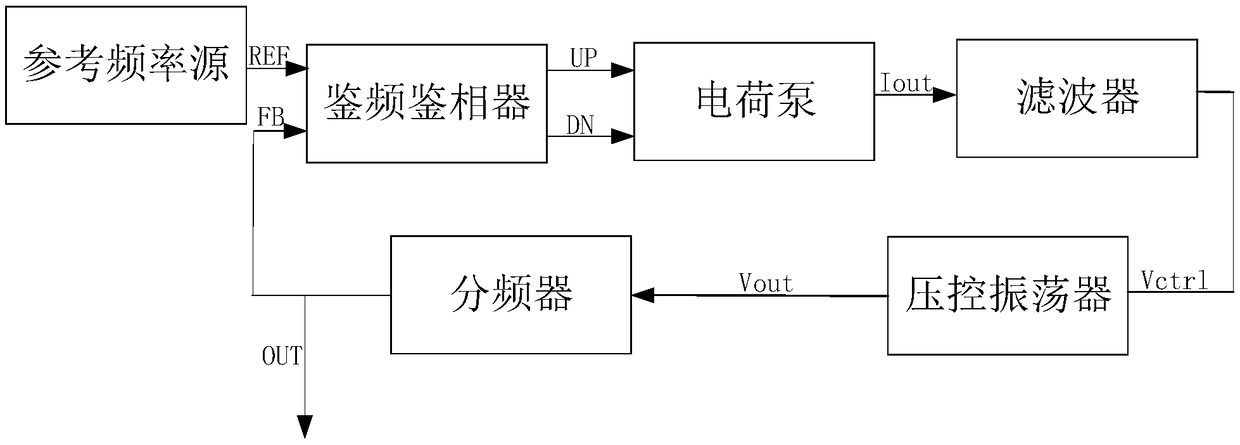

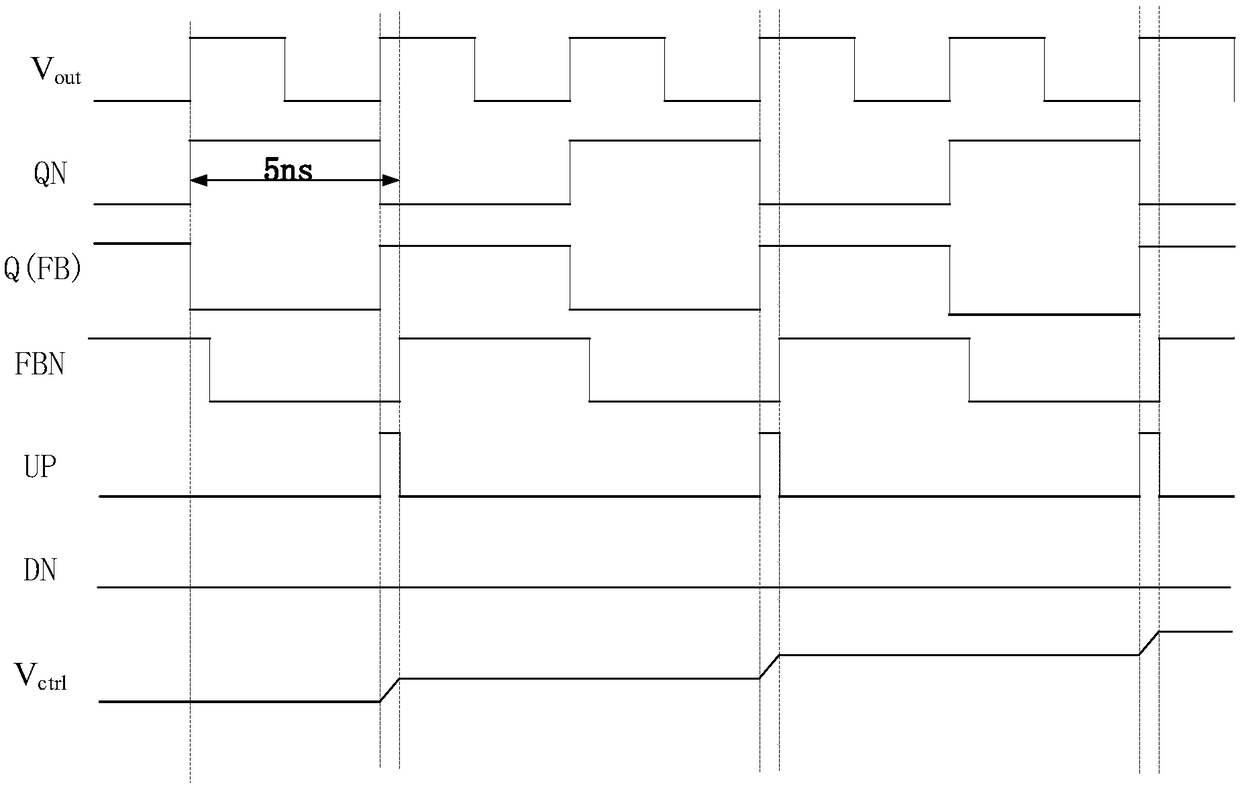

Timing device built based on standard ruler and permanent principle of light velocity

ActiveCN106933090AHigh precisionAdaptability to wide environmentApparatus using electrochemical resonatorsDiscriminatorTime delays

The invention provides a timing device built based on a standard ruler and a permanent principle of light velocity, which is high in precision, high in stability, relatively small in size, light in weight and low in cost and belongs to the field of clocks. The timing device comprises a frequency divider, the standard ruler, a phase discriminator and a voltage-controlled oscillator, wherein a pulse signal output by the voltage-controlled oscillator is input into the frequency divider and the frequency divider outputs a two-sub-frequency clock signal and a four-sub-frequency square wave signal; the square wave signal is divided into two paths, one path is a direct signal, the other path is a time delay signal output by the standard ruler, and a stable time difference exists between the direct signal and the time delay signal; the direct signal and the time delay signal reach the phase discriminator for period and phase detection separately; a detection deviation signal output by the phase discriminator is input into the voltage-controlled oscillator, and the period and the phase of a pulse signal output by the voltage-controlled oscillator are regulated and controlled to achieve negative feedback control; and the standard ruler is a transmission line with a standard length and a stable time delay. The standard ruler is made of an invar alloy of which the thermal expansion coefficient is zero or the thermal expansion coefficient is positive and negative complementary.

