H-shaped beam fitting up device and fitting up method

A technology of pairing and H-shaped steel, applied in the direction of auxiliary equipment, resistance welding equipment, auxiliary welding equipment, etc., can solve the problems of wasting raw materials, manpower, material resources and working time, and can not guarantee the production accuracy, etc., to improve production efficiency, Guarantee the quality of the product and the effect of being suitable for promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

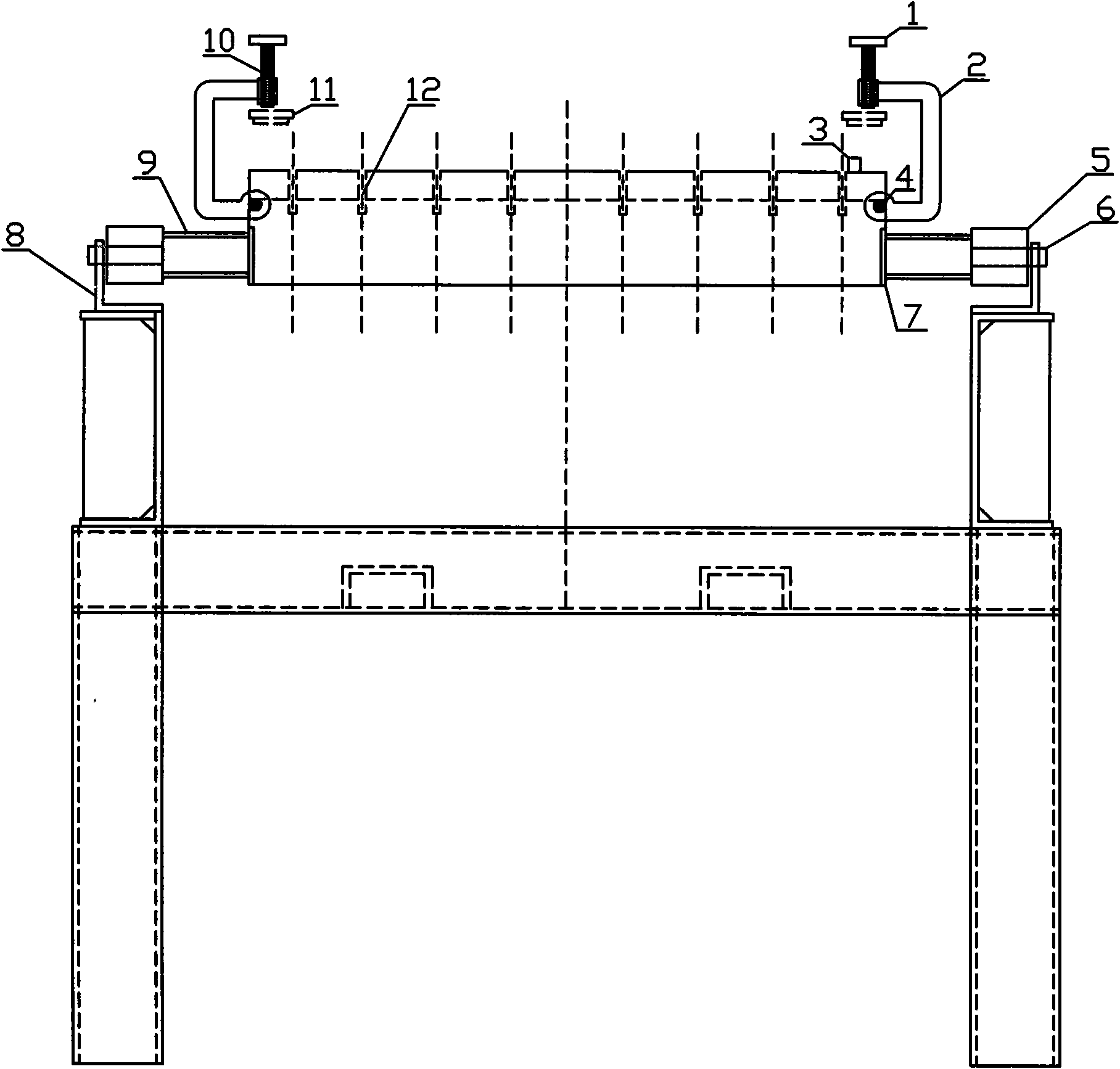

[0030] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0031] The invention includes an H-shaped beam pairing device used for spot welding H-shaped steel and reinforcement plates when making H-shaped beams.

