Full-degree-of-freedom precision detecting device of machine tool linear movement running state

A technology of linear motion and accuracy detection, applied in computer control, instruments, simulators, etc., can solve the problems of complex measurement process, low measurement efficiency, and inability to measure vertical axis linear error and tilt angle error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

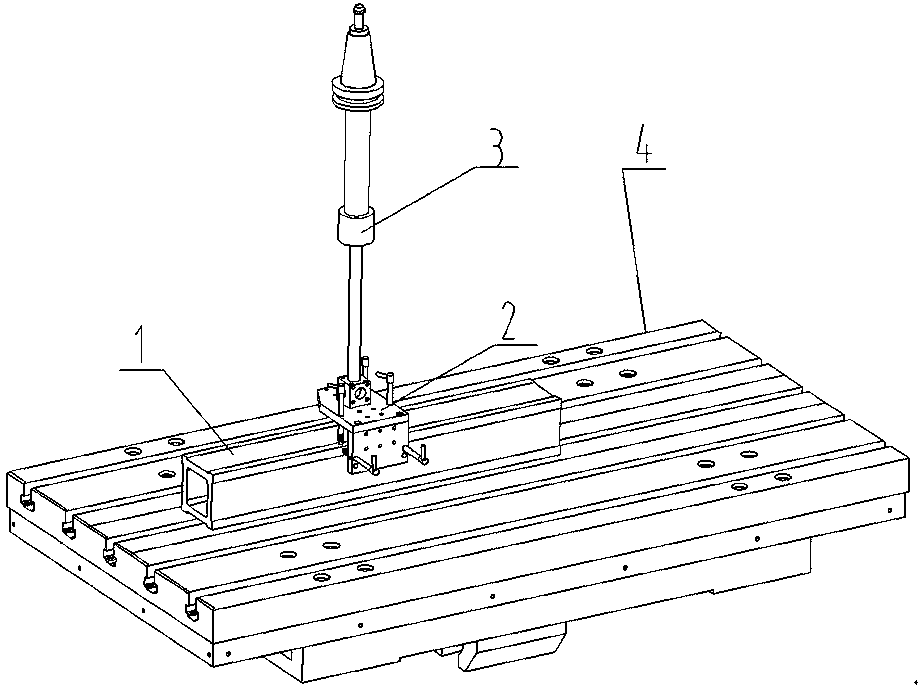

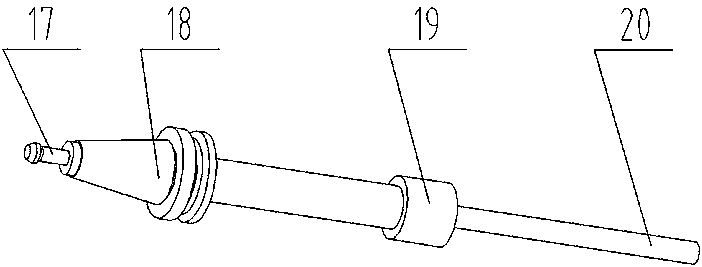

[0021] figure 1 Shown is the full-degree-of-freedom precision detection device of the linear motion running state of the machine tool of the present invention, including a reference ruler 1, a measuring unit 2, and an installation unit 3; the connecting rod 20 of the installation unit 3 and the steering block 11 of the measurement unit 2 pass through screw connection.

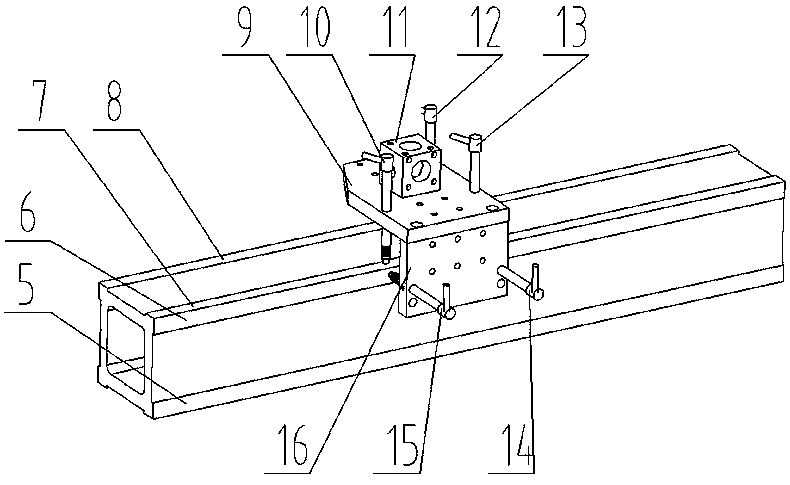

[0022] figure 2 Shown is the axonometric drawing of the measurement unit and the reference ruler in the full-degree-of-freedom precision detection device of the linear motion running state of the machine tool of the present invention, and the reference ruler 1 is parallel to the ZY plane and the XY plane where the Y axis of the machine tool is located and placed on the workbench 4; the measuring unit 2 is composed of a mounting plate I9, a mounting plate II16, a displacement sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com