Owner:HARBIN INST OF TECH

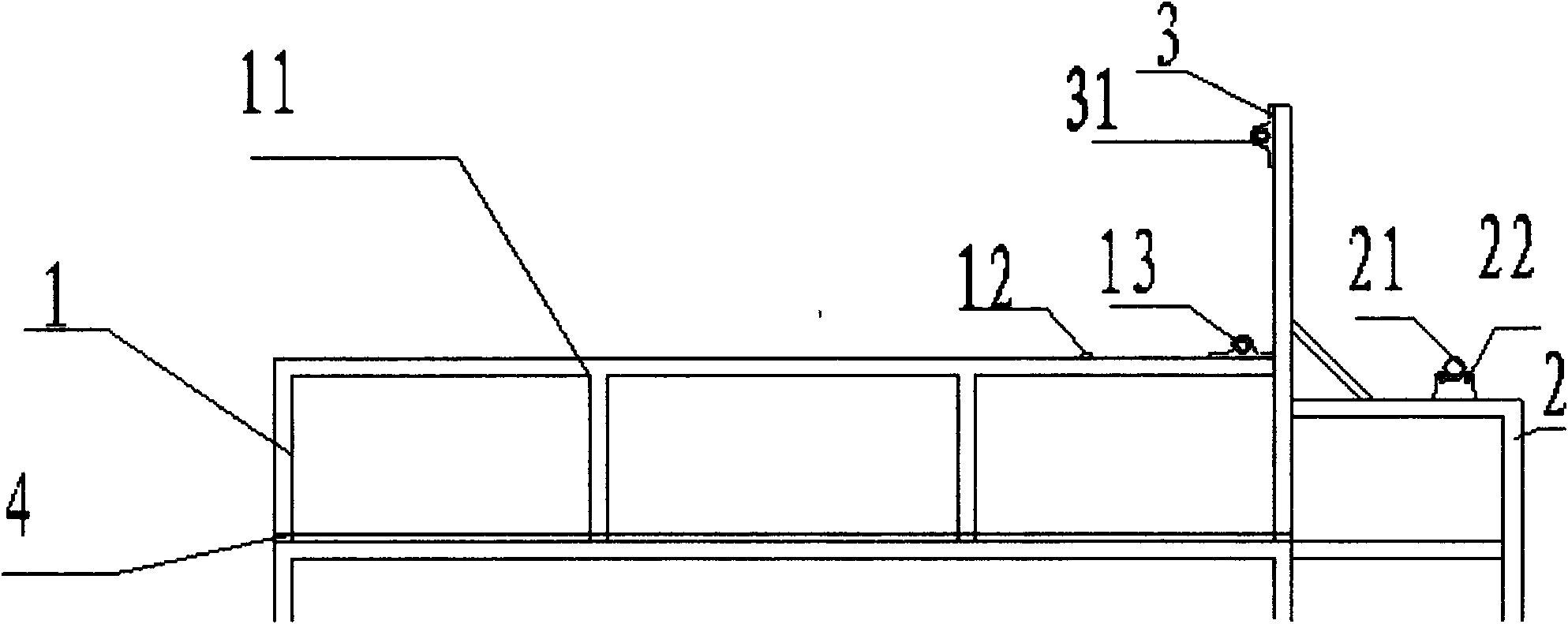

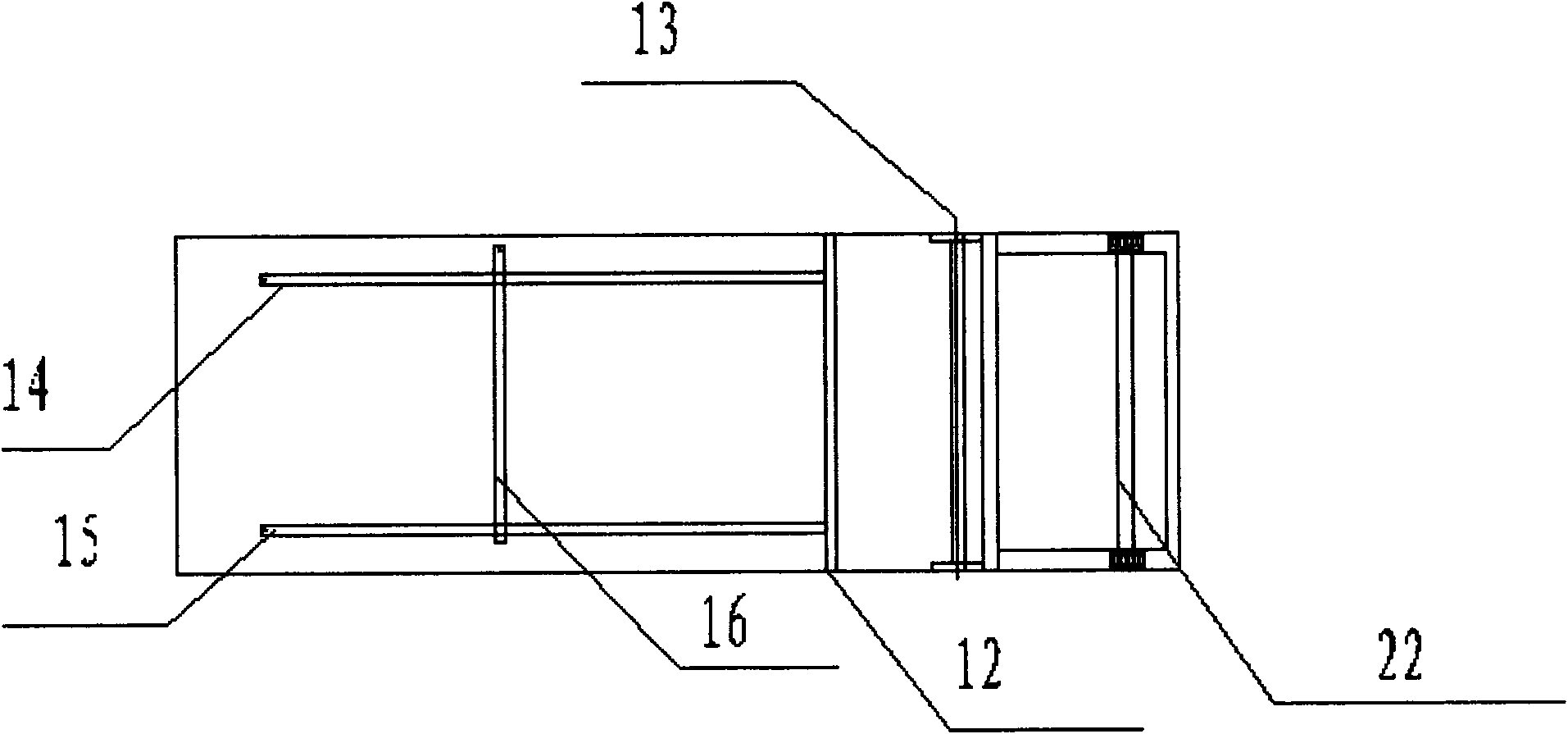

Manual cutting operating platform

InactiveCN102672745ASolve the problem that it is laborious to lift the back film and it is easy to cut crookedlyReduce wasteMetal working apparatusEngineeringStandard ruler

