Manual cutting operating platform

A workbench and manual technology, applied in metal processing, etc., can solve problems affecting production efficiency, inaccurate positioning, waste of materials, etc., and achieve the effects of low cost, waste reduction, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

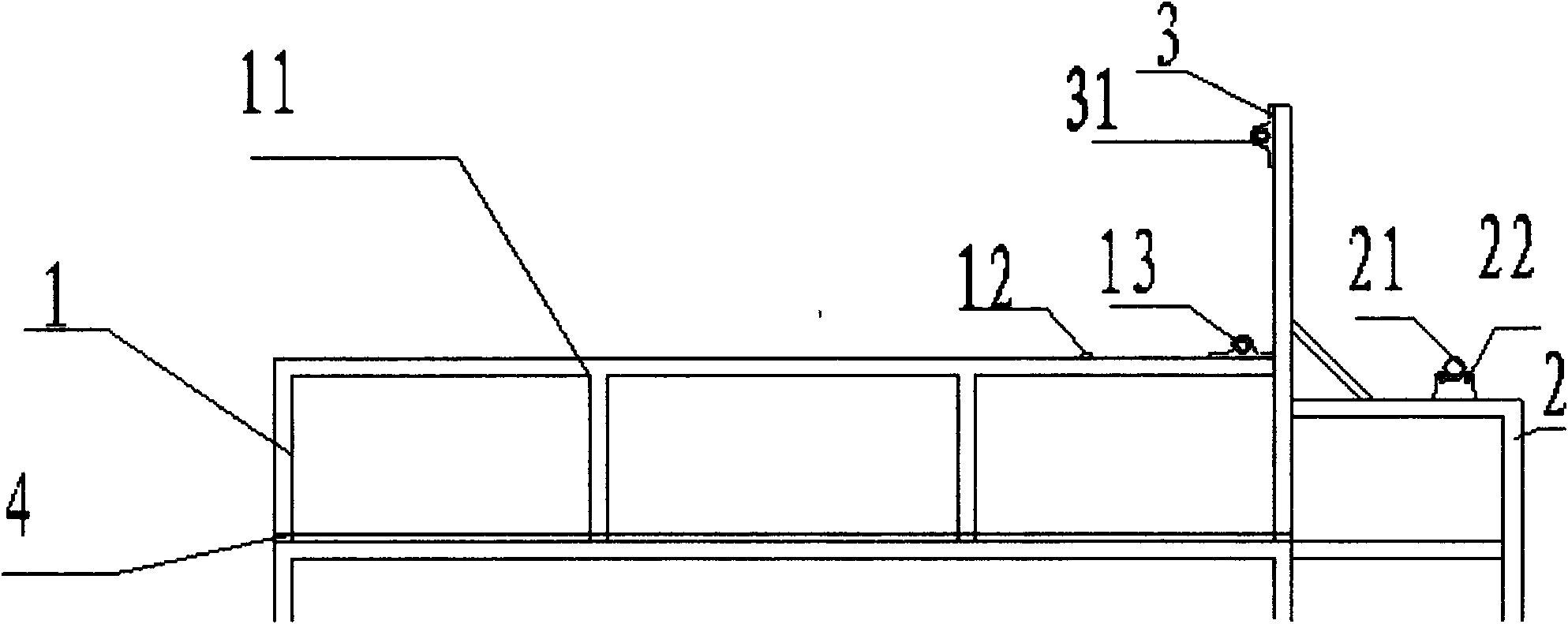

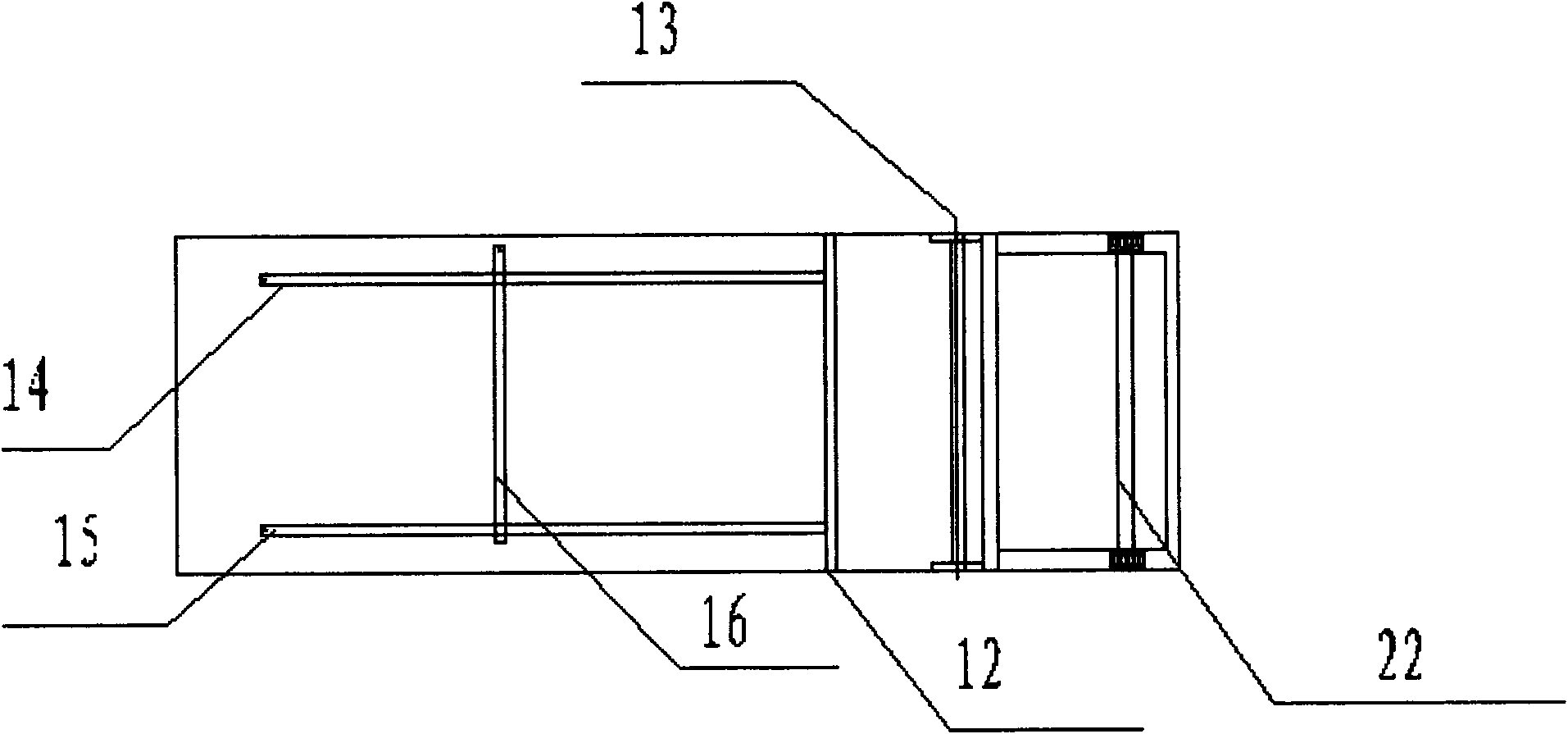

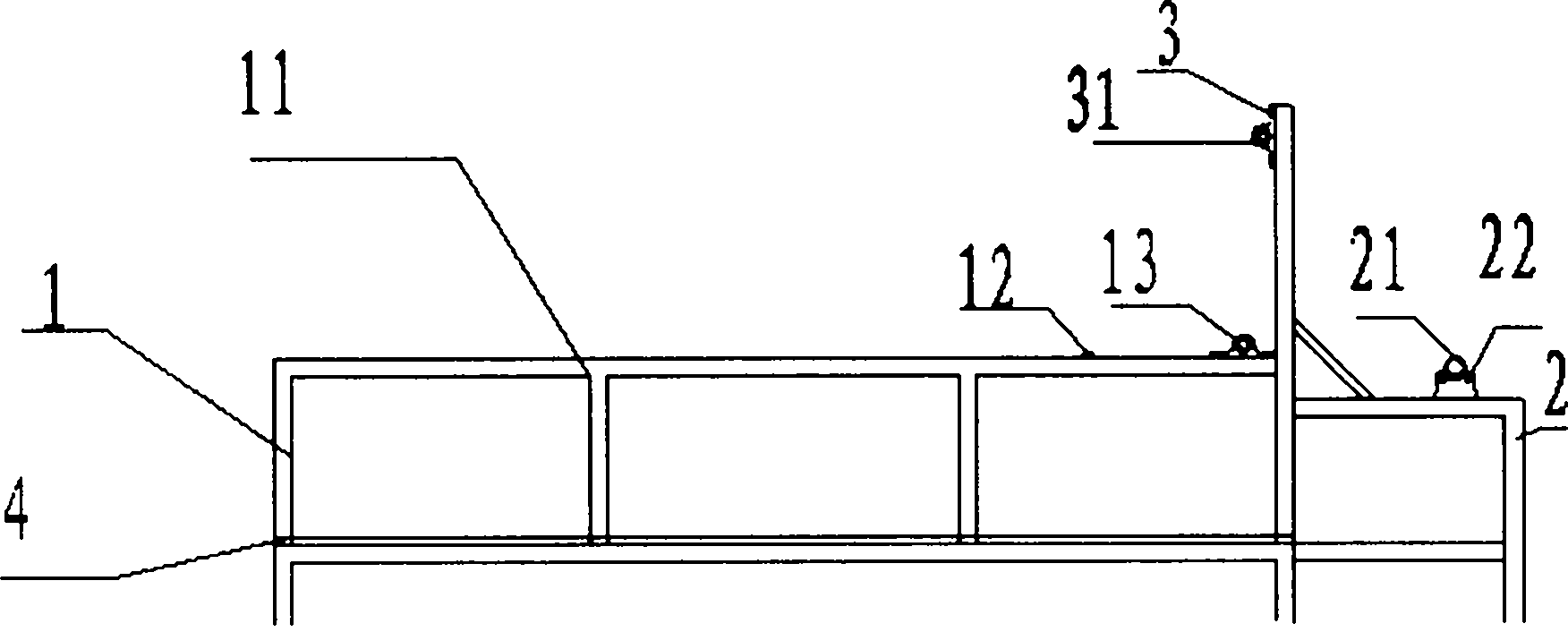

[0014] A manual cutting workbench, comprising a first workbench 1 and a second workbench 2, separated by a partition 3 perpendicular to the workbench body between the first workbench 1 and the second workbench 2, the first workbench The main body is mainly composed of a desktop 11, a cutting module 12, a rolling pinch roller 13, two parallel steel rulers 14; 15 and a reference ruler 16, and the two steel rulers 14; 11, the reference ruler 16 is set across the two steel rulers 14; 15, the rolling pinch roller 13 is fixedly arranged between the reference ruler 16 and the partition 3, and the second workbench 2 is mainly composed of a support tube 21, a bearing 22 Composition, the support tube 21 is arranged on the bearing 22, the upper end of the partition 3 facing the first workbench 1 is provided with another rolling pinch roller 31, and the cutting module 12 is made of stainless steel.

[0015] The reference ruler 16 is rolled and arranged on the two steel rulers 14; 15. Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com