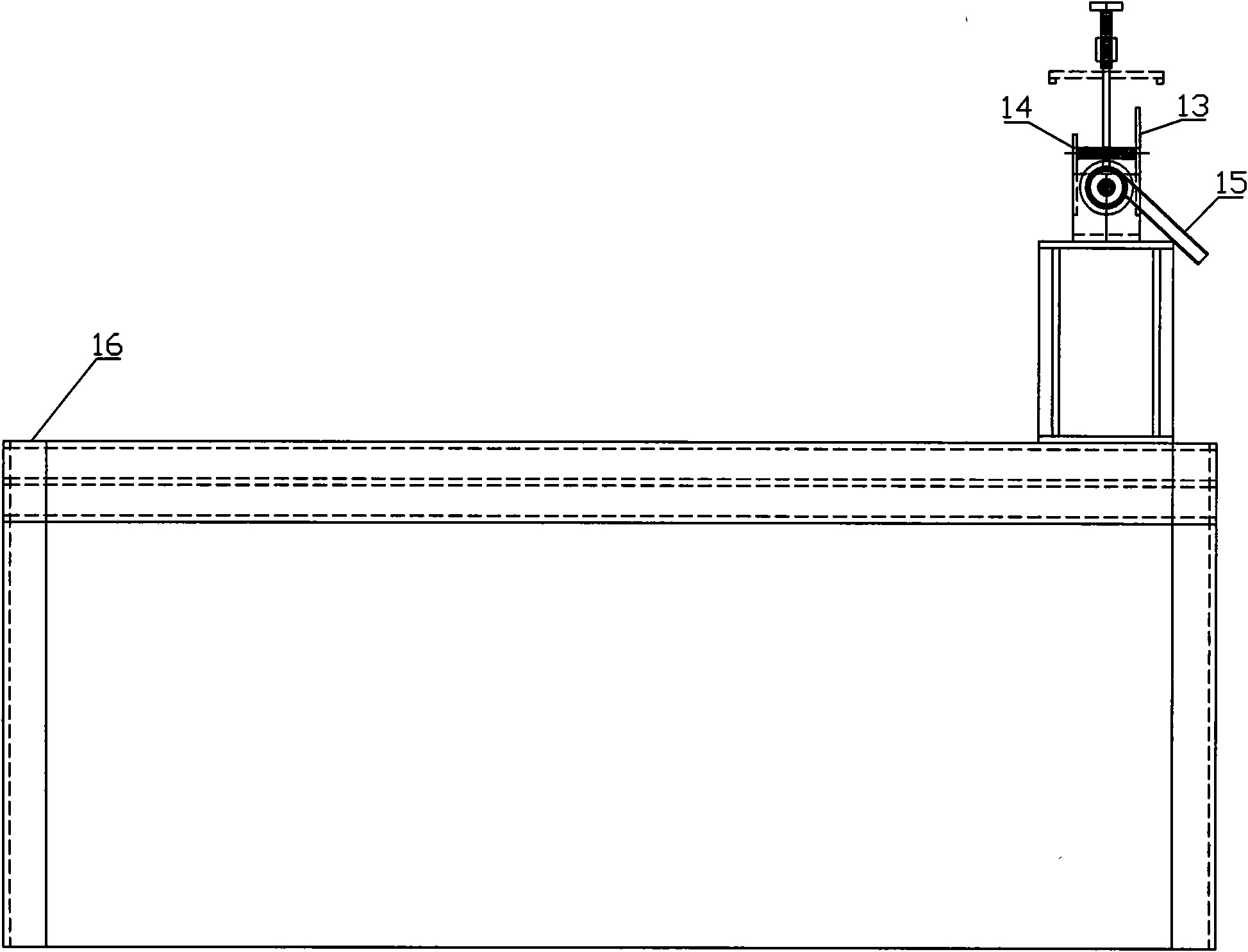

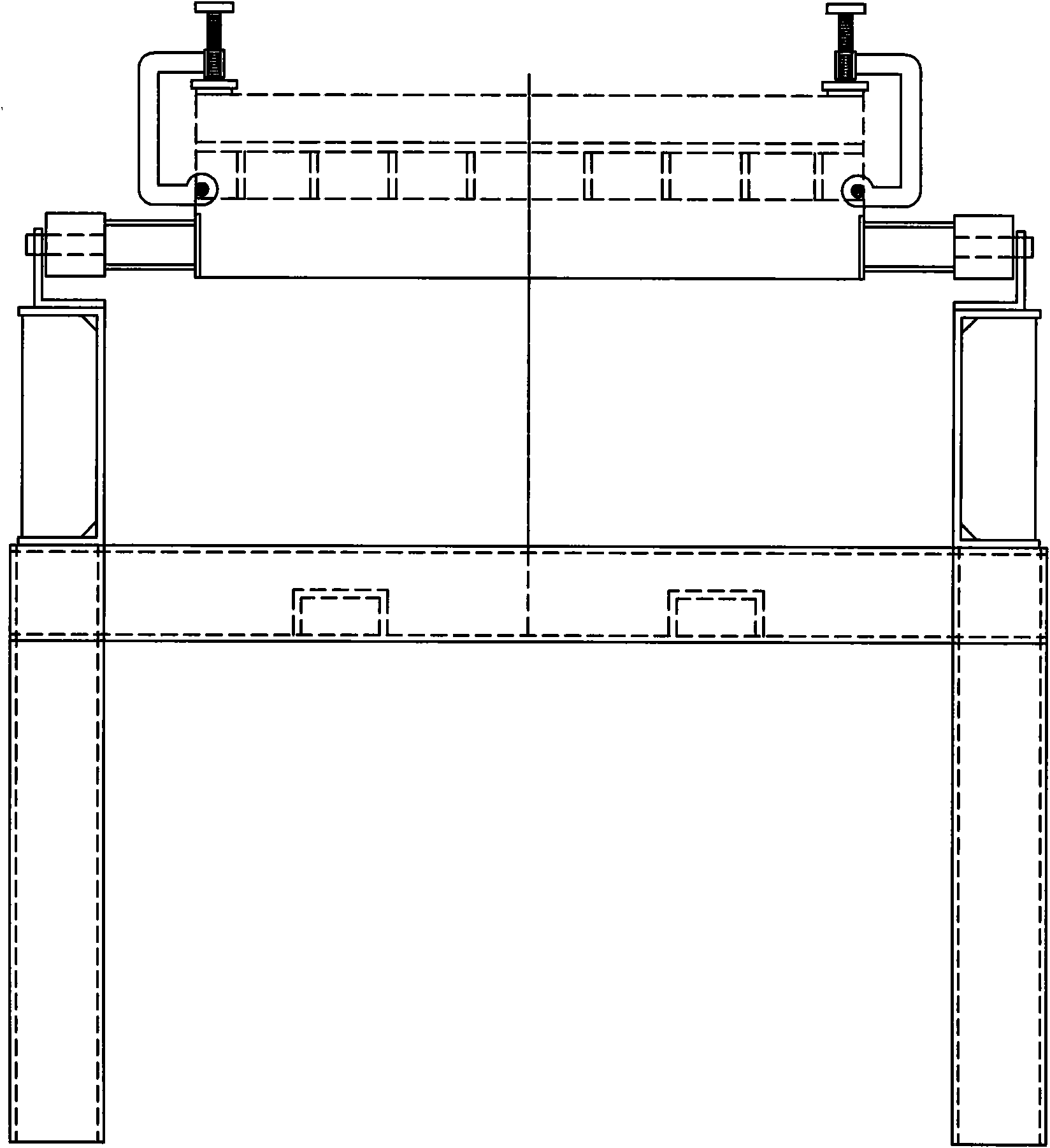

[0032] Such as figure 1 and figure 2 As shown, the device includes a workbench 16, and the workbench 16 is welded into an operation platform by 200# channel steel, which is convenient for the staff to operate standing. One end of the workbench 16 is provided with related devices, and the rest can be used to place pairwise spot-welded H-beams or other workpieces.

[0033] Both sides of one end of the workbench 16 are respectively provided with supports 8 , the lower end of the support 8 is affixed to the upper surface of the workbench 16 , and the upper part of the support 8 is used as a carrier for support and installation. The concrete shape of support 8 is not limited, for example figure 1 The bracket 8 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com