The invention discloses a manual cutting operating platform which comprises a first operating platform and a second operating platform. The first operating platform and the second operating platform are separated through a separation plate vertical to operating platform bodies, a first operating platform body is composed of a desktop, a cutting module, a rolling clamping roller, two mutually-parallel steel rulers and a standard ruler, the steel rulers and the standard ruler are arranged on the desktop in a shape of an I, the standard ruler is arranged on the two steel rulers in a spanned mode, the rolling clamping roller is fixedly arranged between the standard ruler and the separation plate, the second operating platform is mainly composed of a support pipe and a bearing, the support pipe is arranged on the bearing, and the other rolling clamping roller is arranged on one face of the separation plate facing the upper end of one face of the first operating platform. The manual cutting operating platform has the advantages of being simple in structure, convenient to operate and high in cutting accuracy, saves labor, and has irreplaceable effects on improving cutting rate, accuracy rate and work efficiency.

Owner:JUNFENG SOLAR ENERGY JIANGSU

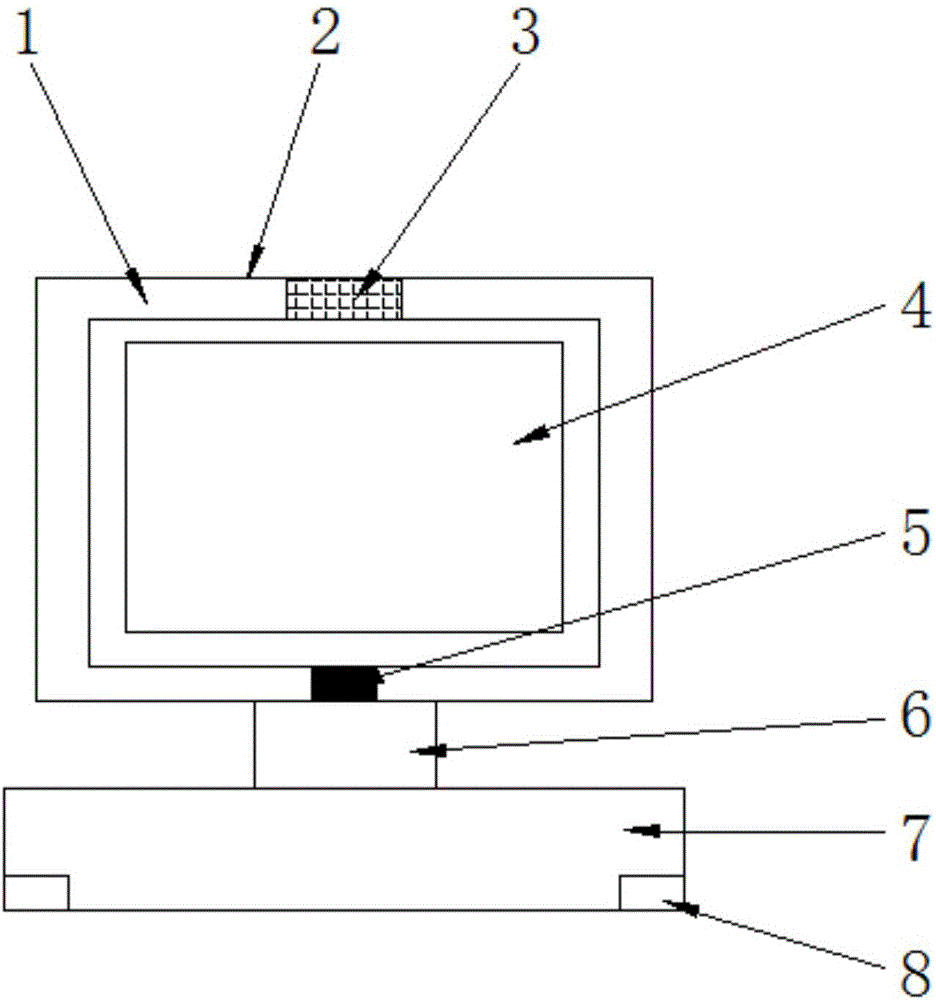

Anti-radiation computer display

The invention discloses an anti-radiation computer display. The anti-radiation computer display comprises a circulating pipe, a display screen frame, a miniature refrigerating device, a display screen, a miniature pressure device, a supporting shaft, a base, a standard ruler, a plurality of control buttons, a connection device, a rotary shaft, a connecting rod and a fixed rotary knob. The standard ruler is arranged on the base, and the supporting shaft is arranged at the upper end of the base and fixedly connected with the connecting rod through the fixed rotary knob; the connecting rod is fixedly connected with the connection device through the rotary shaft; the left end of the connection device is fixedly provided with the display screen frame; the control buttons are arranged on the side face of the display screen frame; the circulating pipe is arranged around the display screen; the miniature refrigerating device is fixedly arranged in the upper end of the circulating pipe; the miniature pressure device is fixedly arranged in the lower end of the circulating pipe; the display screen is arranged on the inner side of the display screen frame. The anti-radiation computer display has the advantages of being capable of reducing the harm of radiation to the human body and convenient and comfortable to use.

