Mechanism for detecting forming accuracy of hot stamped part

A technology of precision detection and hot stamping, which is applied in the direction of measuring devices, instruments, and electrical devices, etc., can solve the problems of low efficiency and unsuitable for large-scale detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

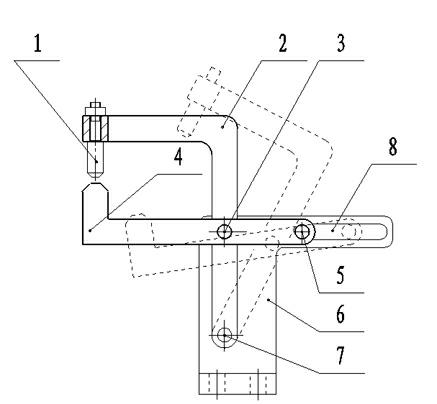

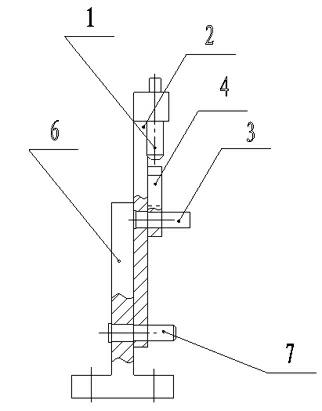

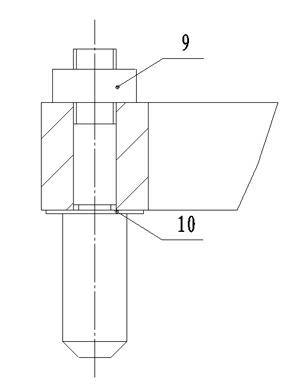

[0014] Measure the position degree of six specific points of a certain anti-collision beam forming part. The thickness of the part is 2.0mm, and the dimensional accuracy is required to be ±0.5mm. The opening degree of the measuring claw when it is closed is composed of the thickness and size requirements of the measuring part, that is, the opening degree Is 3.0mm, such as figure 1 Shown.

[0015] In the measurement circuit, the main switch adopts a self-locking switch with its own light, the self-check switch adopts an inching switch, and the indicator light adopts a light-emitting diode, such as Figure 4 Shown.

[0016] The detection mechanism is connected with the negative pole of the indicator light, and the measuring piece is connected with the negative pole of the power supply. When the measured piece is in contact with the measuring claw, the indicator light will light up, indicating that the accuracy of the measured piece is out of range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com