Owner:LIUZHOU HUANSHAN TECH

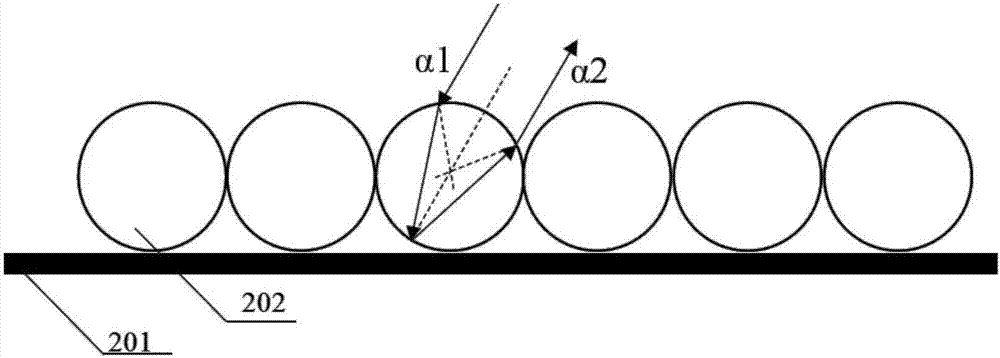

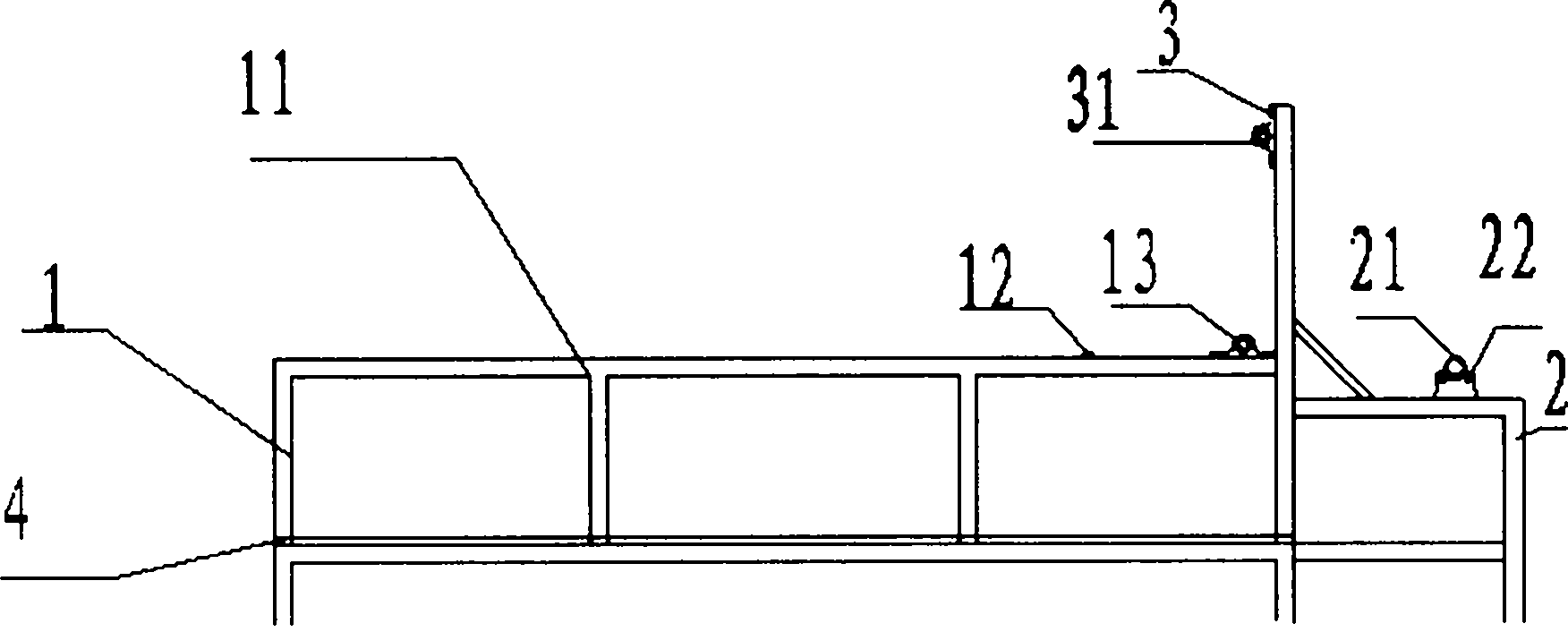

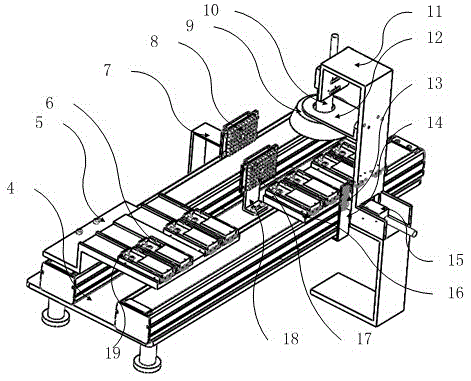

Linear reciprocating-type magnetic tile shape measurement device

ActiveCN105547163ARealize online measurementIncrease productivityUsing optical meansNon destructiveSize measurement

The invention relates to a linear reciprocating-type magnetic tile shape measurement device, and belongs to the technical field of non-destructive testing. The device comprises a magnetic tile conveying apparatus, a magnetic tile positioning apparatus, and a measurement apparatus. The magnetic tile conveying apparatus comprises an input conveying belt, an output conveying belt, a rear linear module group, a front linear module group, and a carrying mechanical arm. The magnetic tile positioning apparatus comprises a rear positioning apparatus installation plate, a measurement positioning apparatus, a front positioning apparatus installation plate, a rear module group sliding block, and a front module group sliding block. The measurement apparatus comprises a rear light source support, a rear area light source, a top light source, a top-view camera, a camera support, a top light source support, a standard ruler, a standard ruler support, a front-view camera, a front area light source, a front light source support, a point light source, and a point light source support. The device can achieve the measurement of the sizes of the outer and inner arcs, length and width of a magnetic tile.

Owner:KUNMING UNIV OF SCI & TECH

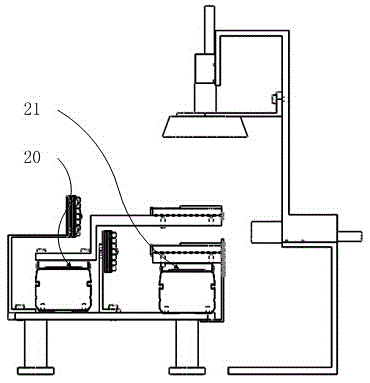

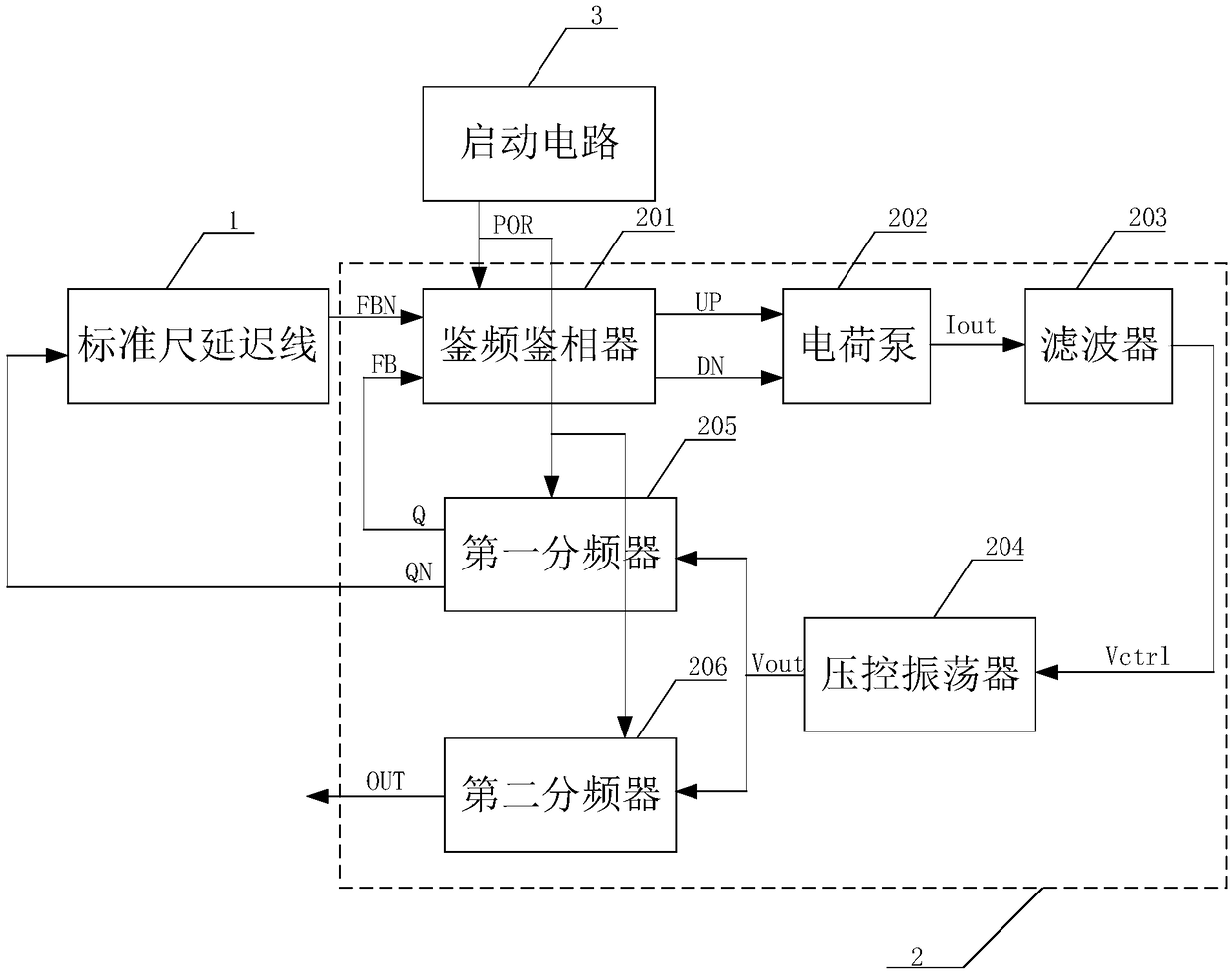

Clock generation device based on phase-locked loop and standard ruler delay line and implementation method thereof

PendingCN108964658AImplement Negative Feedback ControlAchieve conversionPulse automatic controlPhase frequency detectorStandard ruler

The present invention provides a clock generation device based on phase-locked loop and standard ruler delay line and an implementation method thereof, belonging to the technical field of a clock. Theproblem is solved that conversion from frequency to frequency can be only achieved in the prior art. A UP output end and a DN output end of a phase frequency detector are respectively connected witha UP input end and a DN input end of a charge pump, the current output end of the charge pump is connected with a current input end of a filter, an output end of the filter is connected with an inputend of a voltage-controlled oscillator, a clock signal output end of the voltage-controlled oscillator is connected with a clock signal input end of a first frequency divider and a clock signal inputend of a second frequency divider, Q output end of the first frequency divider is connected with an FB input end of the phase frequency detector, the QN output end of the first frequency divider is connected with the input end of the standard ruler delay line, the output end of the standard ruler delay line is connected with the FBN input end of the phase frequency detector, and the output of thesecond frequency divider is taken as output of a clock generation device. The clock generation device based on phase-locked loop and standard ruler delay line and the implementation method thereof areused for clocking metering.

Owner:HARBIN INST OF TECH

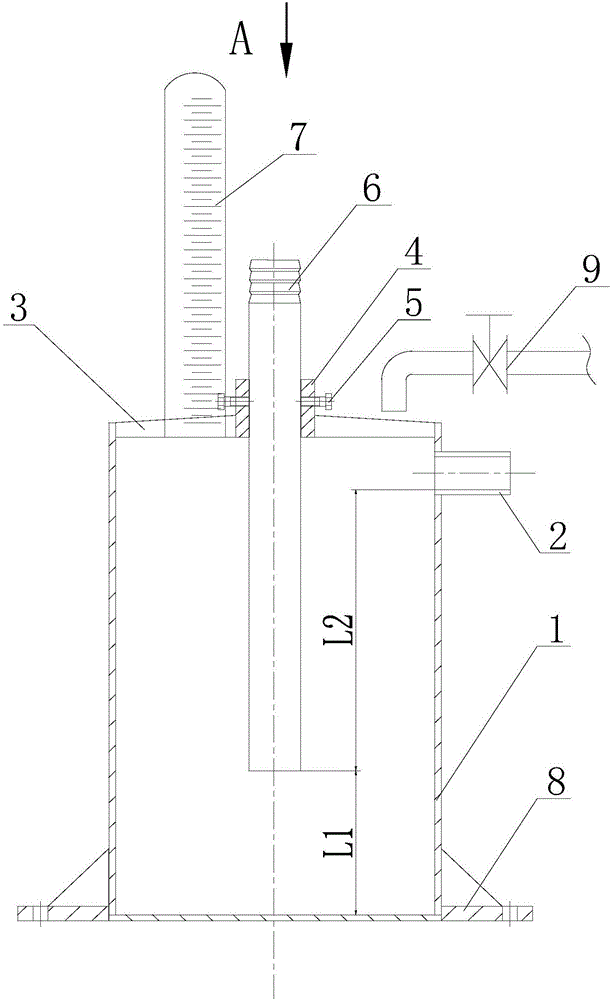

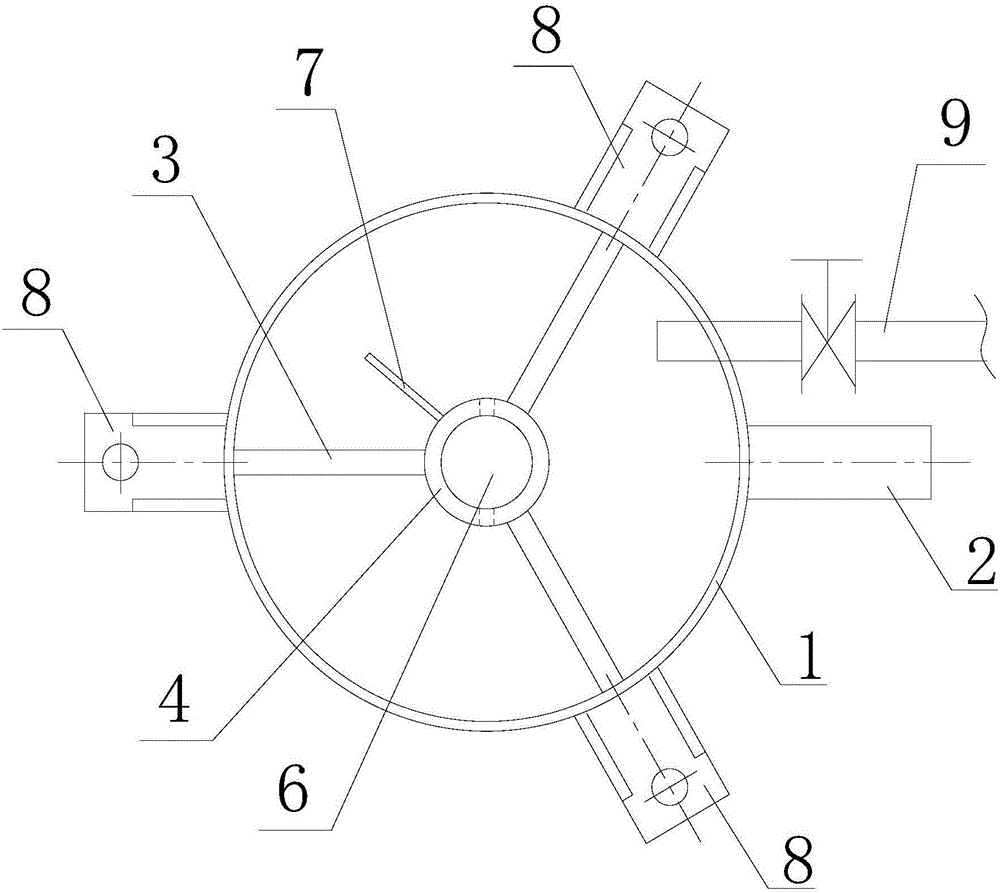

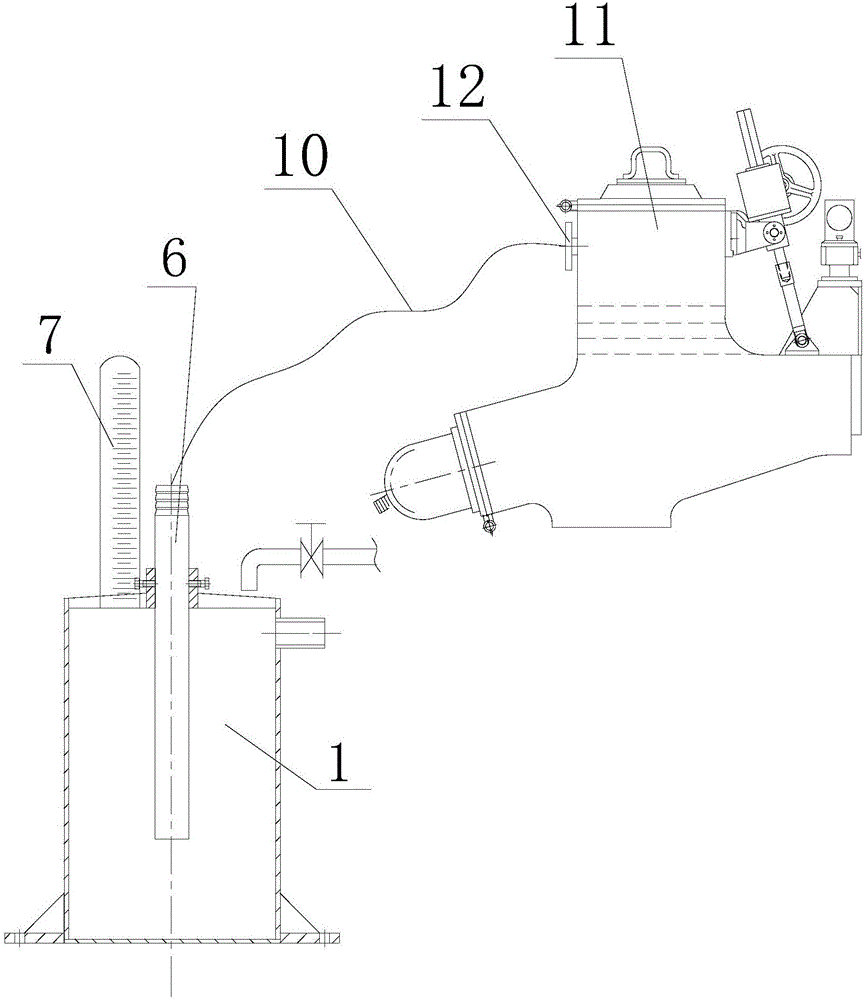

Air cushion pressure regulation device for fluid pulp box and regulation method

The invention discloses an air cushion pressure regulation device for a fluid pulp box and a regulation method. The regulation device comprises a pressure regulation barrel, a pressure regulation pipe and a standard ruler, the pressure regulation pipe is arranged on the middle part of the pressure regulation barrel and its lower end extends into the pressure regulation barrel, the upper end of the pressure regulation pipe is communicated with an air cushion chamber of the fluid pulp box, the standard ruler is fixed on the top face of the pressure regulation barrel and is arranged in parallel with the pressure regulation pipe; a supplement water pipe is arranged on the upper side of the pressure regulation barrel, and an overflow pipe is arranged on the side wall of the pressure regulation barrel. The method comprises the steps that the depth of the pressure regulation pipe extending into the water in the pressure regulation barrel is regulated in advance, so that the depth of the pressure regulation pipe extending into the water is the same as the height of a water column corresponding to the air cushion pressure; in the using process of the fluid pulp box, when the air cushion pressure changes, through the regulation of the opening extent of an air venting outlet, the size of the air cushion pressure and the depth of the pressure regulation pipe extending into the water are kept stable. According to the air cushion pressure regulation device and the regulation method, the stability of the air cushion pressure in the air cushion room is effectively maintained, the device is simple in structure, the regulation cost is very low, and the adoption of precision control components and complex control systems is not necessary.

Owner:SOUTH CHINA UNIV OF TECH

The whole aircraft level measurement method based on the workspace measurement and positioning system

The invention provides a full-airplane horizontal measurement method based on a work space measurement location system. The method comprises first determining the number of measured work spaces and laser scanning base stations according to appearance dimensions and positions of measuring points; then using a standard ruler to calibrate external parameters of the measured work spaces formed by all the laser scanning base stations, and building a work space measurement location system coordinate system; then unifying the work space measurement location system coordinate system and an airplane coordinate system; using vector rods of the work space measurement location system to respectively perform contact measurement on each measuring point; and finally enabling measured coordinate values of each measuring point to be led into a data processor of the work space measurement location system, and comparing the actually-measured coordinate values with a theoretical value so as to judge whether airplane deformation is within an allowed range. The full-airplane horizontal measurement method solves the problems that a traditional airplane horizontal measurement method is poor in measurement precision, large in workload and low in measurement efficiency and is subjected to influences of operator's proficiency and the like.

Owner:吉林航空维修有限责任公司

A precise measurement method for the focal length of an ultra-long focal length space camera

ActiveCN104515671BWide focal length coverageShorten the timeTesting optical propertiesFour quadrantsPlane mirror

A precision measurement method for the focal length of an ultra-long focal length space camera relates to the technical field of optical measurement methods, and solves the existing problems of low measurement accuracy and high cost of supporting equipment when measuring the focal length of a long focal length camera. The invention uses a spherometer to measure the spherical standard mirror of an interferometer radius of curvature, use a mirror locator to measure the lens thickness of the standard mirror, and calculate the focal length of the interferometer spherical standard mirror according to the obtained radius of curvature and lens thickness; Place it on the two-dimensional adjustment platform; place the camera under test, plane mirror and reference ruler in front of the interferometer and perform coarse adjustment and fine adjustment of the plane mirror; make the interferogram of the camera under test image on the detector of the interferometer; use four The quadrant analysis method calculates the imaging on the detector to obtain the length of the image of the reference ruler; according to the focal length of the dry standard mirror, the length of the reference ruler and the length of the reference ruler image, the focal length of the camera under test is obtained.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

A method for surveying and mapping ancient buildings with a digital camera and a measuring tool

The invention discloses a surveying and mapping method for an ancient architecture by matching a digital camera with a measuring tool. The digital camera and the measuring tool are taken as tools to measure vertical-face dimension of an architecture in a single-image mode under a condition that elements of interior orientation are not known and elements of exterior orientation are known or measurable; the surveying and mapping method specifically comprises the following steps: measuring a vertical distance between a photographing point and an external vertical face of the architecture by using the measuring tool; fixing horizontal and vertical standard rulers on the external vertical face of the architecture; keeping the digital camera in a horizontal state for photographing to obtain photos of a to-be-measured area, obtaining image space dimensions of the standard rulers by virtue of the photos; determining a scale value of the image space dimensions and an object space dimension in the horizontal direction and the vertical direction by utilizing proportional relation of similar triangles according to the image space dimension of the standard rulers; respectively obtaining the dimension of each part of the external vertical face of the architecture in the horizontal direction and the vertical direction according to the scale value of the image space dimensions and an object space dimension in the horizontal direction and the vertical direction. The method disclosed by the invention can simply and quickly measure the vertical face dimension of the architecture, and improves surveying and mapping precision and the working efficiency.

Owner:徐州市勘察测绘研究院有限公司

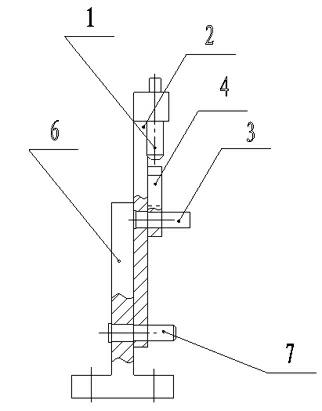

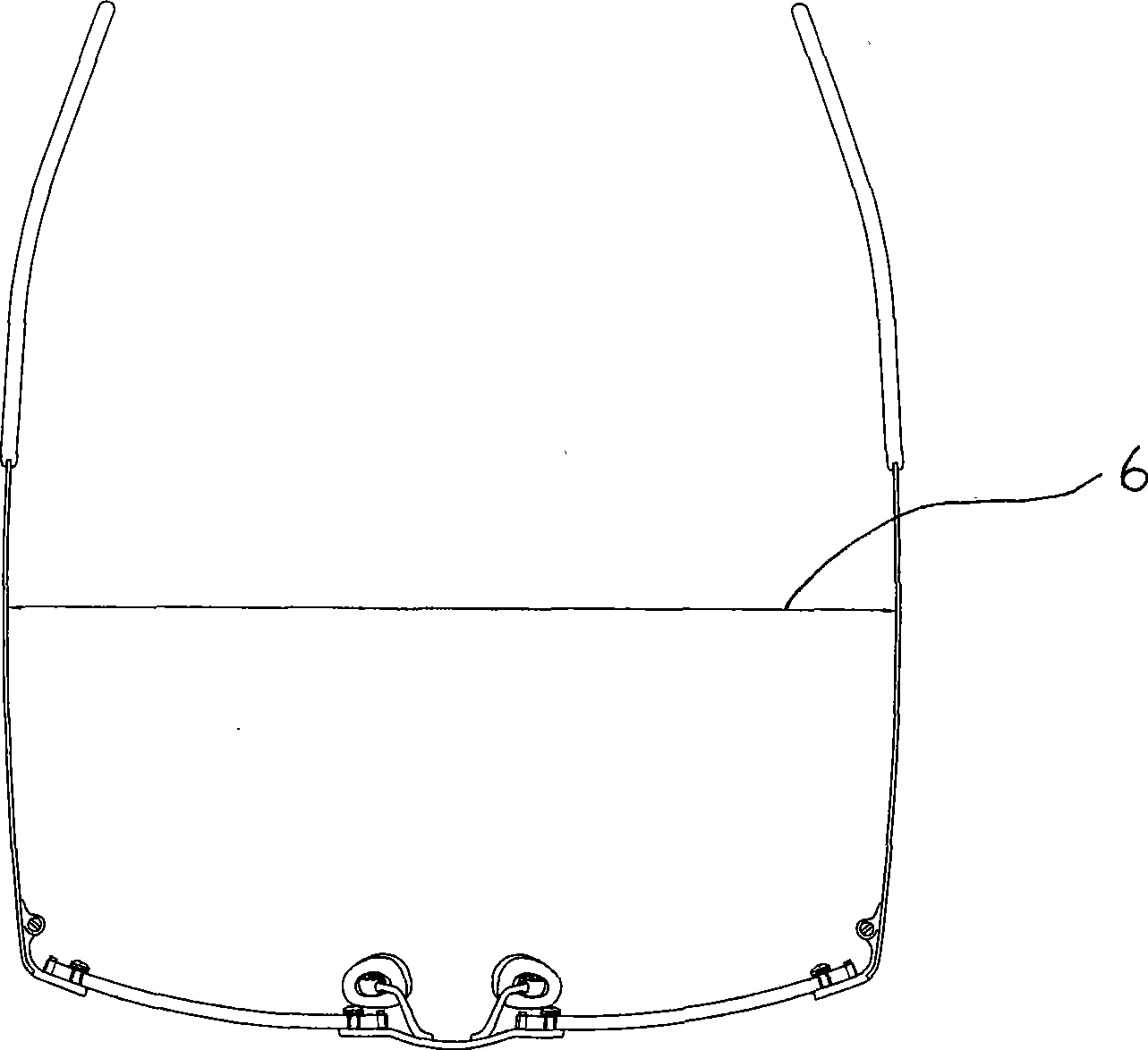

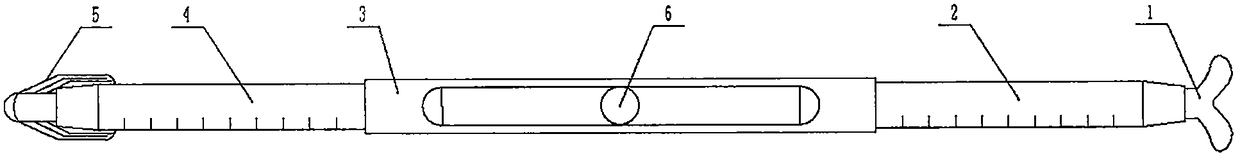

Standard ruler for reading and writing

The invention discloses a standard ruler for reading and writing. The standard ruler comprises a standard ruler body. The standard ruler body adopts the split design and is composed of five components, respectively a nose bridge bracket, a fist rod 1, a grip, a fist rod 2 and an angle bracket. The nose bridge bracket is disposed at the topmost end of the fist rod 1 and is specifically configured to be in a Y shape. The fist rod 1 and the fist rod 2 are respectively inserted into and fixed at the right end and the left end of the grip. The standard ruler can provide standard reading, writing and pen holding distances for a user, so that a reference basis is provided for changing the habit, the user knows what the accurate state is and how to 'sit', and eyesight protection is much easier.

Owner:魏东

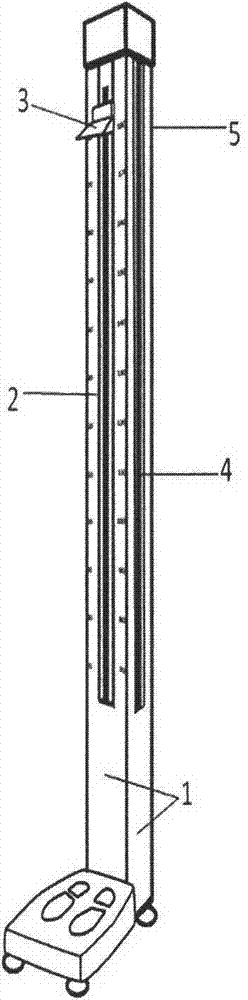

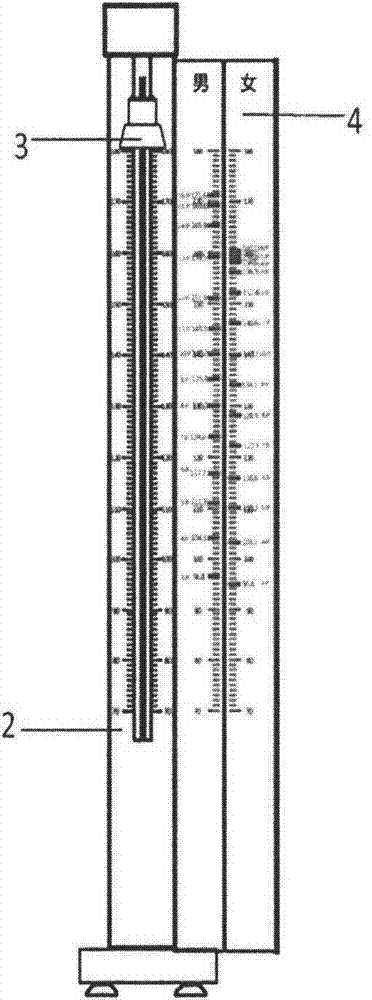

Height ruler embedded with reference standard ruler

InactiveCN103610465AEasy to readEase of evaluationDiagnostic recording/measuringSensorsBody heightStandard ruler

The invention belongs to the field of daily necessities, and particularly relates to a height ruler embedded with a reference standard ruler. The height ruler embedded with the reference standard ruler comprises a ruler body, a scale ruler, a movable board, the height reference standard ruler and the like. The ruler body can be made of wood or plastics. The height value can be read conveniently due to the movable board nested on the scale ruler, and therefore the purpose of accurate measurement is achieved. The height requirements which should be met by people of different ages are listed in detail on the height reference standard ruler embedded in the middle layer according to the different sexes, an estimator can visually estimate the height conditions of children, whether the heights of measured people meet the requirement for growth and development or not can be judged without further searching data, and therefore the measurement, assessment and evaluation processes are simple, scientific and fast.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com